A defect location device for ultrasonic testing

A positioning device, ultrasonic technology, applied to measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc. Accuracy and other issues, to avoid visual measurement errors and facilitate the flaw detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

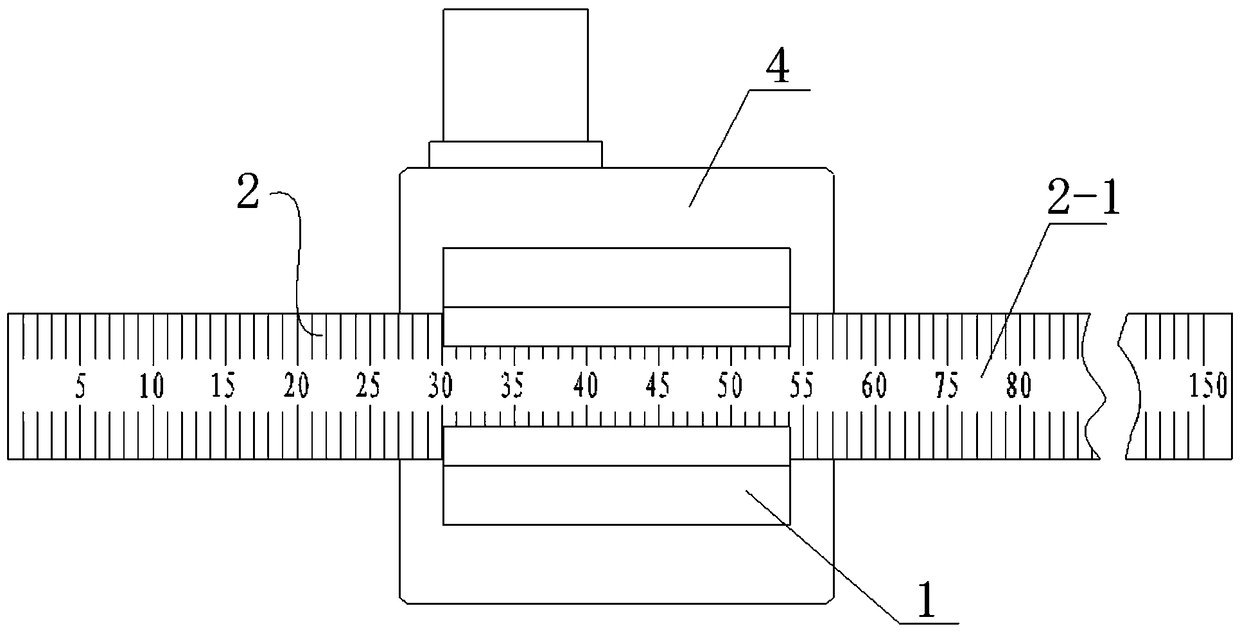

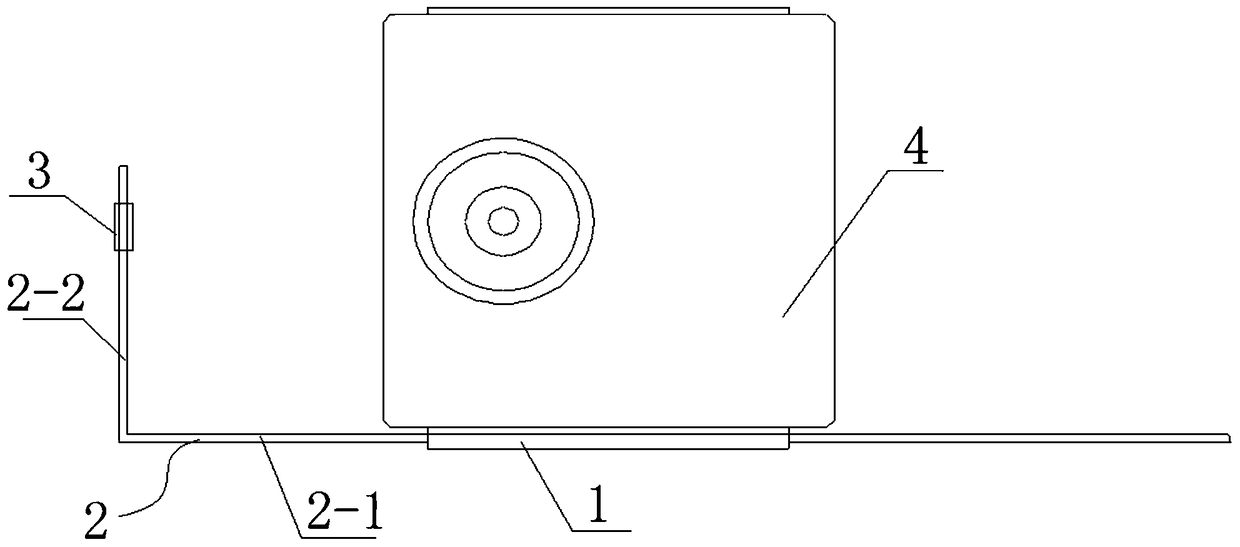

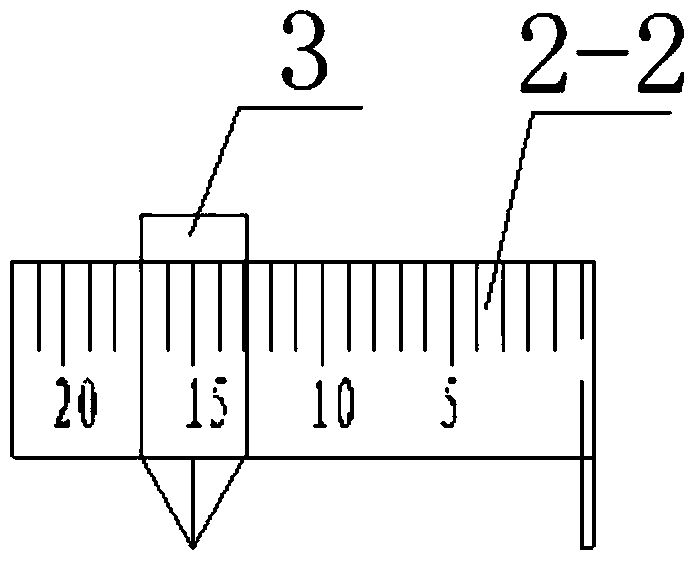

[0018] Such as figure 1 , figure 2 As shown, the present invention includes a mounting base 1 and a rectangular measuring ruler 2 . Wherein, the rectangular measuring ruler 2 comprises a first measuring ruler 2-1 and a second measuring ruler 2-2 fixedly connected to an end of the first measuring ruler 2-1, and the ruler surface of the second measuring ruler 2-2 It is perpendicular to the ruler surface of the first measuring ruler 2-1. A slideway is provided on the mounting base 1 , and the first measuring ruler 2 - 1 is slidably connected in the slideway of the mounting base 1 . Slide to set a movable arrow 3 on the second measuring ruler (such as figure 2 , image 3 shown).

[0019] Further, scale marks are respectively arranged on the first measuring ruler 2-1 and the second measuring ruler 2-2, and the measuring range of the first measuring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com