Method for preparing ferronickel byproduct active smelting electric furnace grain slag through red mud and nickel laterite ore

A technology for laterite nickel ore and iron-nickel alloy, which is applied in the direction of improving process efficiency, can solve problems such as a large amount of ferronickel smelting slag storage, etc., so as to improve the ferronickel smelting process, change chemical composition and mineral composition, and improve hydration. active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

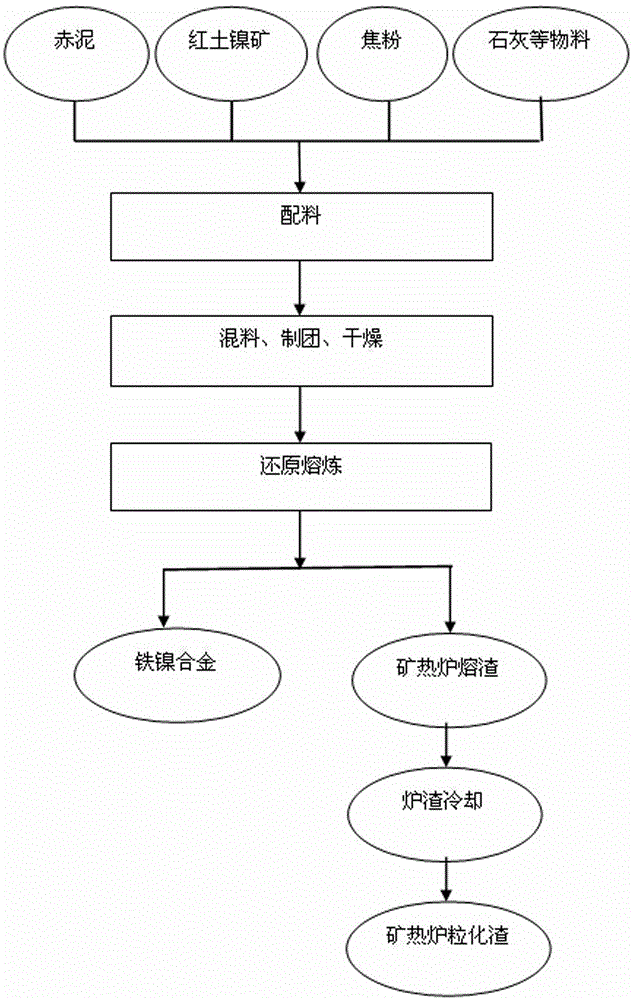

[0026] The present invention utilizes red mud and laterite nickel ore to prepare the method for by-product active submerged arc furnace granulated slag, wherein, the method comprises the following steps:

[0027] 1) The selected raw materials are red mud, laterite nickel ore and coke powder. The main chemical composition and mass percentage of red mud are: Fe 2 O 3 32.96%, Al 2 O 3 17.25%, CaO 14.73%, SiO 2 12.81%, Na 2 O 4.06%; the main chemical composition and mass percentage of laterite nickel ore are: Fe 16.62%, Ni 1.70%, MgO 17.18%, CaO 0.31%, SiO 2 40.12%, Cr 2 O 3 0.86%; coke powder contains fixed carbon 65.02%, SiO 2 13.88%, CaO 2.96%; CaO content in lime is greater than 95%, Na in sodium silicate 2 SiO 3 ≥96%.

[0028] 2) According to the mass ratio of red mud: laterite nickel ore: coke powder: lime: sodium silicate = 100: 60: 10: 8: 3.4, the ingredients are made into dry agglomerates.

[0029] 3) The dry agglomerate obtained by the above steps is se...

Embodiment 2

[0032] The present invention utilizes red mud and laterite nickel ore to prepare the method for by-product active submerged arc furnace granulated slag, wherein, the method comprises the following steps:

[0033]1) The selected raw materials are red mud, laterite nickel ore and coke powder; the main chemical components and mass ratio of red mud are: Fe 2 O 3 32.96%, Al 2 O 3 17.25%, CaO 14.73%, SiO 2 12.81%, Na 2 O 4.06%; the main chemical composition and mass ratio of laterite nickel ore are: Fe 16.62%, Ni 1.70%, MgO 17.18%, CaO 0.31%, SiO 2 40.12%, Cr 2 O 3 0.86%; coke powder contains fixed carbon 65.02%, SiO 2 13.88%, CaO 2.96%; sodium silicate contains Na 2 SiO 3 ≥96%.

[0034] 2) According to the mass ratio of red mud: laterite nickel ore: coke powder: sodium silicate = 20: 80: 10: 2.4, ingredients are made to make dry agglomerates.

[0035] 3) The dried agglomerates obtained by the above steps are sent to a 150kW submerged arc furnace for direct reductio...

Embodiment 3

[0038] The present invention utilizes red mud and laterite nickel ore to prepare the method for by-product active submerged arc furnace granulated slag, wherein, the method comprises the following steps:

[0039] 1) The selected raw materials are red mud, laterite nickel ore, limestone and coke powder; the main chemical composition and mass percentage of red mud are: Fe 2 O 3 32.96%, Al 2 O 3 17.25%, CaO 14.73%, SiO 2 12.81%, Na 2 O 4.06%; the main chemical composition and mass percentage of laterite nickel ore are: Fe 16.62%, Ni 1.70%, MgO 17.18%, CaO 0.31%, SiO 2 40.12%, Cr 2 O 3 0.86%; coke powder contains fixed carbon 65.02%, SiO 2 13.88%, CaO 2.96%; CaCO in limestone 3 Content greater than 97%, Na in sodium silicate 2 SiO 3 ≥96%.

[0040] 2) According to the mass ratio of red mud: laterite nickel ore: coke powder: limestone: sodium silicate = 10: 100: 5: 9: 1.8, ingredients are made to make dry agglomerates.

[0041] 3) The dried agglomerates obtained by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com