A Vertical Tube Falling Film Absorption Reactor

A technology of falling film absorption and reactor, which is applied to the reaction of thin-film liquid and gas, chemical/physical/physicochemical fixed reactor, indirect heat exchanger, etc. It can solve the problem of equipment shutdown, heat exchange tube damage, Affect the shell gas absorption and other issues, to achieve the effect of thinning thickness, reducing resistance and increasing disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

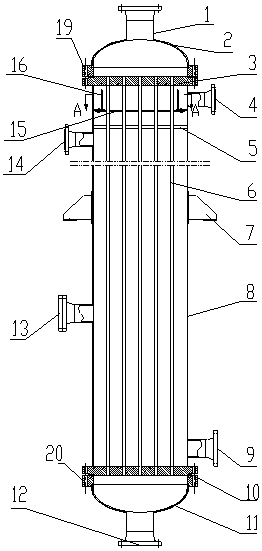

[0029] As shown in the figure, a vertical tube falling film absorption reactor includes an upper tube box 2 , a lower tube box 11 and a shell 8 .

[0030] The upper end of the housing 8 is in sealing connection with the upper tube box 2 , and the lower end of the housing 8 is in sealing connection with the lower tube box 11 .

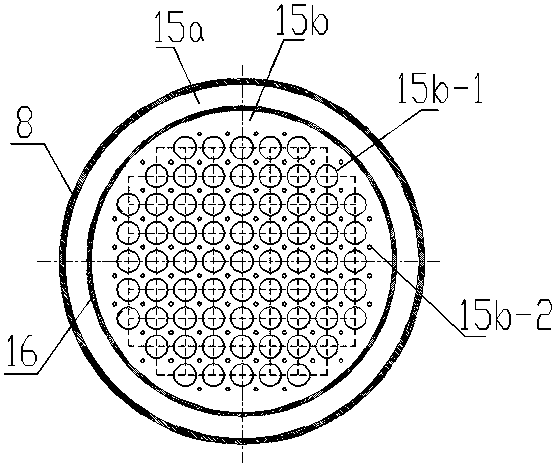

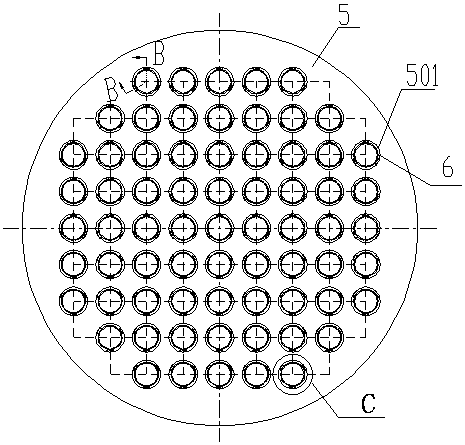

[0031] The upper end of the casing is provided with an upper tube sheet 3, and the lower end of the casing is provided with a lower tube sheet 10. A plurality of installation holes for installing heat exchange tubes are respectively provided on the upper tube sheet and the lower tube sheet. The tubes 6 are vertically installed in an array between the upper tube plate 3 and the lower tube plate 10 through respective mounting holes, forming a tube bundle.

[0032] The outer wall of the heat exchange tubes and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com