High-voltage-resistant insulation material and preparation method thereof

An insulating material and high-voltage-resistant technology, applied in the field of high-voltage-resistant insulating materials and their preparation, can solve the problems of motor insulation aging failure, poor corona performance, and threaten the life insulation reliability of variable frequency motors, and achieve corona resistance and anti-corona performance. The effect of increased ablative power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

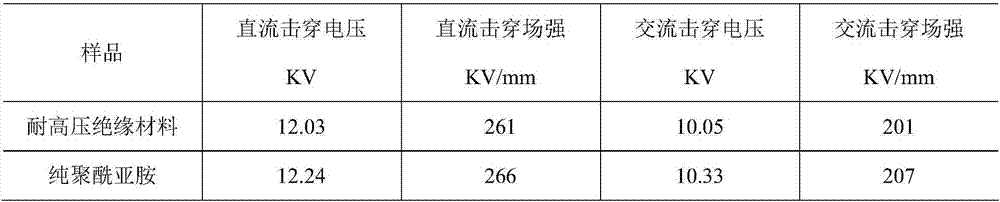

Examples

specific Embodiment approach 1

[0025] A high-voltage resistant insulating material, the high-voltage resistant insulating material is mainly composed of trimellitic anhydride, 5-norbornane-2,3-dicarboxylic acid monomethyl ester, N-methylpyrrolidone, xylene, N,N-dicarboxylate Methylacetamide, phenol, 4,4'-diphenylmethane diisocyanate, modified nanoparticles, modified nanofibers, including 15 parts by weight of trimellitic anhydride, 20 parts of 5-norbornane- 2,3-dicarboxylic acid monomethyl ester, 30 parts of N-methylpyrrolidone, 10 parts of xylene, 15 parts of N,N-dimethylacetamide, 5 parts of phenol, 40 parts of 4,4 '-Diphenylmethane diisocyanate, 1 part of modified nanoparticles, 1 part of modified fibers.

[0026] In the high-voltage insulating material described in this embodiment, the modified nanoparticles are modified nano-SiO 2 and modified nano-Al 2 o 3 A mixture in which the modified nano-SiO 2 and modified nano-Al 2 o 3 The mass ratio is 0.2:1, and the modifying liquid is KH902 silane coupl...

specific Embodiment approach 2

[0034] According to the high-voltage-resistant insulating material described in the first specific embodiment, it includes the following steps:

[0035] Step 1, the weighed nano-SiO 2 and nano Al 2 o 3 Place the modified liquid in the alcohol solution of KH902 silane coupling agent, mix and stir for 120 minutes, let it stand for 24 hours, filter the mixture obtained after suction, and dry it in vacuum to obtain modified nanoparticles, which are ready for use;

[0036] Step 2. Put the weighed glass fiber in the KH902 silane coupling agent alcohol solution as the modification liquid, mix and stir for 120 minutes, then let it stand for 24 hours, filter the mixture obtained after suction, dry it in a vacuum, and carry out surface mechanical grinding. Obtain modified fiber, stand-by;

[0037] Step 3. Add the weighed trimellitic anhydride, 5-norbornane-2,3-dicarboxylic acid monomethyl ester, and N-methylpyrrolidone into a three-necked beaker equipped with nitrogen protection, mec...

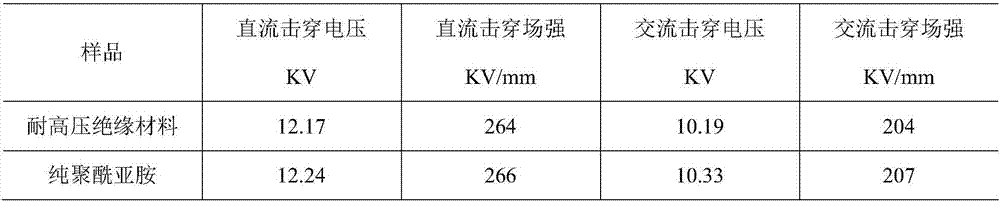

specific Embodiment approach 3

[0045] A high-voltage resistant insulating material, the high-voltage resistant insulating material is mainly composed of trimellitic anhydride, 5-norbornane-2,3-dicarboxylic acid monomethyl ester, N-methylpyrrolidone, xylene, N,N-dicarboxylate Methylacetamide, phenol, 4,4'-diphenylmethane diisocyanate, modified nanoparticles, modified nanofibers, including 30 parts by weight of trimellitic anhydride, 30 parts of 5-norbornane- 2,3-dicarboxylic acid monomethyl ester, 70 parts of N-methylpyrrolidone, 20 parts of xylene, 30 parts of N,N-dimethylacetamide, 10 parts of phenol, 100 parts of 4,4 '-Diphenylmethane diisocyanate, 5 parts of modified nanoparticles, 1 part of modified fiber.

[0046] In the high-voltage insulating material described in this embodiment, the modified nanoparticles are modified nano-SiO 2 and modified nano-Al 2 o 3 A mixture in which the modified nano-SiO 2 and modified nano-Al 2 o 3 The mass ratio is 1:10, and the modifying liquid is KH902 silane coup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com