Pressurization method based on drilling pump provided with T-shaped pump head

A technology for drilling pumps and pump heads, which is applied to parts, pump components, and mechanical equipment of pumping devices for elastic fluids, and can solve problems such as inconvenient maintenance, facilitate flaw detection and inspection, reduce impact loads, and improve Effect of Suction Efficiency and Volumetric Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

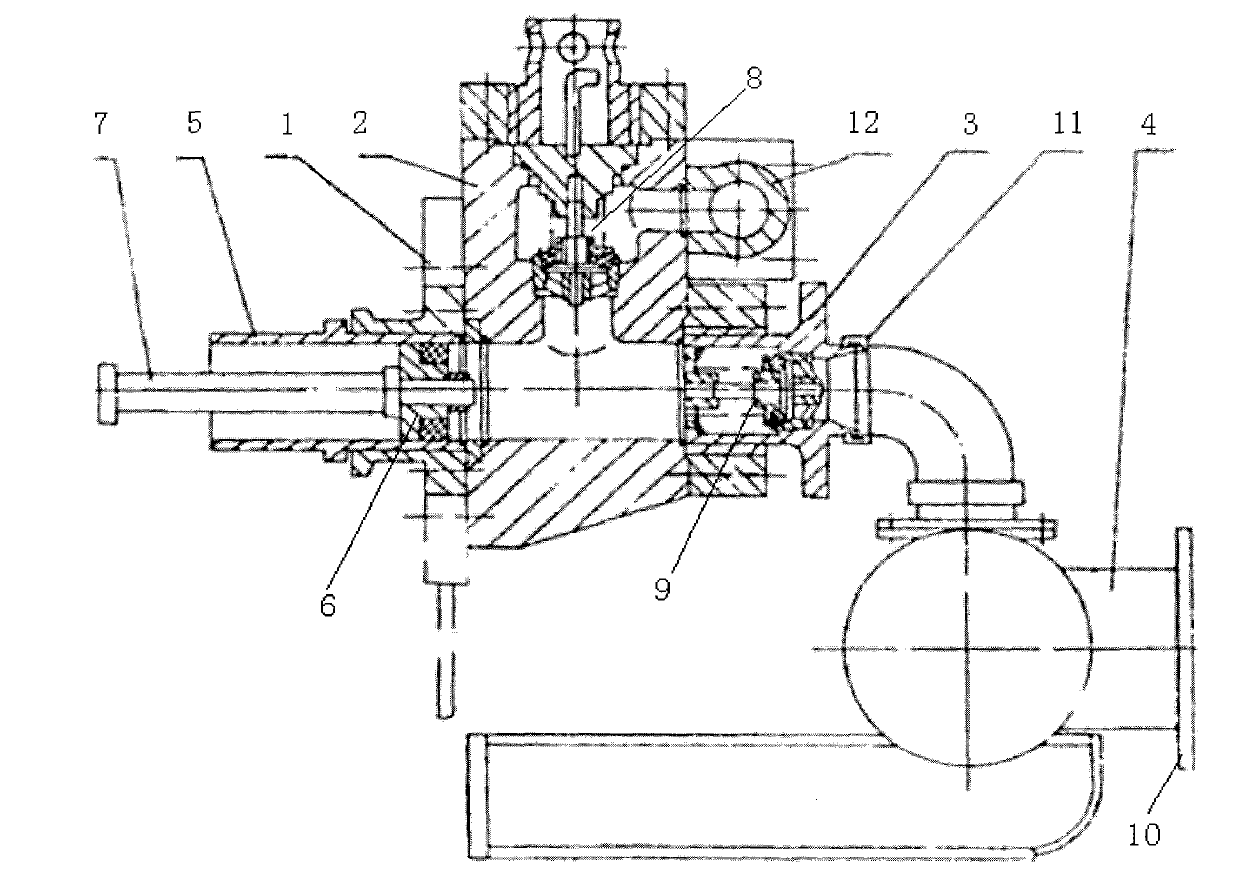

[0033] The pressurization method based on the drilling pump provided with a T-shaped pump head according to the present invention comprises the following steps:

[0034] (a) First, install the suction pipe 4 on the suction liquid cylinder 3, and ensure that it communicates with the inside and the interface is sealed;

[0035] (b) Then open the suction valve 9 and the discharge valve 8, and start the piston device;

[0036] (c) Through the reciprocating movement of the piston device, the liquid is sucked from the suction flange 11 to the suction liquid cylinder 3, and enters the discharge liquid cylinder 2 after passing through the suction valve 9;

[0037] (d) Then, pressurize the liquid entering the discharge cylinder 2 through the reciprocating movement of the piston device;

[0038] (e) After the pressurized liquid passes through the discharge valve 8, it is finally discharged from the discharge pipe 12.

[0039] The suction pipe 4 is installed on the suction cylinder 3 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com