Double-machine flocculant

An inorganic flocculant and flocculant technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of complex water treatment procedures, large amount of flocculant added, high cost of water treatment, etc., and achieve excellent flocculation effect and dosage The effect of less and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Raw materials: black wattle polyphenol, tertiary amine salt, magnesium silicate, trimethylglycidyl ammonium chloride, ethylenediaminetetraacetic acid. Prepare the present invention as follows:

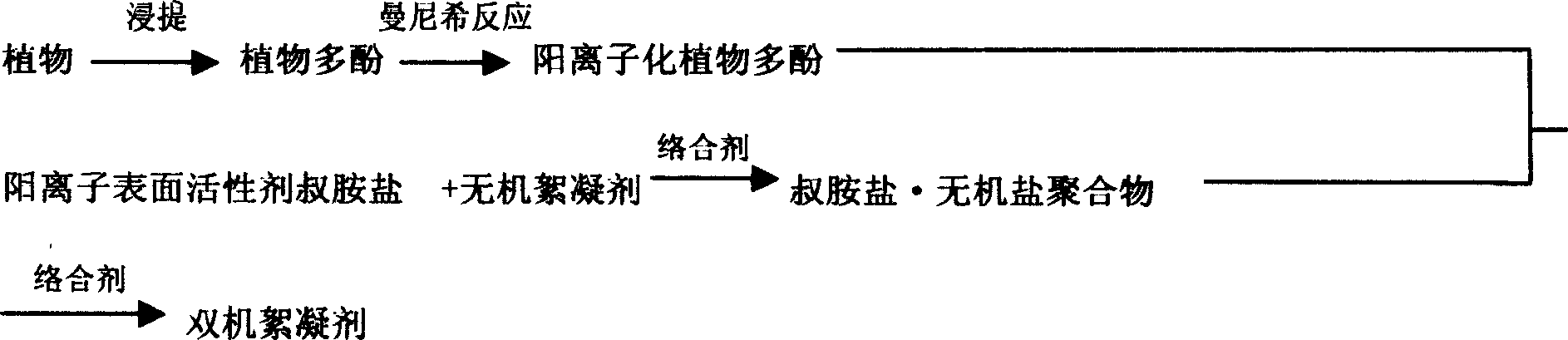

[0025] 1. Extract plant polyphenols from plants, and prepare cationic plant polyphenols through Mannich reaction;

[0026] 2. Use cationic surfactant tertiary amine salt, inorganic flocculant and complexing agent for complexation reaction to prepare tertiary amine

[0027] Salt · Inorganic salt polymer;

[0028] 3. The cationized plant polyphenols and tertiary amine salt inorganic salt polymers obtained in the above two steps of 1 and 2 are placed in the

[0029] In the presence of a complexing agent, a complex reaction is carried out to prepare a dual-machine flocculant. The specific instructions are as follows:

[0030] 1. Modification of plant polyphenols (Mannich reaction):

[0031] Black wattle polyphenols are used as raw materials for extraction, and the obtaine...

Embodiment 2

[0034] In this step reaction, GTAC reagent (trimethylglycidyl ammonium chloride) introduces N in the plant polyphenol R-OH should be greater than 2%, and the positive charge density after the reaction is between 2meq / g~3.2meq / g, The conversion rate of GTAC is over 96%, and the amounts of R-OH and GTAC reagent added are respectively: 81:19. 2. Polymerization of inorganic salts: Polymerize tertiary amine salts and magnesium silicate according to the following reaction formula: In the formula, R 1 R 2 R 3 N HCl is C 12 h 8 C 14 h 9 C 16 h 12 N HCl, A is magnesium silicate, the complexing agent is ethylenediaminetetraacetic acid, the amount added is 0.03% of the total amount, the catalyst is amino catalytic enzyme, the amount added is 0.07% of the total amount, R 1 R 2 R 3 The amounts of N·HCl and A added were: 12:88. 3. Synthesis of dual-machine flocculants: the above-mentioned modified plant polyphenols and R 1 R 2 R 3 N·A is added to the container according ...

Embodiment 3

[0037] Larix polyphenol representative structure In this step reaction, GTAC reagent (trimethylglycidyl ammonium chloride) introduces N into plant polyphenol R-OH should be greater than 2%, and the positive charge density after the reaction is between 2meq / g and 3.2 Between meq / g, the conversion rate of GTAC is over 96%, and the amounts of R-OH and GTAC reagent added are respectively: 68:32. 2. Polymerization of inorganic salts: Polymerize tertiary amine salts and aluminum sulfate according to the following reaction formula: In the formula, R 1 R 2 R 3 N HCl is C 12 h 8 C 13 h 9 C 16 h 12 N HCl, A is aluminum sulfate, the complexing agent is nitrilotriacetic acid, the amount added is 0.19% of the total amount, the catalyst is aminomethyl catalytic enzyme, the amount added is 0.08% of the total amount, R 1 R 2 R 3 The amounts of N·HCl and A added were: 13:87. 3. Synthesis of dual-machine flocculants: the above-mentioned modified plant polyphenols ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com