Modified macroporous adsorption resin, and preparation method and application thereof

An adsorption resin and pore adsorption technology, which is applied in separation methods, chemical instruments and methods, solid adsorbent liquid separation, etc., can solve the problem of affecting the macroporous adsorption resin pore structure parameters of the matrix and the uncontrollable thickness of the grafted polymer graft layer , difficult to control the reaction process, etc., to achieve the effect of hydrophilic or functional modification, easy control of the process, and increased compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

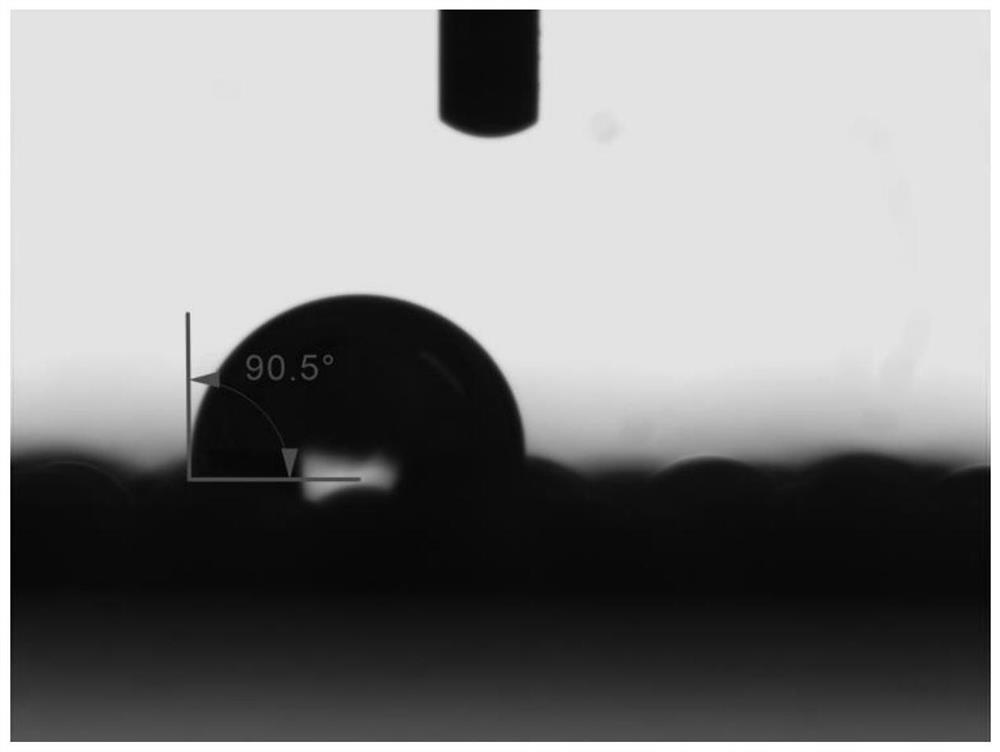

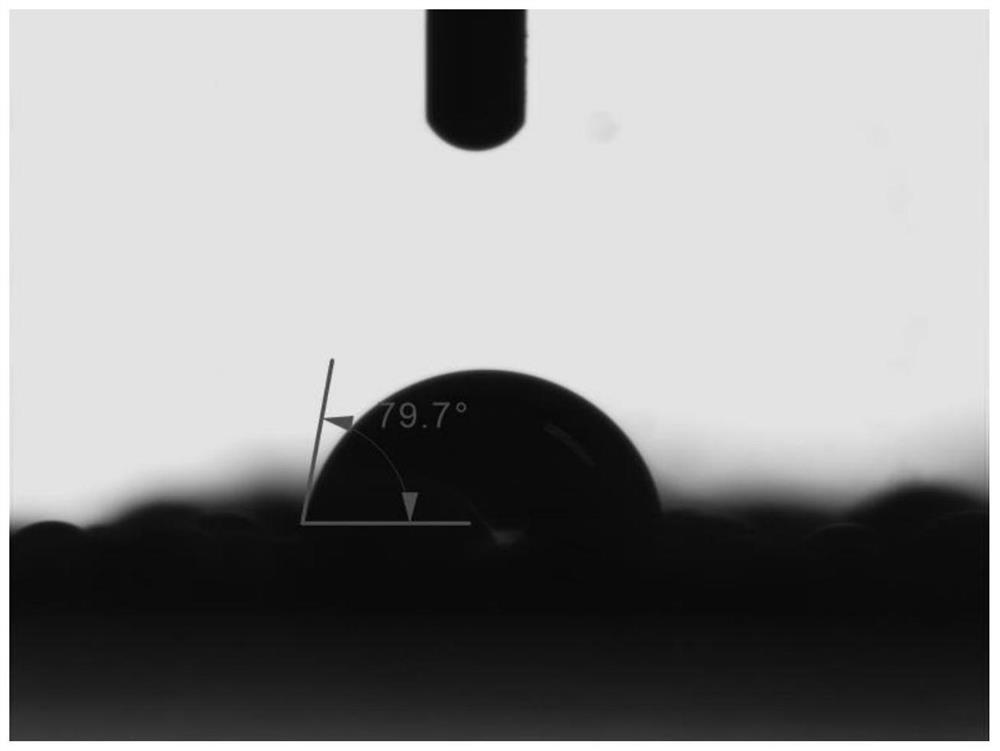

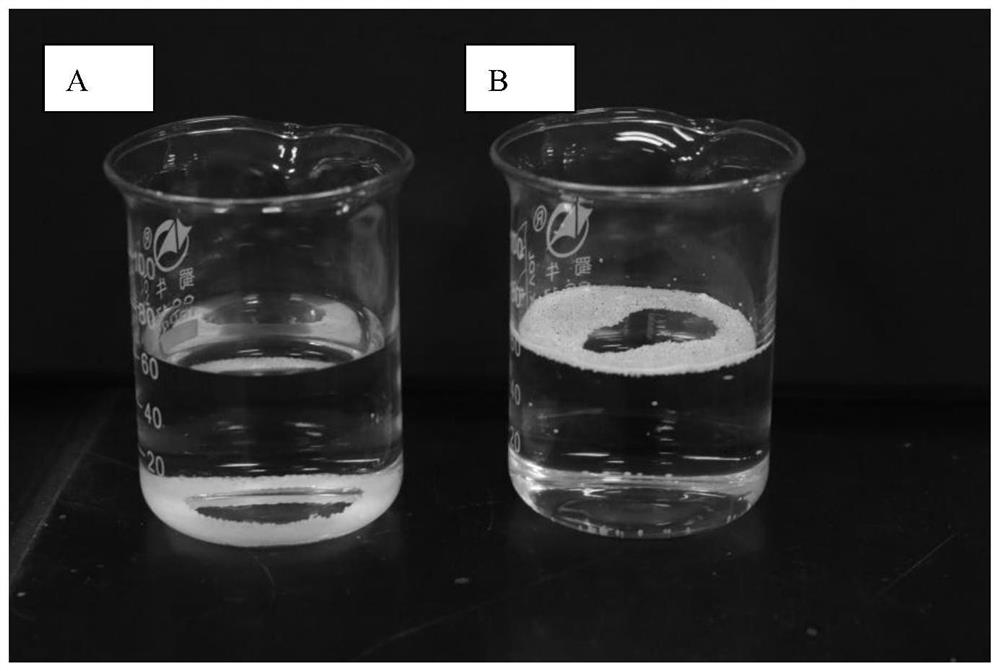

Image

Examples

preparation example Construction

[0045] The present invention provides a kind of preparation method of modified macroporous adsorption resin, comprising the following steps:

[0046] Obtaining a macroporous adsorbent resin, the surface of which contains double bonds;

[0047] Mix (solvent) water, oxidizing agent and macroporous adsorption resin to carry out one-step oxidation reaction to oxidize the double bond to hydroxyl.

[0048] It can be understood that the one-step oxidation reaction means that the double bonds contained on the surface of the macroporous adsorption resin can be oxidized to hydroxyl groups through a one-step reaction without other intermediate treatment processes or intermediate products. Corresponding to the traditional method, the one-step oxidation reaction refers to the process without going through the epoxy intermediate product.

[0049] In one specific example, the one-step oxidation reaction does not involve other solvents except water. Furthermore, the one-step oxidation reactio...

Embodiment 1

[0088] This embodiment provides a preparation method of a modified macroporous adsorption resin, using sulfuric acid and peracetic acid as oxidants, the steps are as follows:

[0089] (1) Get 10 g of macroporous adsorption resin, add 50 mL of aqueous solution containing 2% sulfuric acid and 2% peracetic acid, and react the resulting reaction solution for 6 hours at a temperature of 20° C. and a stirring speed of 180 rpm;

[0090] (2) After the reaction is completed, the obtained macroporous adsorption resin is cleaned with absolute ethanol and purified water;

[0091] (3) Add 5 times the volume of 1M sodium hydroxide aqueous solution to the washed macroporous adsorbent resin for washing, and then wash with purified water until neutral to obtain a modified macroporous adsorbent resin.

Embodiment 2

[0093] This embodiment provides a method for preparing a modified macroporous adsorption resin, using sodium hypochlorite as an oxidizing agent, and the steps are as follows:

[0094] (1) Take 10 g of macroporous adsorption resin, add 50 mL of 1% sodium hypochlorite aqueous solution, and react the resulting reaction solution for 6 hours at a temperature of 20° C. and a stirring speed of 180 rpm;

[0095] (2) After the reaction is completed, the obtained macroporous adsorption resin is cleaned with absolute ethanol and purified water;

[0096] (3) Add 5 times the volume of 1M sodium hydroxide aqueous solution to the washed macroporous adsorbent resin for washing, and then wash with purified water until neutral to obtain a modified macroporous adsorbent resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com