Pump part machining and flaw detection equipment

A technology of parts and equipment, which is applied in the field of pump parts processing flaw detection equipment, can solve problems such as low cleaning efficiency, waste of water resources, and environmental damage, and achieve the effects of improving work efficiency, saving water resources, and reducing occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

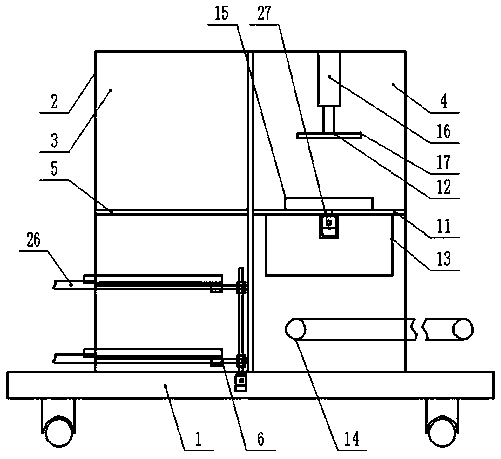

[0017] Embodiment 1: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Now, a kind of flaw detection equipment for pump parts processing provided by the present invention will be described, including machine base 1, universal wheels provided at the four corners of the bottom end of machine base 1 and a processing flaw detection box provided at the middle of the upper end of machine base 1 2. The middle part of the processing flaw detection box 2 is provided with a partition along the vertical direction, and the partition divides the inner cavity of the processing flaw detection box 2 into a left processing chamber 3 and a right cleaning flaw detection chamber 4. The middle part of the inner cavity of the left processing chamber 3 is provided with a first support plate 5, the upper end of the first support plate 5 is provided with intelligent processing equipment for pump parts, and the lower end of the inner cavity of the left processing chamber 3 is provided with...

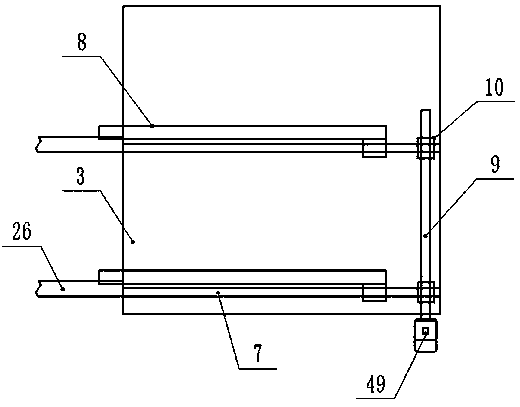

Embodiment 2

[0018] Example 2: see figure 1 , figure 2 , the present invention provides a description of a pump parts processing flaw detection equipment, the number of the first screw 7 is two, the first screw 7 is respectively set in the left processing chamber 3 cavity width direction The middle part, and one end of the first screw 7 is movably connected with the partition respectively, the connection ends of the first screw 7 are respectively covered with the worm wheel 10, and the worm 9 is set corresponding to the position of the worm wheel 10 and The worm 9 and the worm wheel 10 cooperate with each other for transmission. The inner cavity of the base 1 is provided with a first rotating motor 49 and the output shaft of the first rotating motor 49 is connected to the bottom end of the worm 9 through a coupling. Shaft connection, the bottom of the side end of the feeding plate 8 close to the position of the worm wheel 10 and the first screw rod 7 are respectively provided with a firs...

Embodiment 3

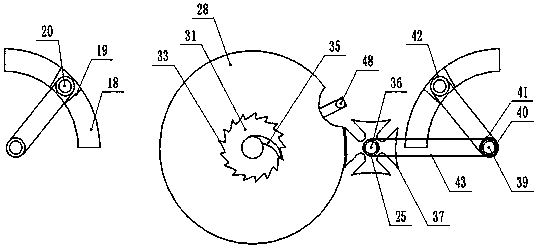

[0019] Embodiment 3: see figure 1 , image 3 , Figure 4 Now, a kind of flaw detection equipment for pump parts processing provided by the present invention will be described. The second support plate 11 has a water permeable hole and the water permeable hole is connected with the inner cavity of the water collection tank 13 through a pipeline. The middle part of the second support plate 11 lower end is provided with a second rotating motor 27, and the disc-shaped placing frame 15 comprises a first disc-shaped placing frame 28 and a second disc-shaped placing frame 29, and the first disc-shaped placing frame The position of frame 28 is movably arranged, and described second disc-shaped placing frame 29 is movably arranged on the upper end of described first disc-shaped placing frame 28, and the middle part of the lower end of described second disc-shaped placing frame 29 has a circular groove 30 , the middle part of the first disk-shaped placement frame 28 has a circular thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com