Concrete waterproof additive

An additive and concrete technology, applied in the field of concrete waterproofing additives, can solve the problems of frequent repairs, wall openings, etc., and achieve the effects of improving compactness, improving protection effect and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

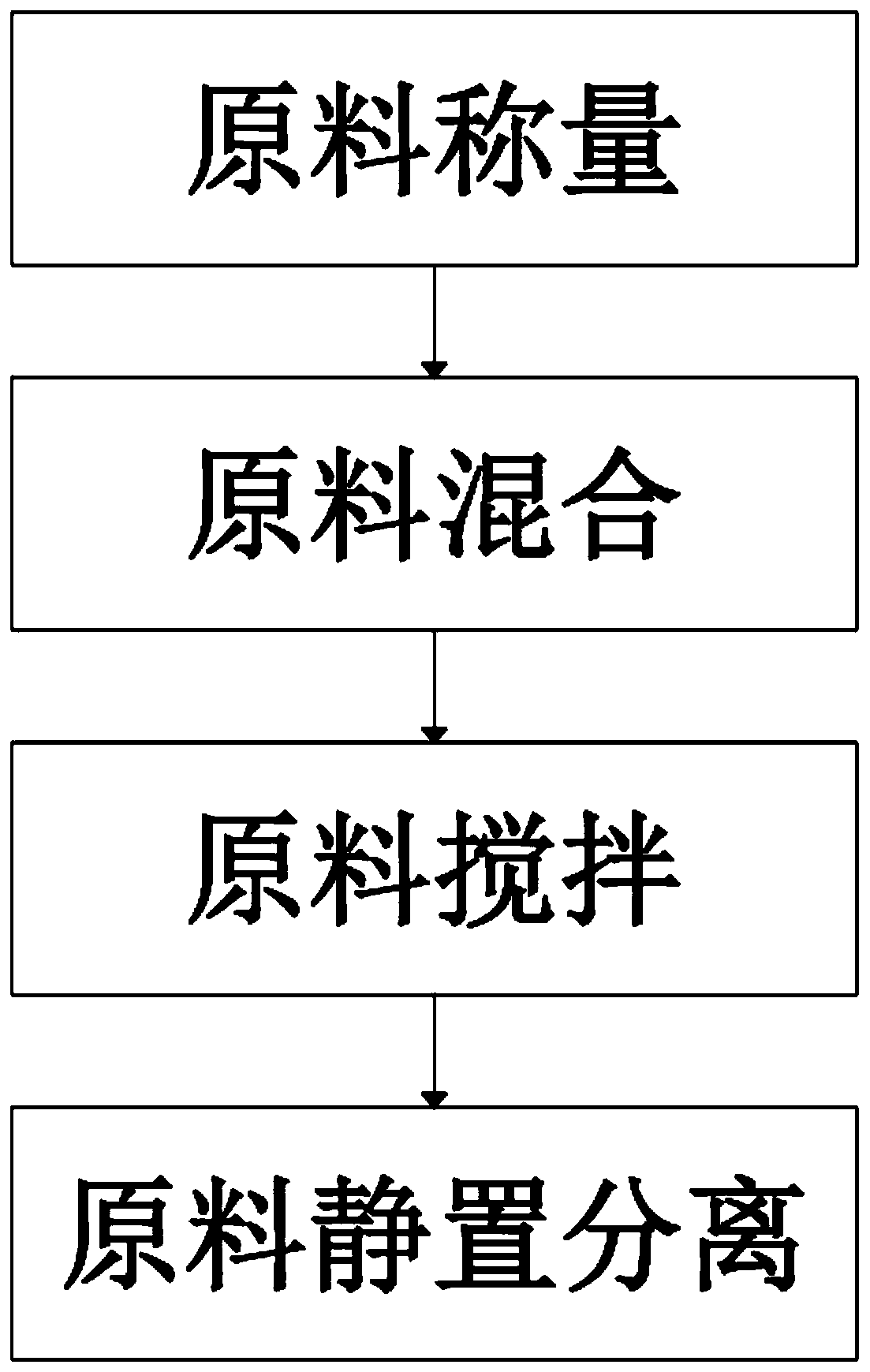

[0024] Weighing of raw materials: select 100 parts of silica fume, 50 parts of sodium methyl silanolate, 20 parts of triethoxysilane, 20 parts of organic silicon aqua, 100 parts of calcium carbonate, 10 parts of expansion agent, 10 parts of crosslinking agent, pozzolan 20 parts, 50 parts of ferric chloride, 10 parts of superplasticizer.

[0025] Mixing and stirring of raw materials: add silicon powder, sodium methyl siliconate, triethoxysilane, silicone water, calcium carbonate, 1 / 2 volcanic ash, cross-linking agent and ferric chloride to mix and stir, and perform on-site configuration. Then mix and stir 1 / 2 of the volcanic ash and expansion agent.

[0026] Standing separation of raw materials: After fully dissolving the mixed suspension, let it stand for 2 hours, and separate the solution, then add the silicon powder mixture to the concrete, and then add the expansion agent to add the waterproofing agent of the concrete to improve Sealing effect, and reduce the occurrence of...

Embodiment 2

[0028] Weighing of raw materials: select 150 parts of silica fume, 80 parts of sodium methyl silanolate, 40 parts of triethoxysilane, 30 parts of silicone aqua, 150 parts of calcium carbonate, 15 parts of expansion agent, 15 parts of crosslinking agent, pozzolan 30 parts, 80 parts of ferric chloride, 15 parts of superplasticizer.

[0029] Mixing and stirring of raw materials: add silicon powder, sodium methyl siliconate, triethoxysilane, silicone water, calcium carbonate, 1 / 2 volcanic ash, crosslinking agent and ferric chloride to mix and stir, and configure on site. Then mix and stir 1 / 2 of the volcanic ash and expansion agent.

[0030] Standing separation of raw materials: After fully dissolving the mixed suspension, let it stand for 2.5 hours, and separate the solution, then add the silicon powder mixture to the concrete first, and then add the expansion agent to add the waterproofing agent of the concrete. Improve the sealing effect and reduce the occurrence of expansion ...

Embodiment 3

[0032] Weighing of raw materials: select 200 parts of silica fume, 100 parts of sodium methyl silanolate, 50 parts of triethoxysilane, 40 parts of organic silicon aqua, 200 parts of calcium carbonate, 20 parts of expansion agent, 20 parts of crosslinking agent, volcanic ash 50 parts, 100 parts of ferric chloride, 20 parts of superplasticizer.

[0033] Mixing and stirring of raw materials: add silicon powder, sodium methyl siliconate, triethoxysilane, silicone water, calcium carbonate, 1 / 2 volcanic ash, crosslinking agent and ferric chloride to mix and stir, and configure on site. Then mix and stir 1 / 2 of the volcanic ash and expansion agent.

[0034] Standing separation of raw materials: After fully dissolving the mixed suspension, let it stand for 3 hours, and separate the solution, then add the silicon powder mixture to the concrete, and then add the expansion agent to add the waterproofing agent of the concrete to improve Sealing effect, and reduce the occurrence of expans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com