Composite silicate high-viscosity cold-hot coating heat preservation slurry

A technology of composite silicate and thermal insulation slurry, which is applied in alkali metal silicate coatings, fireproof coatings, and other chemical processes, and can solve the problems of cold coating of thermal insulation slurry, low tensile strength, and poor structural stability, etc. Problems, to achieve significant thermal insulation effect, good oil resistance, good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Raw material composition: expanded perlite 6.6wt%, sodium diatomite 4.3wt%, mountain cork 1.9wt%, bentonite 4.7wt%, alumina fiber 1.7wt%, glass fiber 1.7wt%, aluminum silicate fiber 1.7wt% , 0.9wt% of vermiculite, 1.9wt% of polyvinyl alcohol, 0.1wt% of sodium silicate solution with a concentration of 5%, and the balance of water.

[0016] According to the ingredients of the above-mentioned raw materials, mix various raw materials with water, and stir evenly at room temperature to make FME-composite silicate high-viscosity cold and hot coating and thermal insulation slurry.

[0017] Among them, expanded perlite, diatomite and mountain cork are used as base materials, alumina fibers, glass fibers and aluminum silicate fibers are used as auxiliary reinforcement materials, and polyvinyl alcohol (PVA), sodium silicate solution or aluminum phosphate solution is used as bonding materials. agent, bentonite as a suspension stabilizer, and vermiculite as a filler. Mountain cork ...

Embodiment 2

[0021] Raw material composition: expanded perlite 4.2wt%, diatomite 3wt%, mountain cork 1.3wt%, bentonite 6.5wt%, alumina fiber 1wt%, glass fiber 1wt%, aluminum silicate fiber 2.3wt%, vermiculite 0.5wt %, polyvinyl alcohol 2.5wt%, water balance.

[0022] Wherein, the diatomite is a mixture of sodium diatomite and calcium diatomite, and the weight ratio of sodium diatomite to calcium diatomite is 1:0.5-2. The preparation process is the same as in Example 1.

Embodiment 3

[0024] Raw material composition: expanded perlite 8.5wt%, calcium-based diatomite 5.5wt%, mountain cork 2.5wt%, bentonite 3.5wt%, alumina fiber 2.3wt%, glass fiber 2.3wt%, aluminum silicate fiber 1wt%, 1.2 wt% of vermiculite, 1.3 wt% of polyvinyl alcohol, 0.18 wt% of sodium silicate solution with a concentration of 6%, 0.15 wt% of an aluminum phosphate solution with a concentration of 5%, and the balance of water.

[0025] The concentration of the aluminum phosphate solution can be 5-6%. The preparation process is the same as in Example 1.

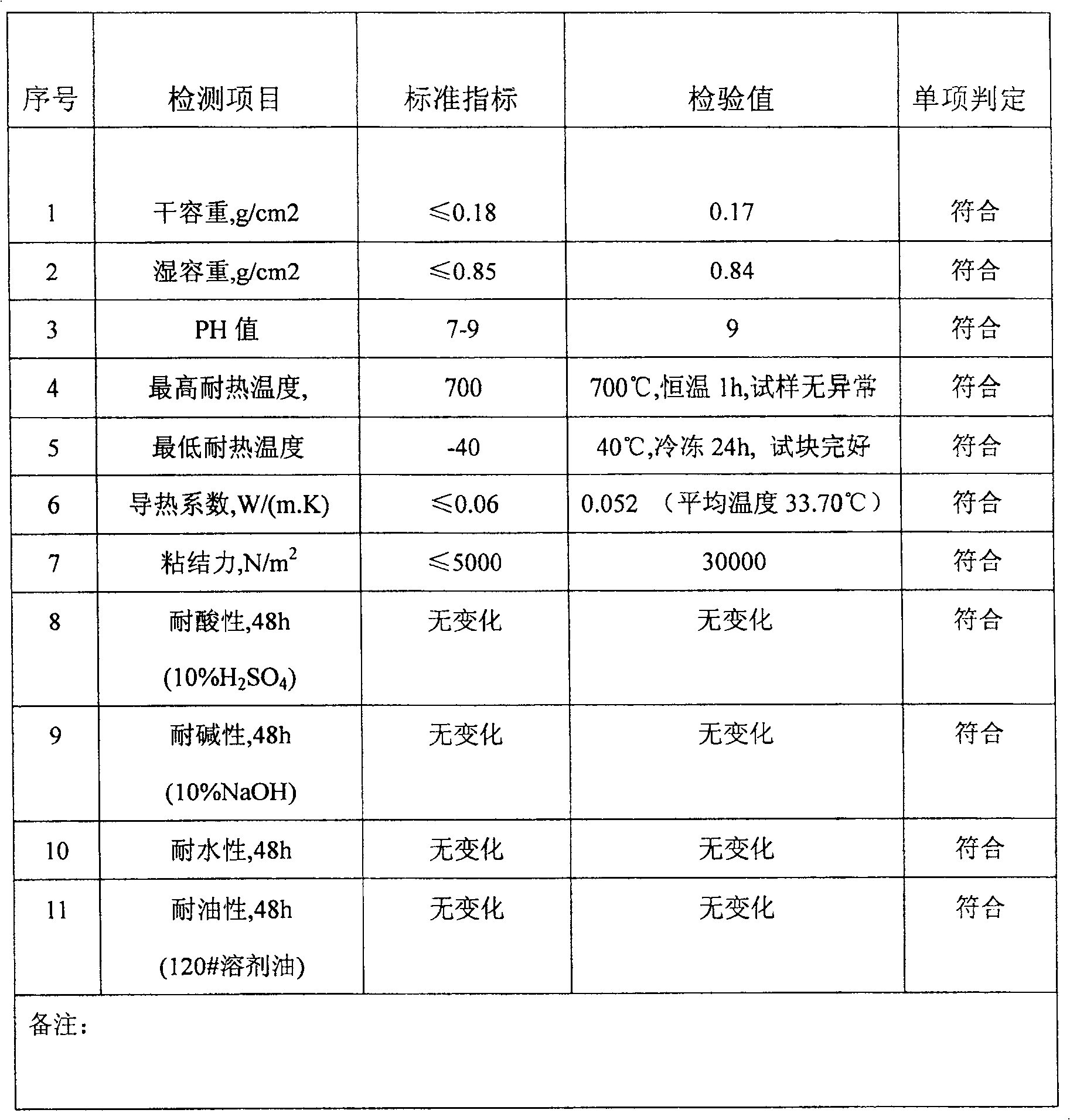

[0026] The FME-composite silicate high-viscosity cold and heat coating thermal insulation slurry of the present invention, the test results of the National Building Materials Testing Center on January 25, 2007 are shown in Table 1, and the product sample test results meet the Q / GGJA001-2005 standard Technical specification requirements. The product has light bulk density, low thermal conductivity, remarkable thermal insulation effect, go...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com