Hydrophilia polypropylene hollow fiber membrane and preparation method thereof

A polypropylene and fiber membrane technology, applied in the field of membrane materials, can solve problems such as unfavorable industrial implementation, complex synthesis reactions, etc., and achieve the effects of less pollution, simple process, and large water flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

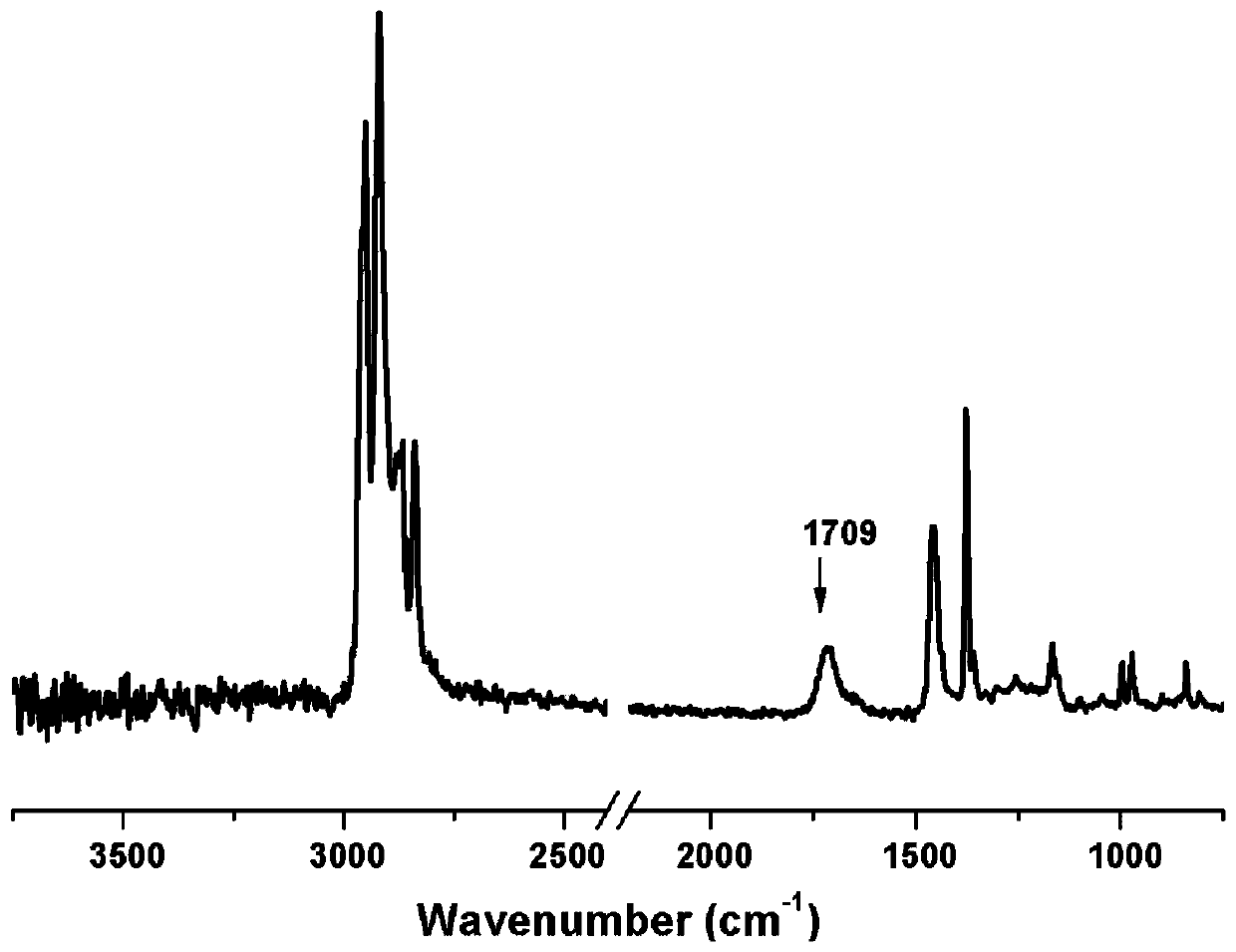

Image

Examples

Embodiment 1

[0030] A kind of hydrophilic polypropylene hollow fiber membrane, preparation method comprises the following steps:

[0031] S1. Casting solution configuration:

[0032] Dissolve 1.5 parts of methacrylic acid in 10 parts of DBP, dissolve 0.005 parts of AIBN in 5 parts of DOP, and then dissolve these 10 parts of DBP, 20 parts of polypropylene F401 (melt index 2.3g / 10min), 50 parts of DOP and 0.5 parts of β-type polypropylene nucleating agent were added to the reactor, stirred at 180°C and 120rpm for 2 hours, then 5 parts of DOP containing the initiator were added to the kettle, and continued at 180°C and 150rpm Stirring for 3 hours resulted in a homogeneous solution. Then, vacuum defoaming was performed for 6 hours under the condition of 20 rpm to form a casting solution.

[0033] S2. Thermally induced phase separation spinning

[0034] Add the casting liquid to the twin-screw extruder, the extrusion temperature is 180°C, after extrusion, it is spun into hollow fibers throug...

Embodiment 2

[0038] A kind of hydrophilic polypropylene hollow fiber membrane, preparation method comprises the following steps:

[0039] S1. Casting solution configuration:

[0040] Dissolve 1 part of acrylamide in 6 parts of GTA, add 20 parts of polypropylene F401 (melt index 2.3g / 10min) and 0.4 parts of polypropylene nucleating agent into the reactor, and stir for 3 hours at 170°C and 120rpm , and then 10 parts of Dinch containing the initiator was added into the kettle, and the stirring was continued for 2 hours under the conditions of 170° C. and 160 rpm to form a homogeneous solution. Then, vacuum defoaming was performed for 5 hours under the condition of 15 rpm to form a casting solution.

[0041] S2. Thermally induced phase separation spinning

[0042]Add the casting solution to the twin-screw extruder, the extrusion temperature is 170°C, after extrusion, it is spun into hollow fibers through the spinneret, the core liquid is Dinch, the temperature is 130°C, and then it is formed...

Embodiment 3

[0046] S1. Casting solution configuration:

[0047] Dissolve 2.5 parts of 2-acrylamido-2 methylpropanesulfonic acid in 20 parts of DBP, dissolve 0.001 parts of BP in 8 parts of DOP, and then dissolve these 20 parts of DBP, 30 parts of polypropylene FY-4012 ( Melt index 2.5g / 10min), 55 parts of DOP and 0.5 parts of polypropylene nucleating agent were added to the reactor, stirred at 180°C and 100rpm for 2 hours, and then 10 parts of DOP containing the initiator were added to the kettle, Stirring was continued for 4 hours under the conditions of 180° C. and 150 rpm to form a homogeneous solution. Then, vacuum defoaming was performed for 4 hours under the condition of 10 rpm to form a casting solution.

[0048] S2. Thermally induced phase separation spinning

[0049] Add the casting liquid to the twin-screw extruder, the extrusion temperature is 180°C, after extrusion, it is spun into hollow fibers through the spinneret, the core liquid is DOP, the temperature is 60°C, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com