Amphiphobic fluorine-containing nanofluid as well as preparation method and application thereof

A nano-fluid, amphiphobic technology, applied in chemical instruments and methods, drilling compositions, etc., to achieve the effects of stable product properties, simple preparation methods, and easy control of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

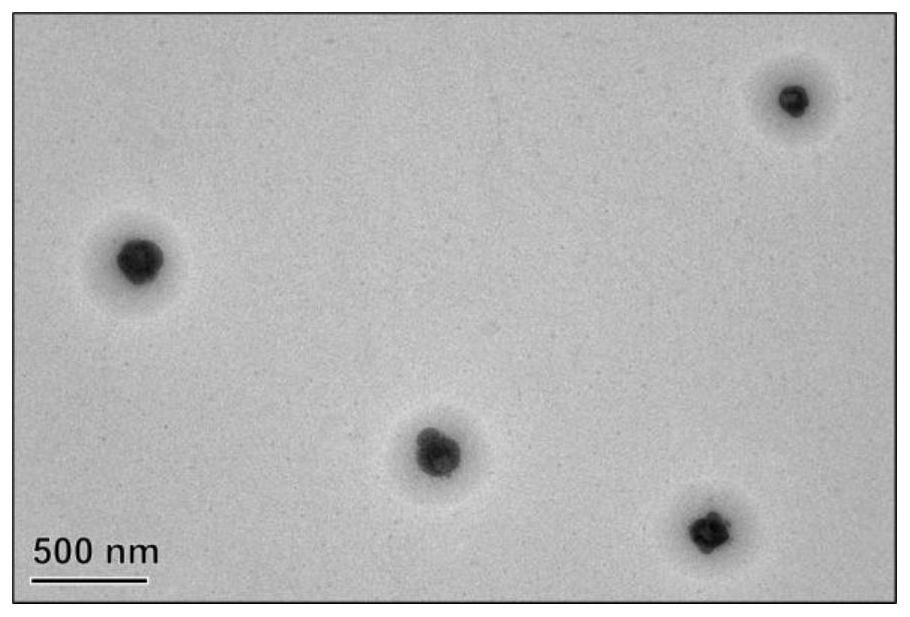

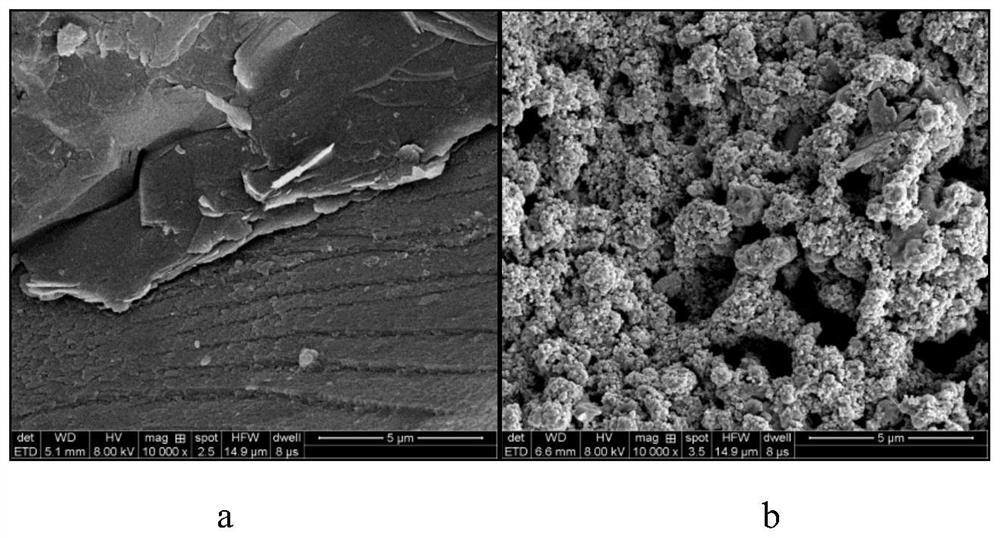

[0047] A method for preparing an amphobic fluorine-containing nanofluid. In a 250mL three-neck flask with a reflux device and electromagnetic stirring, add 0.1g of hydrophilic nano-silicon dioxide and 50mL of absolute ethanol respectively, and adjust the pH with 1mol / L hydrochloric acid To 4, add 0.01mol vinyltrimethoxysilane (1.5g) after ultrasonication for 10min at room temperature, and react at 80°C for 1h to obtain a nano core material; then add 0.01mol 1,1,1,3,3,3 - Add hexafluoroisopropyl acrylate (2.2g), 0.1g sodium lauryl sulfate and 0.1g azobisisobutyronitrile into 50mL N,N-dimethylformamide, and add the prepared The nano-core material was ultrasonically emulsified for 30 minutes, and then heated to 80° C. for 4 hours. After complete reaction, the obtained light yellow emulsion product is amphiphobic fluorine-containing nanofluid with core-shell structure. Yield about 98%.

Embodiment 2

[0049] The preparation method is as described in Example 1, except that the silane coupling agent is vinyltriethoxysilane.

Embodiment 3

[0051] The preparation method is as described in Example 1, except that the silane coupling agent is allyltriethoxysilane, and the emulsifier is 0.1 g sodium perfluorononenyloxybenzenesulfonate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com