Method for co-production of light calcium carbonate and ammonium chloride in preparation of potassium chlorate by carbide slag

A light calcium carbonate and potassium chlorate technology, applied in the direction of calcium carbonate/strontium/barium, chloric acid, chlorate, etc., can solve the problems of land erosion, large land, easy leakage and polluted road surface, etc., and achieve low equipment investment, The effect of simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

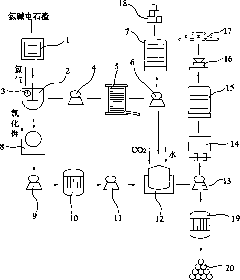

[0028] A method for producing potassium chlorate with calcium carbide slag to co-produce light calcium carbonate and ammonium chloride, comprising the steps:

[0029] A: Put the chlor-alkali carbide slag into the ash tank (1), mix it with water to form an emulsion, and make the content of calcium hydroxide reach 120 grams per liter;

[0030] B: Send the calcium carbide slag containing 200kg calcium hydroxide to the chlorination tower (2) with the first pressure pump, and at the same time, input chlorine gas in the chlorination tower (2), so that the mass ratio of calcium hydroxide to chlorine gas is 1 : 0.76 to carry out chlorination reaction, control the chlorination reaction temperature, keep the reaction solution not boiling, display the reaction end point with the chlorination meter (3), when the pointer of the chlorination meter (3) is fixed, it shows that the solution no longer absorbs chlorine , to achieve deep chlorination, that is, chlorination is completed, and a rea...

Embodiment 2

[0040] A method for producing potassium chlorate with calcium carbide slag to co-produce light calcium carbonate and ammonium chloride, comprising the steps:

[0041] A: Put the chlor-alkali carbide slag into the ash tank (1), mix it with water to form an emulsion, and make the content of calcium hydroxide reach 120 grams per liter;

[0042] B: Send the calcium carbide slag containing 300kg calcium hydroxide to the chlorination tower (2) with the first pressure pump, and at the same time, input chlorine gas in the chlorination tower (2), so that the mass ratio of calcium hydroxide to chlorine gas is 1 : 1.00 carry out chlorination reaction, control the chlorination reaction temperature, keep the reaction solution not boiling, show the reaction end point with the chlorination meter (3), when the pointer of the chlorination meter (3) is fixed, it shows that the solution no longer absorbs chlorine , to achieve deep chlorination, that is, chlorination is completed, and a reaction ...

Embodiment 3

[0052] A method for producing potassium chlorate with calcium carbide slag to co-produce light calcium carbonate and ammonium chloride, comprising the steps:

[0053] A: Put the chlor-alkali carbide slag into the ash tank (1), mix it with water to form an emulsion, and make the content of calcium hydroxide reach 120 grams per liter;

[0054] B: send the calcium carbide slag containing 200kg calcium hydroxide to the chlorination tower (2) with the first pressure pump, at the same time, input chlorine gas in the chlorination tower (2), make calcium hydroxide and chlorine gas pure substance mass ratio be 1:1.16 for chlorination reaction, control the chlorination reaction temperature, keep the reaction solution from boiling, use the chlorination meter (3) to display the reaction end point, when the needle of the chlorination meter (3) is fixed, it indicates that the solution is no longer absorbed Chlorine gas reaches deep chlorination, that is, chlorination is completed, and a rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com