Film distributing device for horizontal tube type spraying falling-film evaporator

A technology of falling film evaporator and film distribution device, which is applied to horizontal tube evaporators, evaporator accessories, evaporation, etc., can solve problems such as uneven film distribution, no film distribution, and film breakage, and avoid dry film, cloth distribution, etc. The effect of uniform film and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

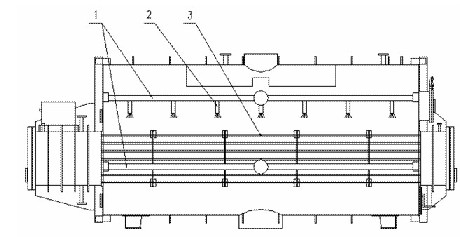

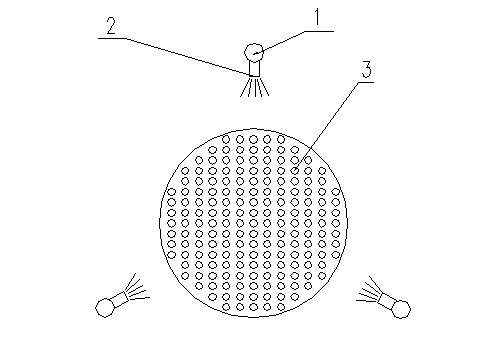

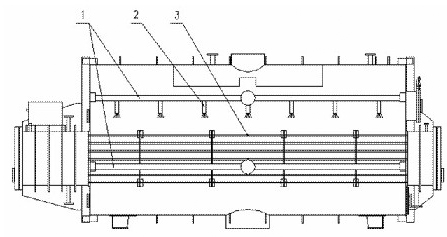

[0012] Such as figure 1 figure 2 As shown, the film distribution device of the horizontal tube spray falling film evaporator according to the present invention includes three spray pipes 1 and several mist nozzles 2 arranged on the spray pipes 1 . Three spray pipes 1 are distributed at an angle of 120 degrees around the heating tube bundle 3 of the horizontal tube spray falling film evaporator, and one of the spray tubes 1 is located at the front of the heating tube bundle 3 of the horizontal tube spray falling film evaporator. above. Several mist nozzles 2 are arranged on each spray pipe 1 .

[0013] When in use, the material spreads film on the heating tube bundle 3 of the horizontal tube spray falling film evaporator through the mist nozzle 2 on the spray pipe 1 from different angles. Since the spray tube 1 and the nozzle 2 are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com