Method for preparing epitaxial graphene by thermal cracking silicon carbide

A graphene and silicon carbide technology, applied in the field of materials, can solve the problems of reducing the quality and uniformity of epitaxial graphene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

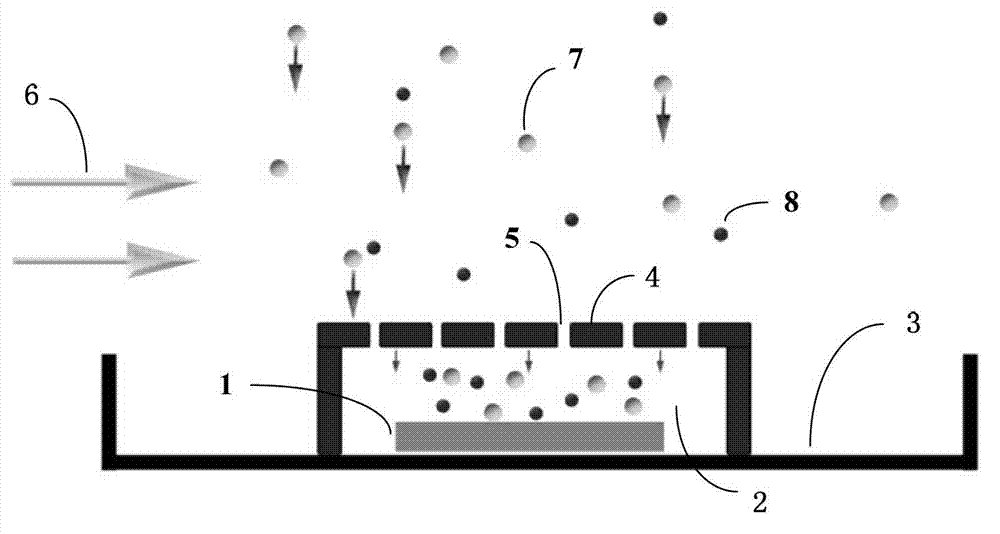

[0013] Attached below figure 1 and specific examples to further illustrate specific embodiments of the present invention.

[0014] The 5×5 mm silicon carbide substrate 1 was washed successively with acetone, isopropanol, and hydrofluoric acid solution, rinsed with deionized water, and dried with a nitrogen gun. Place the cleaned substrate 1 in the epitaxial region 2 of the graphite boat 3, and put it into the pyrolysis silicon carbide system until the vacuum degree reaches 1×10 -5 After Pa, 0.7-0.9 atmospheric pressure of high-purity hydrogen is introduced, and the temperature is kept at 1550° C. for 15-20 minutes to etch the surface of the substrate 1 to form a regular step shape. Naturally cool down to room temperature under the protection of hydrogen, and discharge hydrogen. Fasten the graphite cap 4 with pores 5 on top of the silicon carbide substrate 1 . It is then put into a pyrolysis silicon carbide system. When the vacuum reaches 1×10 again -5 Pa, through the 0.7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com