Flaw detection equipment for pump parts processing

A technology for parts and equipment, applied in the field of pump parts processing flaw detection equipment, can solve the problems of low cleaning efficiency, waste of water resources, increased costs, etc., and achieve the effects of improving work efficiency, saving water resources, and facilitating cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

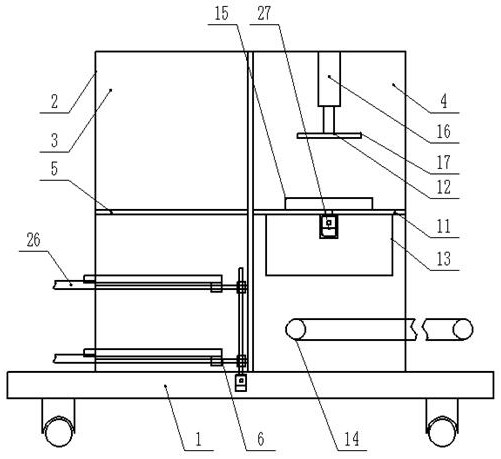

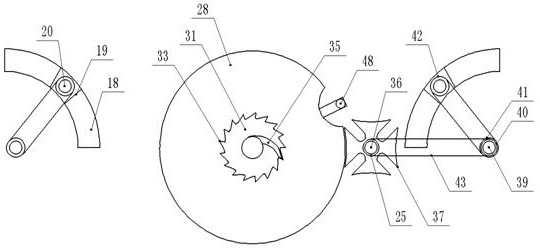

[0014] Embodiment 1: see figure 1, figure 2 , image 3 , Figure 4 , Figure 5 Now, a kind of flaw detection equipment for pump parts processing provided by the present invention will be described, including machine base 1, universal wheels provided at the four corners of the bottom end of machine base 1 and a processing flaw detection box provided at the middle of the upper end of machine base 1 2. The middle part of the processing flaw detection box 2 is provided with a partition along the vertical direction, and the partition divides the inner cavity of the processing flaw detection box 2 into a left processing chamber 3 and a right cleaning flaw detection chamber 4. The middle part of the inner cavity of the left processing chamber 3 is provided with a first support plate 5, the upper end of the first support plate 5 is provided with intelligent processing equipment for pump parts, and the lower end of the inner cavity of the left processing chamber 3 is provided with ...

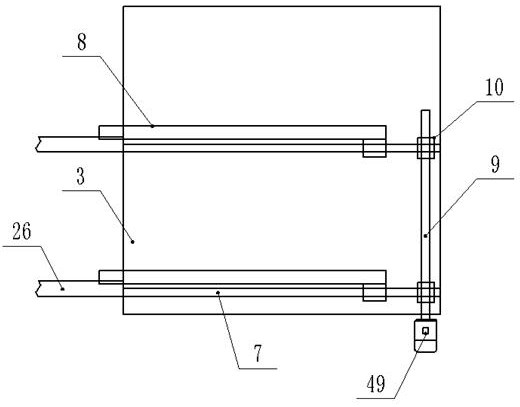

Embodiment 2

[0015] Example 2: see figure 1 , figure 2 , the present invention provides a description of a pump parts processing flaw detection equipment, the number of the first screw 7 is two, the first screw 7 is respectively set in the left processing chamber 3 cavity width direction The middle part, and one end of the first screw 7 is movably connected with the partition respectively, the connection ends of the first screw 7 are respectively covered with the worm wheel 10, and the worm 9 is set corresponding to the position of the worm wheel 10 and The worm 9 and the worm wheel 10 cooperate with each other for transmission. The inner cavity of the base 1 is provided with a first rotating motor 49 and the output shaft of the first rotating motor 49 is connected to the bottom end of the worm 9 through a coupling. Shaft connection, the bottom of the side end of the feeding plate 8 close to the position of the worm wheel 10 and the first screw rod 7 are respectively provided with a firs...

Embodiment 3

[0016] Embodiment 3: see figure 1 , figure 2 , Figure 5 , a pump parts processing flaw detection equipment provided by the present invention will now be described. The pump parts intelligent processing equipment is an existing pump parts processing device, and it includes a punching machine and a grinding machine. The upper end of the cavity is provided with a filter net, and the outer end of the processing flaw detection box 2 is provided with a water storage tank and a fan. The water storage tanks are connected, the fan is connected to the drying head 23 through the air supply pipe, and the second connecting piece and the first connecting piece both include a moving nut and a moving nut respectively set on the outside of the screw rod. There are bearings respectively sleeved on the outside, and the outside of the bearings is connected with the bottom of the feeding plate 8 and one side of the slide seat 21. The internal thread of the moving nut on the first screw rod 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com