Patents

Literature

46results about How to "Lower boiling temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

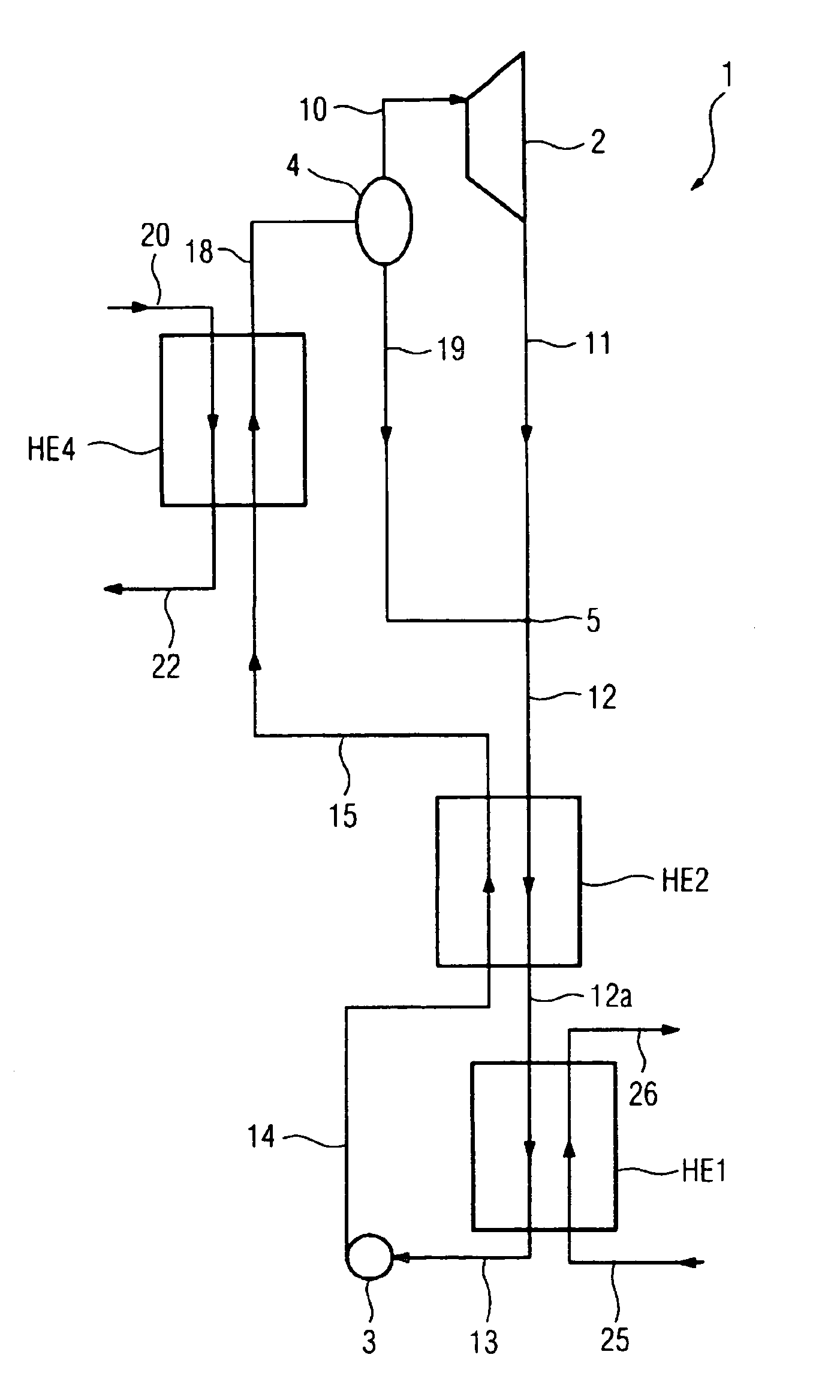

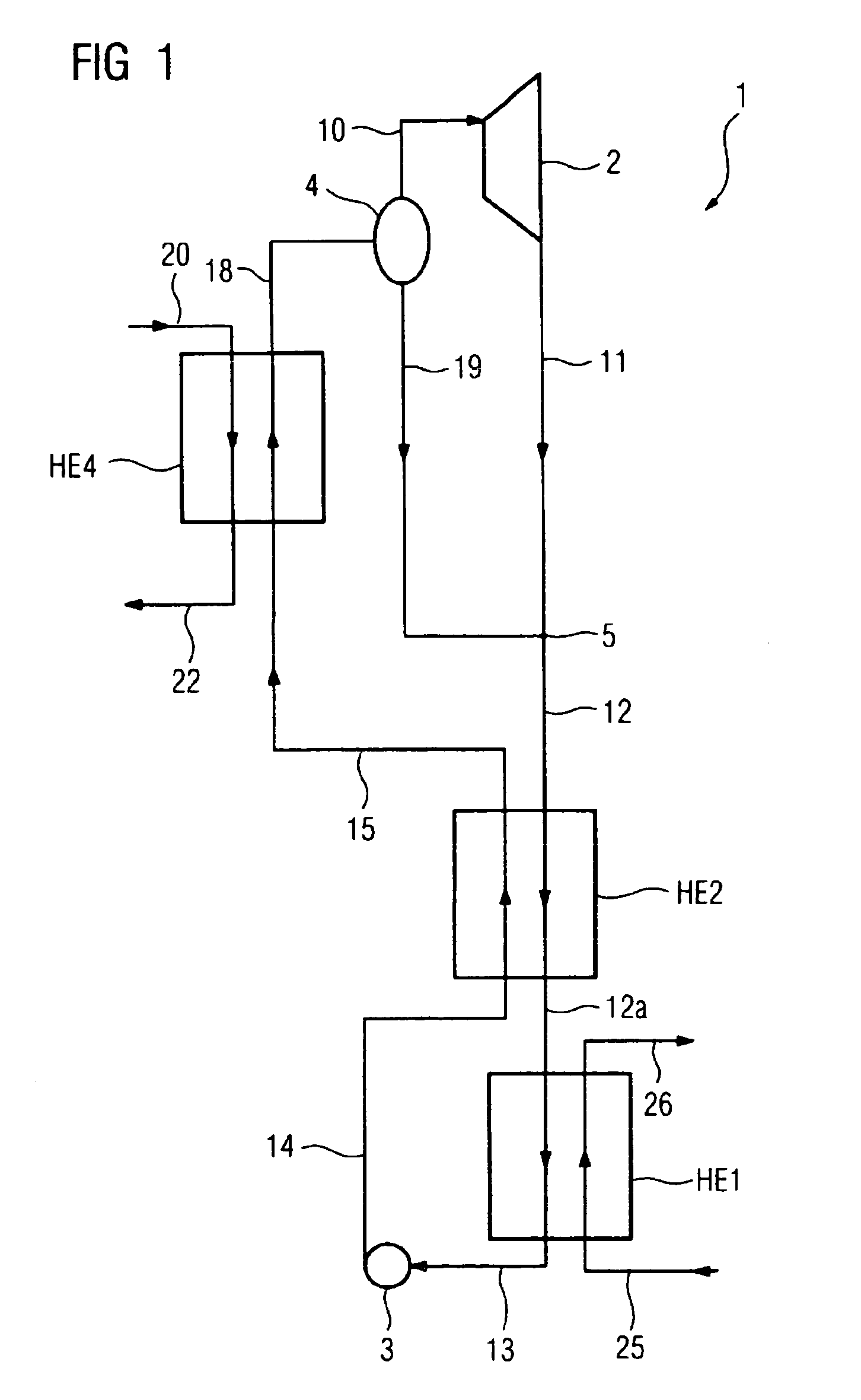

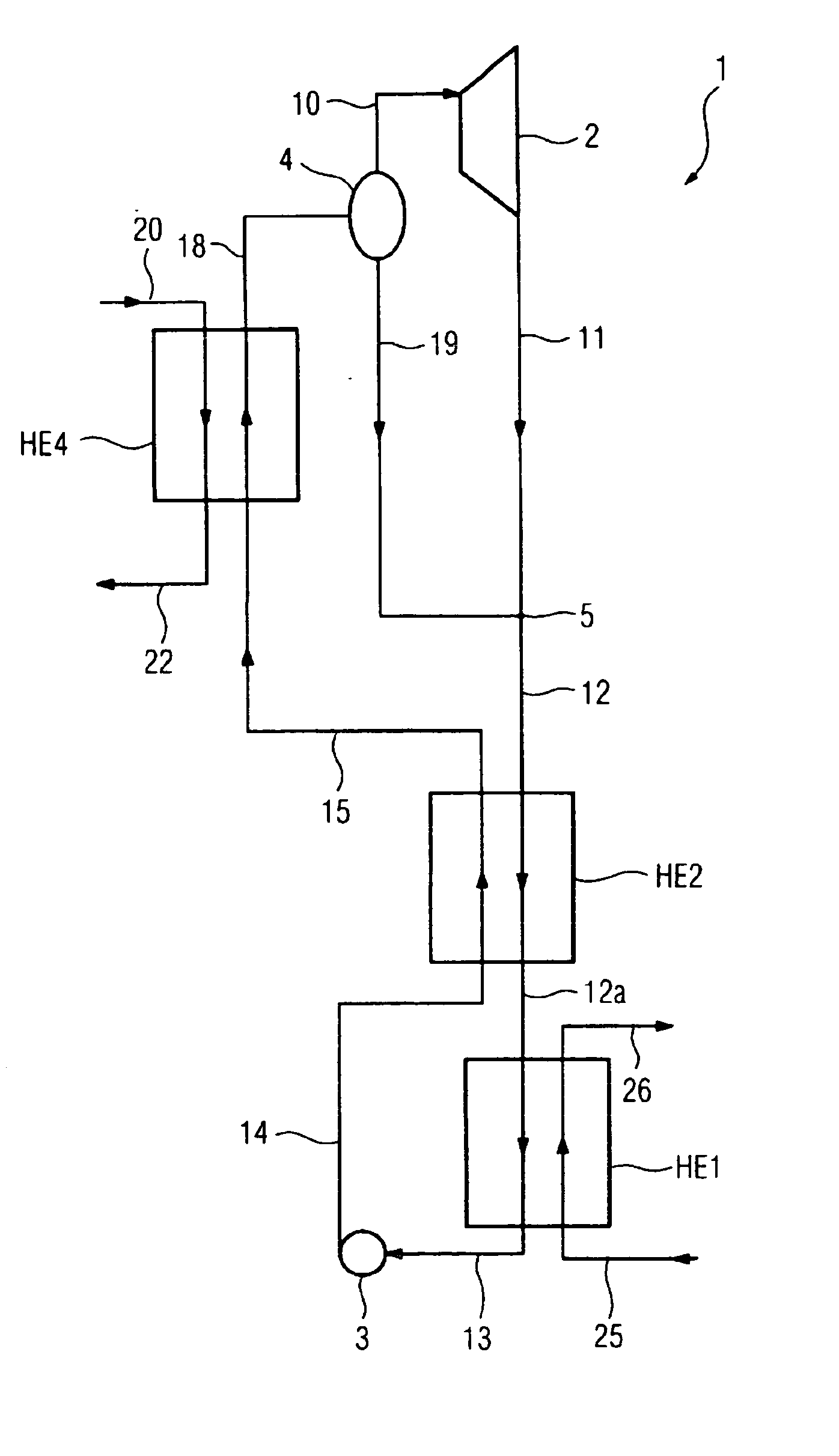

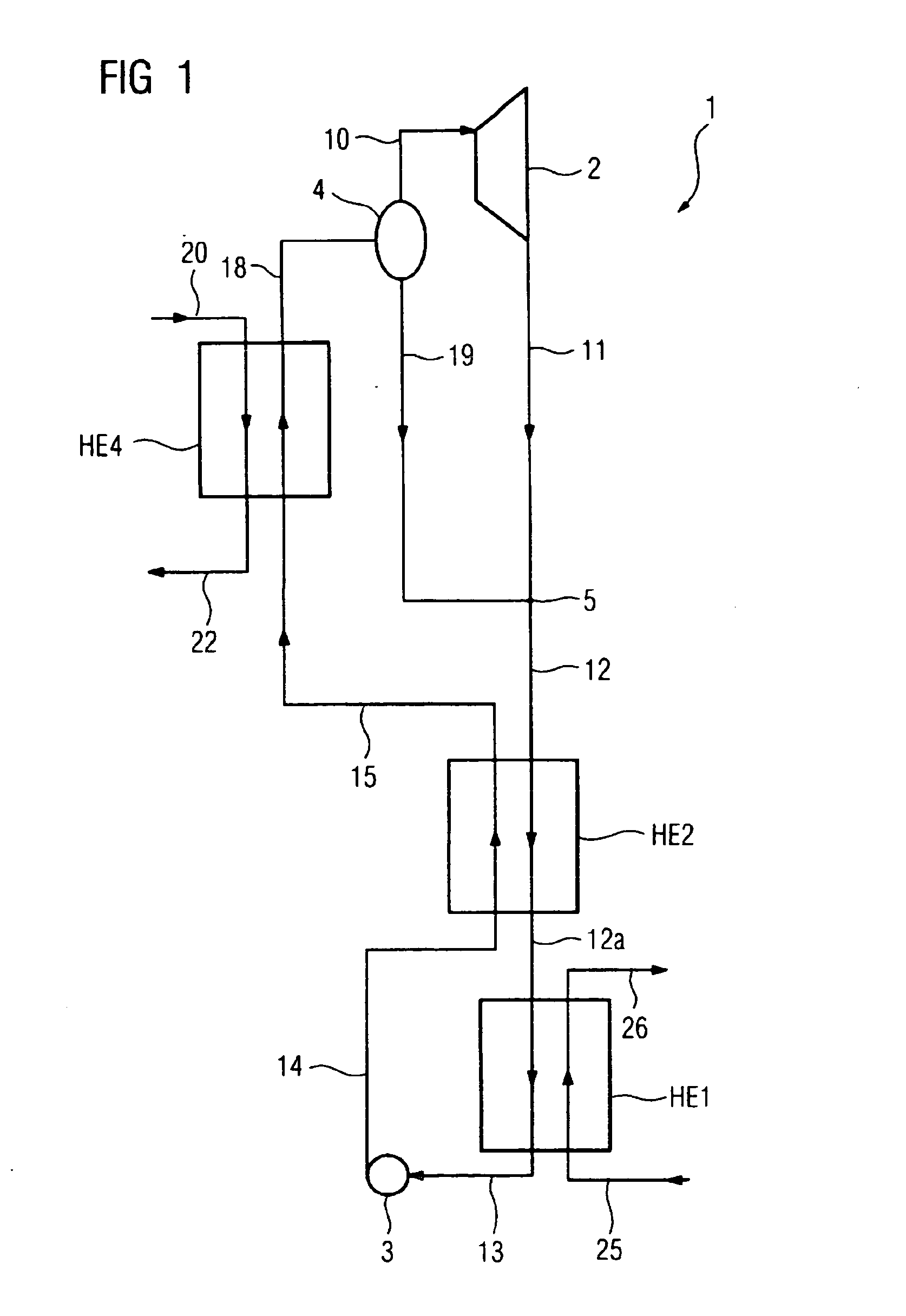

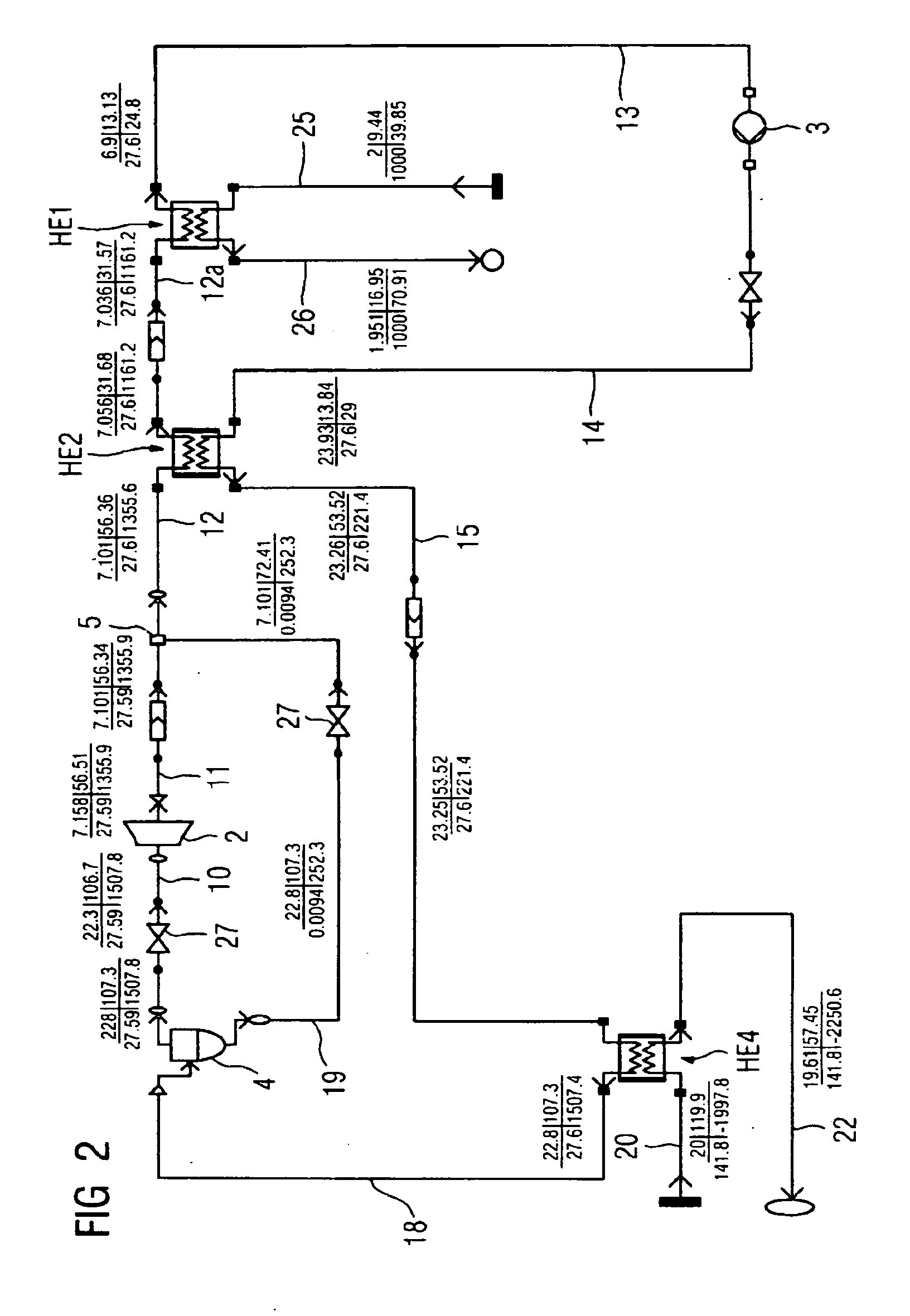

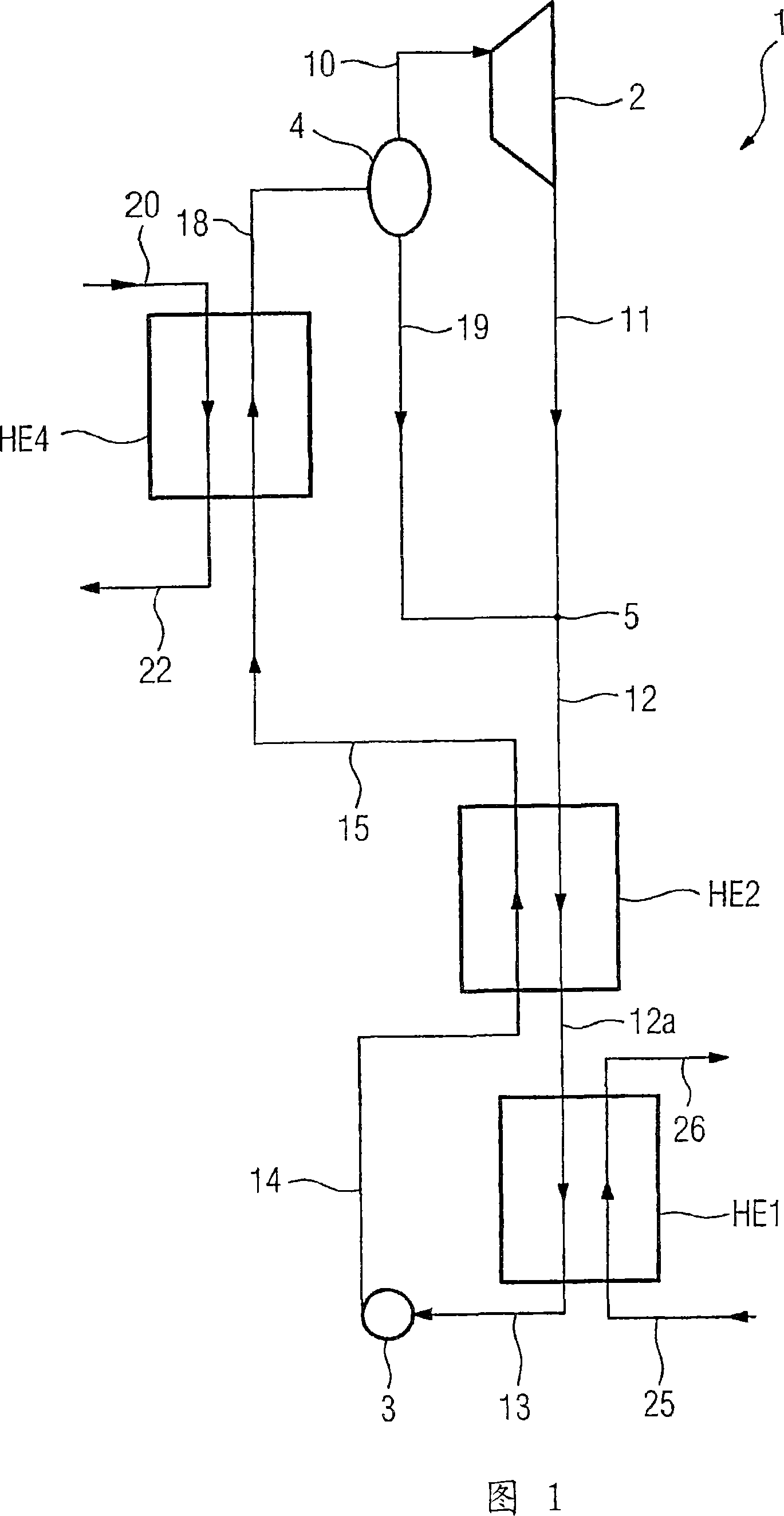

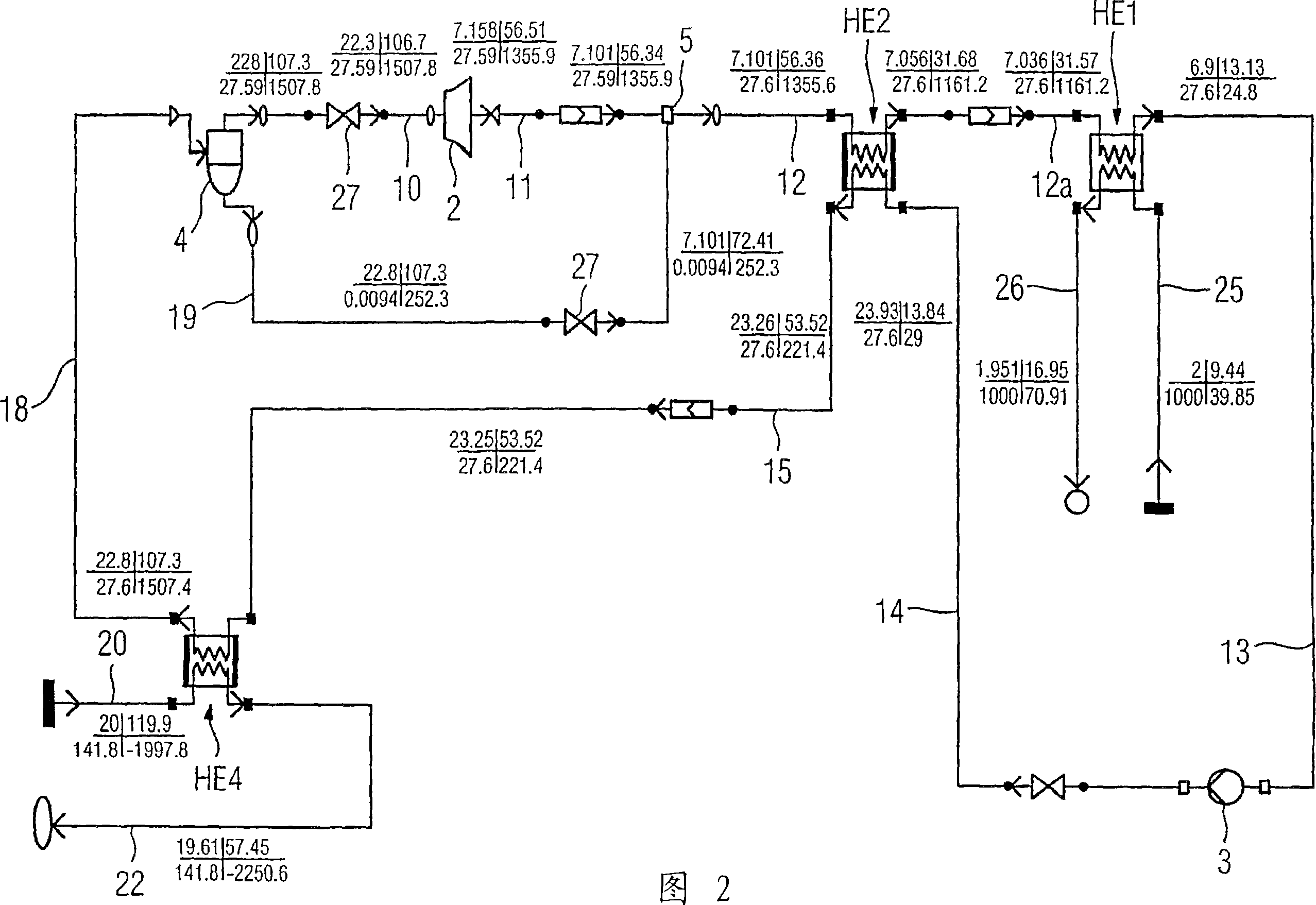

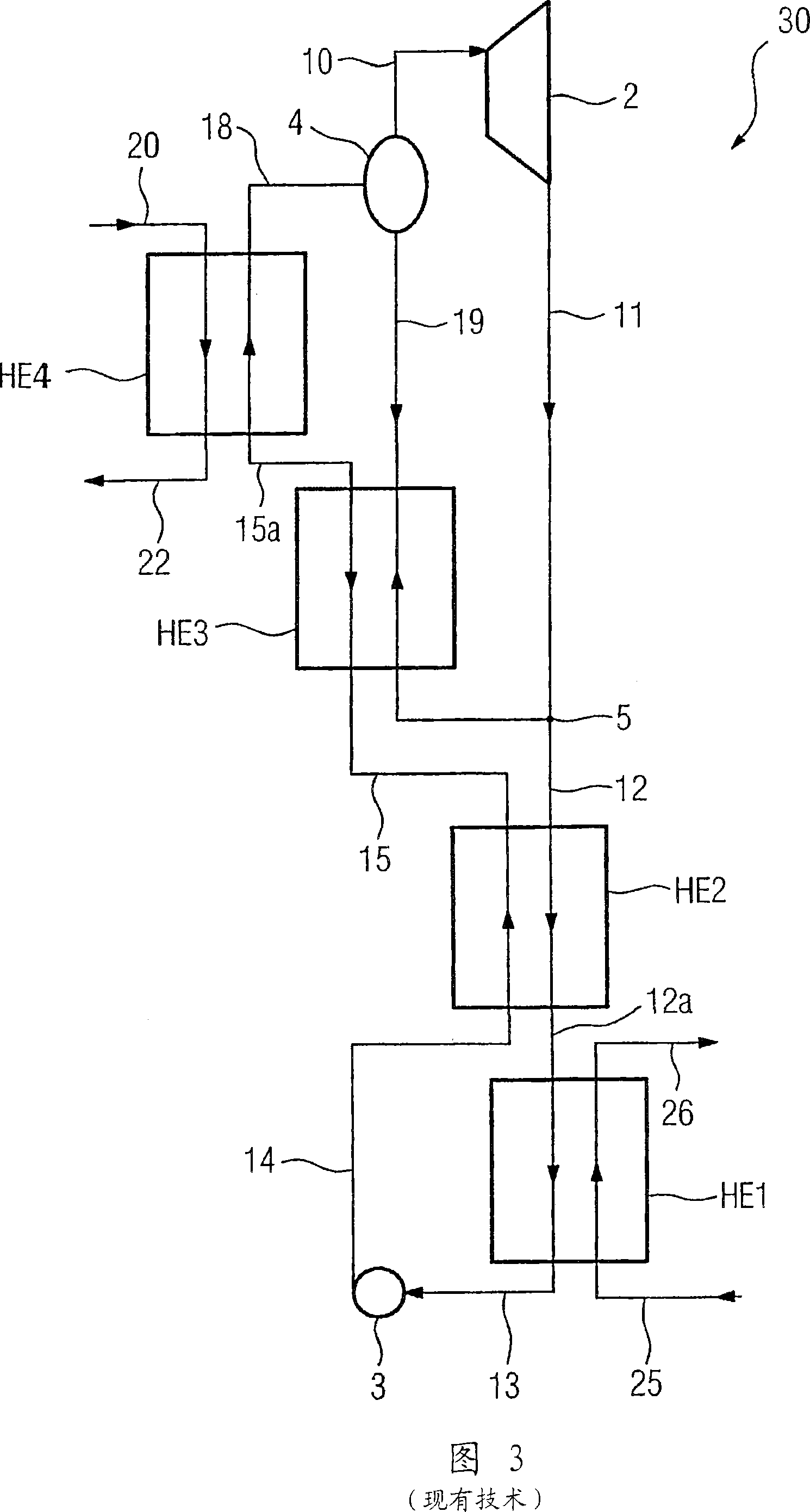

Method and device for carrying out a thermodynamic cyclic process

ActiveUS8272217B2Improve the level ofImprove cycle efficiencyGeothermal energy generationSteam engine plantsCyclic processVaporization

Owner:KALINA POWER LTD

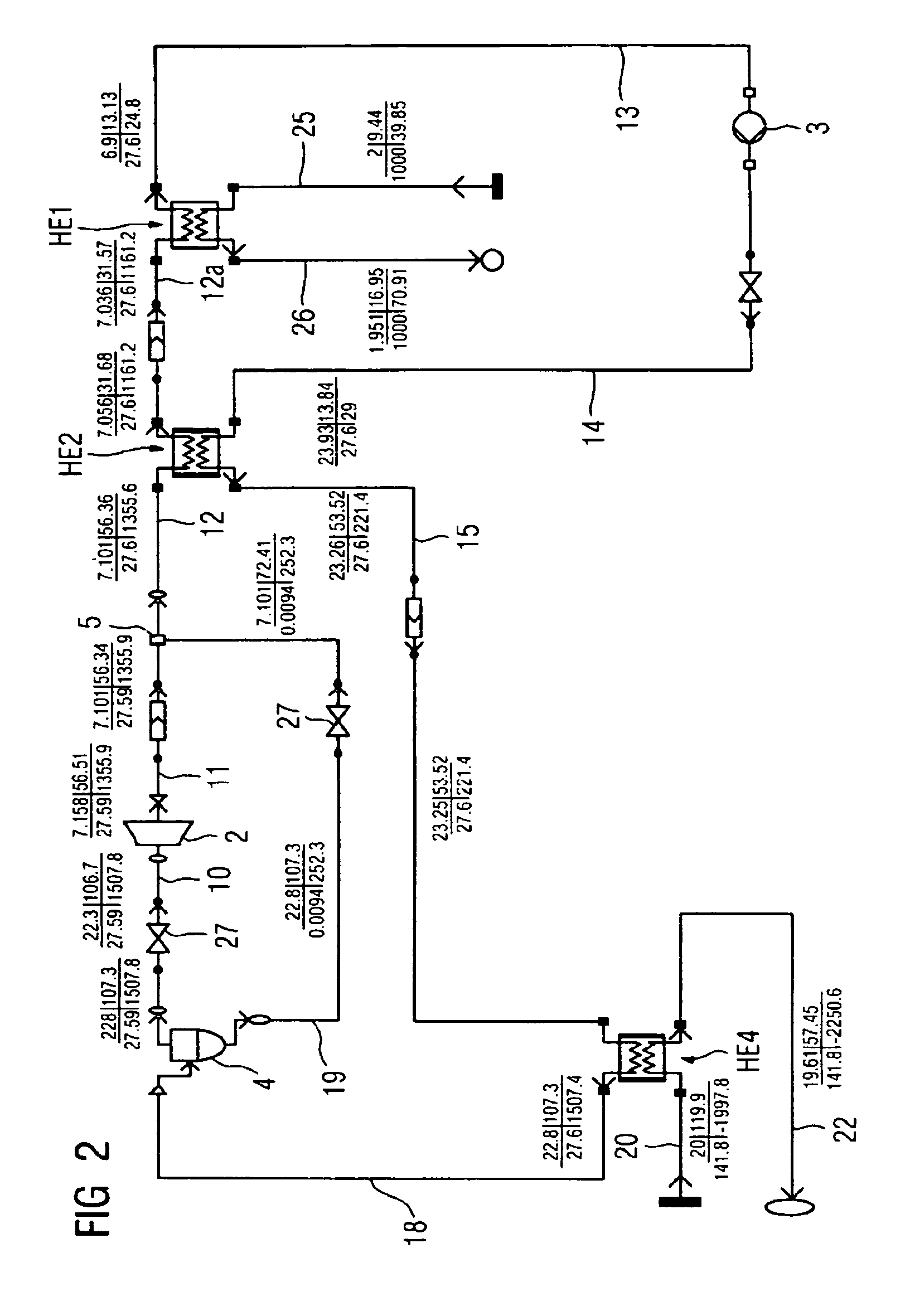

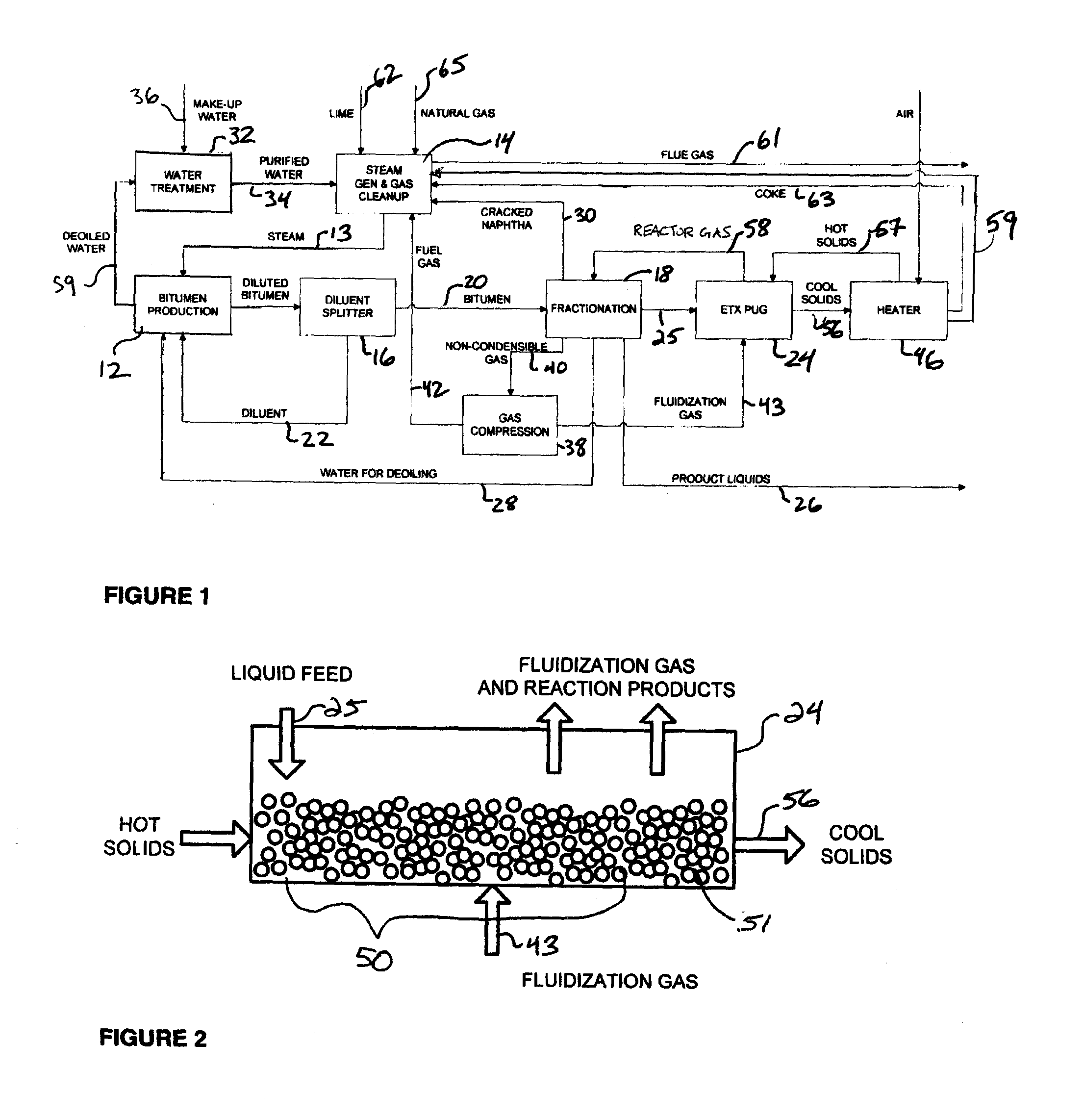

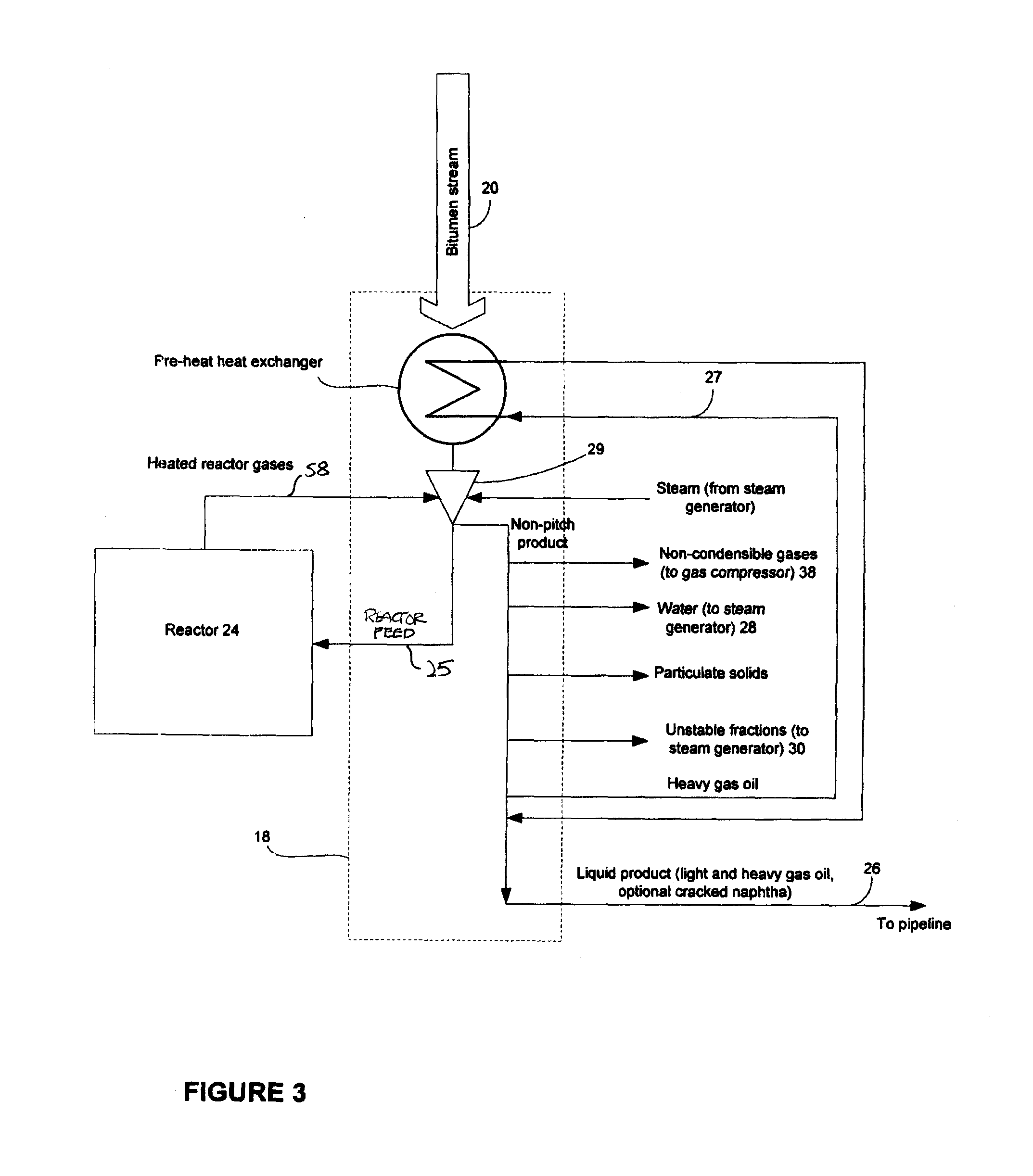

Process for upgrading heavy oil and bitumen products

InactiveUS20120000830A1Lower boiling temperatureEliminate needThermal non-catalytic crackingCatalytic crackingLiquid productGas phase

A process for upgrading bitumen recovered from an oil reservoir without hydrogen production is particularly useful in field upgrading applications. In this process, recovered bitumen enters a fractionator and is contacted with heated gases from a fluidized bed reactor. The bitumen and heated gases are fractionated into segregated products including at least a liquid pitch, unstable fractions, and an upgraded liquid product. The liquid pitch is introduced into the reactor to produce a vapor phase liquid product; the reactor comprises solid particles moving through the reactor and a fluidizing gas fluidizing the solid particles at a conversion temperature which is suitable for facilitating the conversion of at least some of the liquid pitch into the vapor phase liquid product. The heated gases comprising the vapor phase liquid product and fluidizing gas are directed from the reactor to the fractionator to contact the bitumen stream. In this process, enough of the segregated unstable fractions are burned that the liquid product and any remaining unstable fractions meets pipeline specifications without hydrogen treatment of any of the remaining unstable fractions.

Owner:ETX SYST

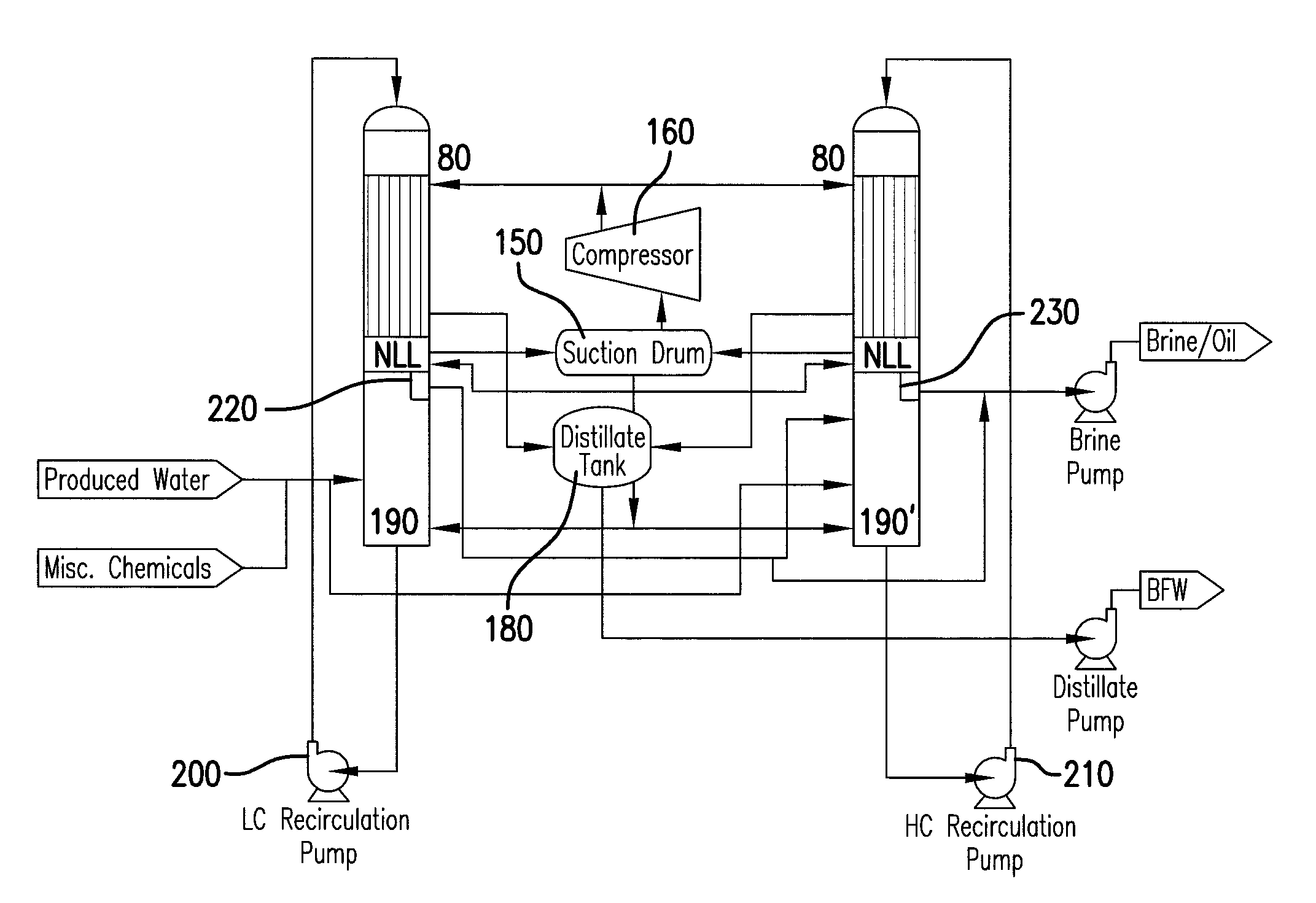

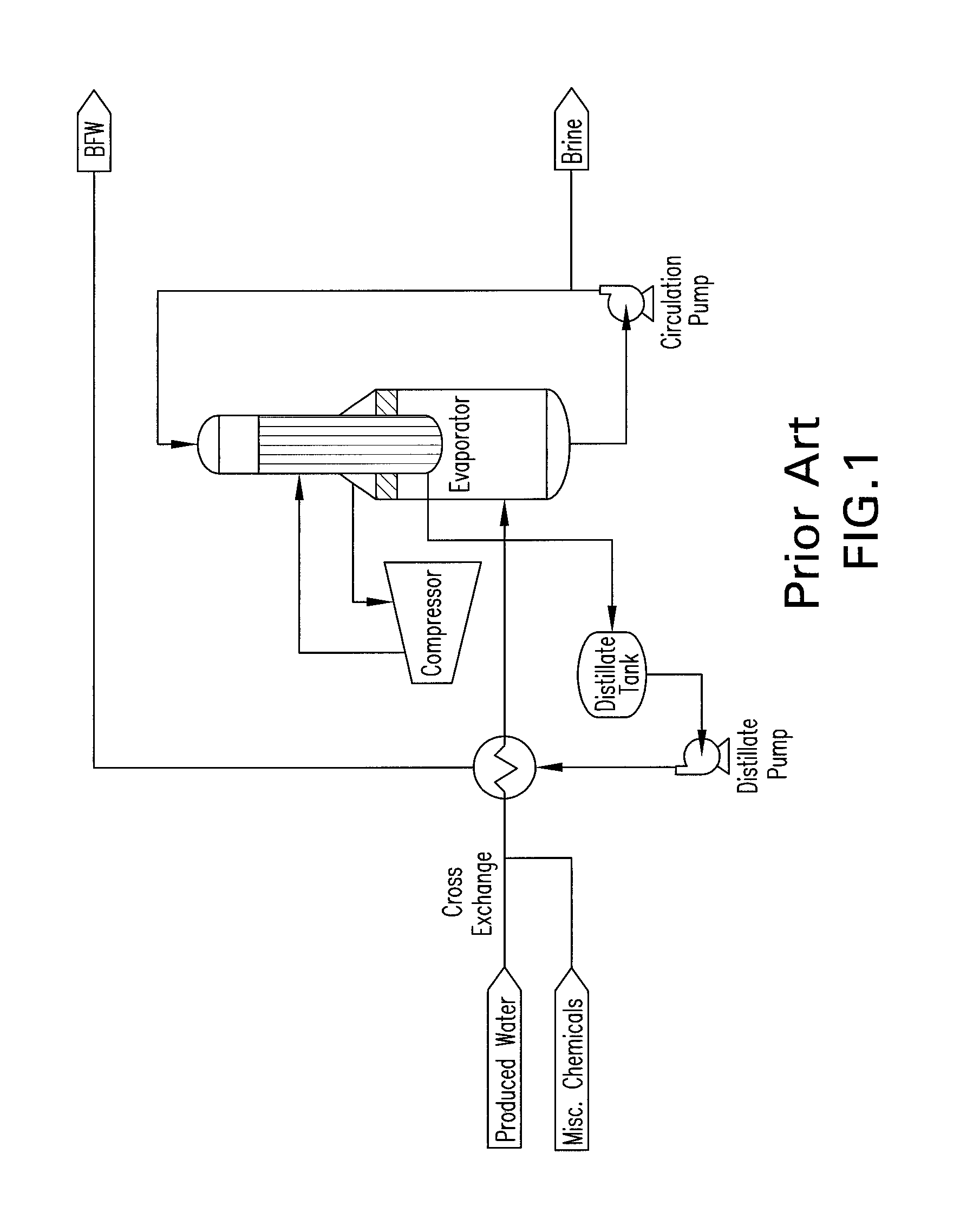

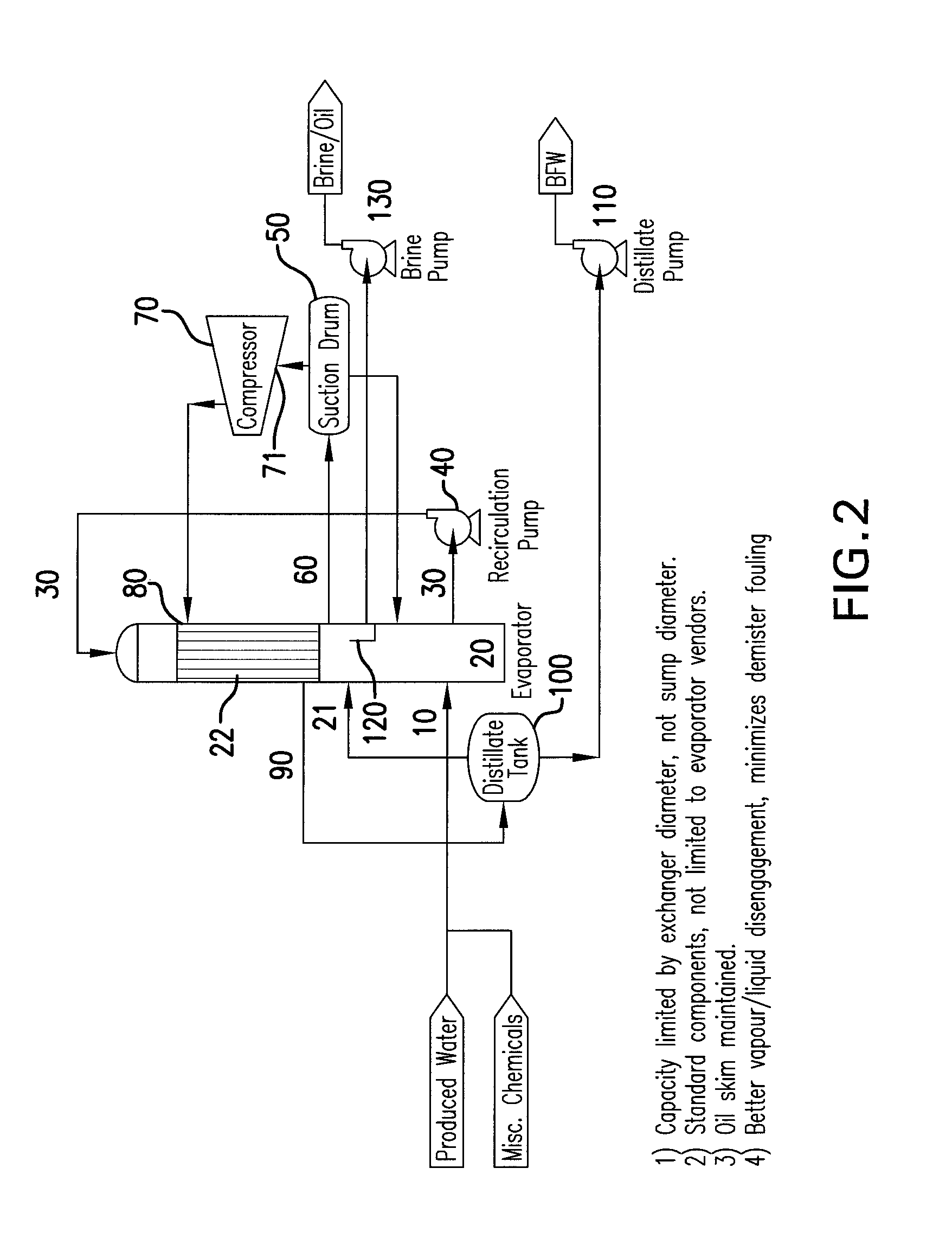

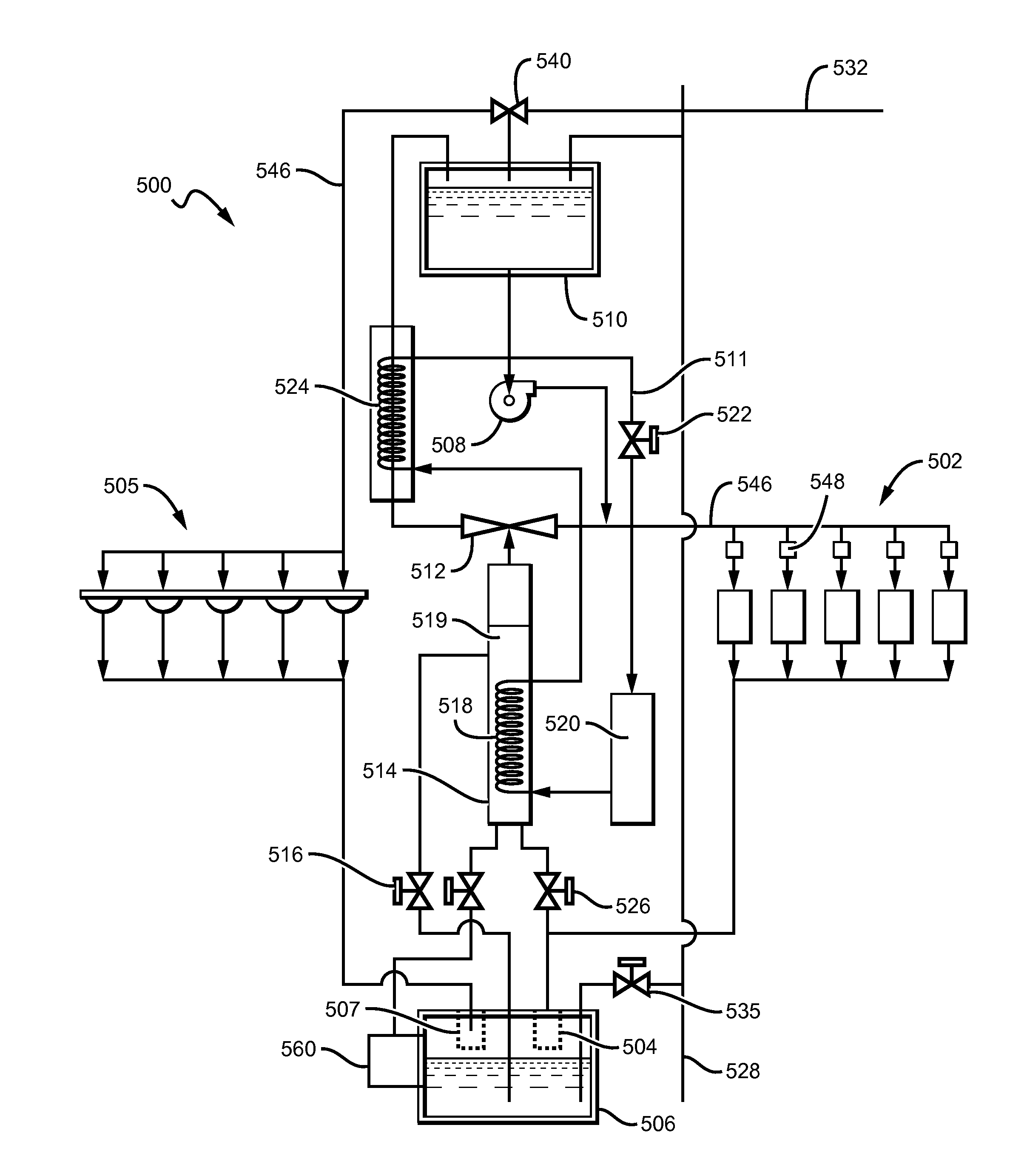

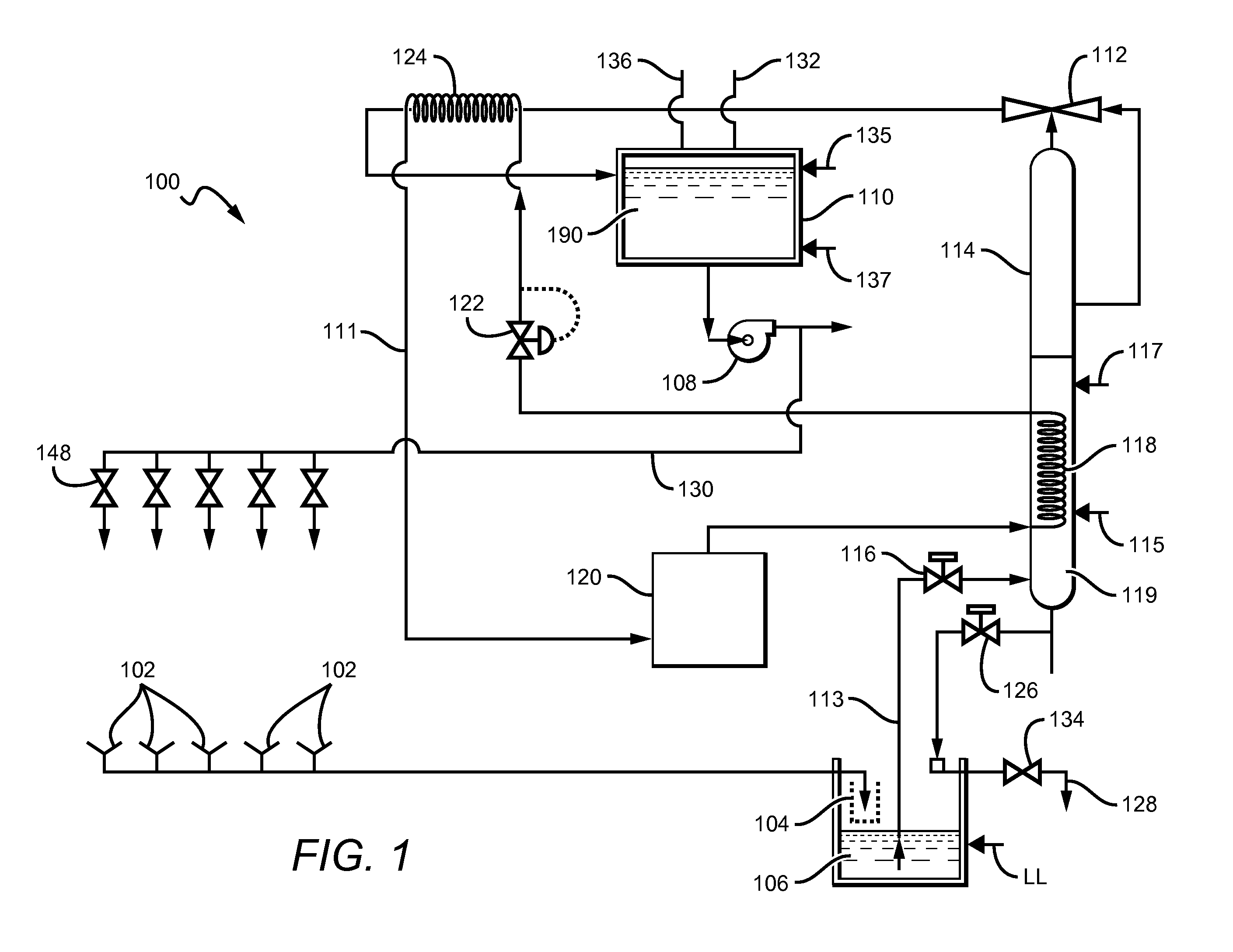

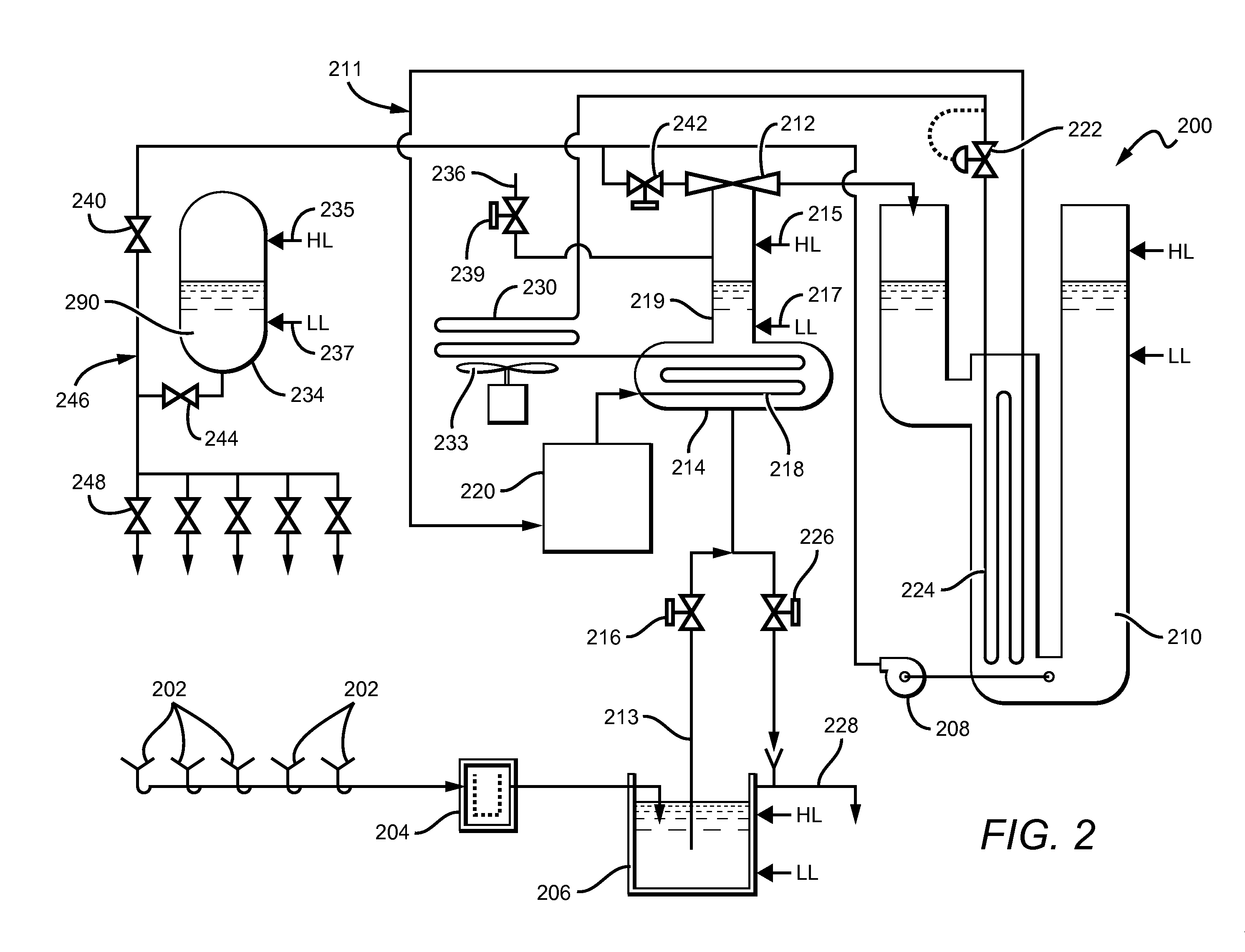

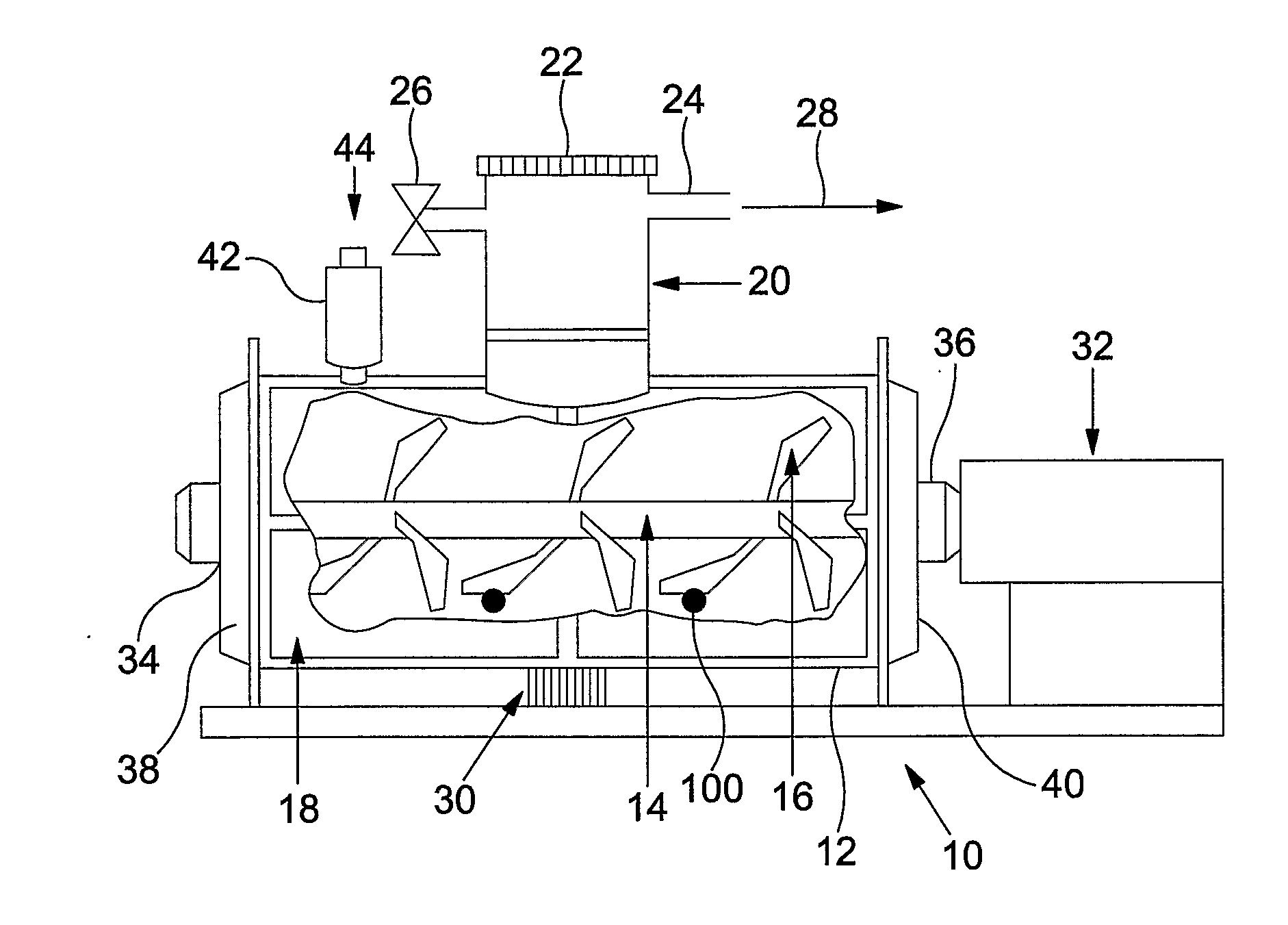

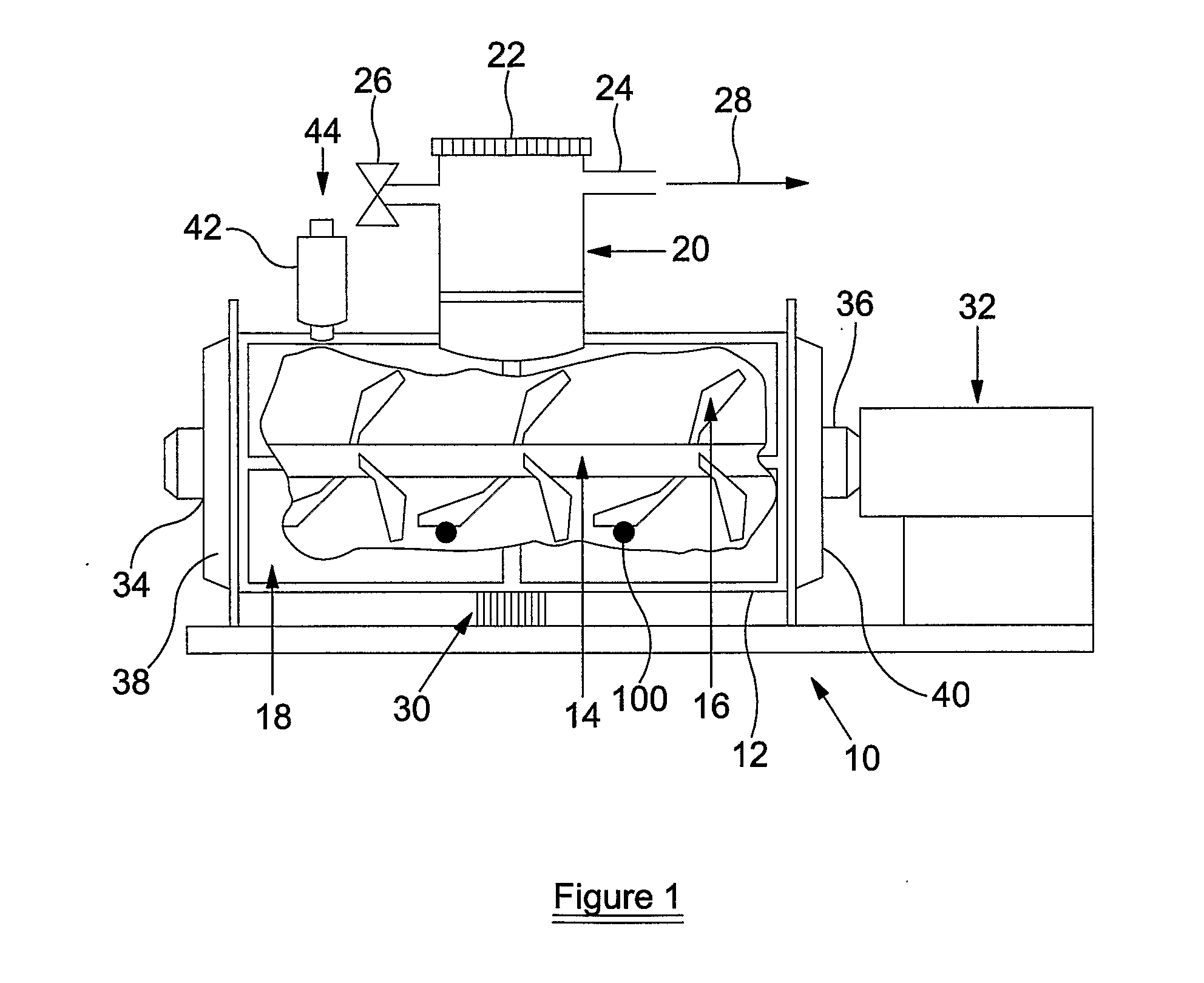

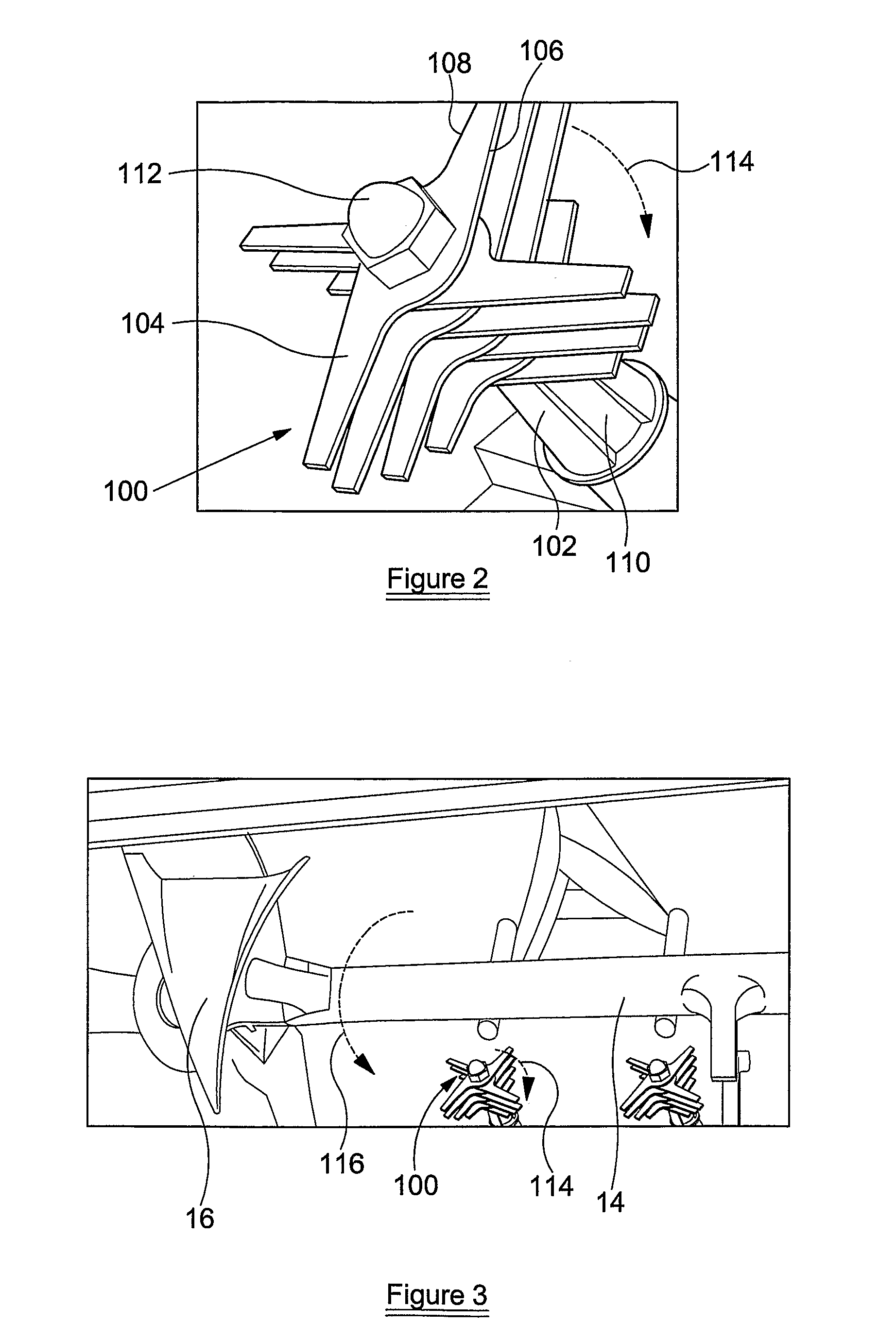

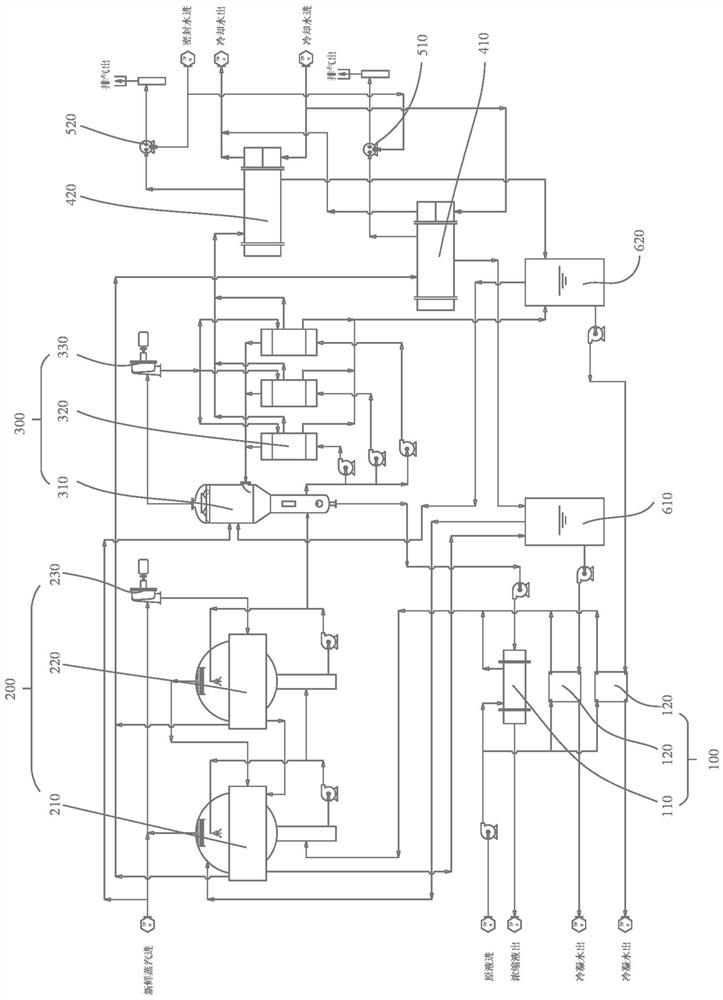

Compact evaporator for modular portable SAGD process

ActiveUS8951392B2Lower potentialShorten the lengthLiquid separation auxillary apparatusDistillation regulation/controlDistilled waterEngineering

A modular portable evaporator system for use in a Steam Assisted Gravity Drainage (SAGD) systems having an evaporator, with a sump including an oil skimming weir, a short tube vertical falling film heat exchanger including an outer shell containing short tubes provided for lower water circulation rate. The system further having external to the evaporator, a compressor for compressing evaporated steam from the tube side of the heat exchanger and routing to the shell side of the same exchanger, a distillate tank to collect hot distilled water, a recirculation pump to introduce liquids from the sump into the heat exchanger and an external suction drum protecting the compressor from liquid impurities. The evaporator system receives produced water from the SAGD process into the sump and provides cleaned hot water to a boiler.

Owner:PRIVATE EQUITY OAK LP

Method and device for carrying out a thermodynamic cyclic process

ActiveUS20070022753A1Improve the level ofImprove cycle efficiencyGeothermal energy generationSteam engine plantsCyclic processGas phase

In accordance with the invention, to reduce the complexity of a cycle process, a liquid working medium flow (13) is brought up to an increased pressure and through part condensation of an expanded working medium flow (12) a first partly vaporized working medium flow (15) is created. Through further vaporization of the first partly vaporized working medium flow (15) with heat which is transferred from an external heat source (20), a second at least partly vaporized working medium flow (18) is created. In this second at least partly vaporized working medium flow (18) the vapor phase (10) is separated from the liquid phase (10), subsequently the energy of the vapor phase (10) is converted into a usable form and an expanded vapor phase (11) created. The expanded vapor phase (11) is mixed with the liquid phase (19) and the expanded working medium flow (12) is formed. Through complete condensation of the partly condensed, expanded working medium flow (12a) the liquid working medium flow (13) is obtained in its turn.

Owner:KALINA POWER LTD

Polymeric Micelle Formulations of Hydrophobic Compounds and Methods

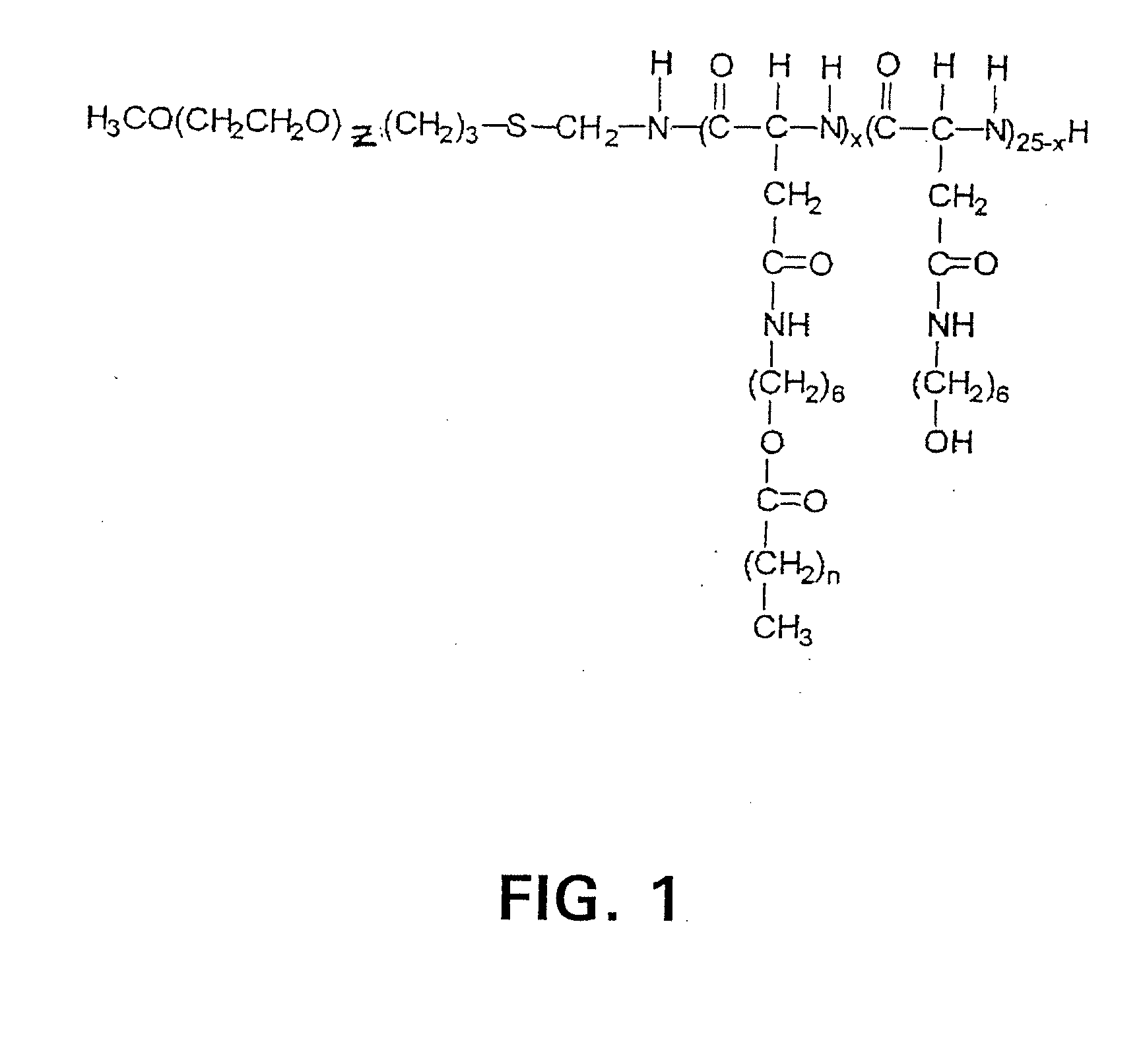

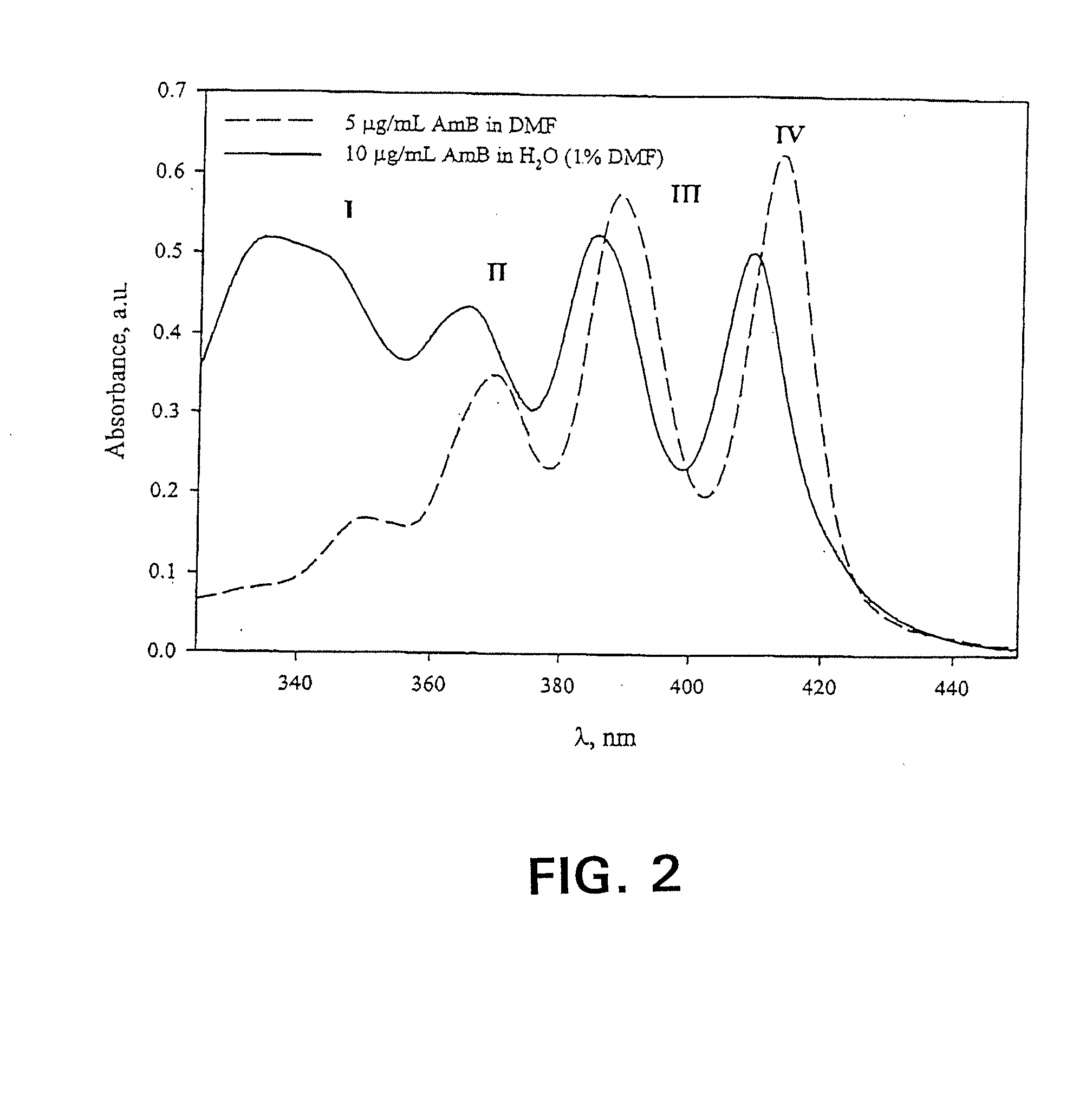

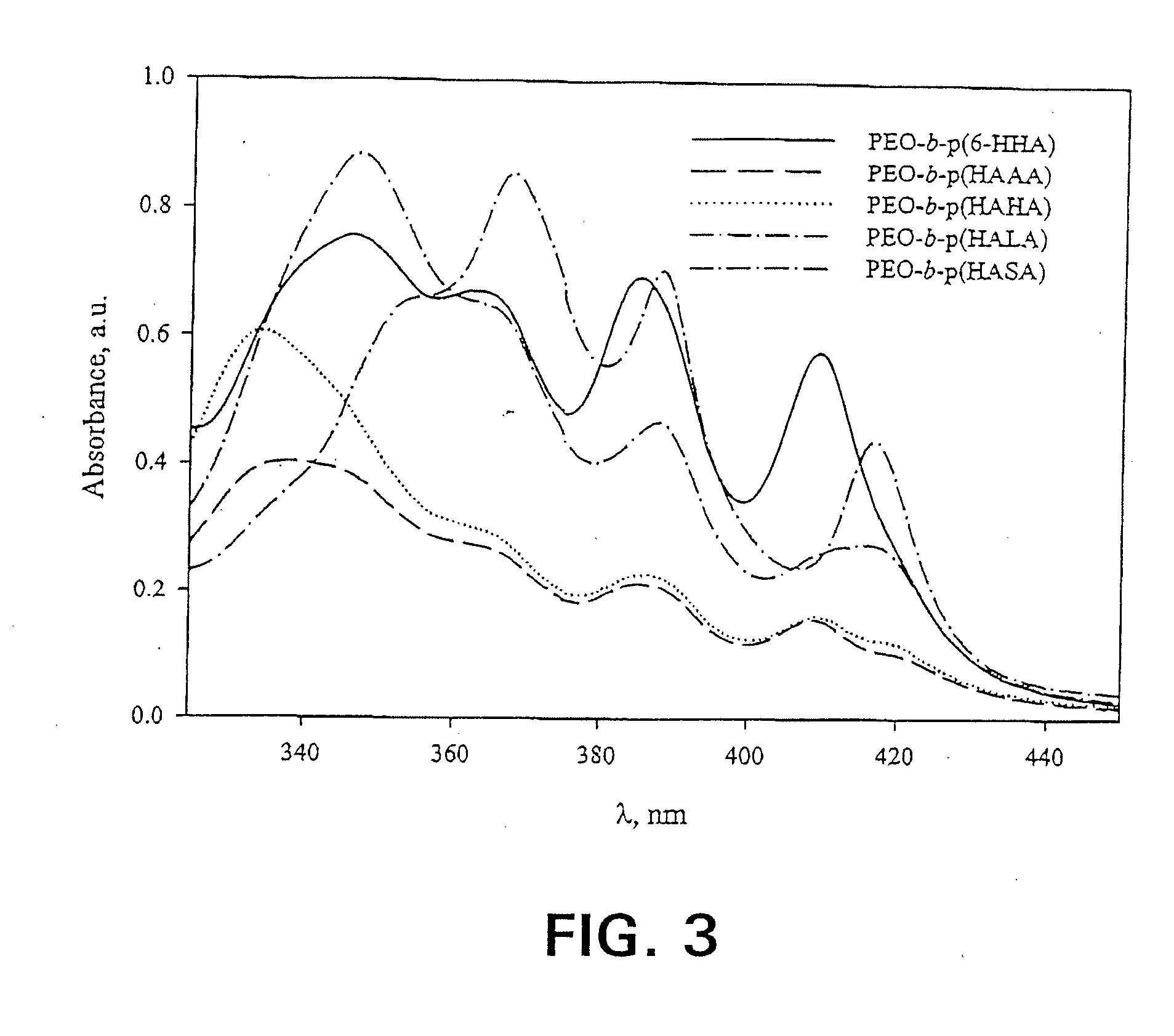

InactiveUS20090036389A1Low toxicityPromote formationPowder deliveryBiocideAntibiotic YAntilipidemic Agent

Provided are cosolvent evaporation methods and compositions for improving the solubility of hydrophobic compounds, including therapeutic agents such as anticancer drugs, polyene antibiotics, antilipidemic agents, and hydrophobic compounds used in various industries, and / or for reducing the toxicity of certain hydrophobic therapeutic agents, especially polyene antibiotics, in particular, Amphotericin B (AmB), and therapeutics such as paclitaxel, tamoxifen, an acylated prodrug or an acylated cis-platin, by incorporating these agents within micelles comprising an amphiphilic block-forming copolymer.

Owner:ABBOTT LAB INC +1

Distillation Urine Recycling Systems and Methods

InactiveUS20120055777A1Suitable for collectionReduce system costWater treatment parameter controlWater/sewage treatment by irradiationHolding tankWastewater disposal

Systems and methods for processing wastewater into a flushing fluid are described, in which wastewater flows into a holding tank from one or more restroom fixtures. A vacuum distillator can be coupled to the holding tank, and a heater can be configured to heat at least a portion of the wastewater in the vacuum distillator to produce a vapor. The vapor can be condensed by a condenser fluidly coupled to the vacuum distillator to produce a distilled stream. The stream can either be fed into a tank or passed to one or more restroom fixtures.

Owner:LIQUIDBREAKER

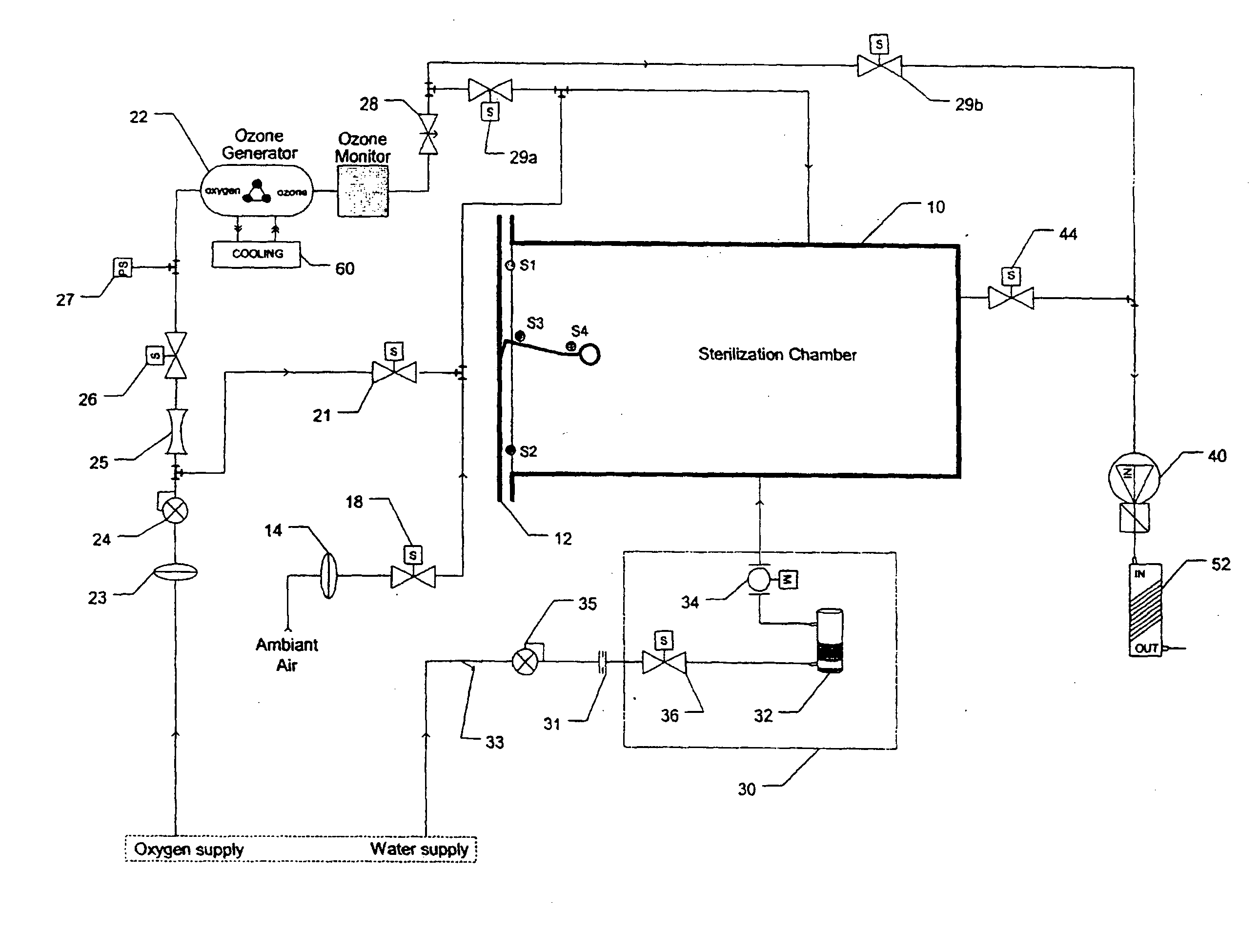

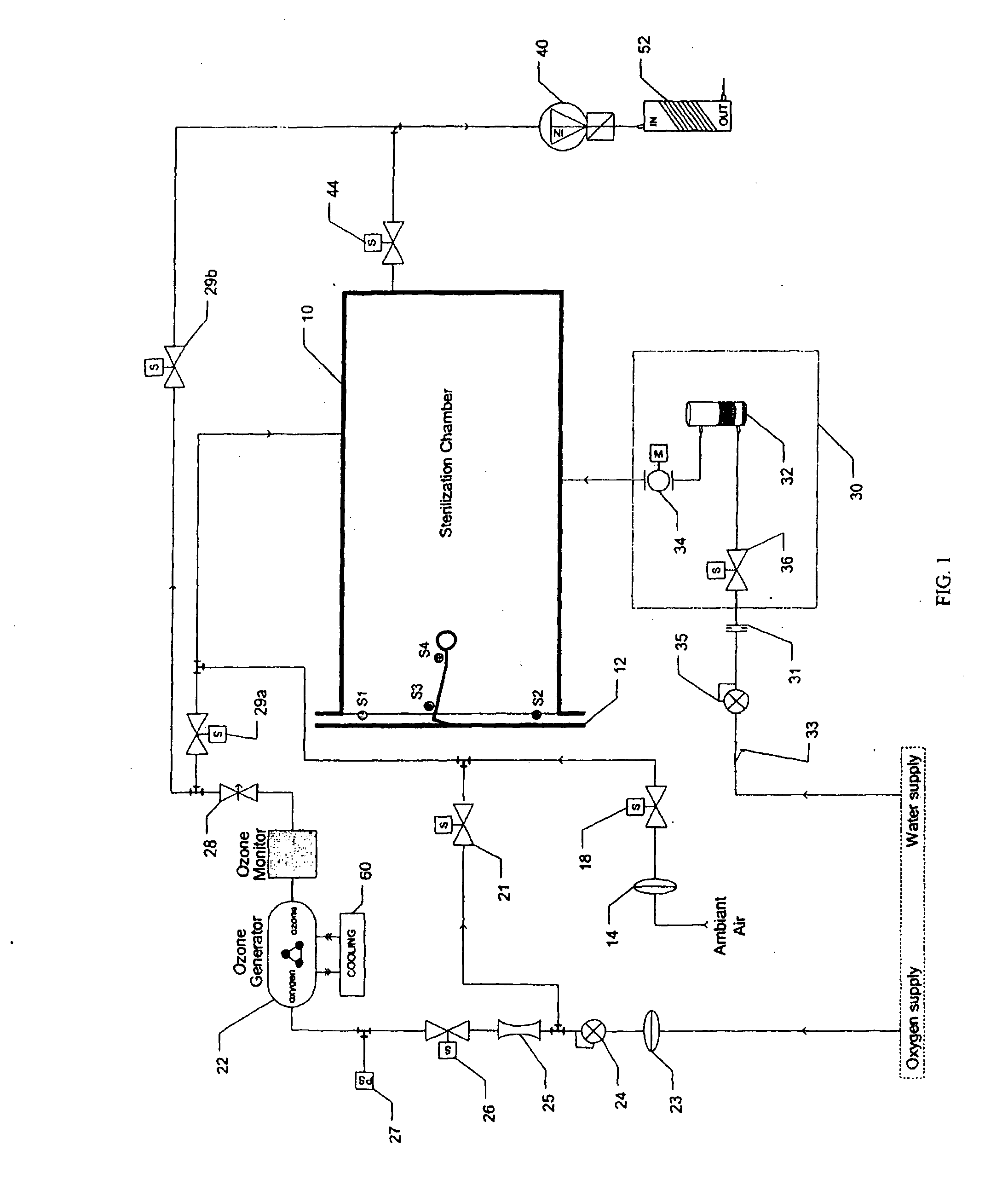

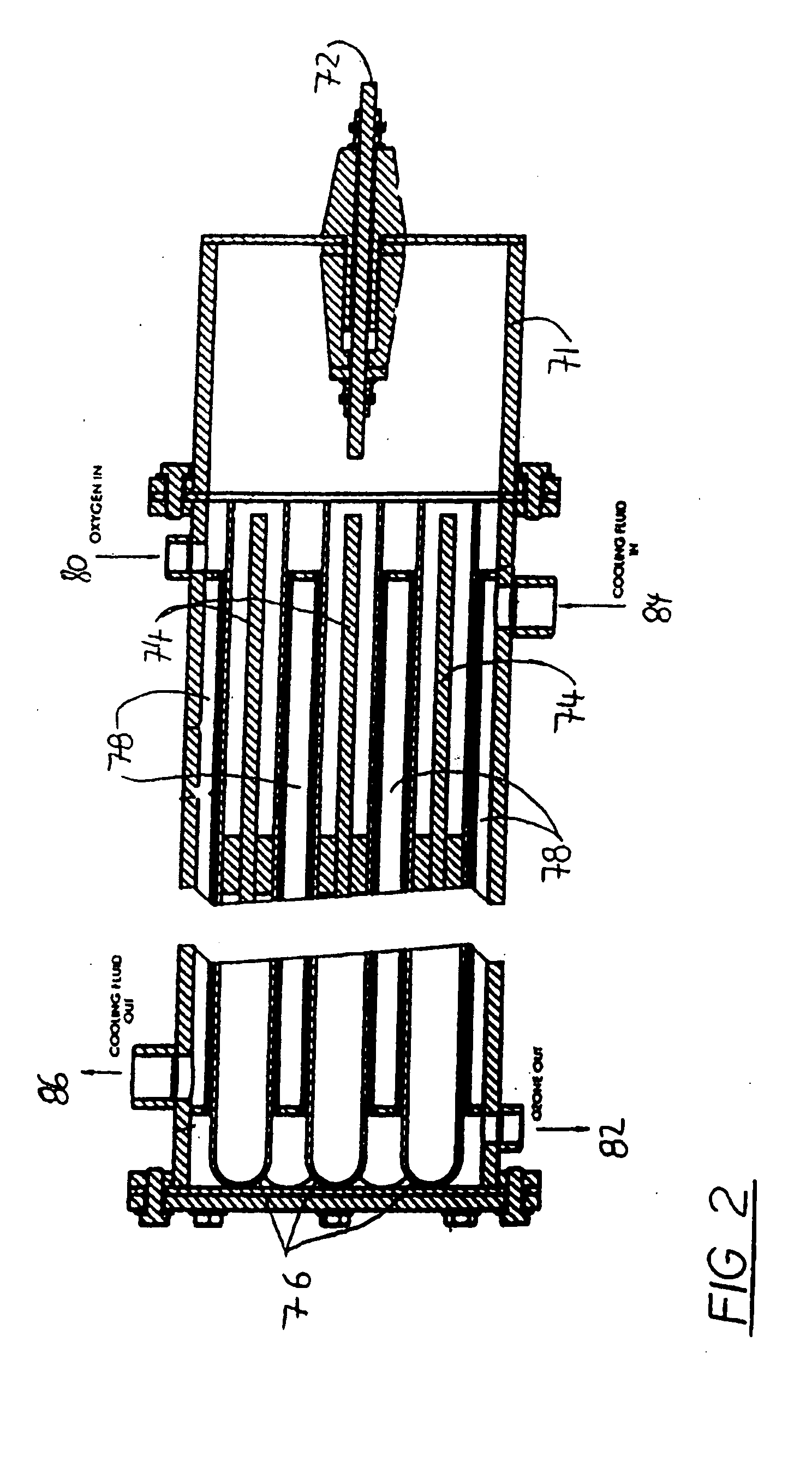

Ozonoe sterilizaation process and apparatus

InactiveUS20100196198A1Economical and reliableShortened sterilizationLavatory sanitoryChemicalsVacuum pressureEngineering

A sterilization method is disclosed, which includes the steps ofproviding a sterilization chamber;placing the article into the sterilization chamber;applying a vacuum of a preselected vacuum pressure to the sterilization chamber;humidifying a sterilization atmosphere in the sterilization chamber;maintaining the sterilization atmosphere at a temperature above 40° C. and at most 60° C.;supplying ozone-containing gas to the sterilization chamber;maintaining the sterilization chamber sealed for a preselected treatment period; andreleasing the vacuum in the sterilization chamber.

Owner:TSO3

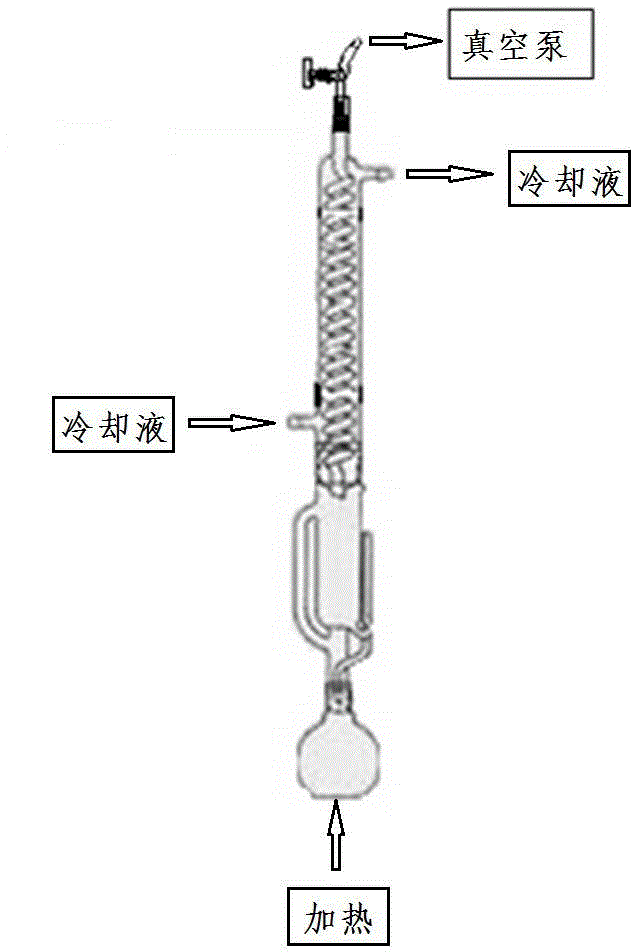

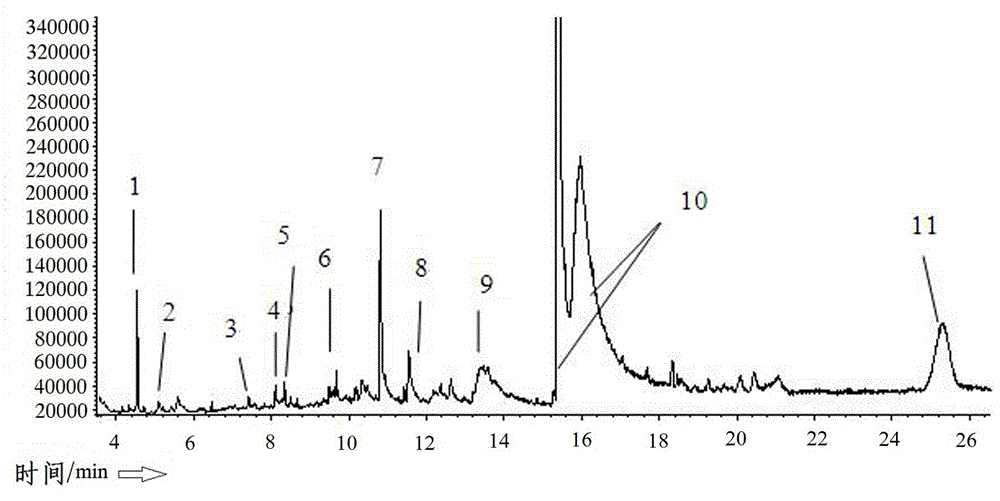

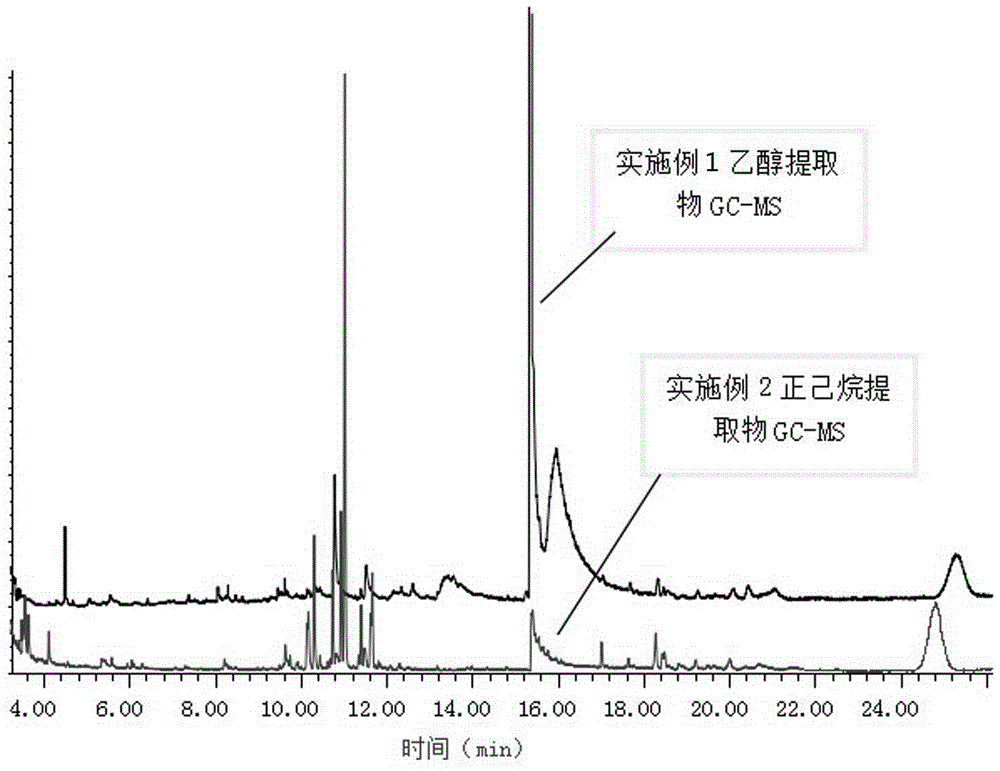

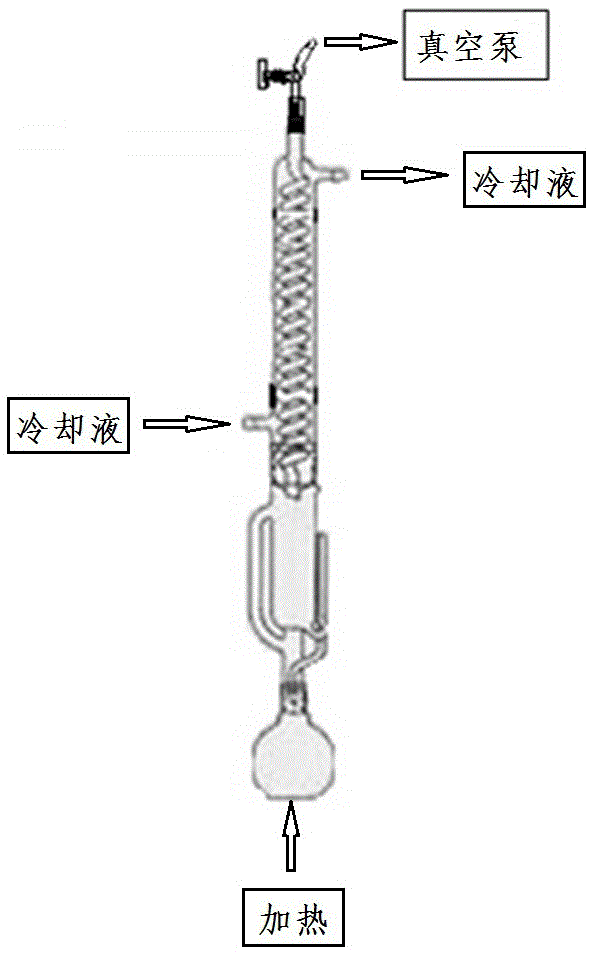

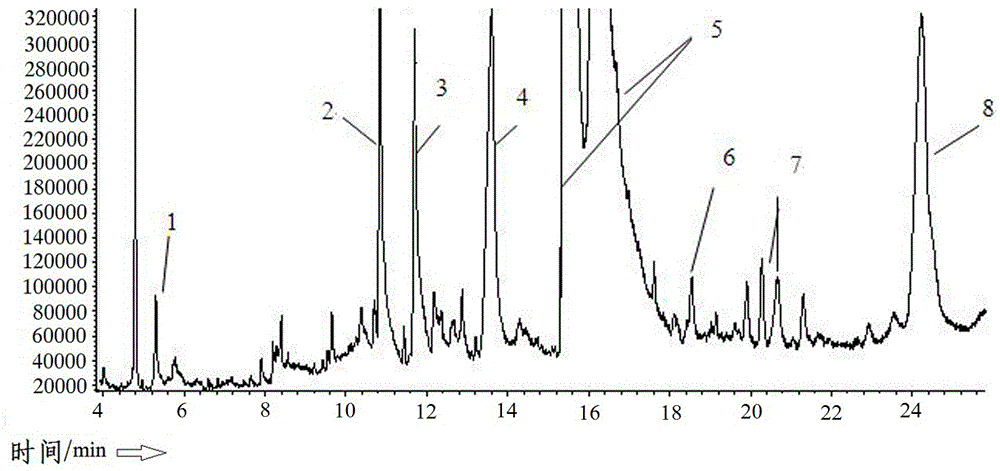

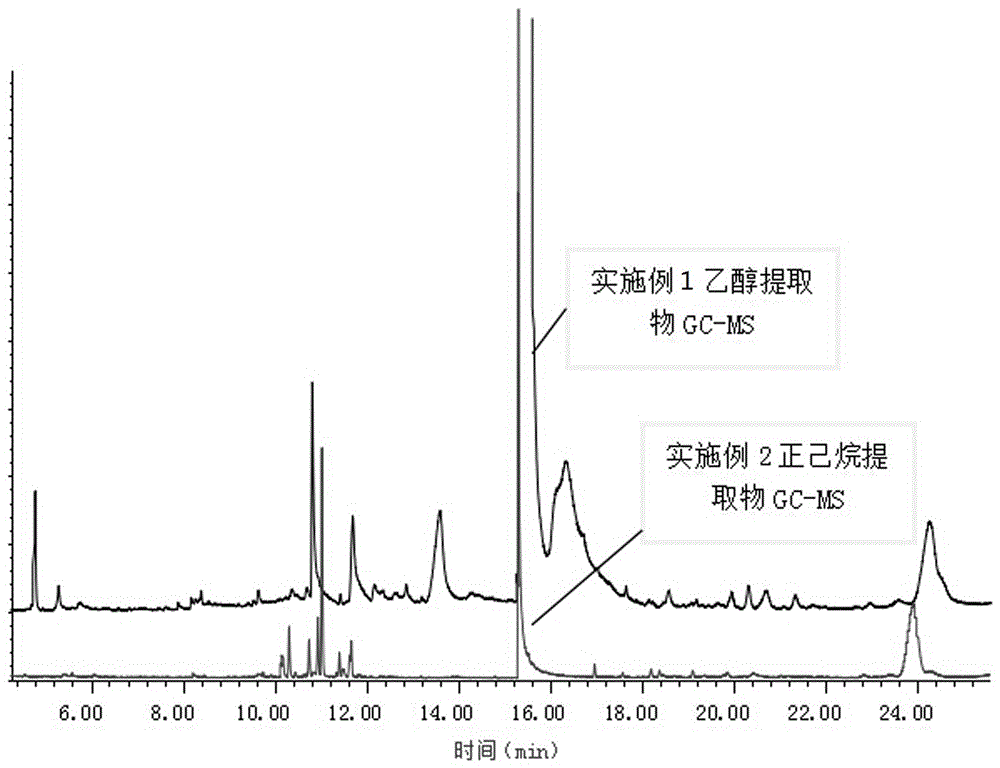

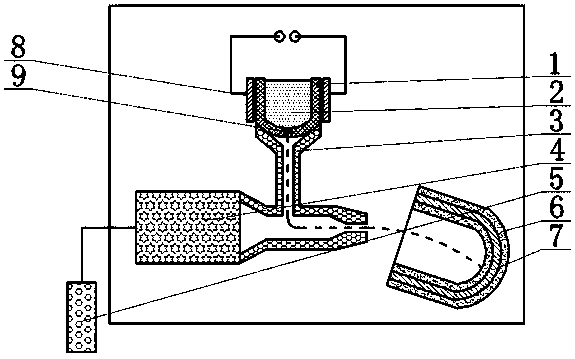

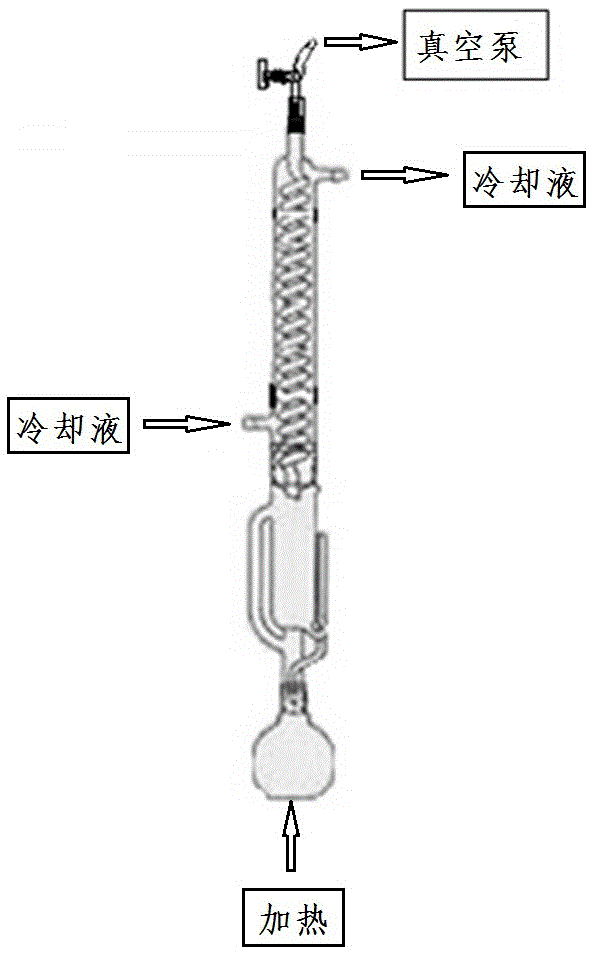

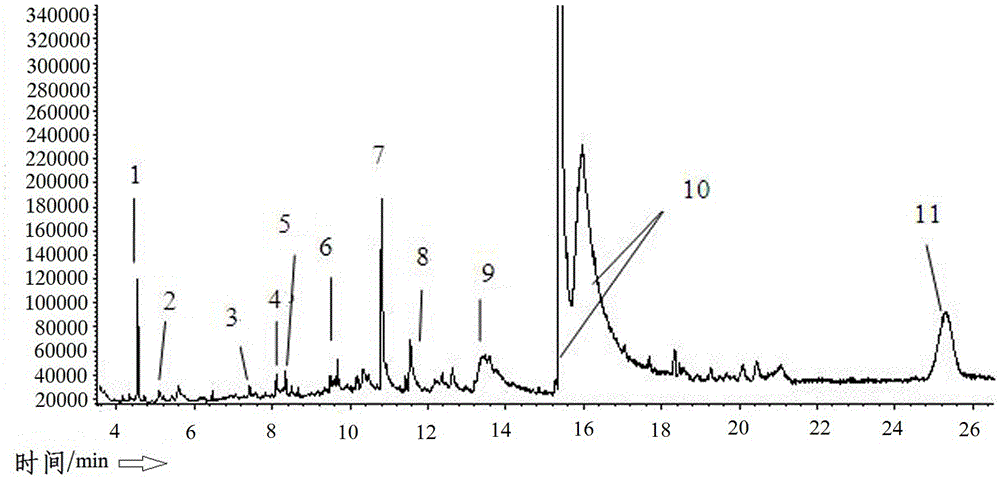

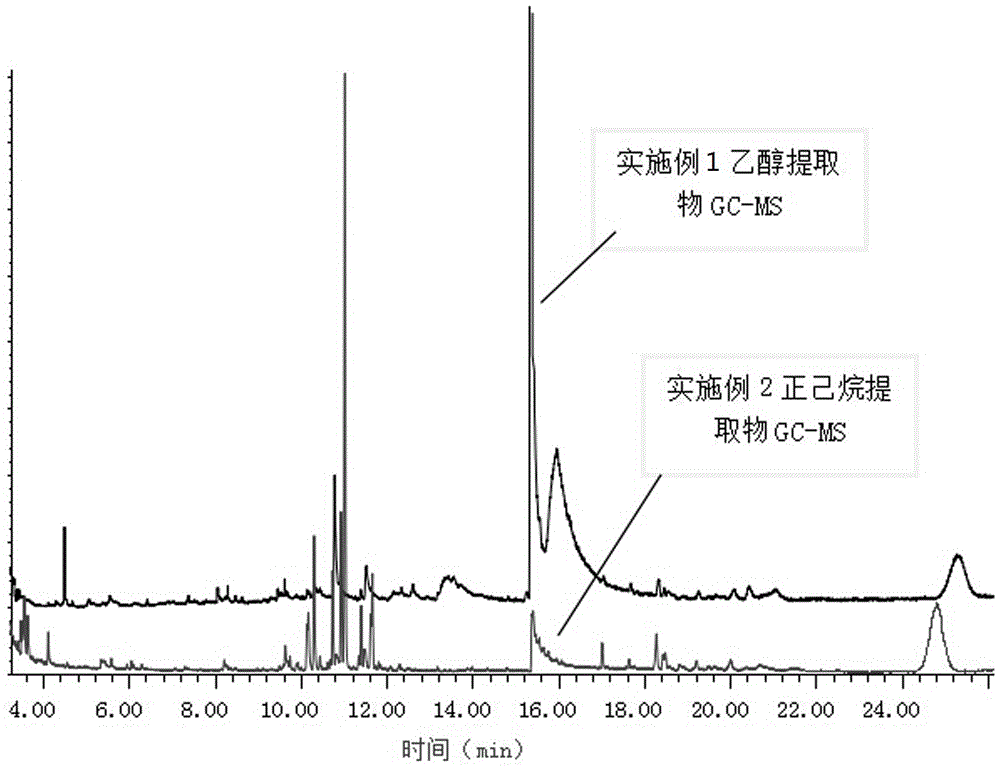

Aromatic tobacco extractive and electronic cigarette juice

ActiveCN104621707ALower boiling temperatureLow heating temperatureTobacco treatmentEssential-oils/perfumesChemistryFlavor

The invention discloses aromatic tobacco extractive and electronic cigarette juice. According to the aromatic tobacco extractive, the tobacco leaves, the pipe tobacco, the tobacco waste and / or the soot of aromatic tobacco are used as raw materials, and an extraction solvent is added into a Soxhlet extractor to carry out Soxhlet extraction on the raw materials. Improvement lies in the fact that a condensation pipe of the Soxhlet extractor is connected with a vacuum pump, so that the vacuum degree of the Soxhlet extractor is maintained at 20-80 mmHg. The temperature of condensation liquid in the condensation pipe is below -5 DEG C. After Soxhlet extraction, extraction liquid is collected and is concentrated, and the aromatic tobacco extractive is obtained. A whole Soxhlet extraction system is at a negative-pressure state, the boiling point of the extraction solvent is lowered, extraction temperature is lowered, during extraction, solvent circulating is accelerated, extraction frequency is accelerated, and efficiency is high. Meanwhile, solvent heating temperature is low, the extraction condition is mild, excessive chemical reaction between aroma components in the extractive caused by solvent high-temperature heating is avoided, and the amount of extractive offensive odor is small.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Method and device for carrying out a thermodynamic cyclic process

ActiveCN1993536AEasy to condenseEasy to pressurizeGeothermal energy generationSteam engine plantsCyclic processEvaporation

The aim of the invention is to reduce the complexity of a cyclic process. To this end, the pressure of a liquid working substance flow (13) is increased and a first partially evaporated working substance flow (15) is produced by the partial condensation of a working substance flow (12) with a low surface tension. Further evaporation of the first partially evaporated working substance flow (15) with heat transmitted by an external heat source (20) produces a second at least partially evaporated working substance flow (18). In said second at least partially evaporated working substance flow (18), the vaporous phase (10) is separated from the liquid phase, the energy of the vaporous phase (10) is converted into a usable form, and a vaporous phase (11) with a low surface tension is combined with the liquid phase (19) in such a way as to form the working substance flow (12) with a low surface tension. The liquid working substance flow (13) is, in turn, obtained by complete condensation of the partially condensed working substance flow (12a) with a low surface tension.

Owner:KALINA POWER LTD

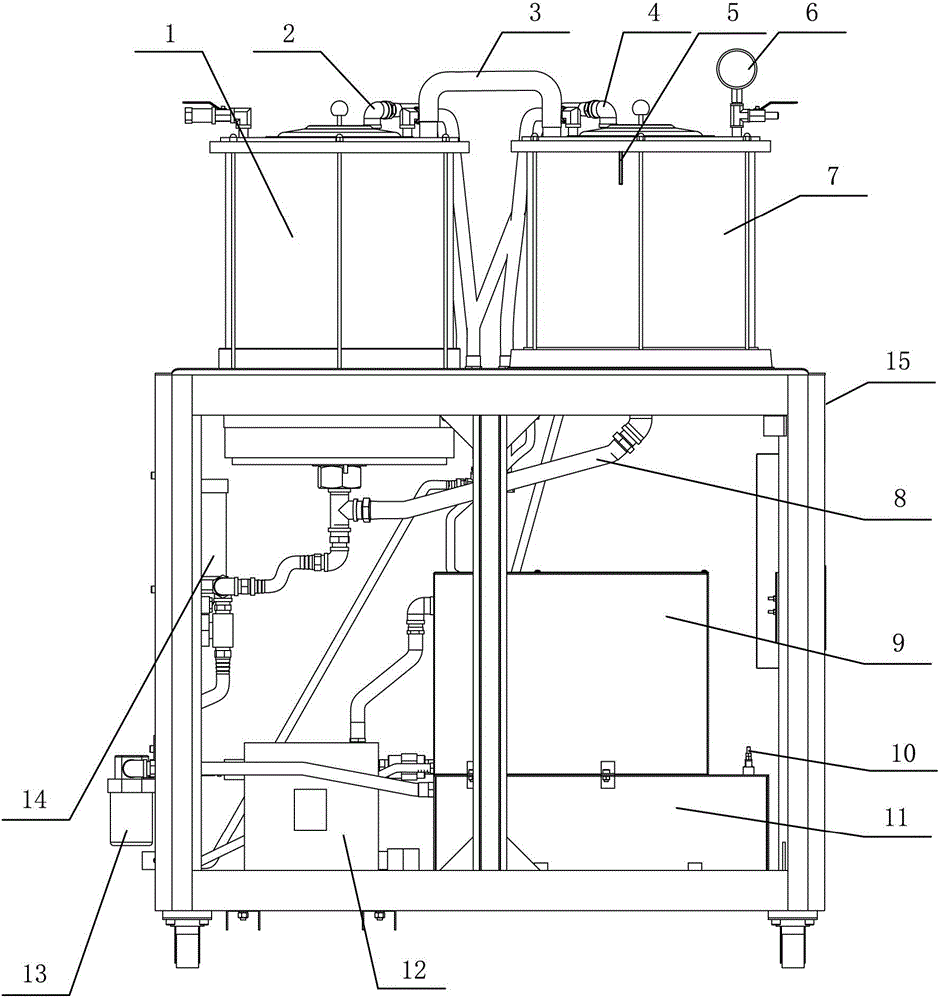

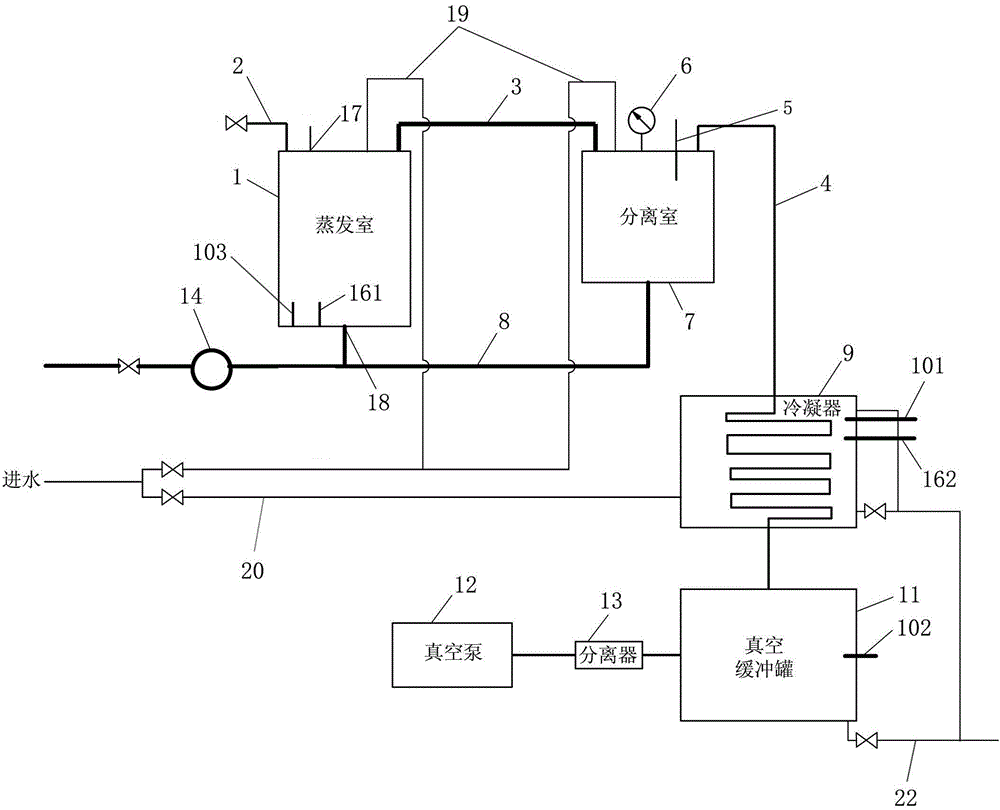

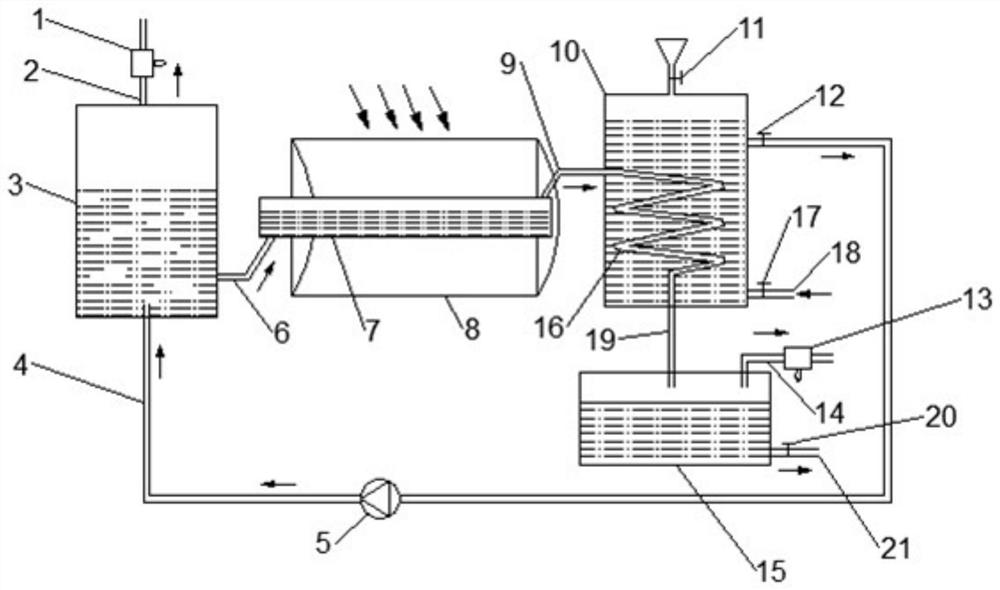

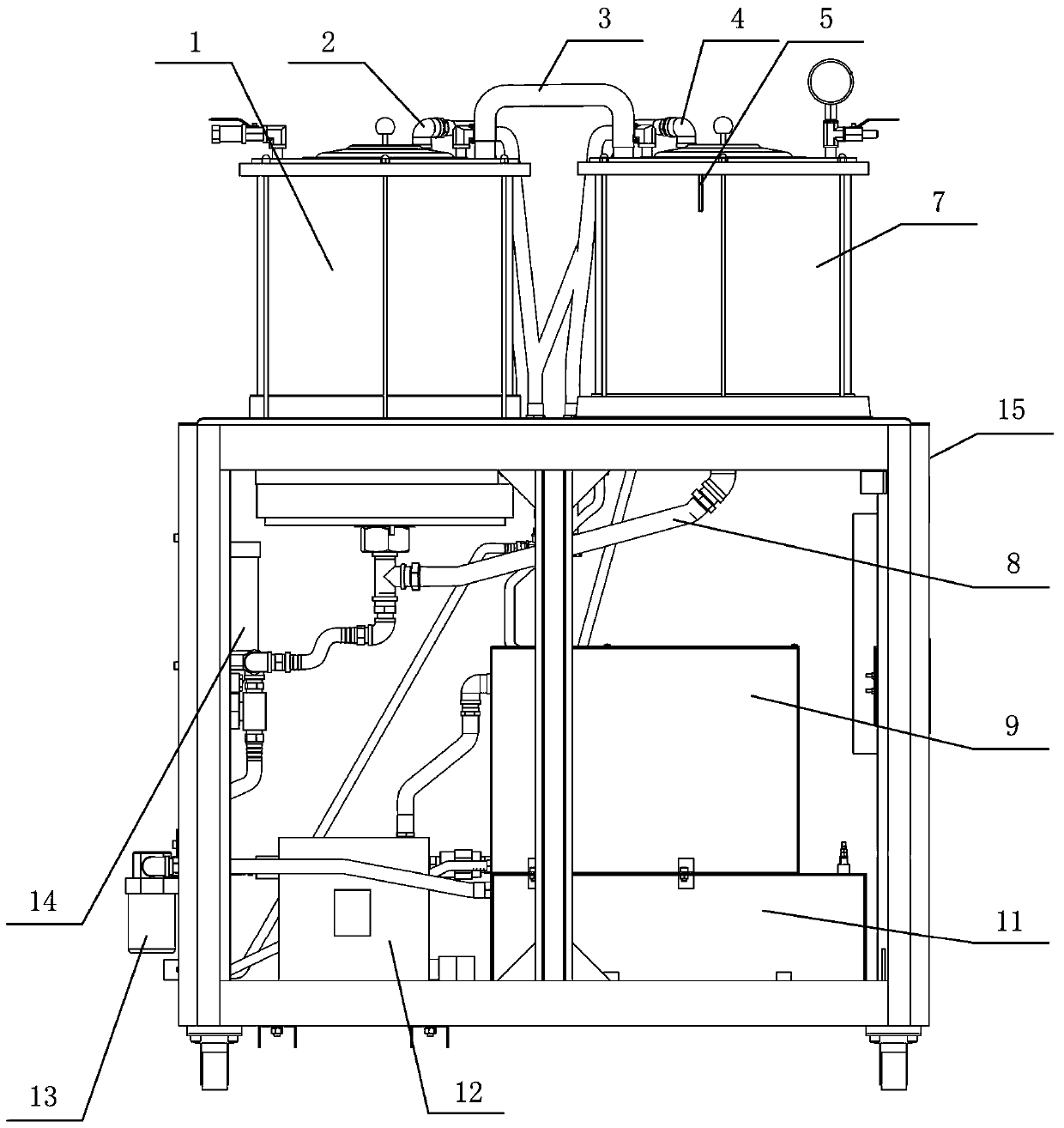

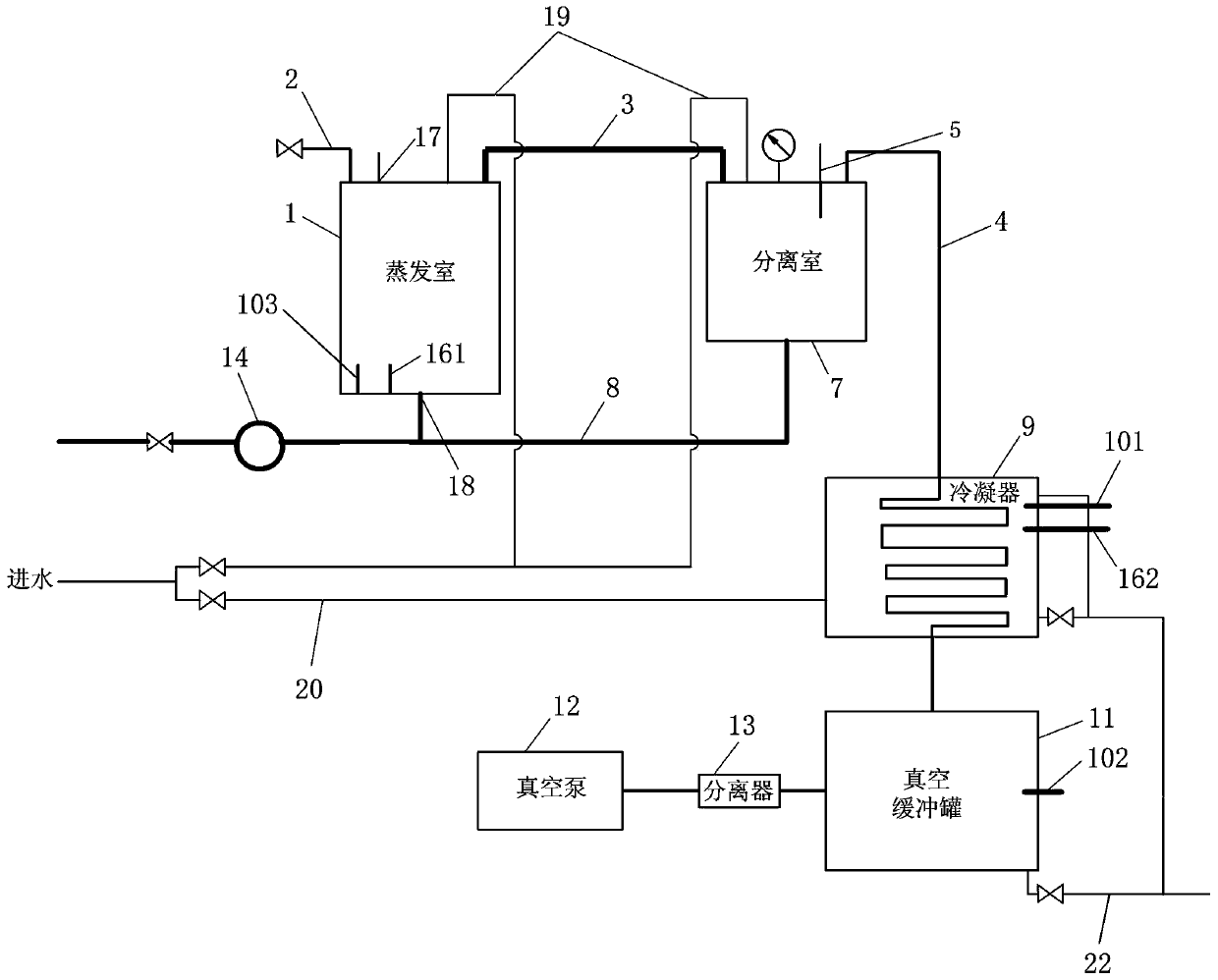

Liquid vacuum concentration device and method

ActiveCN106139622ALow boiling temperatureImprove qualityEvaporator accessoriesCondensed waterEngineering

The invention provides a liquid vacuum concentration device and method. The liquid vacuum concentration device comprises a box, an evaporation chamber, a separation chamber, a condenser and a vacuum pump, wherein the box is provided with an internal space; the evaporation chamber is provided with a liquid inlet and a liquid outlet, liquid enters the evaporation chamber through the liquid inlet and is heated in the evaporation chamber, and finally concentrated liquid is discharged outside through the liquid outlet; the separation chamber is communicated with the evaporation chamber through fluid, liquid and bubbles generated by heating the liquid enter the separation chamber from the evaporation chamber to achieve gas and liquid separation in the separation chamber, and liquid obtained after gas and liquid separation flows back to the evaporation chamber from the separation chamber; gas obtained after gas and liquid separation enters the condenser from the separation chamber and is condensed into condensed water in the condenser; by means of the vacuum pump, the evaporation chamber, the separation chamber and the condenser are in the vacuum state. By means of the liquid vacuum concentration device, original components can be kept not to be lost, and energy consumption is low.

Owner:BEIJING DONGHUAYUAN MEDICAL EQUIP CO LTD

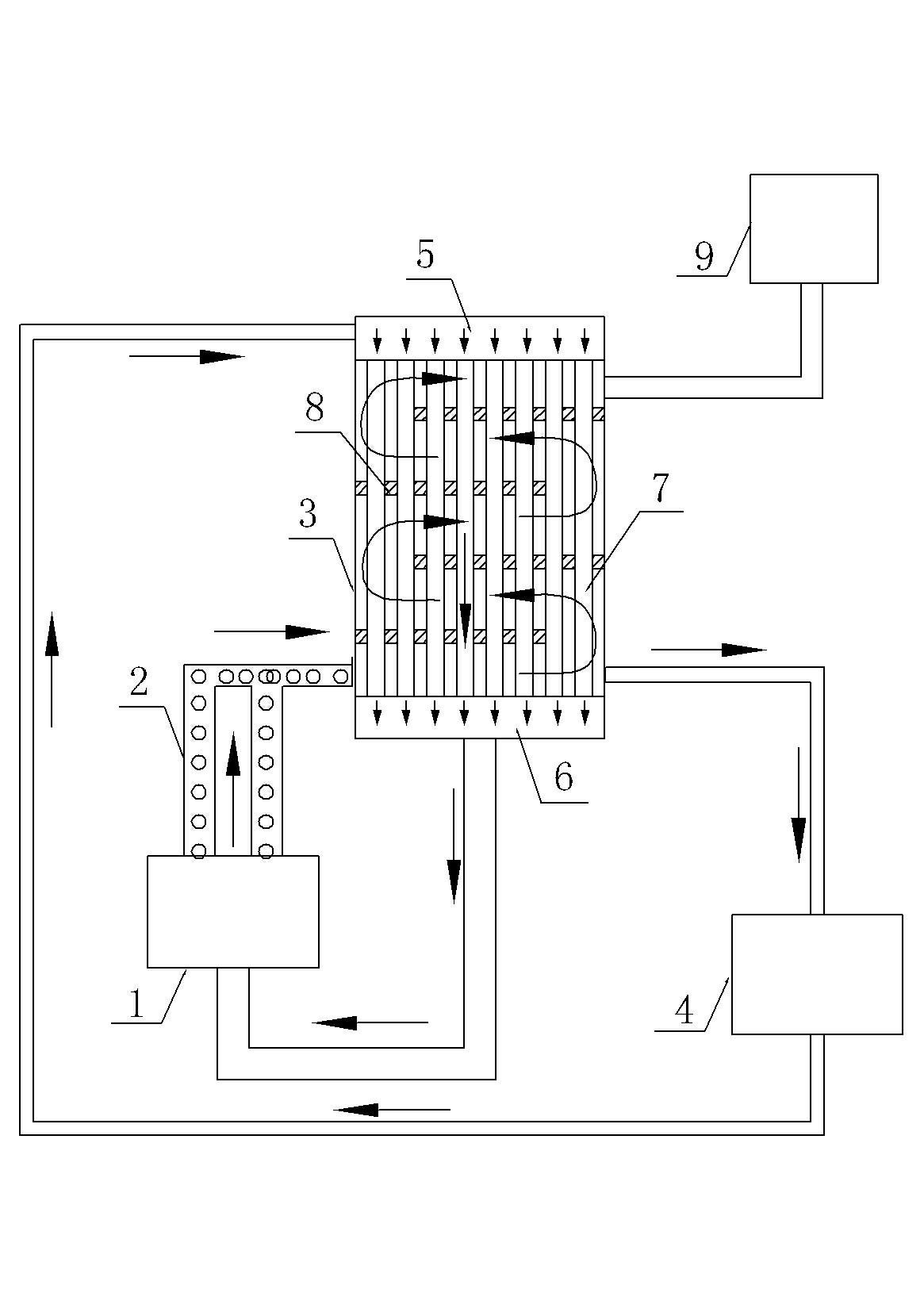

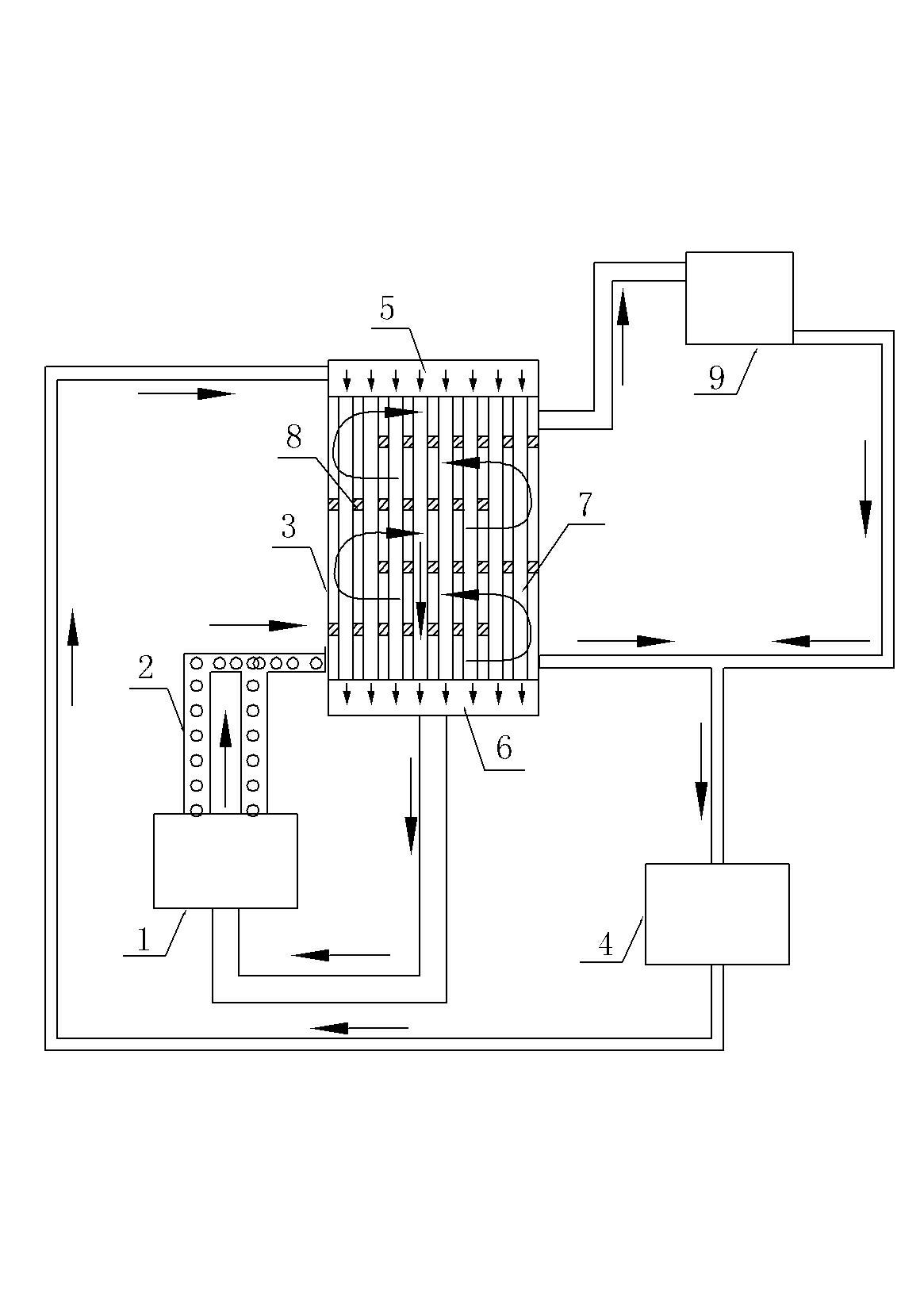

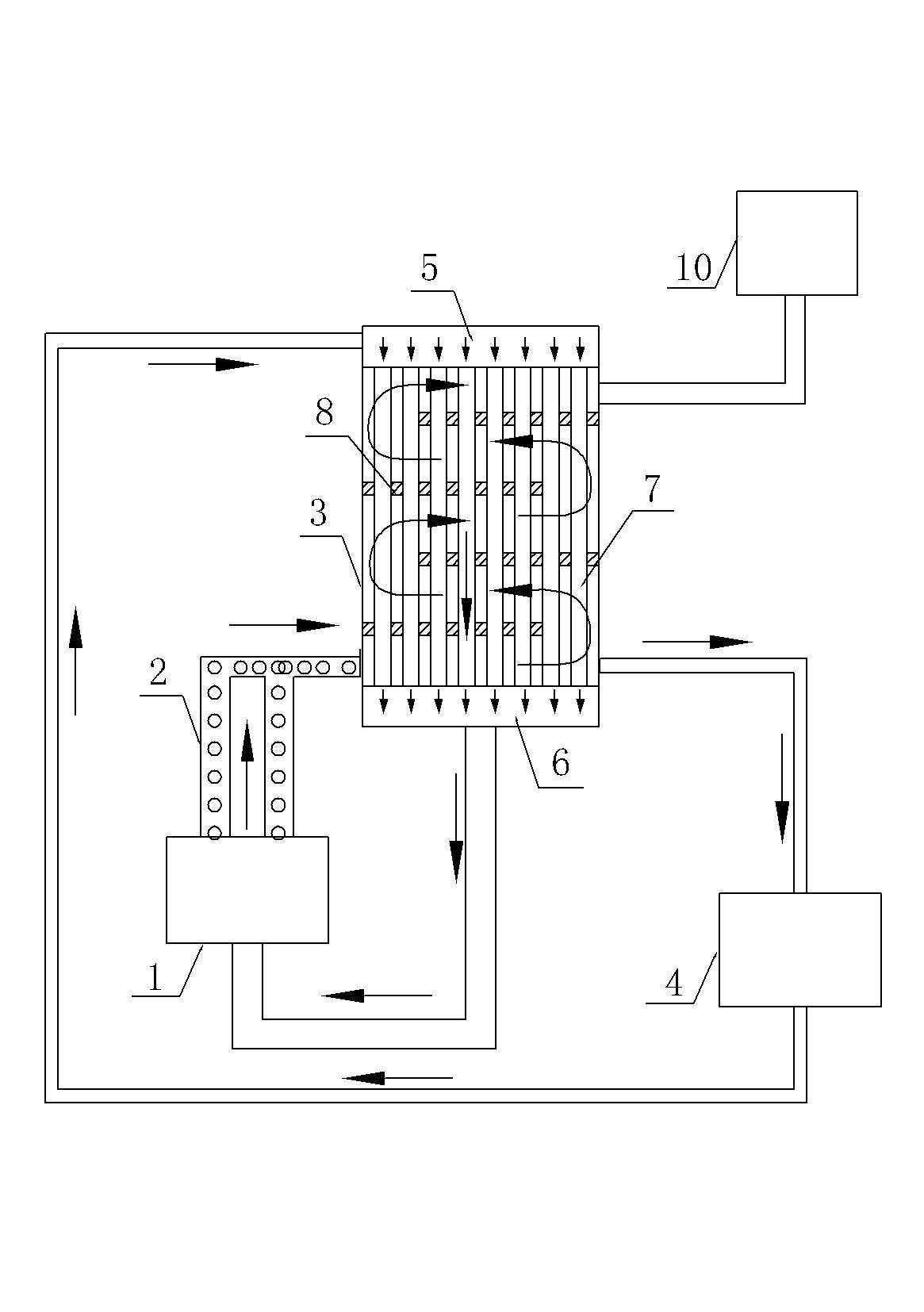

Low-temperature hot-water warming system

ActiveCN102679441ASolve condensationSave electricityLighting and heating apparatusCentral heating systemEngineeringThermal water

The invention relates to a low-temperature hot-water warming system. Two heat exchange tube fixing plates are arranged in a cavity of a steam heat exchanger; the inner chamber of the cavity is divided into an upper chamber, a lower chamber and a middle chamber by the two heat exchange tube fixing plates; heat exchange tubes are arranged in the middle chamber of the cavity; two ends of each of the heat exchange tubes are respectively fixed on the two heat exchange tube fixing plates and are respectively communicated with the upper chamber and the lower chamber; a steam inlet communicated with the middle chamber is arranged on the cavity; a generator is communicated with the steam inlet through an airlift pump; a steam outlet communicated with the upper part of the middle chamber is arranged on the cavity; a storage with a steam chamber is communicated with the steam outlet; a lower edge of the steam chamber of the storage is higher than an upper edge of the upper chamber; a hot water outlet communicated with the middle chamber is arranged on the cavity; the hot water outlet is communicated with an inlet of a first heat exchanger; an outlet of the first heat exchanger is communicated with a water inlet which is communicated with the upper chamber on the cavity; a collected water outlet communicated with the lower chamber is arranged on the cavity; and the collected water outlet is connected with the inlet of the generator.

Owner:HEIMDALLR SHANGHAI ENERGY SAVING TECH

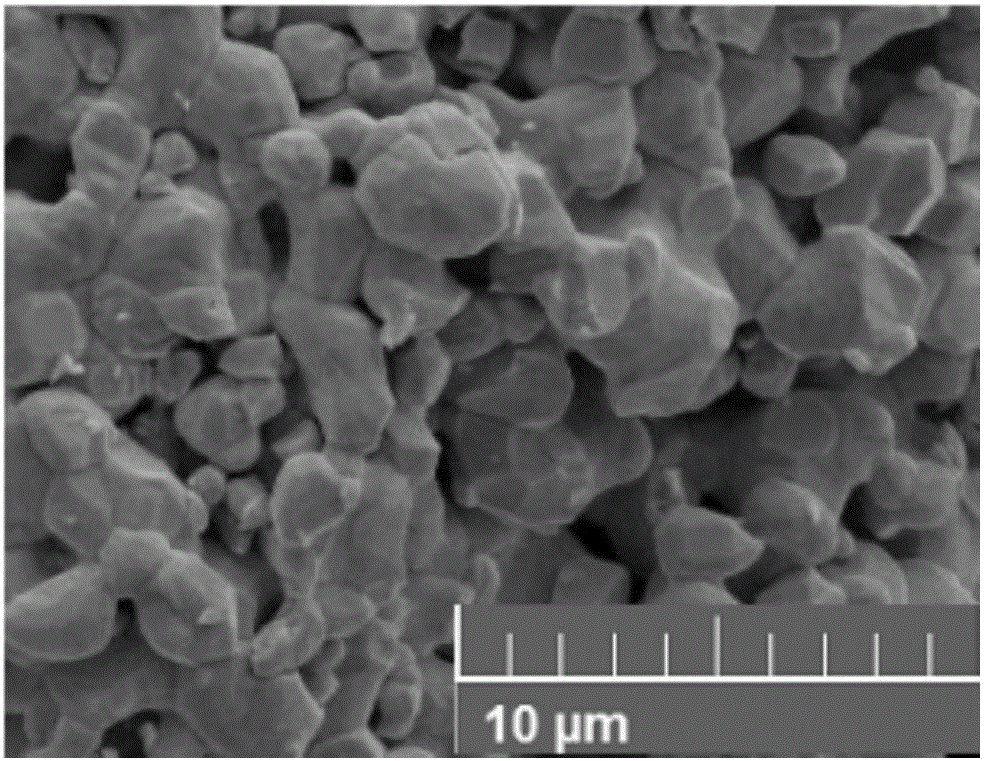

Aluminum-manganese alloy and powder metallurgical molding method thereof

The invention discloses an aluminum-manganese alloy and a powder metallurgical molding method thereof. The aluminum-manganese alloy comprises, by weight percent, 70% to 75% of aluminum and 25% to 30% of manganese. The powder metallurgical molding method of the alloy comprises the steps of firstly, preparing of raw materials, auxiliary materials, tools and devices; secondly, vacuum induction smelting of the alloy; thirdly, preparing of mother alloy powder; and fourthly powder metallurgical molding. The aluminum-manganese alloy is low in impurity content, fine in grain, uniform in component and high in manganese content; the powder metallurgical molding method of the alloy is high in purification, free of pollutants, free of waste gas, easy to control, stable in quality and high in yield.

Owner:JIANGSU HUAQI ALUMINUM SCI & TECH

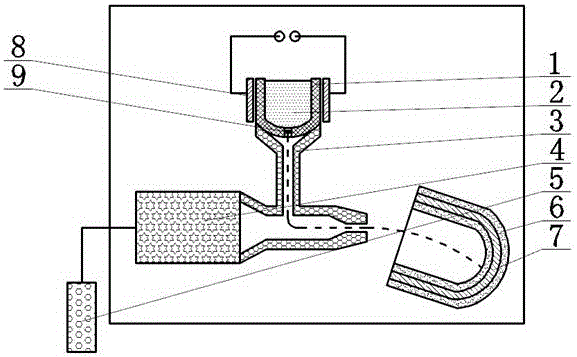

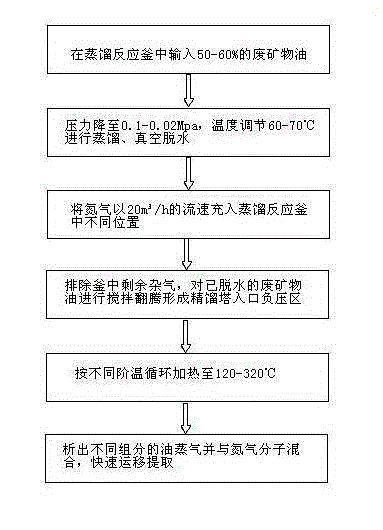

Method for regenerating and extracting waste mineral oil by filling nitrogen extracting

InactiveCN103146423ALower boiling temperatureBoiling temperature achievedTreatment with plural serial refining stagesLubricant compositionDistillationNitrogen gas

The invention discloses a method for regenerating and extracting waste mineral oil by filling nitrogen. The method comprises the following steps of: (1) delivering waste mineral oil into a distillation reactor, distilling at reduced pressure after reducing the pressure to -0.1MPa to -0.02Mpa, and dehydrating in vacuum; (2) filling nitrogen into different parts of the distillation reactor, removing other residual miscellaneous gases in the space of the distillation reactor, stirring the dehydrated waste mineral oil, and forming a negative-pressure zone at the inlet of a rectification tower; and (3) circularly heating the stirred waste mineral oil to 120-320 DEG C according to different thermophases, separating out oil steam with different components, mixing the oil steam with nitrogen molecules, transporting quickly, and extracting. The method effectively solves the problems of low regeneration yield of the waste mineral oil, low extraction efficiency and environment pollution.

Owner:佛山市和挚承环保科技有限公司

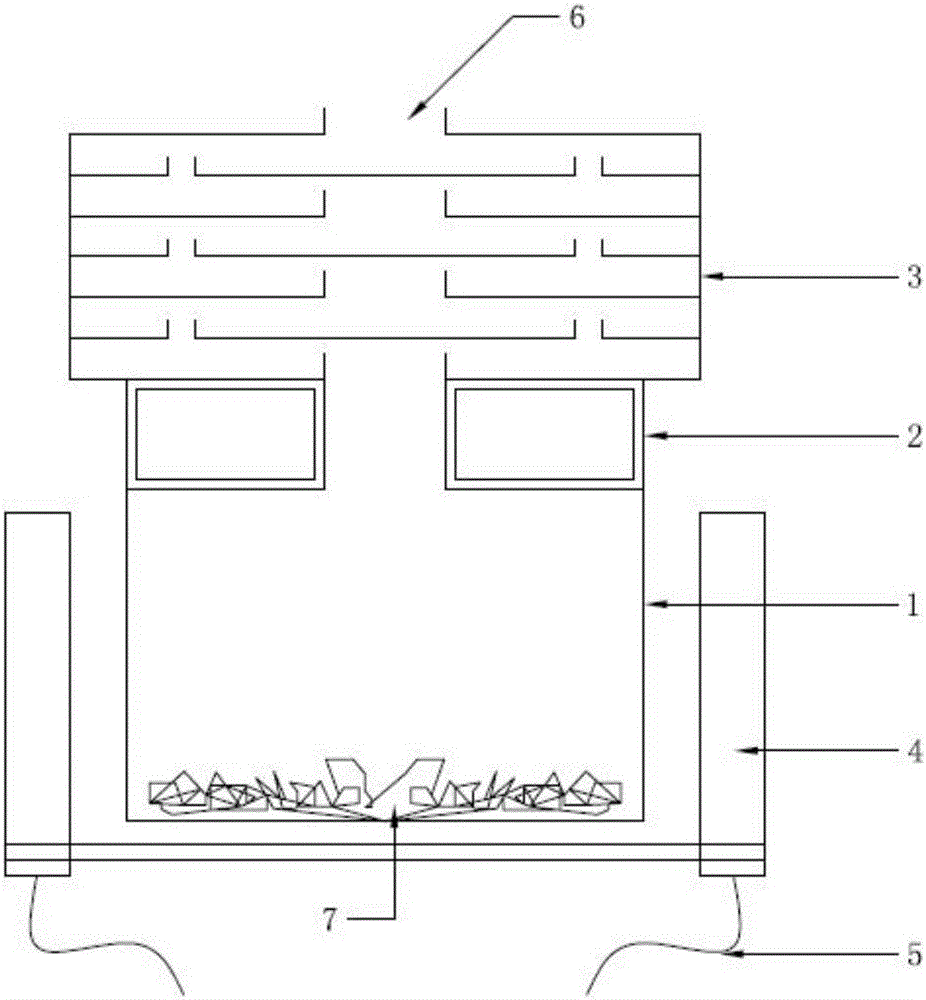

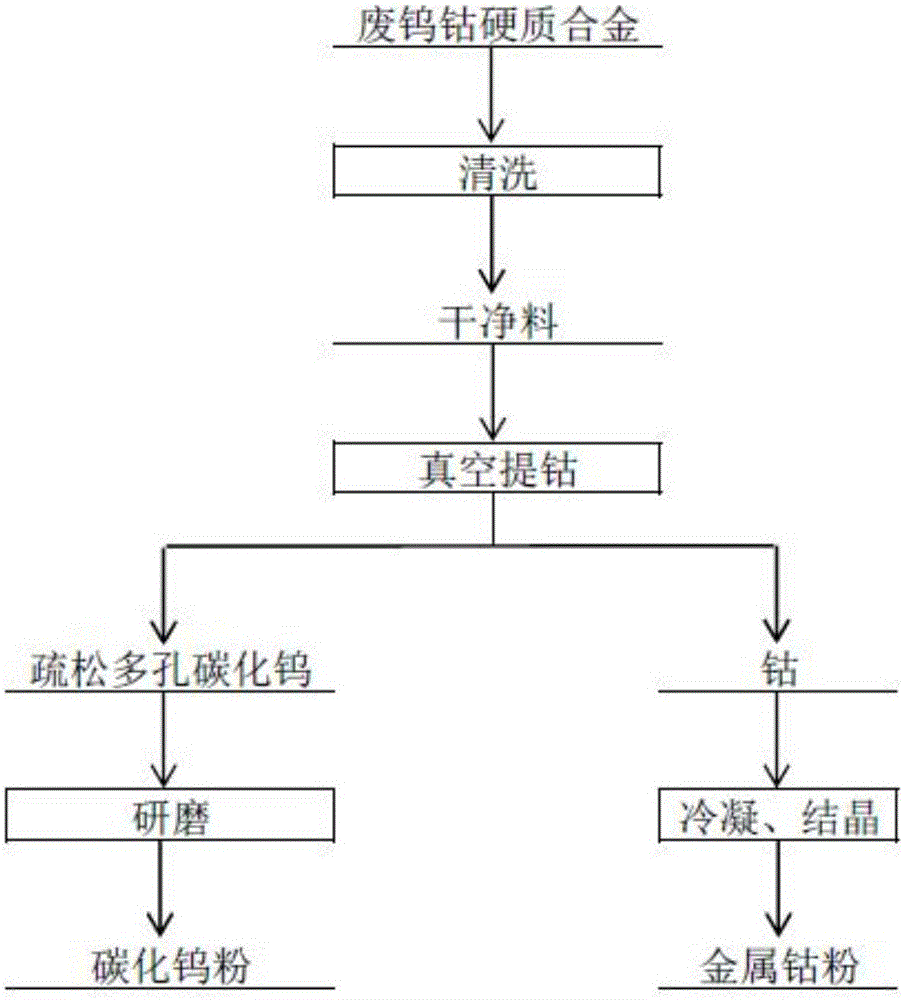

Method for recycling tungsten carbide and metallic cobalt through waste tungsten-cobalt cemented carbide

ActiveCN106145114AWide applicabilitySolve the long process processProcess efficiency improvementCemented carbideCobalt

The invention relates to the technical field of recycling of waste tungsten alloy, and provides a method for recycling tungsten carbide and metallic cobalt through waste tungsten-cobalt cemented carbide. The technological process comprises the steps that waste tungsten-cobalt cemented carbide is cleaned and dried, vacuum cobalt extraction is conducted in a graphite crucible, tungsten carbide with a loose and porous structure is obtained in the crucible, loose and porous tungsten carbide is subjected to crushing and grinding to obtain tungsten carbide power, cooling crystallization is conducted in a cobalt crystallizer, and metallic cobalt powder is obtained. According to the method for recycling tungsten carbide and metallic cobalt through waste tungsten-cobalt cemented carbide, the cobalt extraction process is conducted in a high vacuum closed environment, smudging does not exist, impurities are removed through volatilization, a product is subjected to purification, and high-quality tungsten carbide can be obtained; the purity of cobalt powder extracted through a vacuum method is high, the condition of extracting cobalt is adjusted, and the cobalt powder with different particle sizes can be obtained. The method for recycling tungsten carbide and metallic cobalt through waste tungsten-cobalt cemented carbide is wide in applicability, simple in equipment, low in energy consumption, not prone to smudge, free of pollution, high in recovery rate, low in cost and flexible in scale, and a new way for recycling waste tungsten-cobalt cemented carbide in an efficient and green mode is opened up.

Owner:GANZHOU HUAXIN METAL MATERIAL CO LTD

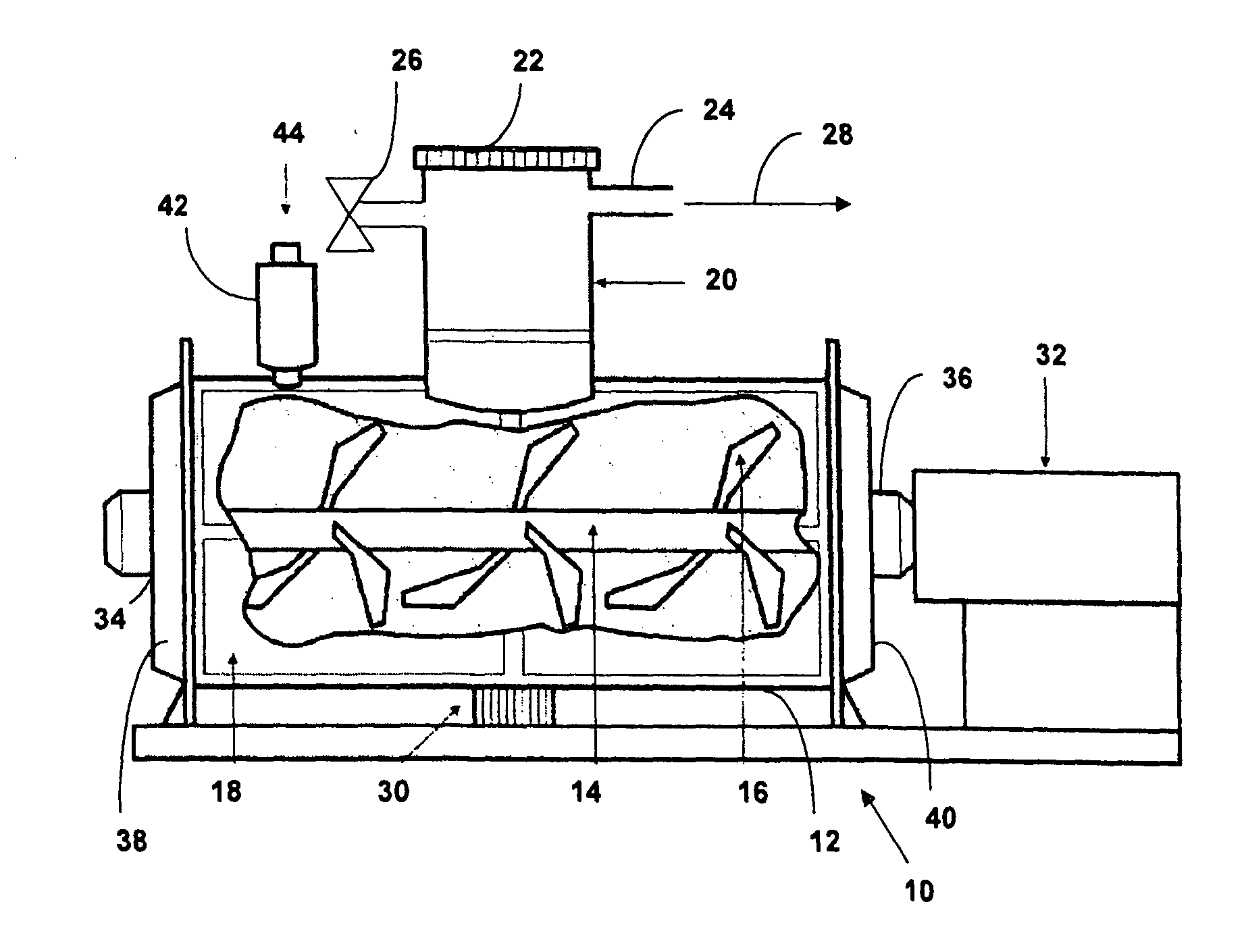

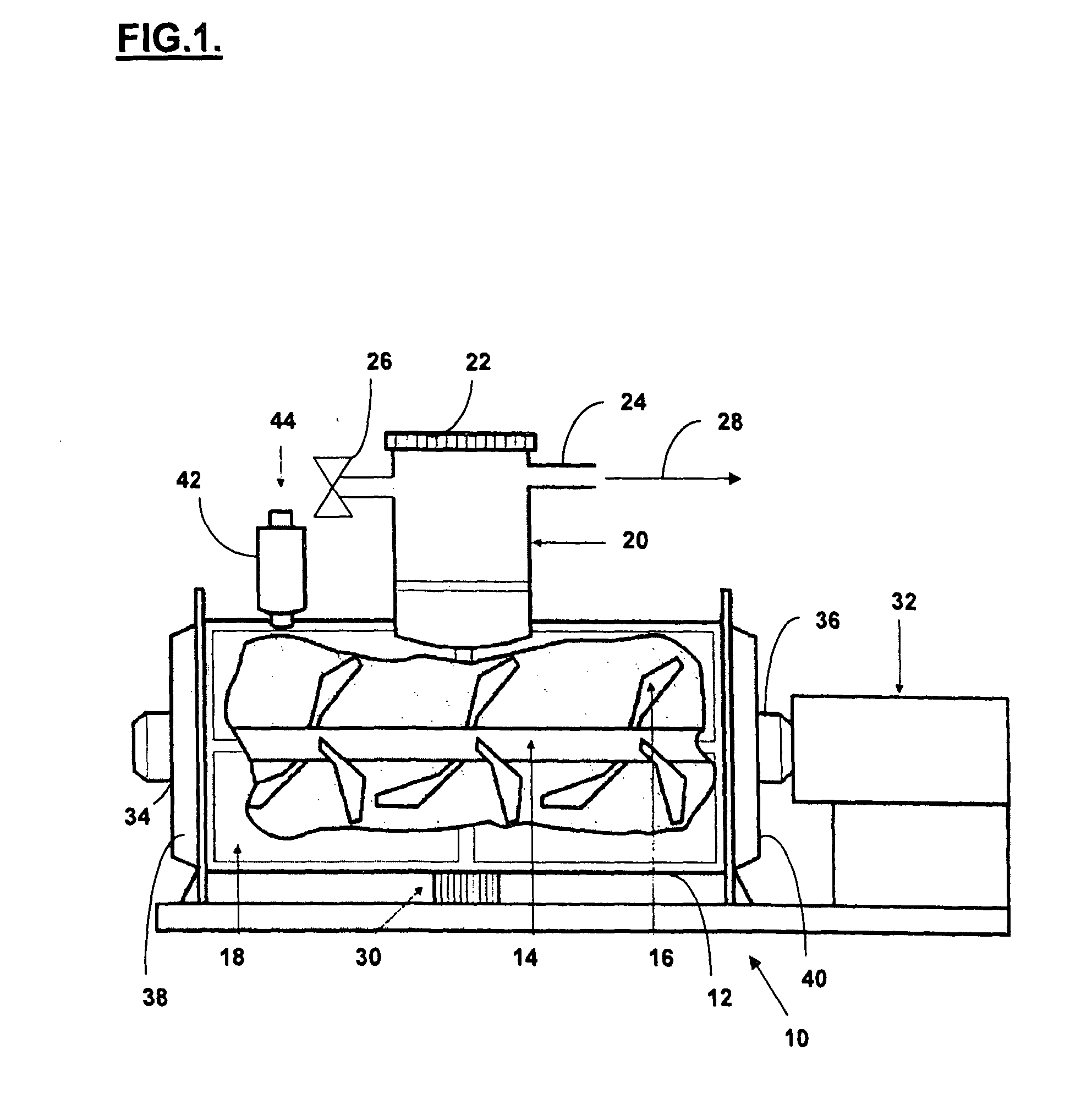

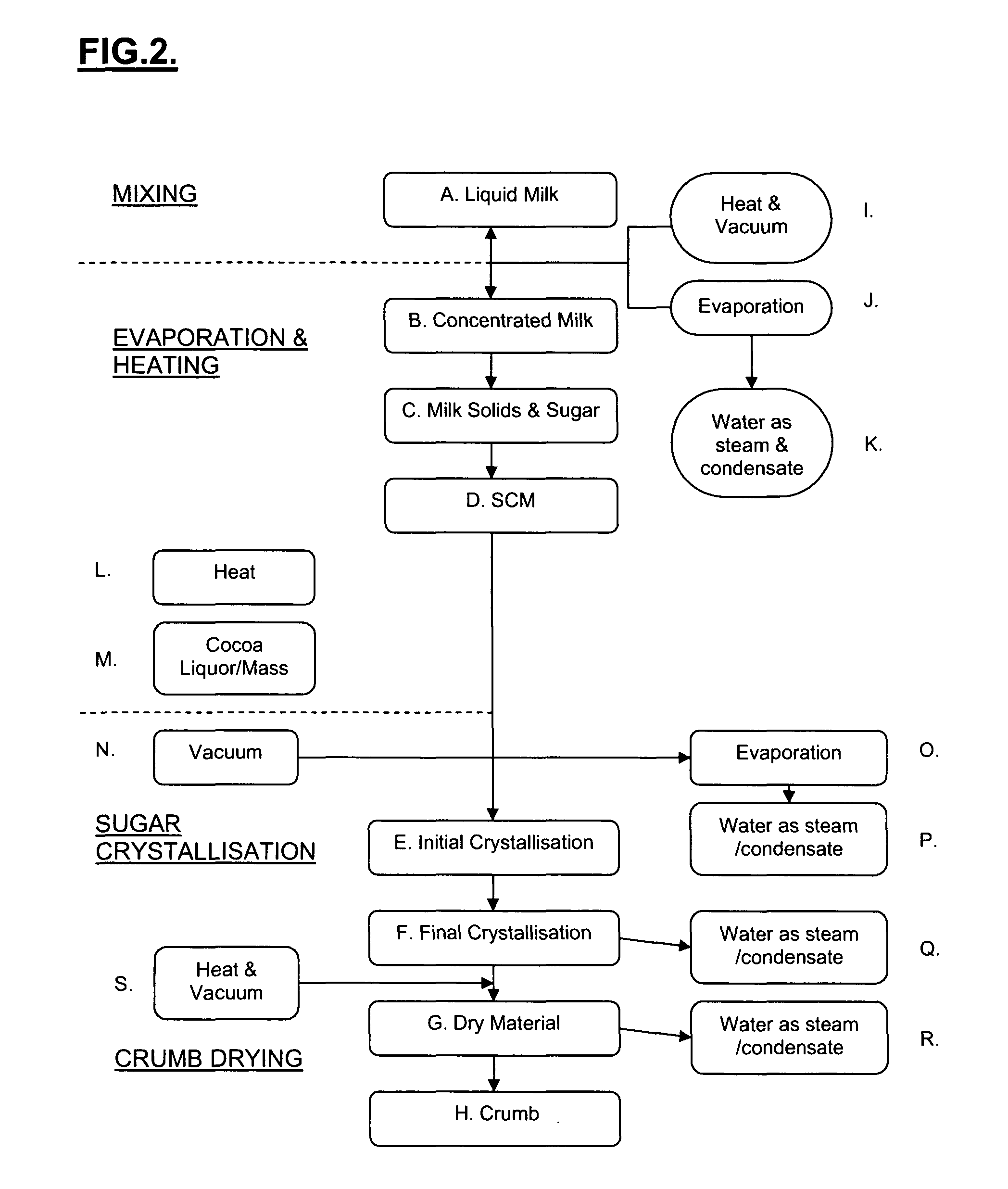

Process for preparing chocolate crumb

InactiveUS20110300286A1Reduce construction costsGood texture and processing and flavour profileCocoaBaking plantsProcess engineeringCondensed milk

A process for chocolate crumb manufacture and an apparatus for preparing chocolate crumb. The process for preparing chocolate crumb comprises: a) supplying a milk and sugar mixture, or mixing together milk and sugar, in a reaction vessel; b) evaporating excess liquid from the mixture in the reaction vessel so as to form sweetened condensed milk; c) adding cocoa mass / liquor to the reaction vessel during and / or after steps (a) and / or (b); d) subjecting the mixture in the reaction vessel to conditions effective to bring about sugar crystallisation in the mixture; and e) drying the mixture so as to form chocolate crumb. The process is efficient in that initial evaporation of excess liquid takes place in the same vessel used for mixing and processing the constituents of the crumb. In one embodiment all of the steps a to e take place in a single reaction vessel.

Owner:MONDELEZ UK HLDG & SERVICES

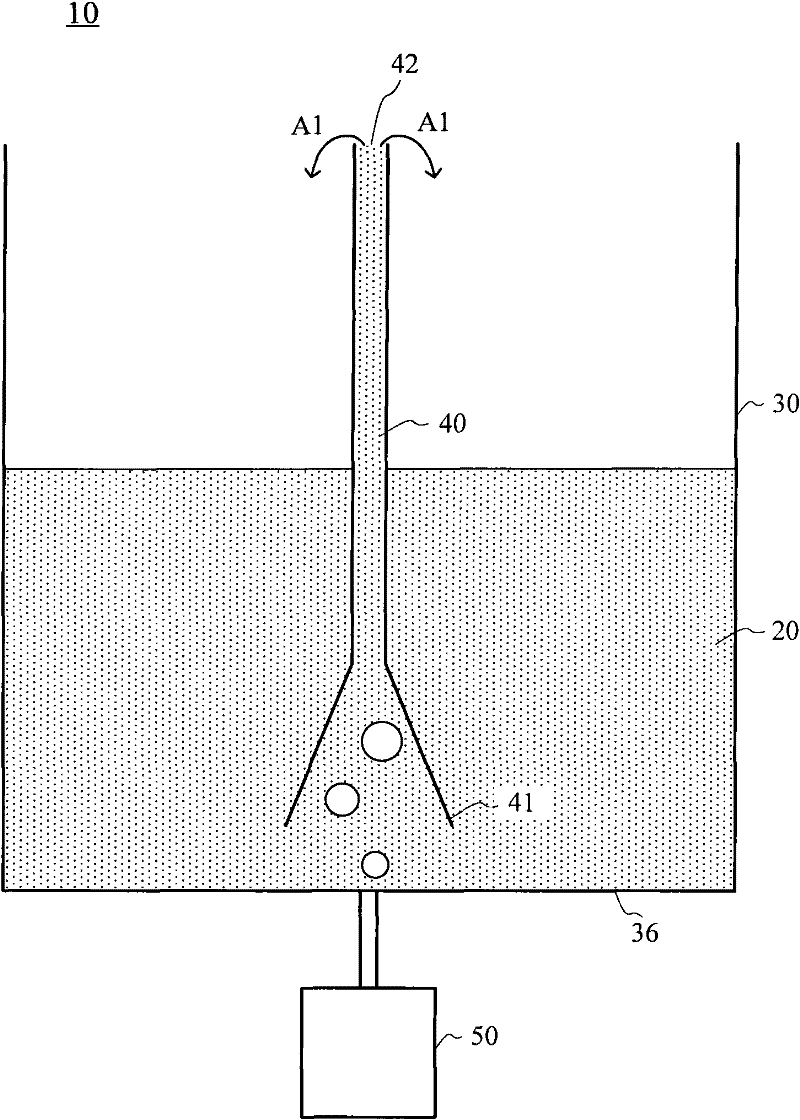

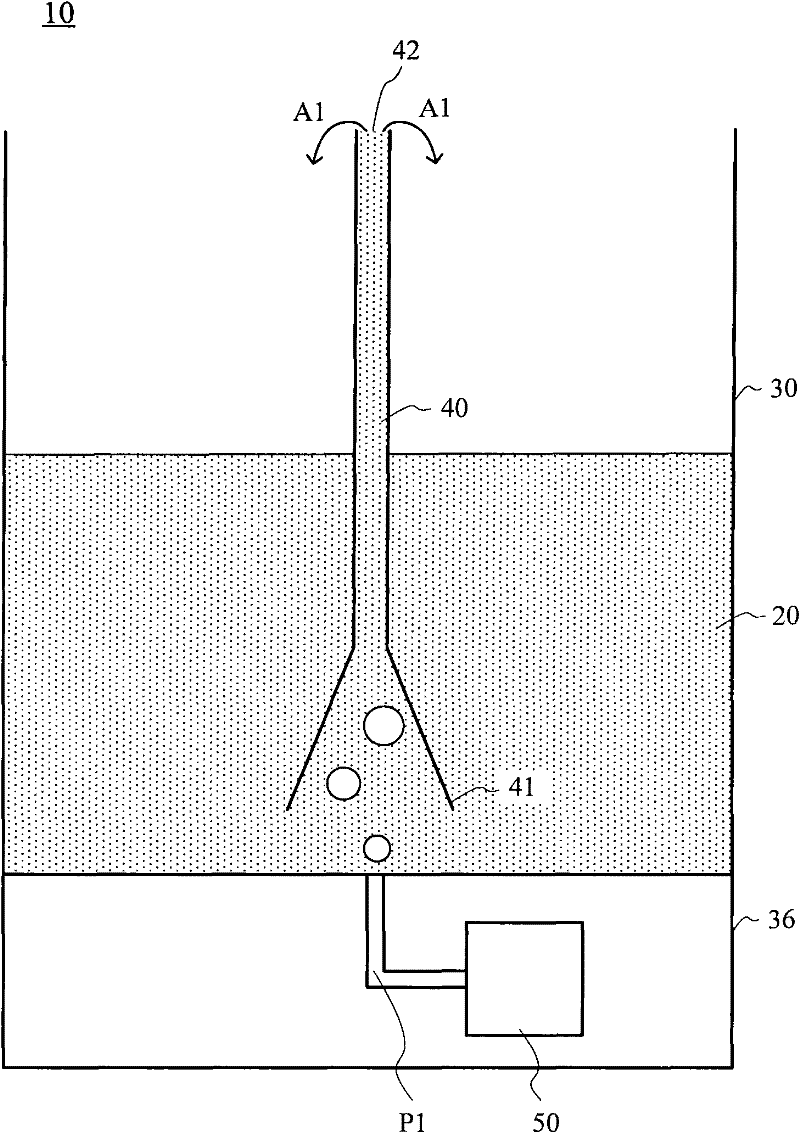

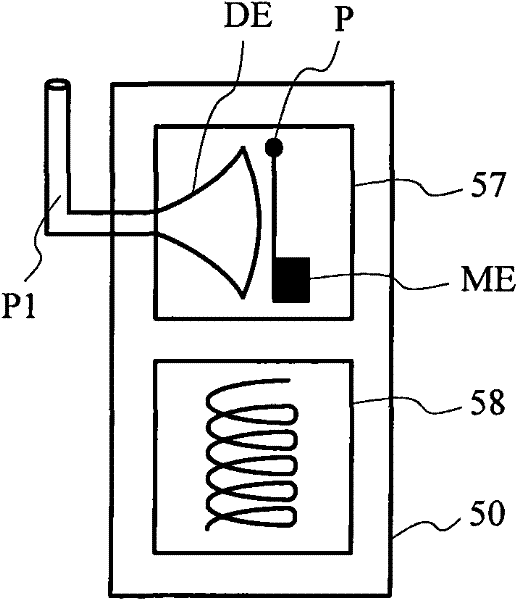

Method and system for conveying solvent and equipment using the system

InactiveCN102440686ALower boiling temperatureReduce the temperatureBeverage vesselsEngineeringSolvent

The invention provides an improved system and method for conveying a solvent. For this reason, the system 10 for conveying the solvent 20, provided by the invention, comprises a container 30, a pipe 40 and an air pump 50, wherein the container 30 is used for accommodating the solvent; the pipe 40 is positioned in the container and provided with a first tail end 41 and a second tail end 42; the first tail end 41 is positioned at one part 36 of the container close to the bottom; the second tail end 42 reaches the upper part of the container; and the airflow 50 is used for generating airflow exhausted from the bottom part so that at least partial airflow can enter the pipe at the first tail end so as to convey the solvent in the pipe from the first tail end to the second tail end. By using the airflow generated by the air pump but not steam bubbles naturally generated by the locally boiled solvent, the solvent can reach the upper part of the pipe and obtain a temperature which is much less than the boiling temperature of the solvent.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Aluminium-zirconium alloy and powder metallurgic forming method thereof

The invention discloses an aluminium-zirconium alloy and a powder metallurgic forming method thereof. The aluminium-zirconium alloy comprises the following components in percent by weight: 70-75 percent of aluminium and 25-30 percent of zirconium. The powder metallurgic forming method comprises the four steps of (1) preparing raw materials, auxiliary materials, tools and devices; (2) conducting vacuum induction melting on the alloy; (3) preparing master alloy powder; and (4) conducting powder metallurgic forming. The aluminium-zirconium alloy is low in impurity content, fine in crystal particle, homogeneous in component, and high in zirconium content, and the powder metallurgic forming method is high in purity, free of pollutants and waste gas, easy to control, stable in quality, and high in finished product ratio.

Owner:JIANGSU HUAQI ALUMINUM SCI & TECH

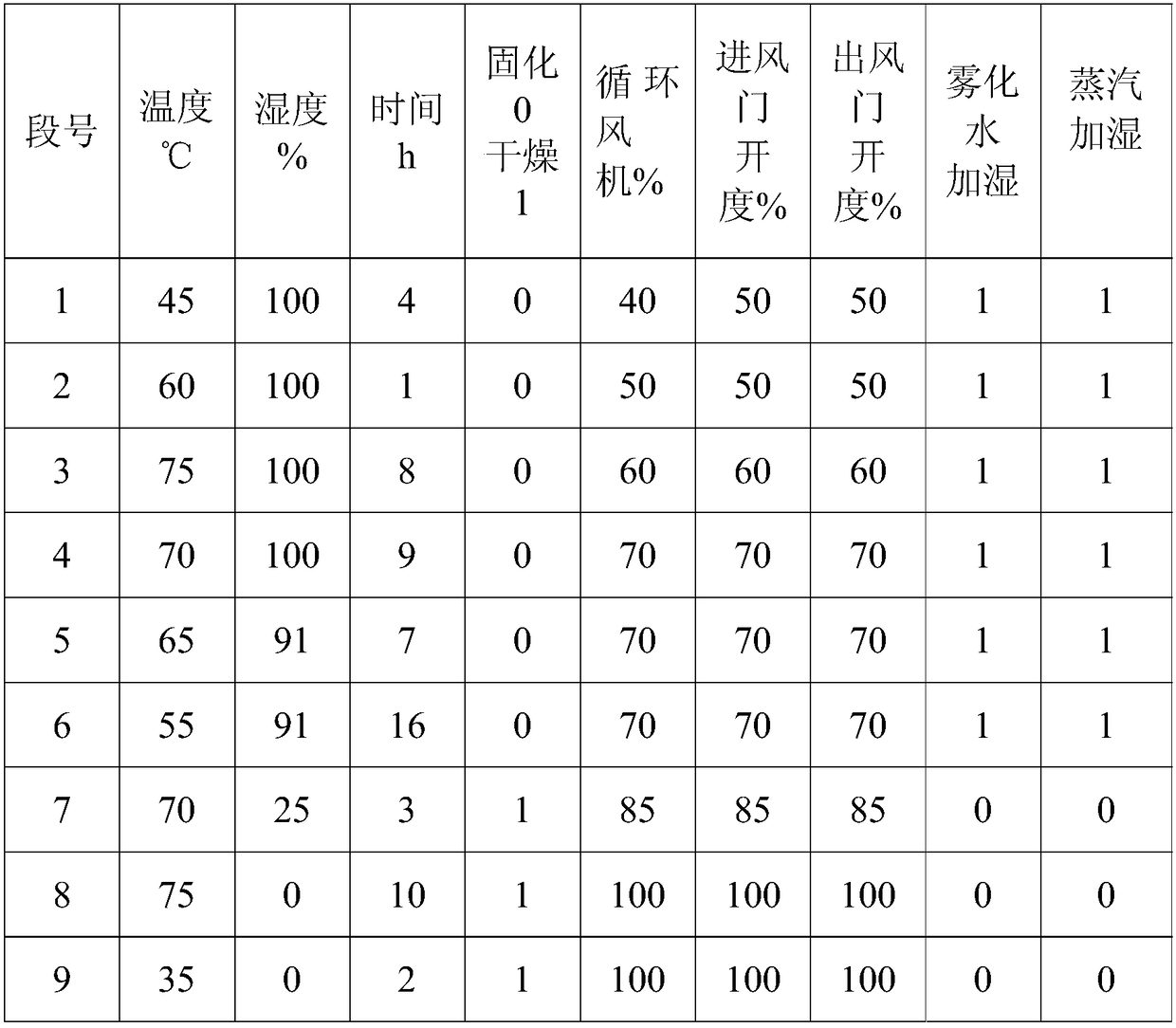

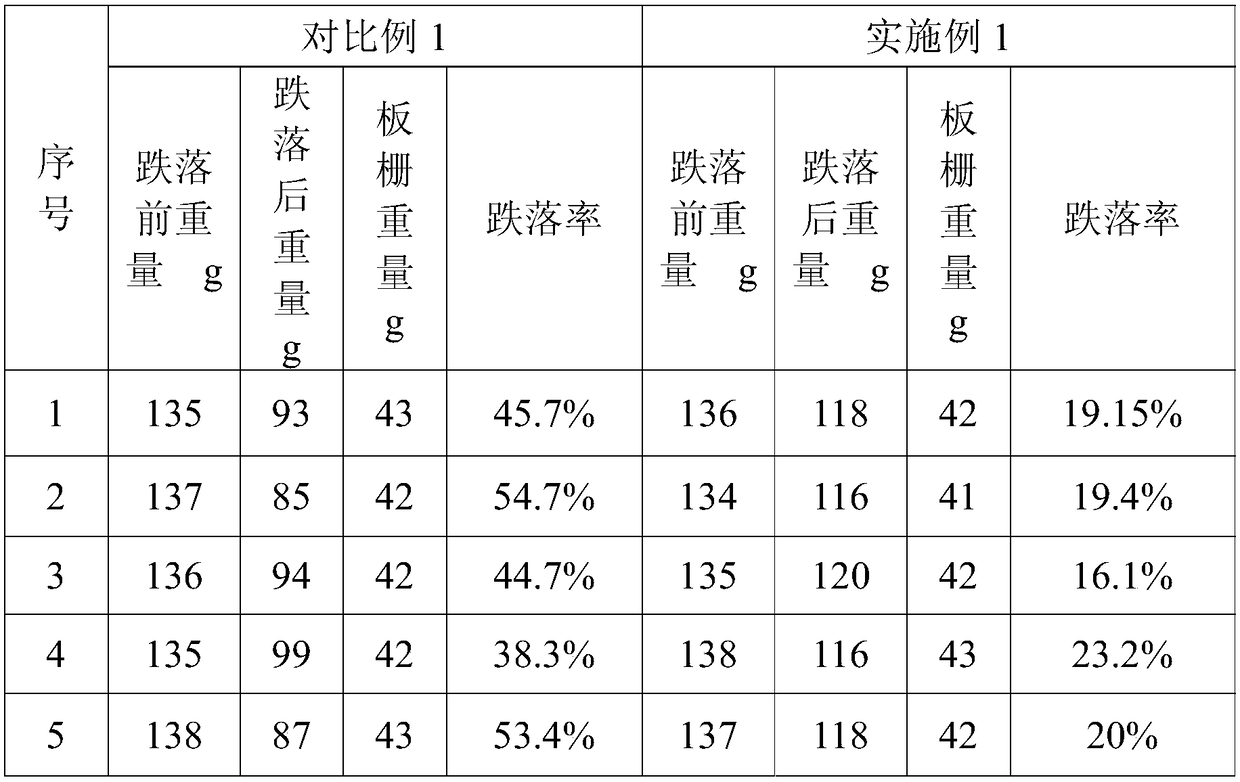

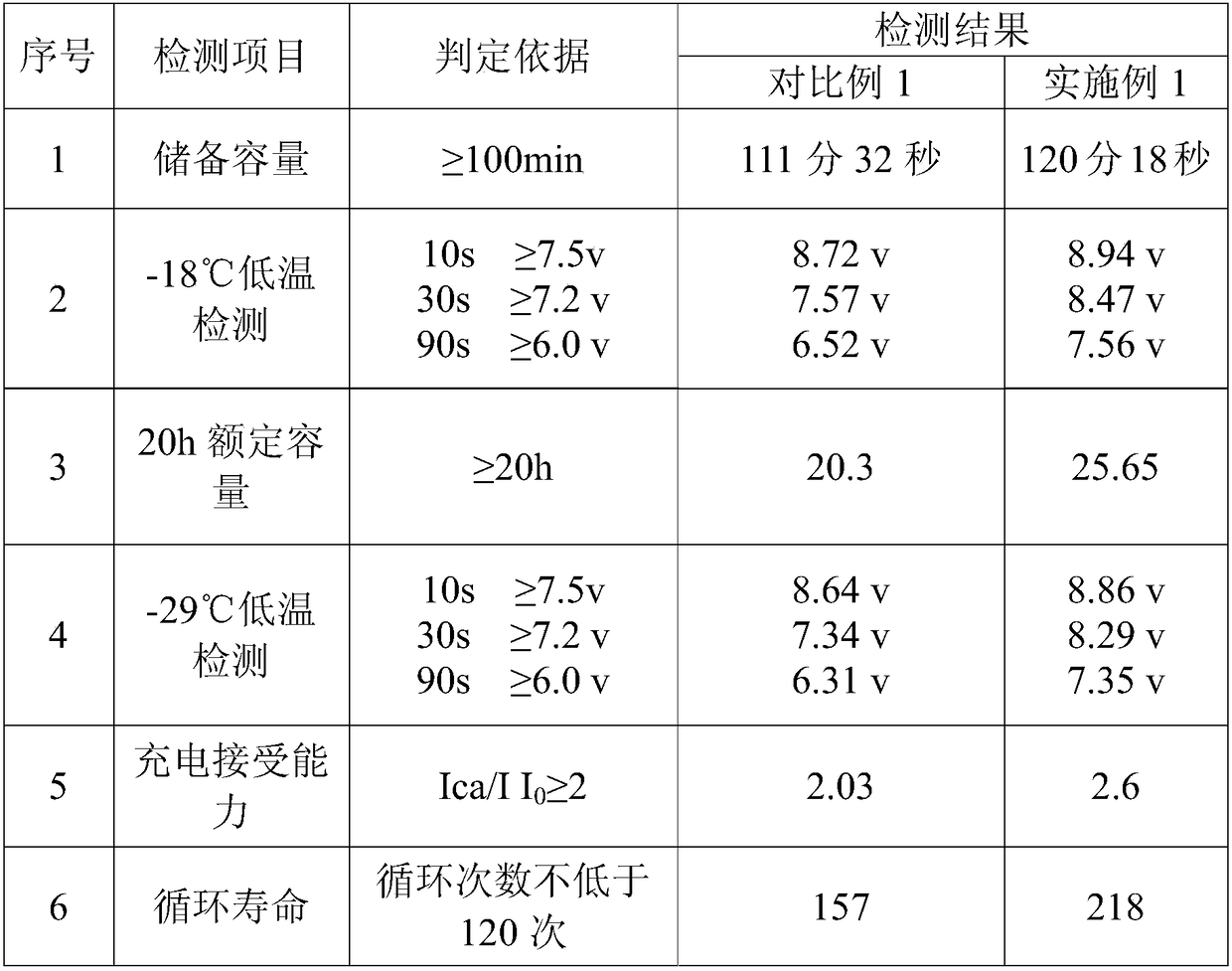

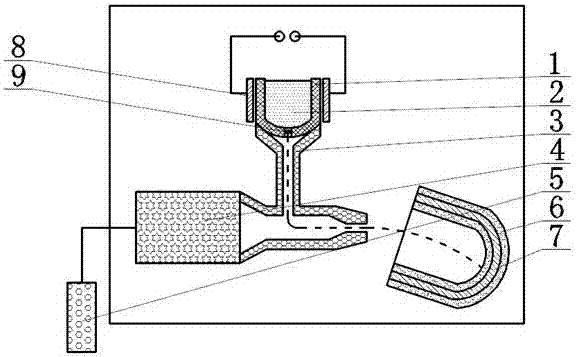

Lead storage battery pole plate curing-drying process

ActiveCN108711610ALower evaporation temperatureSolve lossLead-acid accumulator electrodesPulp and paper industryHigh pressure

The invention discloses a lead storage battery pole plate curing-drying process, and belongs to the technical field of the storage battery preparation. The curing-drying process comprises two stages of oxidation and drying; the oxidation stage orderly comprises reducing pressure and reducing humidity, rising pressure and rising temperature, reducing temperature and reducing humidity and rising pressure, reducing temperature and reducing humidity and reducing the pressure and like steps; the drying stage comprises reducing humidity and reducing pressure, reducing temperature and reducing humidity and reducing the pressure. Through the process disclosed by the invention, the curing is performed under the high-pressure condition, the circulating gas and liquid are high-concentration oxidant,and can penetrate into the pole plate to promote lead plaster internal free lead oxidation reaction and promote the oxidation between the lead plaster and the grid; the high-concentration oxygen catalysis and high-temperature and high-pressure environment improve the reaction rate, improve the oxidation quality and shorten the curing time; the vacuum fast drying is performed to reduce the moistureboiling temperature and promote the moisture evaporation. By adopting the process disclosed by the invention, the curing-drying time can be controlled within 24h, the efficiency is improved by twiceand more, the whole curing-drying process is operated in a closed way and energy-saving and less in pollution gas discharge rate.

Owner:浙江天能汽车电池有限公司

A kind of aluminum-manganese alloy and its powder metallurgy forming method

The invention discloses an aluminum-manganese alloy and a powder metallurgical molding method thereof. The aluminum-manganese alloy comprises, by weight percent, 70% to 75% of aluminum and 25% to 30% of manganese. The powder metallurgical molding method of the alloy comprises the steps of firstly, preparing of raw materials, auxiliary materials, tools and devices; secondly, vacuum induction smelting of the alloy; thirdly, preparing of mother alloy powder; and fourthly powder metallurgical molding. The aluminum-manganese alloy is low in impurity content, fine in grain, uniform in component and high in manganese content; the powder metallurgical molding method of the alloy is high in purification, free of pollutants, free of waste gas, easy to control, stable in quality and high in yield.

Owner:JIANGSU HUAQI ALUMINUM SCI & TECH

Process

InactiveUS20120114826A1Lower boiling temperatureReduce riskFood preparationMeat/fish preservation by dryingCocoa PowdersFlavor

A process for preparing a dried malted beverage product. The process comprises: a) mixing together solid and liquid constituents of the beverage product in a single vessel so as to form a mixture; b) subjecting the mixture in the vessel to heat at a lowered pressure so as to effect drying and granulation of the mixture and form the dried malted beverage product; and c) discharging the dried malted beverage product from the vessel. The process is carried out in a single vessel for mixing, drying and granulation. Suitable solid constituents include one or more selected from malt extract powder, maltodextrin, cocoa powder, milk powder / dairy creams, whey powder, salt, flavours, natural colours and mixtures thereof. Suitable liquid constituents include one or more selected from water, malt extract, caramelised sugar syrup, natural colours, flavours, soya lecithin, maltodextrin, and mixtures thereof.

Owner:CADBURY UK

High-efficiency treatment method for arsenic chemical wastewater

InactiveCN107954562AEnergy savingLow costWater contaminantsMultistage water/sewage treatmentChemistryCompound (substance)

The invention discloses a high-efficiency treatment method for arsenic chemical wastewater. The method comprises the following steps: treating high-salt arsenic-containing wastewater through reduced-pressure distillation; adding the arsenic chemical wastewater into a standing slot for standing precipitation so as to layer the arsenic chemical wastewater; pumping the arsenic chemical wastewater intermediate liquid layered by standing into a reduced-pressure distillation concentration kettle for reduced-pressure distillation treatment, wherein after the reduced-pressure distillation, the condensate water quality reaches an arsenic chemical product reuse water standard in which the arsenic content is lower than 100mg / L and the Na<+> content is lower than 50mg / L. The method disclosed by the invention has the advantages of simple equipment, low production cost and no secondary pollution; and the condensate water quality can meet the requirement on arsenic chemical product reuse water.

Owner:红河砷业有限责任公司

Novel power-enhanced evaporation focusing type solar seawater desalination device

ActiveCN113735213ALower boiling temperatureSpeed up evaporationGeneral water supply conservationSeawater treatmentCollector deviceSolar thermal collector

The invention discloses a novel power-enhanced evaporation focusing type solar seawater desalination device which is characterized in that a solar absorption pipe is mounted on a focal line of a groove-shaped paraboloid focusing heat collector of a focusing type solar heat collector, and the left end of the solar absorption pipe is connected with a seawater storage tank through a first absorption pipe pipeline; the right end connected with a condensing coil through a second absorption pipe pipeline; the other end of the condensing coil is connected with a fresh water storage tank through a fresh water collecting pipe, the condensing coil is located in the water-cooled condenser, the upper portion of the fresh water storage tank is connected with a second low-pressure pump through a second exhaust pipe, and the lower end of the fresh water storage tank is connected with a fresh water outlet. The lower portion of the water-cooled condenser is connected with a cold seawater inlet pipe, and the upper portion of the water-cooled condenser is connected with a seawater outlet pipe, the other end of the seawater outlet pipe is connected with the seawater storage tank. The upper portion of the seawater storage tank is connected with the a low-pressure pump through a first exhaust pipe. According to the device, evaporation of seawater is enhanced, the water production rate of the device is increased, condensation latent heat of water vapor is fully utilized, and the utilization rate of solar energy is increased.

Owner:SHANDONG UNIV OF SCI & TECH

High-purity and high-density aluminum-titanium alloy ingot and manufacturing method thereof

The invention discloses a high-purity and high-density aluminum-titanium alloy ingot and a manufacturing method thereof. The aluminum-titanium alloy ingot is 15% of aluminum-titanium which comprises 83%-86% of aluminum, 14%-16% of titanium and not larger than 0.05% of impurities. Raw materials including, by weight, 83-85 parts of aluminum ingots, 9.5-10.5 parts of titanium sponges and 5.5-6.5 parts of titanium nitrate are adopted, vacuum electroslag remelting, carbon monoxide deoxygenization and degassing and homogenization of an electromagnetic stirring device are adopted, a ceramic hydraulicsystem is adopted as a pressure source and a container, a stainless steel mold with circulating water inside is used for rapid cooling, the hydraulic system is used for pressurization, and rapid andcontinuous casting is achieved. The high-purity and high-density aluminum-titanium alloy ingot has the technical effects of high purity, high density, convenient smelting and one-time forming.

Owner:JIANGSU HUAQI ALUMINUM SCI & TECH

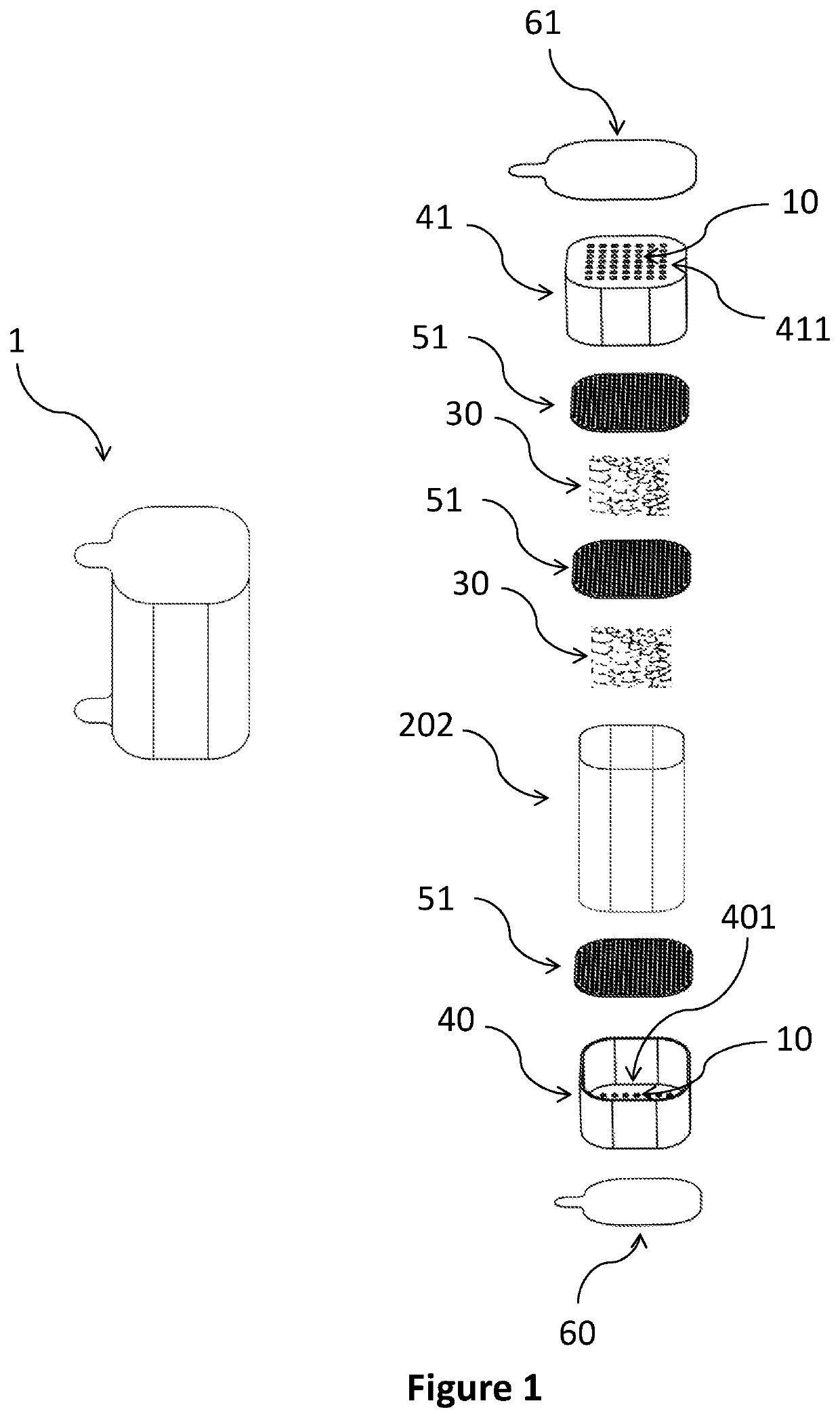

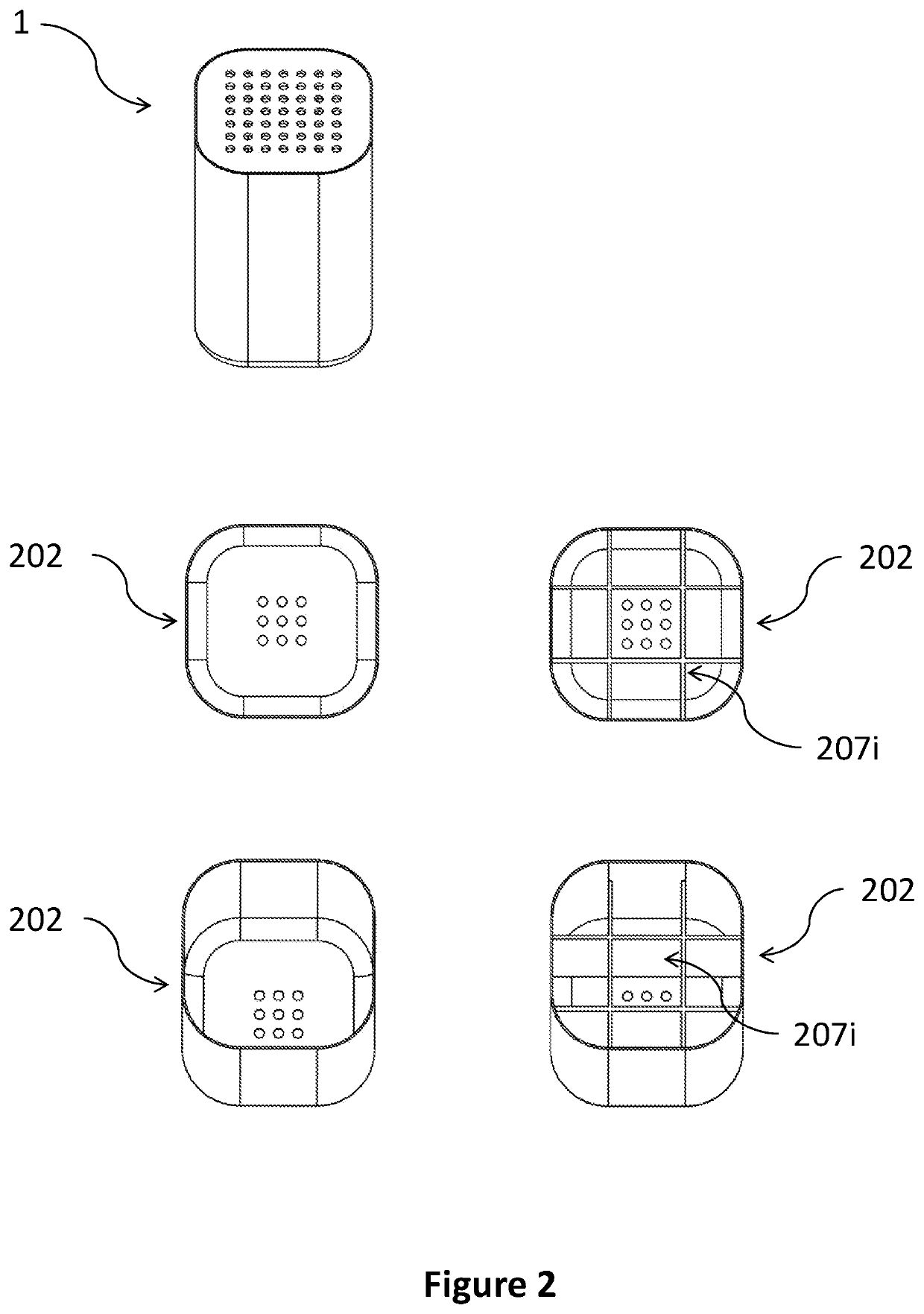

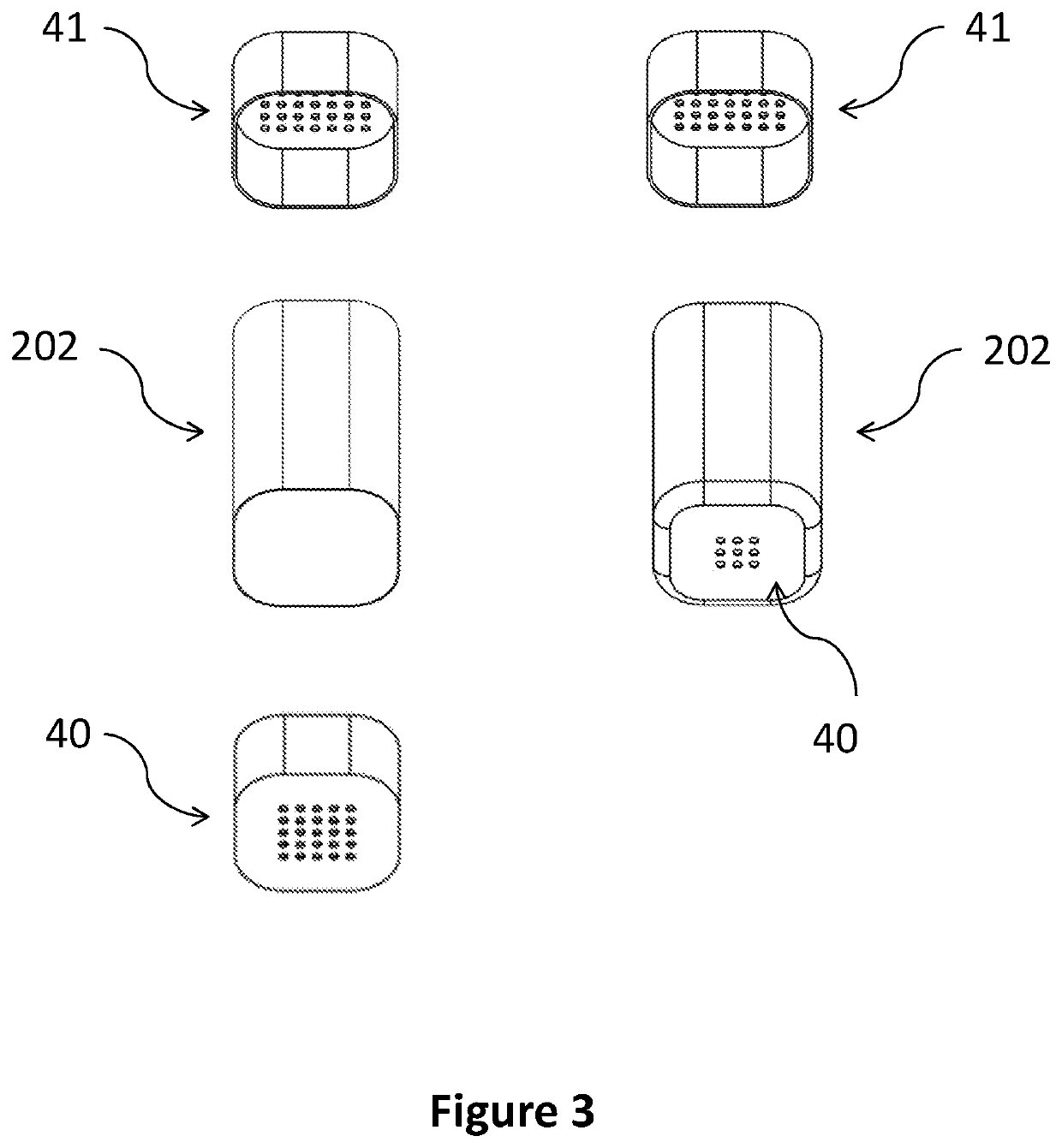

Disposable capsule for the efficient generation of herbal vapor with vapor producing devices

PendingUS20210235758A1Improve vaporization efficiencyLeakage flow can be preventedMedical devicesTobaccoCannabisMaterial Perforation

A disposable capsule, containing herbal product such as Cannabis, can be used with a vaporizer for vaporizing the volatile constituents. The limited battery capacity of portable vaporizers necessitates efficient energy use in order to generate vapor from the herbal product. This is achieved through various features of the invention. Aided by airtightness of the vaporizer capsule connection, the airflow through the capsule can be guided in a controlled fashion. In fact, the capsule (1) is for use in a vapor producing device, the capsule (1) being filled with a herbal product (30) and comprising a shell (202), an upstream part (40) and a downstream part (41), wherein an inlet orifice (401) is in the upstream part (40) and / or in the shell (202) and an outlet orifice (411) is in the downstream part (41), the inlet orifice (401) and the outlet orifice (411) comprising a multitude of perforations (10), and wherein a flow-through-area A2, being a combined surface area of the perforations (10) of the outlet orifice (411), is larger than a flow-through-area A1, being a combined surface area of the perforations (10) of the inlet orifice (401).

Owner:KERAMATI NOORI NARIMAN +3

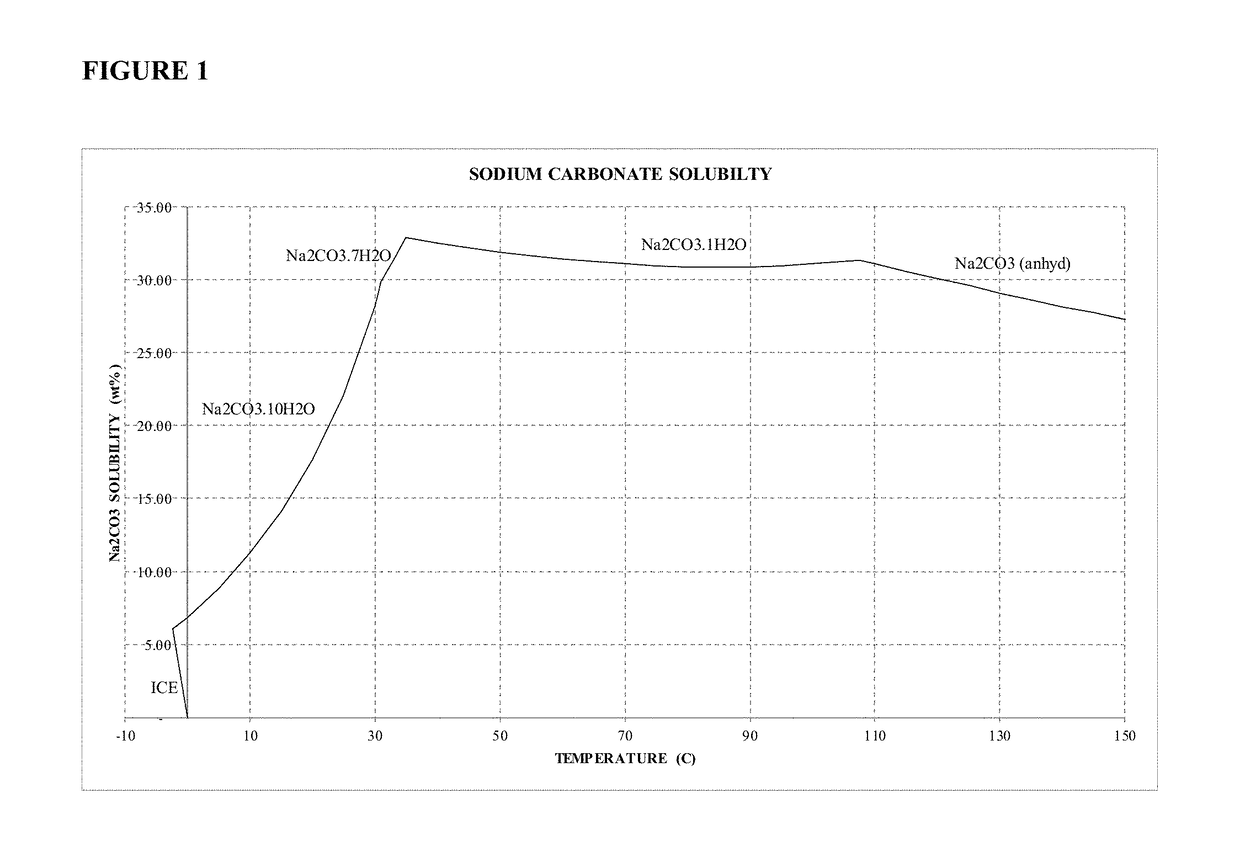

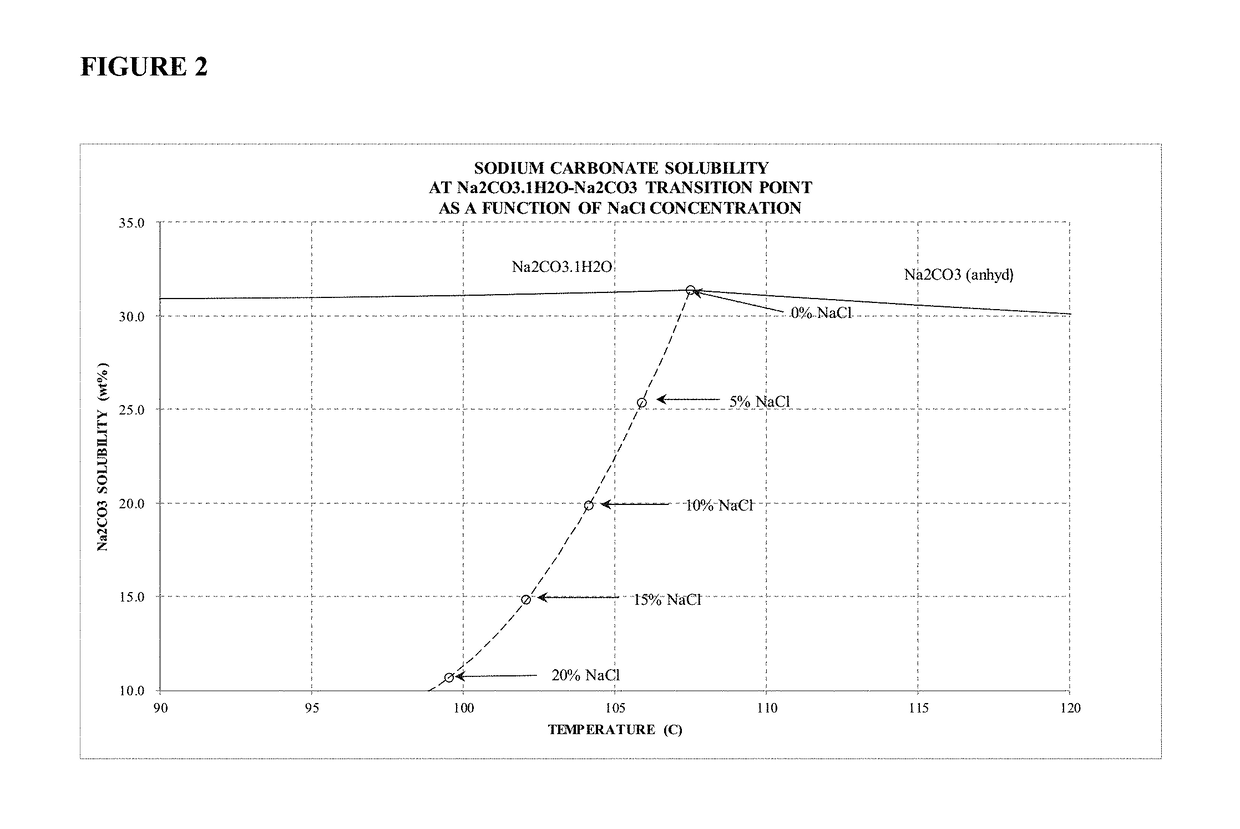

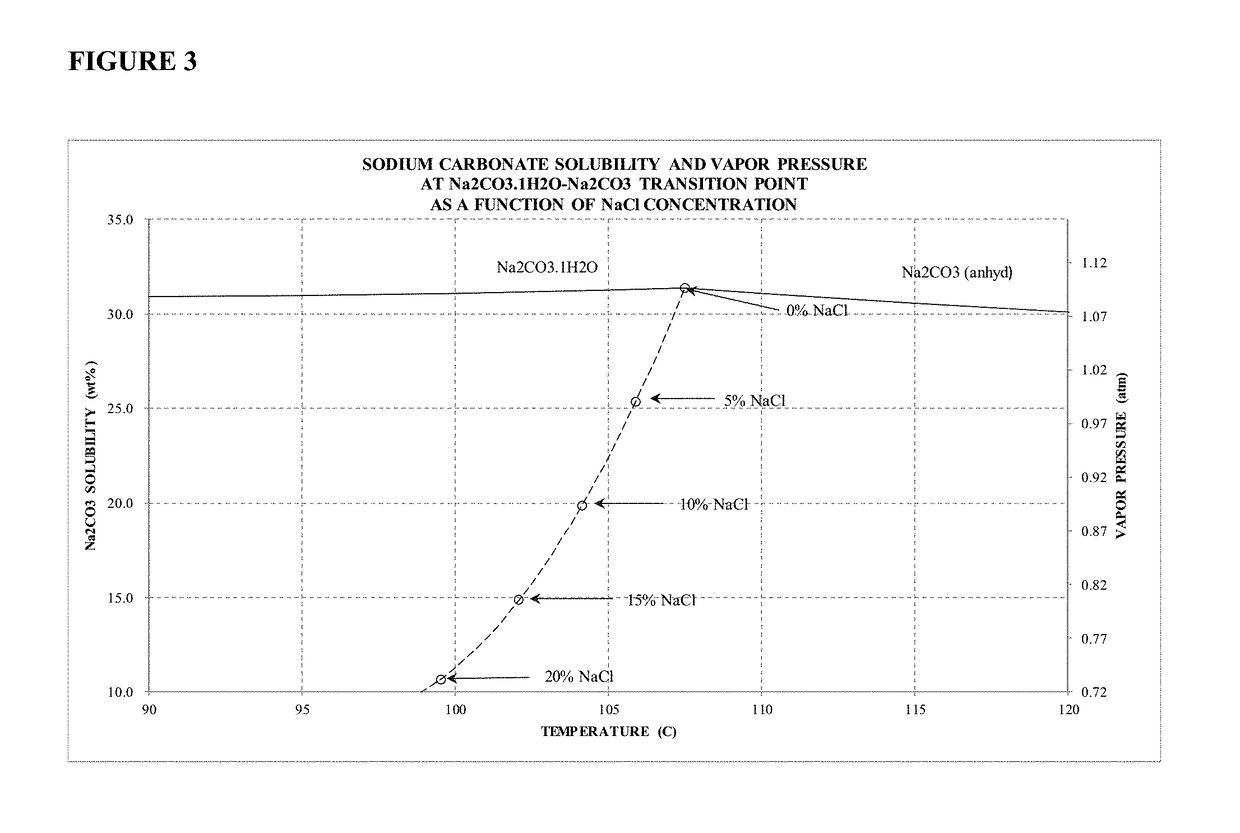

Sodium carbonate monohydrate crystallization

InactiveUS10059600B2Increase concentrationIncrease productionCrystallization by component evaporationAlkali metal carbonatesCrystallizationSodium Carbonate Monohydrate

Owner:SWENSON TECH INC

A kind of flue-cured tobacco extract and electronic cigarette liquid

ActiveCN104621709BLow extraction temperatureKeep it authenticTobacco treatmentEssential-oils/perfumesChemical reactionLiquid smoke

The invention discloses flue-cured tobacco extract and electronic cigarette liquid. Tobacco leaves, tobacco shreds, tobacco powder and / or tobacco ash of flue-cured tobacco serve as raw materials for the flue-cured tobacco extract, and extract solvent is added into a Soxhlet extractor so that Soxhlet extraction can be conducted on the raw materials; as an improvement, a vacuum pump is connected to a condensation pipe of the Soxhlet extractor so that the vacuum degree in the Soxhlet extractor can be kept within the range of 20 mmHg to 80 mmHg; the temperature of condensate in the condensation pipe is 5 DEG C below zero or lower; after Soxhlet extraction is completed, the condensate is collected and concentrated into the flue-cured tobacco extract. A whole Soxhlet extraction system is in a negative pressure state, the boiling point of the extract solvent is reduced, the extraction temperature is reduced, the solvent circulation in the extraction process is accelerated, the extraction frequency is increased, and efficiency is higher. Meanwhile, the solvent heating temperature is lower, and therefore the extraction condition is more moderate, the excessive chemical reaction, caused by solvent high-temperature heating, between aroma components in the extract is avoided, and the extract contains less offensive odor.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Dilute sulfuric acid wastewater treatment system and method

PendingCN112194216AGuaranteed uptimeReduce maintenance costsWater treatment parameter controlSpecific water treatment objectivesWater treatment systemProcess engineering

The invention relates to a dilute sulfuric acid wastewater treatment system and a method. The dilute sulfuric acid wastewater treatment system comprises a preheating device, a pre-concentration device, an evaporation crystallizer, a condensation device and a vacuum device. Wherein the evaporation crystallizer comprises at least two heaters which work independently, so that the long-time stable operation of the system is ensured. The preheating device makes full use of heat energy generated in a dilute sulfuric acid wastewater treatment system, so that the operation energy consumption of the system is greatly reduced. Equipment for dilute sulfuric acid wastewater to pass through is made of zirconium and graphite, so that corrosion of acid waste liquid to system equipment is reduced. According to the dilute sulfuric acid wastewater treatment method, dilute sulfuric acid wastewater is concentrated at the temperature not higher than 70 DEG C, corrosion of sulfuric acid waste liquid to equipment at high temperature is avoided, and long-term stable operation is facilitated.

Owner:GUANGDONG WENYANG ENVIRONMENTAL TECH CO LTD

Liquid vacuum concentration device and concentration method thereof

ActiveCN106139622BLower boiling temperatureMeet different enrichment needsEvaporator accessoriesEngineeringEvaporation chamber

Owner:BEIJING DONGHUAYUAN MEDICAL EQUIP CO LTD

A kind of aluminum-zirconium alloy and its powder metallurgy forming method

The invention discloses an aluminium-zirconium alloy and a powder metallurgic forming method thereof. The aluminium-zirconium alloy comprises the following components in percent by weight: 70-75 percent of aluminium and 25-30 percent of zirconium. The powder metallurgic forming method comprises the four steps of (1) preparing raw materials, auxiliary materials, tools and devices; (2) conducting vacuum induction melting on the alloy; (3) preparing master alloy powder; and (4) conducting powder metallurgic forming. The aluminium-zirconium alloy is low in impurity content, fine in crystal particle, homogeneous in component, and high in zirconium content, and the powder metallurgic forming method is high in purity, free of pollutants and waste gas, easy to control, stable in quality, and high in finished product ratio.

Owner:JIANGSU HUAQI ALUMINUM SCI & TECH

A kind of oriental tobacco extract and electronic cigarette liquid

ActiveCN104621707BLow extraction temperatureKeep it authenticTobacco treatmentEssential-oils/perfumesChemical reactionLiquid smoke

The invention discloses aromatic tobacco extractive and electronic cigarette juice. According to the aromatic tobacco extractive, the tobacco leaves, the pipe tobacco, the tobacco waste and / or the soot of aromatic tobacco are used as raw materials, and an extraction solvent is added into a Soxhlet extractor to carry out Soxhlet extraction on the raw materials. Improvement lies in the fact that a condensation pipe of the Soxhlet extractor is connected with a vacuum pump, so that the vacuum degree of the Soxhlet extractor is maintained at 20-80 mmHg. The temperature of condensation liquid in the condensation pipe is below -5 DEG C. After Soxhlet extraction, extraction liquid is collected and is concentrated, and the aromatic tobacco extractive is obtained. A whole Soxhlet extraction system is at a negative-pressure state, the boiling point of the extraction solvent is lowered, extraction temperature is lowered, during extraction, solvent circulating is accelerated, extraction frequency is accelerated, and efficiency is high. Meanwhile, solvent heating temperature is low, the extraction condition is mild, excessive chemical reaction between aroma components in the extractive caused by solvent high-temperature heating is avoided, and the amount of extractive offensive odor is small.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com