A laser remanufacturing method for power lithium battery of heavy-duty equipment

A laser remanufacturing and lithium battery technology, which is applied in the manufacture of electrolyte batteries, battery electrodes, and final product manufacturing, can solve the problems of plate resource waste and increase maintenance costs, and achieve maintenance cost savings, prolong service life, and reduce bending The effect of the probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example 1

[0082] Based on a laser remanufacturing method of a power lithium battery for heavy-duty equipment in the first embodiment of the present invention, the second embodiment of the present invention provides another laser remanufacturing method for a power lithium battery for heavy-duty equipment, wherein the second embodiment does not The independent implementation of the technical solution of the first embodiment will not be hindered.

[0083] Specifically, the present invention provides another heavy-duty equipment power lithium battery laser remanufacturing method that is different in that:

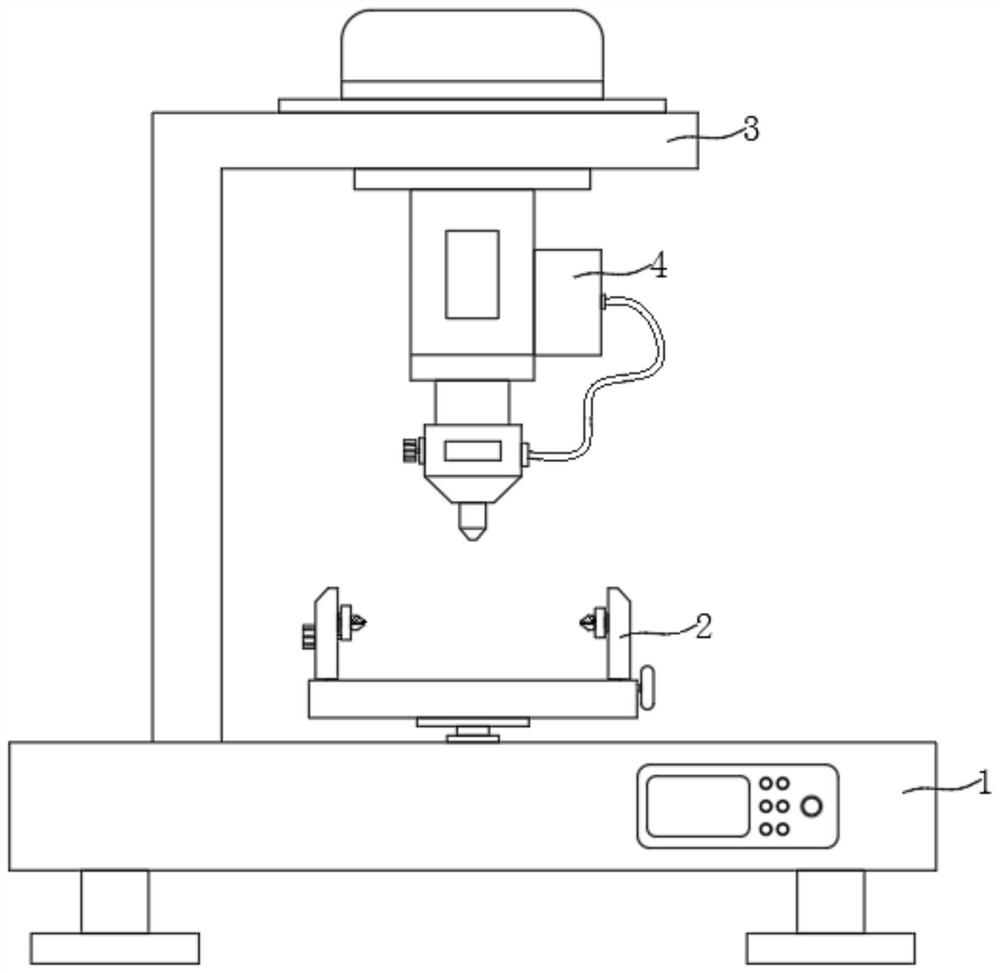

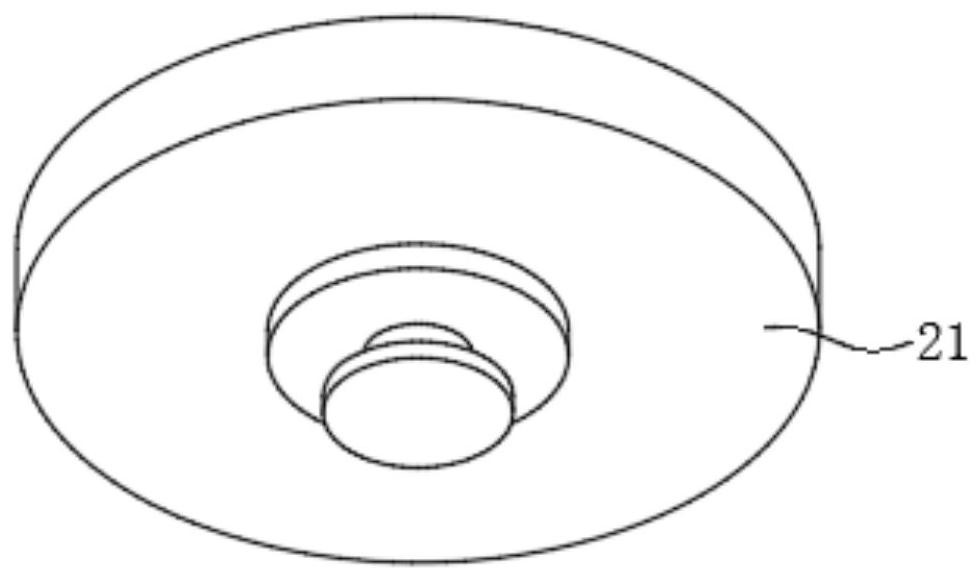

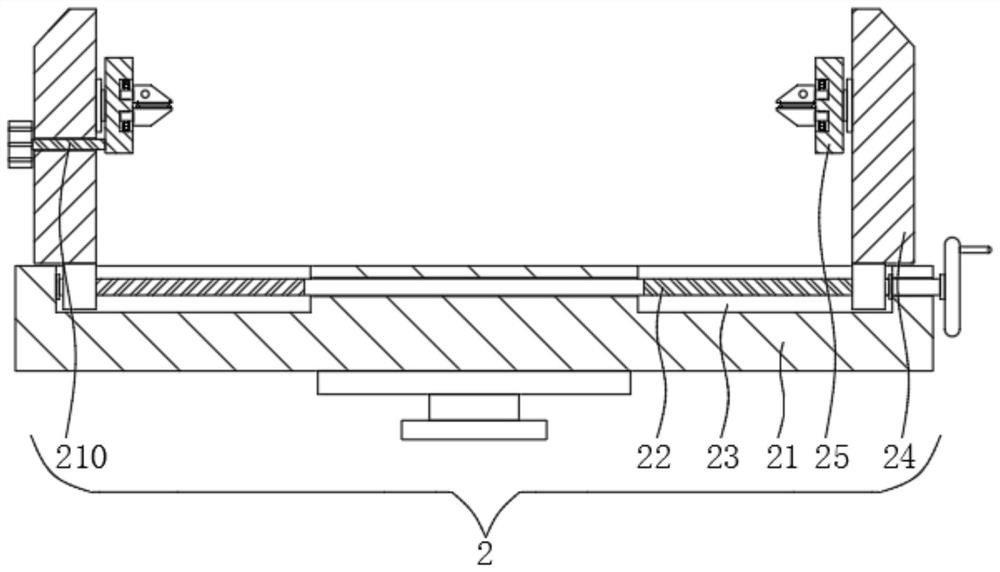

[0084] The laser processing equipment used for repairing the electrode plate in S4, the laser processing equipment includes a workbench 1, and the top of the workbench 1 is provided with a positioning structure 2, and the positioning structure 2 includes a rotating disk 21, so A screw rotating member 22 is rotatably connected to the inside of the rotating disk 21 , a moving groove 23 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com