Continuous modification equipment and hydrophilic modification method of e-ptfe hollow fiber membrane

A fiber membrane and hollow technology, applied in the field of continuous modification equipment and hydrophilic modification, can solve the problems of hydrophilic agent loss, large footprint, poor uniformity of hydrophilic layer, etc., to improve production efficiency and automation high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

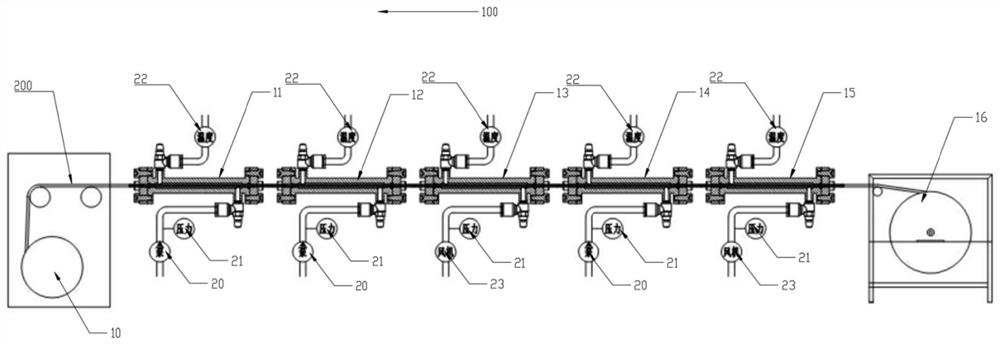

[0049] This embodiment relates to a method for hydrophilic modification of e-PTFE hollow fiber membranes, comprising the following steps:

[0050] 1. At first install the spool full of e-PTFE hollow fiber membrane filaments (hereinafter referred to as membrane filaments) soaked with ethanol on the wire feeding device 10, and at this time, the membrane filaments are soaked in the water tank attached to the device;

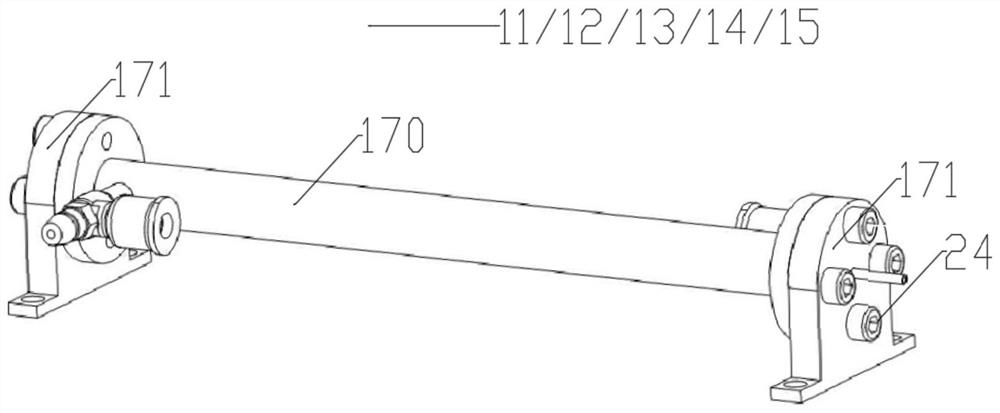

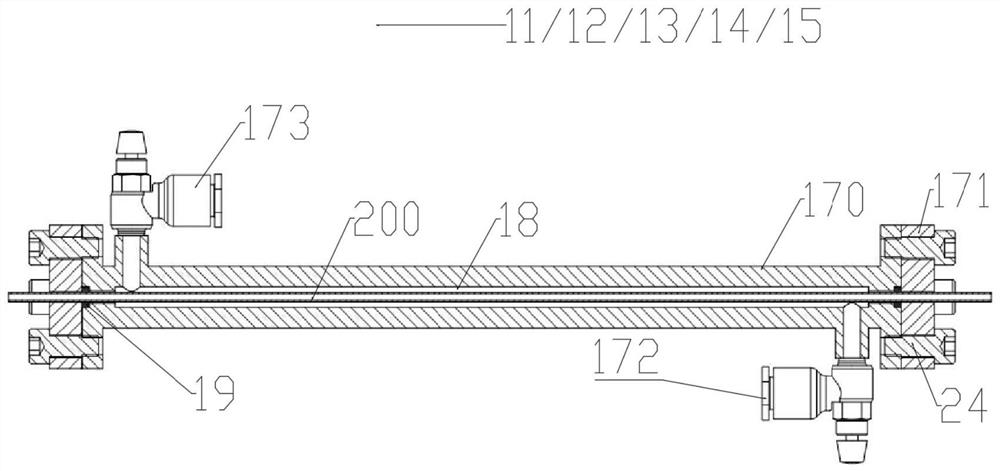

[0051] 2. The e-PTFE hollow fiber membrane is guided by the guide wheel to the polyol polymer infiltration device 11, and passes through the threading channel 18 of the polyol polymer infiltration device 11; the threading channel of the polyol polymer infiltration device 11 18 is filled with a polyol polymer solution with a mass percentage concentration of 1% and a temperature of 30°C through a metering pump to form a pressure of 0.1Mpa. Contact and press into the membrane silk wall hole in the silk channel 18;

[0052] 3. The membrane silk enters the cross-linked ...

Embodiment 2

[0058] This embodiment relates to a method for hydrophilic modification of e-PTFE hollow fiber membranes, comprising the following steps:

[0059] 1. At first install the spool full of e-PTFE hollow fiber membrane filaments (hereinafter referred to as membrane filaments) soaked with ethanol on the wire feeding device 10, and at this time, the membrane filaments are soaked in the water tank attached to the device;

[0060] 2. The e-PTFE hollow fiber membrane is guided by the guide wheel to the polyol polymer infiltration device 11, and passes through the threading channel 18 of the polyol polymer infiltration device 11; The silk channel 18 is filled with a polyol polymer solution with a mass percentage concentration of 2% and a temperature of 50° C. through a metering pump to form a pressure of 0.1 Mpa. The polyol polymer solution is in contact with the membrane silk in the spray plate and pressed into the membrane In the hole of the silk wall;

[0061] 3. The membrane silk en...

Embodiment 3

[0067] This embodiment relates to a method for hydrophilic modification of e-PTFE hollow fiber membranes, comprising the following steps:

[0068] 1. At first install the spool full of e-PTFE hollow fiber membrane filaments (hereinafter referred to as membrane filaments) soaked with ethanol on the wire feeding device 10, and at this time, the membrane filaments are soaked in the water tank attached to the device;

[0069] 2. The e-PTFE hollow fiber membrane is guided by the guide wheel to the polyol polymer infiltration device 11, and passes through the threading channel 18 of the polyol polymer infiltration device 11; the feed liquid chamber of the polyol polymer infiltration device 11 It is filled with a polyol polymer solution with a mass percentage concentration of 1.5% and a temperature of 40°C through a metering pump to form a pressure of 0.1Mpa. The polyol polymer solution is in contact with the membrane silk in the spray plate and pressed into the wall hole of the membr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com