Online nondestructive flaw detector for pressure pipeline detection

A non-destructive flaw detection and pressure pipeline technology, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of time-consuming, laborious, cracks, and insufficient detection accuracy, and achieve accurate detection, avoid spontaneous rotation, and reliable detection results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

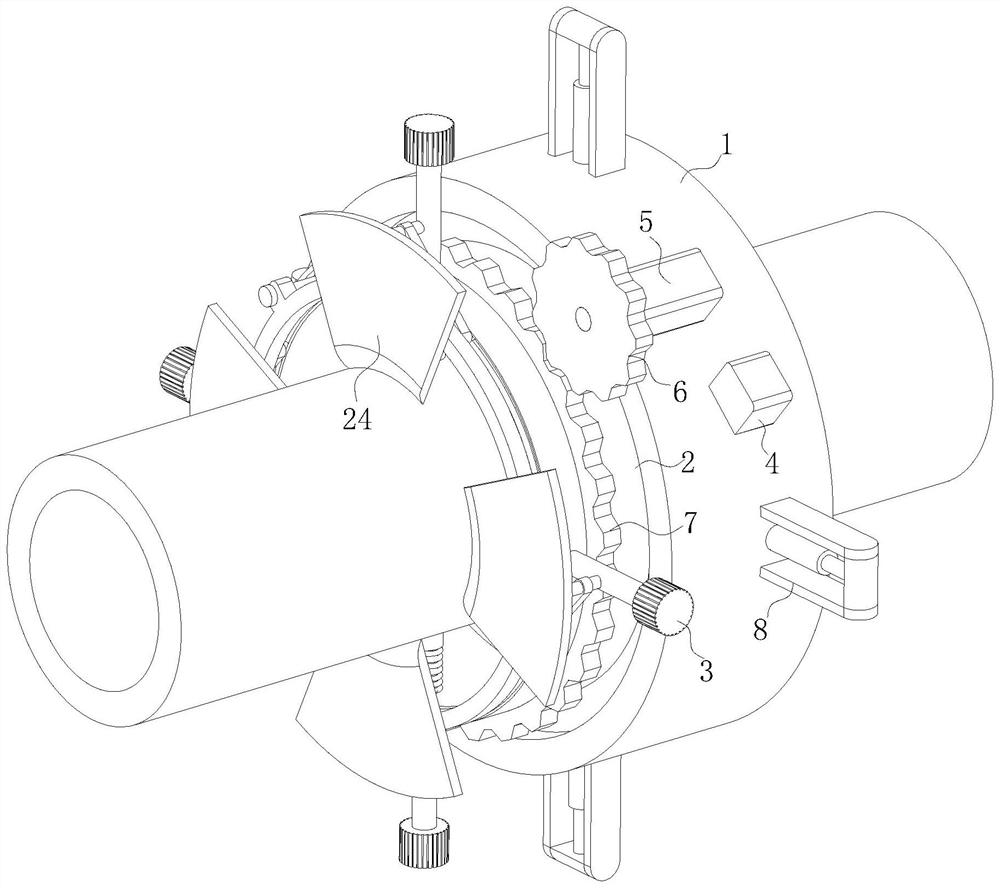

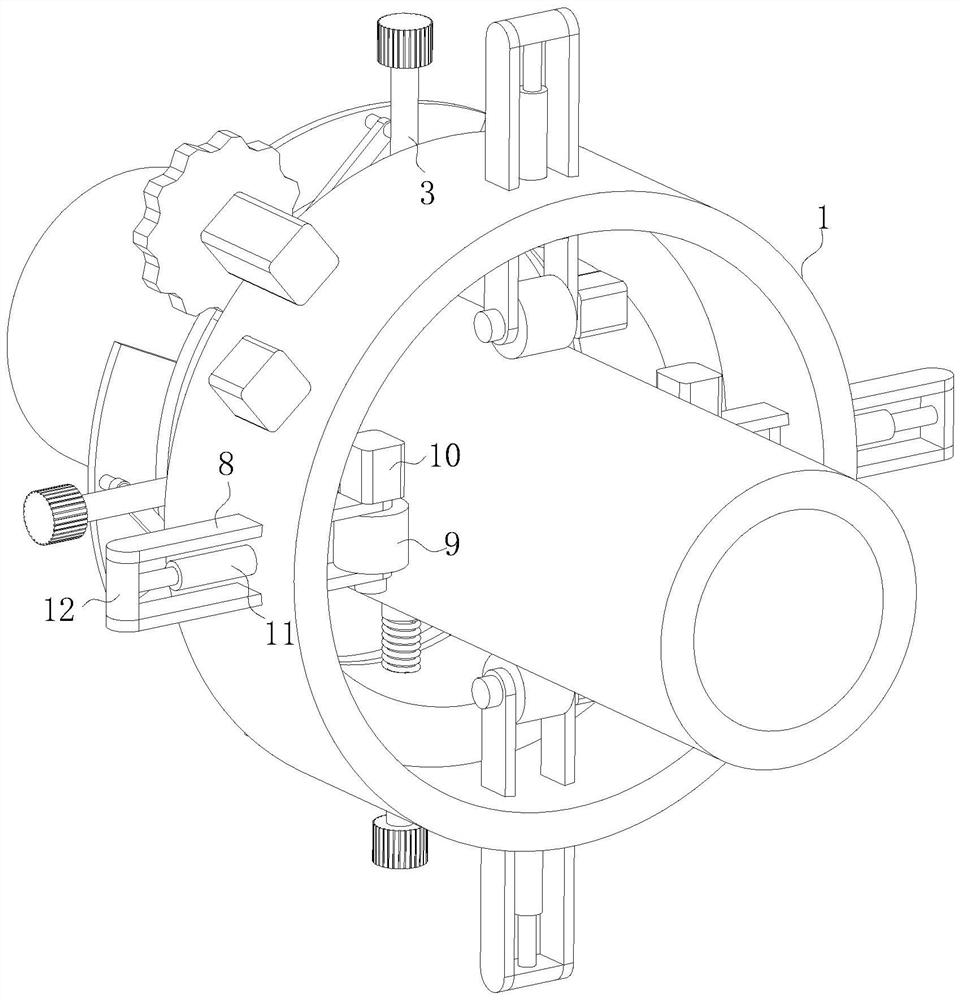

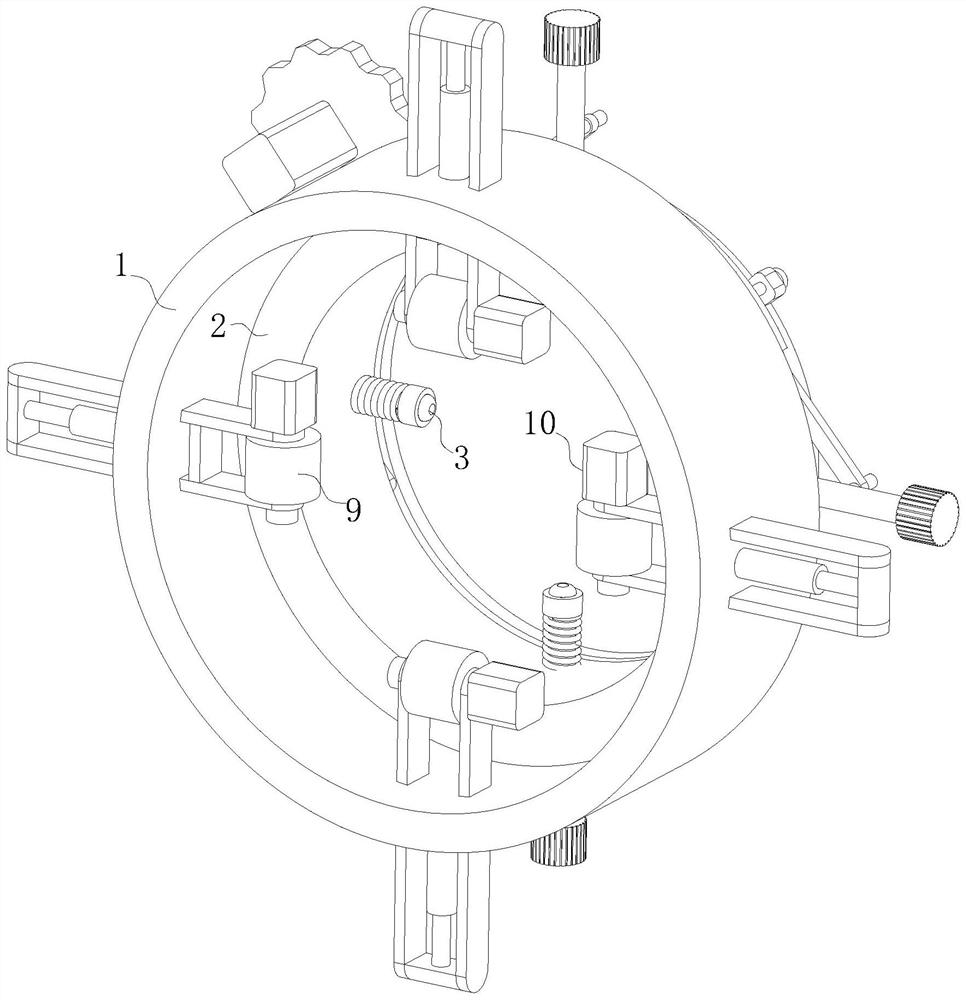

[0026] see Figure 1-7 , the present invention provides a technical solution: an online non-destructive flaw detector for pressure pipeline detection, including a fixed ring 1, the fixed ring 1 is internally connected with a drive mechanism for driving the fixed ring 1 to move along the pipeline, the drive mechanism can be along different Pipelines with large diameters are moved, and the inner wall of the fixed ring 1 is rotatably connected with a first swivel 2, and inside the first swivel 2 is slidingly connected with several flaw detectors 3 in a circular array, and the flaw detectors 3 are arranged in pairs, and the flaw detection The detector 3 surrounds the pipeline and is used to detect the pipeline. An adjustment mechanism for adjusting several flaw detectors 3 is provided on the outside of the first swivel ring 2. A rotating mechanism for driving the first swivel ring 2 is connected to the outer surface of the fixed ring 1. The fixed ring 1. A controller 4 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com