Heat exchanger for air and freezer device

a technology of air and freezer device and heat exchanger, which is applied in the field of air heat exchanger and refrigeration apparatus, can solve the problems of reducing refrigerating capacity, heat exchanger reducing evaporation performance and heating performance, and heat exchanger reducing heat exchange capacity, so as to suppress the reduction of energy efficiency, prevent the reduction of an effect of refrigerating operation, and reduce the effect of heating comfor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

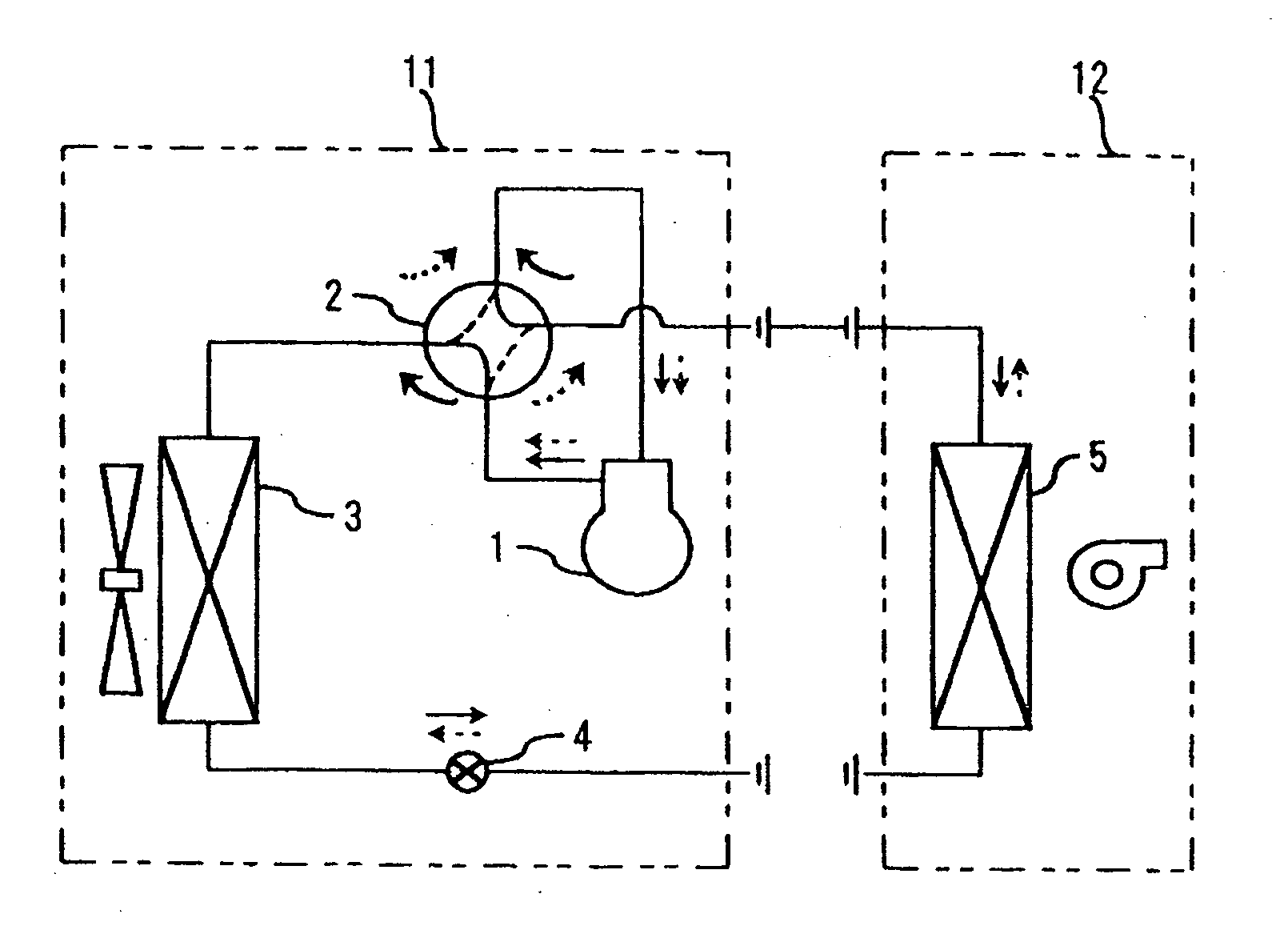

[0509] Embodiment 1 will be described with reference to FIGS. 29 and 30. FIG. 29 is a view showing a refrigerant circuit of the refrigeration apparatus of Embodiment 1. FIG. 30 is a perspective view showing an outdoor heat exchanger used in the same refrigeration apparatus.

[0510] The refrigeration apparatus of Embodiment 1 is a separate heat pump air conditioner, as shown in FIG. 29. The discharge side and the suction side of a compressor 1 are connected to a discharge port 2a and a suction port 2b of a four-way selector valve 2. Between switching ports 2c and 2d of the four-way selector valve 2, an outdoor heat exchanger 3, an expansion mechanism 4, and an indoor heat exchanger 5 are connected to each other. The compressor 1, the four-way selector valve 2, and the outdoor heat exchanger 3 are stored in an outdoor unit 11, and the indoor heat exchanger 5 is stored in an indoor unit 12. By switching the four-way selector valve 2, during cooling, a refrigerant is caused to flow as in...

embodiment 2

[0518] Embodiment 2 is a refrigeration apparatus using slit plate fins (slit fins) 21 instead of the flat plate fins 15 in Embodiment 1. FIG. 31 is a cross-sectional view of an outdoor heat exchanger 3 of the refrigeration apparatus of this Embodiment 2 cut with the cross-section of slit plate fins 21. FIG. 32 is a cross-sectional view of an outdoor heat exchanger 3 of the refrigeration apparatus of Embodiment 2 cut with the plane of a slit plate fin 21. FIG. 32 shows only the slit plate fin 21 for one row of heat exchange pipes 22.

[0519] As shown in the figures, in the slit plate fins 21 of the outdoor heat exchanger 3 in this embodiment, large or small trapezoid slits 21a and 21b are formed between the adjacent heat exchange pipes 22.

[0520] According to the refrigeration apparatus of this Embodiment 2, since the heat exchange surface of the outdoor heat exchanger 3 has the same surface structure as in Embodiment 1, the embodiment can exhibit the same effect as in Embodiment 1.

[...

embodiment 3

[0522] Embodiment 3 is a refrigeration apparatus using louver plate fins (louver fins) 31 instead of the flat plate fins 15 in Embodiment 1. FIG. 33 is a cross-sectional view of an outdoor heat exchanger 3 of the refrigeration apparatus of this Embodiment 3 cut with the cross-section of louver plate fins 31.

[0523] As shown in the figure, in the louver plate fins 31 of the outdoor heat exchanger 3 in this embodiment, louvers 31a are formed at a predetermined pitch.

[0524] Because of this, according to the refrigeration apparatus of this Embodiment 3, since the heat exchange surface of the outdoor heat exchanger 3 has the same surface structure as in Embodiment 1, the embodiment can exhibit the same effect as in Embodiment 1.

[0525] Since the refrigeration apparatus of this Embodiment 3 uses the louver plate fins 31, frost or ice can be easily cut with the louvers 31a during defrost operation. Thus, a mass of frost or ice attached to the heat exchange surface can be made suitably sma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com