Dyeing wastewater treatment device and method for treating wastewater by using device

A printing and dyeing wastewater and treatment device technology, applied in the field of water treatment, can solve problems such as unsatisfactory results, high treatment costs, secondary pollution, etc., and achieve the effects of avoiding high costs, realizing decolorization and toxicity reduction, and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

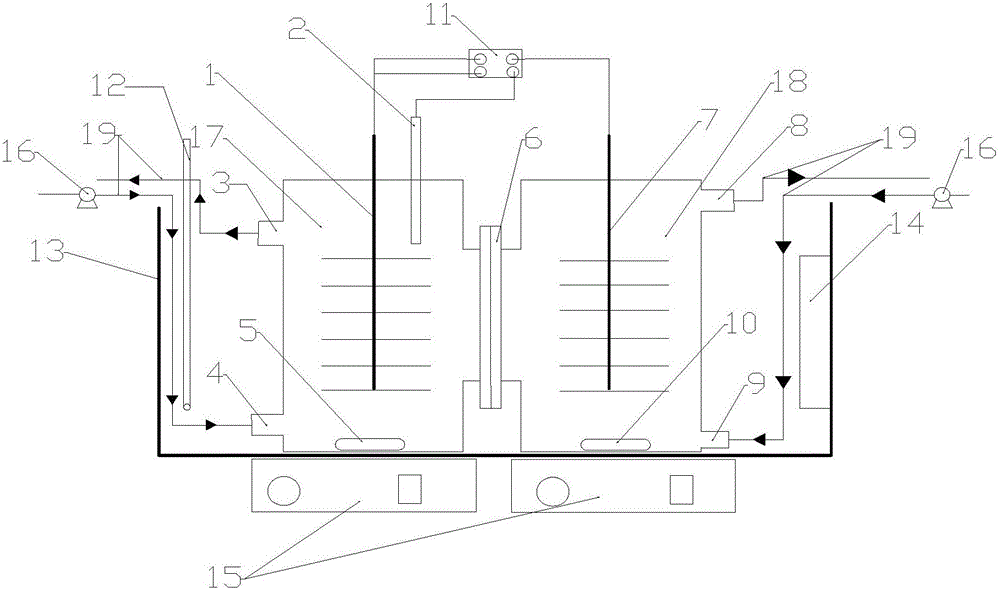

[0025] Figure 1 shows the specific implementation of this invention: a printed and dyeing wastewater treatment device, including the sink, anode chamber, and the cathode chamber.The cation exchange membrane is separated, and the top and bottom of the anode and cathode chamber are equipped with anode outlet, cathode room outlet, anode room water inlet, and cathode inlet, anode room outlet, cathode room water outlet, anode room room, anode room roomThere are silicone tubes at the water inlet of the water inlet and the cathode room. The anode and the cathode indoor are equipped with carbon brushing anode and carbon brushing cathode, carbon brushing anode and carbon brushing cathode.The top of the anode chamber is a sealing cover, with electrode pores in the middle of the sealing cover, and titanium wire through the electrode pores.

[0026] Below the sink corresponds to the anode and cathode chamber with a magnetic mixer. The position of the corresponding magnetic mixer in the anode ...

specific Embodiment approach 1

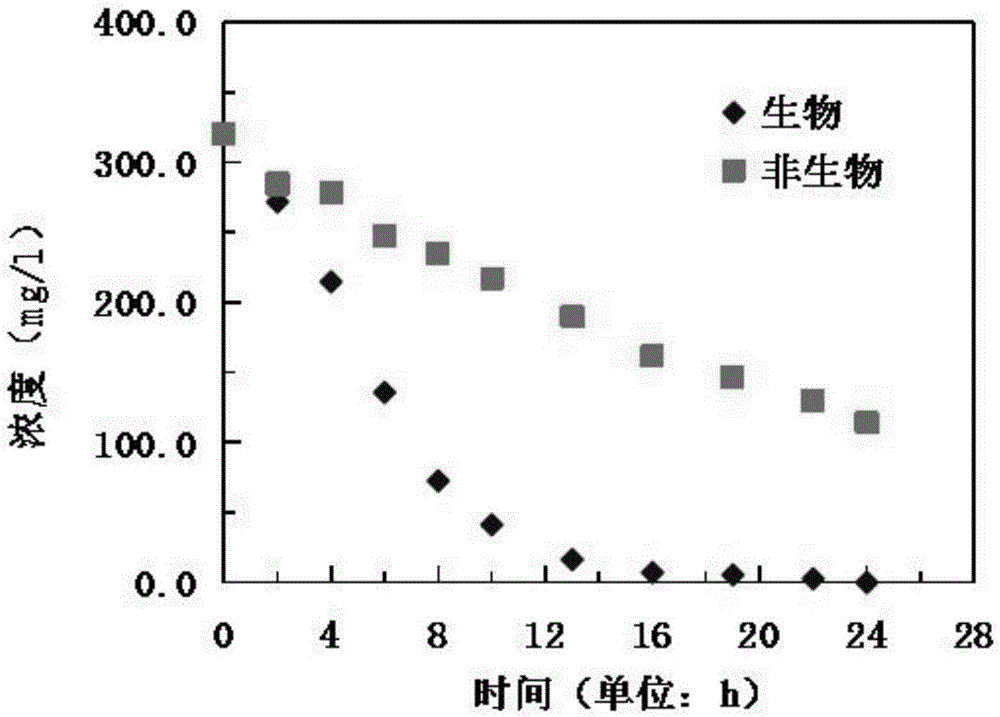

[0038] Specific implementation plan 1: By regulating the hydraulic residence time of the dye wastewater is 24 hours, pH is between 7, the COD concentration of water inlet is 800mg / L, and the external voltage is 0.3V, and the temperature of the reactor is 25 ° C. The system reaches a stable state. The dye dyesWastewater can achieve better discoloration and treatment effects in the cathode room.

[0039] The programmable DC power supply can provide voltage between 1.2V; the cathode and anode room control the temperature through the temperature control heating rod in the sink, and the temperature of the reactor is controlled at 25 ° C.The removal efficiency of the Congo Red reached 98.8 %.

specific Embodiment approach 2

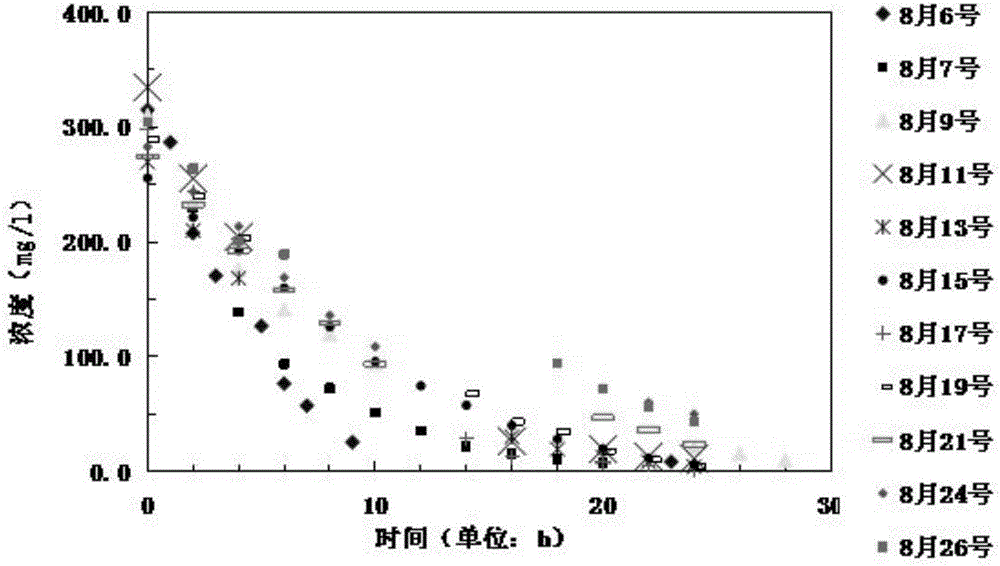

[0040] Specific implementation plan 2: By regulating the hydraulic residence time of dye wastewater is 24 hours, pH is between 7.2, the COD concentration of water inlet is 580mg / L, and the external voltage is 0.3V, and the temperature of the reactor is 27 ℃.Wastewater can achieve better discoloration and treatment effects in the cathode room.

[0041]The programmable DC power supply can provide a voltage between 0.8V; the cathode and anode room control the temperature through the temperature control heating rod in the sink, and the temperature of the reactor is controlled at 26 ° C.The removal efficiency of the Congo Red reached 98.2 %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com