Electrocoagulation treatment method of wastewater from oil-field work

A treatment method and electro-flocculation technology, applied in flocculation/sedimentation water/sewage treatment, mining wastewater treatment, filtration treatment, etc., can solve the problems of complicated equipment maintenance, complicated manual operation, and high chemical operation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

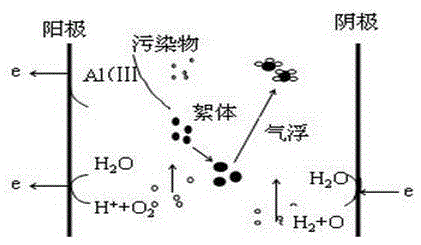

Method used

Image

Examples

Embodiment 1

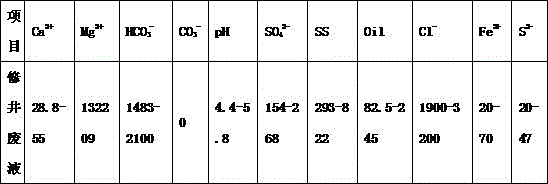

[0047] 1. Complete analysis of the water quality of waste liquid from an oilfield operation.

[0048] Table 1 Water Quality Full Analysis Data Table Unit: mg / l

[0049]

[0050] 2. After the above-mentioned sewage is treated, it must finally meet the following standards;

[0051] Table 2 Water quality compliance data table unit: mg / l

[0052] project

SS

Oil

Fe 2+

S 2-

Workover waste fluid

≤10

≤10

≤1.0

≤2.0

[0053] 3. Conventional processing method:

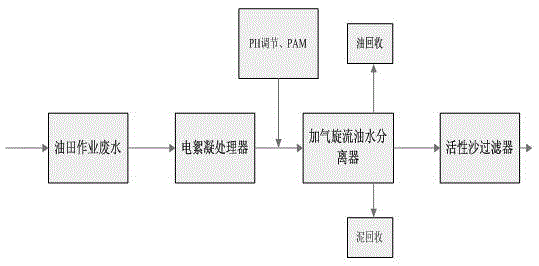

[0054] At this stage, the main process flow is: oilfield operation wastewater→gravity degreasing→coagulation sedimentation→filtration→reinjection.

[0055] Main steps: the first step, a kind of oilfield operation wastewater is separated from the floating oil in the degreasing device and waits until the mixed liquid. In the second step, the mixed liquid in the degreasing device enters the reaction tank through the lift pump for dosing reaction. The mixed solution is coag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com