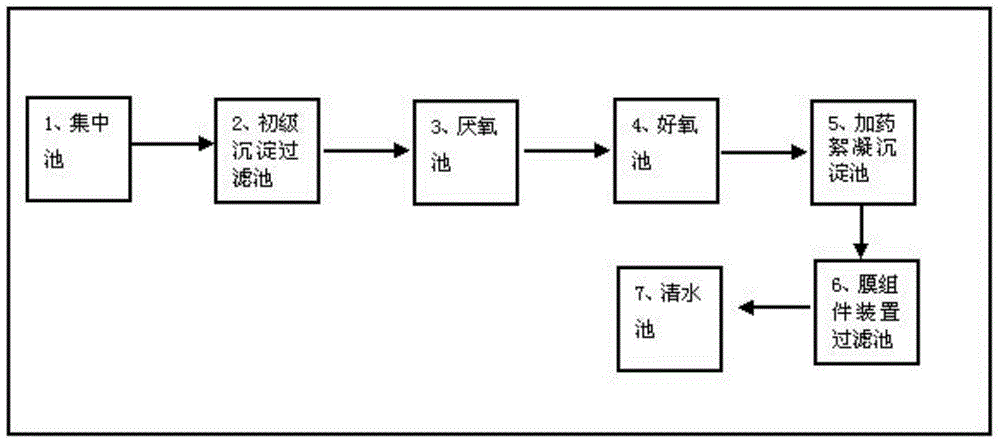

Process for treating livestock and poultry breeding sewage entering Lake Taihu

A technology for livestock and poultry breeding and sewage treatment, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Normal promotion and application, high cost and other problems, to achieve the effect of low operating cost and management cost, good sewage treatment effect, and reduced load and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Farm with 4,500 pigs on hand: sewage flows into 150m 3 The concentrated pool adopts grille and mud-water separator to remove solid matter such as feces in sewage, and the collected solid matter is used as organic fertilizer for planting. The filtrate enters 120m through the overflow pipe 3 The primary sedimentation filter tank, in which the bottom of the tank is paved with graded sand and gravel with a fineness of 2-6mm and a thickness of 80cm, and stands still for 1.5 hours for preliminary adsorption and sedimentation filtration.

[0028] The sewage filtered by the primary sedimentation enters the 80m through the overflow port 3 In the anaerobic tank, the sewage is subjected to biological nitrification reaction for 8 hours in the anaerobic tank equipped with biological contact elastic fiber filler and compound microbial preparation nitrifying bacteria.

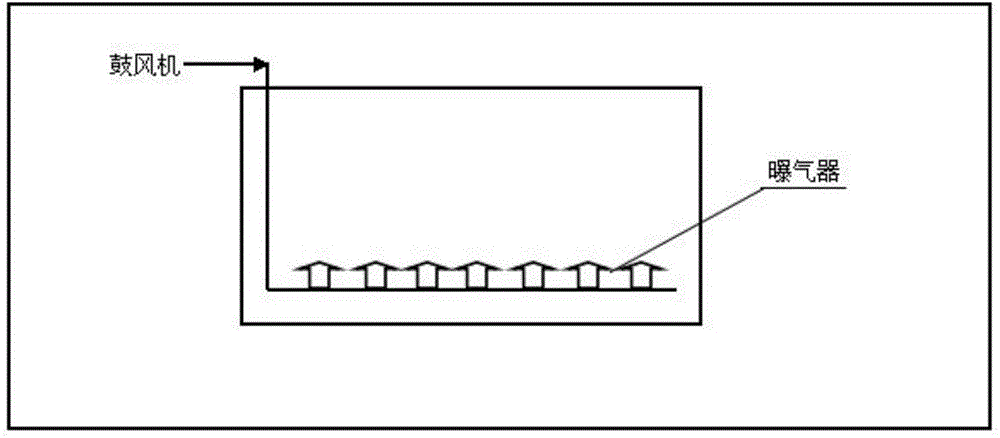

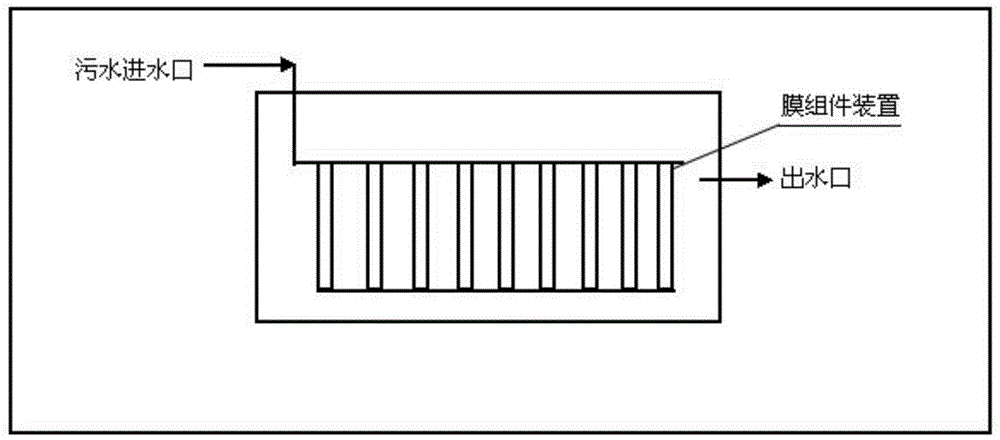

[0029] After the anaerobic reaction, the sewage enters the 80m through the overflow port 3 In the biological conta...

Embodiment 2

[0033] Pig farm with 6000 pigs on hand: the sewage flows into 150m 3 The concentrated pool adopts grille and mud-water separator to remove solid matter such as feces in sewage, and the collected solid matter is used as organic fertilizer for planting. The filtrate enters 120m through the overflow pipe 3 The primary sedimentation filter tank, in which the bottom of the tank is paved with graded sand and gravel with a fineness of 2-6mm and a thickness of 80cm, and stands still for 2 hours for preliminary adsorption and sedimentation filtration.

[0034] The sewage filtered by the primary sedimentation enters the 80m through the overflow port 3 In the anaerobic tank, the sewage was subjected to biological nitrification reaction for 10 hours in the anaerobic tank equipped with biological contact elastic fiber filler and compound microbial preparation lactic acid bacteria.

[0035] After the anaerobic reaction, the sewage enters the 80m through the overflow port 3 In the biologic...

Embodiment 3

[0039] Breeding scale 20,000 broiler chicken farms: the sewage flows into 150m 3 The concentrated pool adopts grille and mud-water separator to remove solid matter such as feces in sewage, and the collected solid matter is used as organic fertilizer for planting. The filtrate enters 120m through the overflow pipe 3 The primary sedimentation filter tank, in which the bottom of the tank is paved with graded sand and gravel with a fineness of 2-6mm and a thickness of 80cm, and stands still for 1.5 hours for preliminary adsorption and sedimentation filtration.

[0040] The sewage filtered by the primary sedimentation enters the 80m through the overflow port 3 In the anaerobic tank, the sewage was subjected to biological nitrification reaction for 9 hours in the anaerobic tank equipped with biological contact elastic fiber filler and compound microbial preparation nitrifying bacteria.

[0041] After the anaerobic reaction, the sewage enters the 80m through the overflow port 3 In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com