Treatment method of processing wastewater of jade

A technology for processing wastewater and treatment methods, applied in the field of environmental engineering, can solve problems such as inability to process heavy metals and chroma in wastewater, imperfect processes, and inability to meet wastewater treatment and drainage standards, and achieve the effect of improving the removal rate of heavy metals and decolorization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

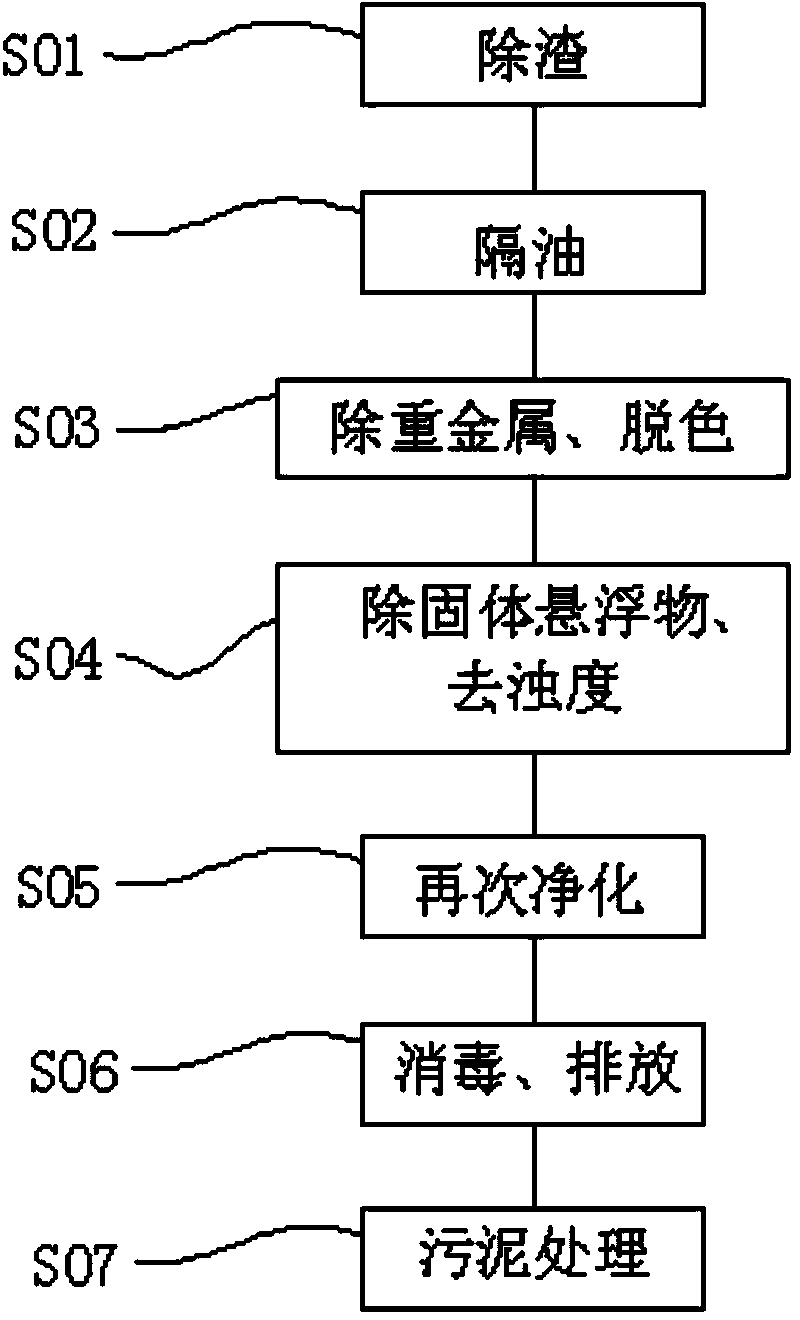

[0046] When the treatment method of jade processing wastewater described in the present invention is used in a treatment device with a daily treatment capacity of 800 tons of wastewater, the treatment process is: S01 slag removal—S02 oil separation—S03 heavy metal removal, decolorization—S04 solid suspended matter removal, and turbidity removal degree—S05 re-purification—S06 disinfection, discharge—S07 sludge treatment; for specific operations, it should be noted that due to the large daily processing volume, the total nitrogen, total phosphorus or chemical oxygen demand in the water treated by S04 did not reach According to the discharge standard, the water discharged from the purification tank is transported to the integrated bioreactor. The integrated bioreactor is equipped with a membrane module, and fillers are added to the integrated bioreactor. Under the action of negative pressure, the membrane The components filter the effluent; in addition, in the S06 disinfection ste...

Embodiment 2

[0051] When the treatment method of jade processing wastewater according to the present invention is used in a treatment device with a daily treatment capacity of 60 tons of wastewater, the difference from Example 1 is that the above-mentioned S05 re-purification step is canceled, and the treatment process is: S01 slag removal-S02 Oil separation—S03 to remove heavy metals, decolorization—S04 to remove solid suspended matter, deturbidity—S06 disinfection, discharge—S07 sludge treatment.

[0052] Both the swirling filter membrane purification tank and the integrated bioreactor of the present invention are provided with a dispensing system and a dosing system; An upper and lower double circulation stirring dispensing system, the patent publication number of which is CN203360030U discloses a water treatment dosing system.

[0053] The mechanical grill sump, automatic oil separator, swirl filter membrane purification tank and integrated bioreactor involved in the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com