Start-up heating furnace coil pipe production method of synthetic ammonia device

A technology for starting heating furnaces and ammonia synthesis devices, which is applied in the field of chemical device manufacturing, which can solve problems such as high labor costs, difficulty in flaw detection, and difficult groove shape, etc., and achieves improved mechanization and automation, reduced welding and flaw detection costs, and welding repairs Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

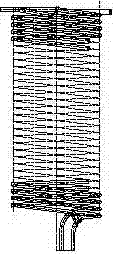

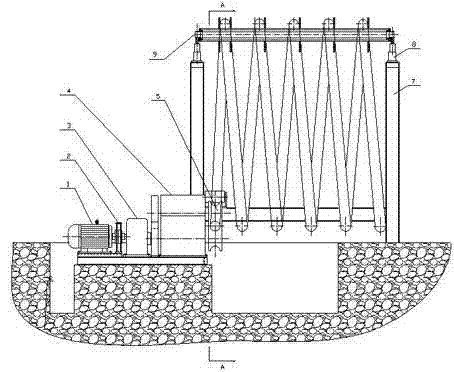

[0044] The key of the present invention is to design and manufacture a coil machine that can directly process the heating furnace coil of the synthetic ammonia device. Bracket, screw pitch positioning device, coil outer diameter limiting device, and straight pipe feeding guide device are combined to form a coil machine.

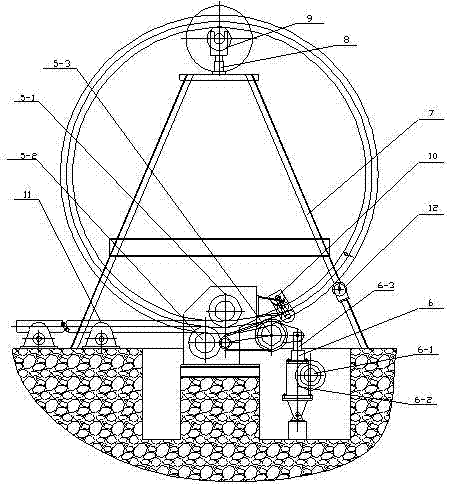

[0045] see diagram 2-1 , Figure 2-2 , Figure 2-3 , the pipe bending machine includes a drive motor 1, a brake 2, a reducer 3, a gear box 4, and a pipe bending wheel set 5 arranged in sequence, and the pipe bending wheel set 5 has a driving fixed wheel 5-1, an auxiliary fixed wheel Wheel 5-2, a liftable movable wheel 5-3, the active fixed wheel 5-1 is fixedly connected to the output shaft of the gearbox 4, the three wheels are arranged in a triangle on the same plane, and the rotation centers of the three wheels They are respectively located at the three vertices of the triangle, and the material straight pipe is bent through the three wheels. By adjusti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com