Device and method for preparing calcium hypochlorite, calcium chlorate and calcium perchlorate

A technology of calcium hypochlorite and calcium perchlorate, which is applied in the field of calcium perchlorate preparation device, calcium hypochlorite and calcium chlorate, can solve the problem of high-salt waste liquid discharge environment, low effective chlorine content and stable product To solve problems such as poor performance, to achieve the effect of wide range of raw materials, increase chlorine content, and solve emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing.

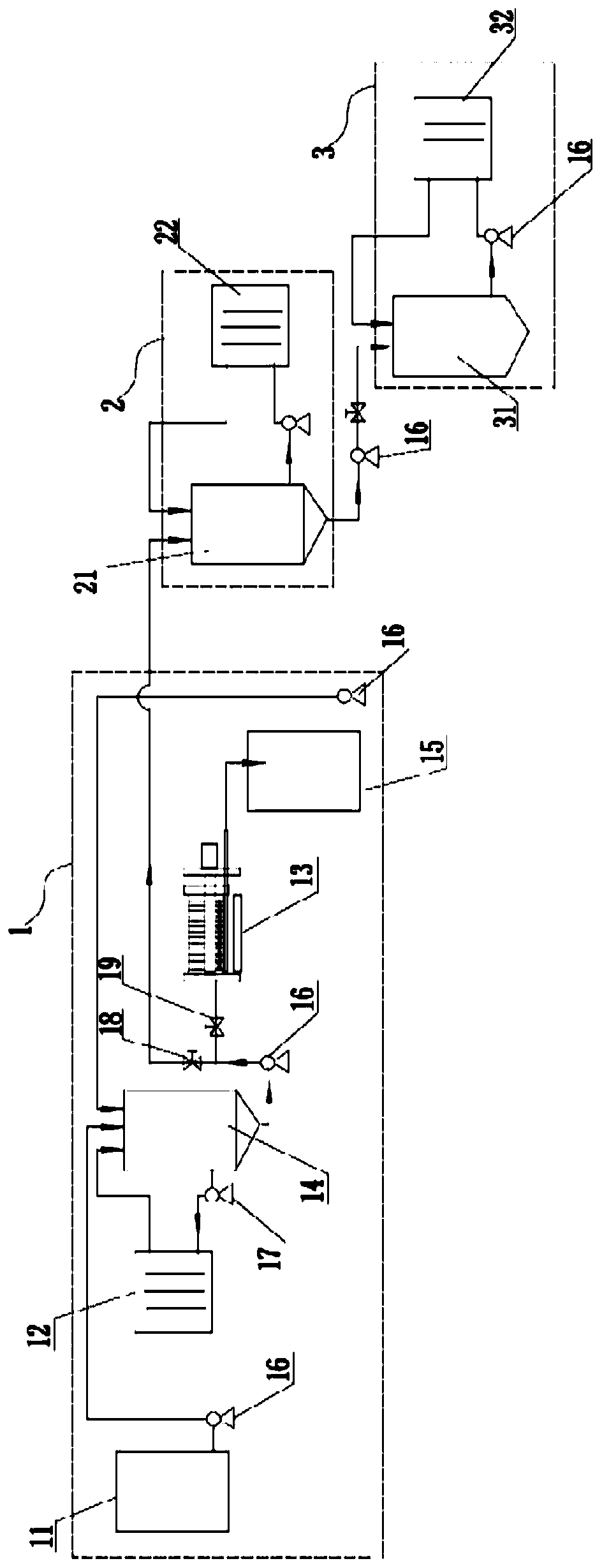

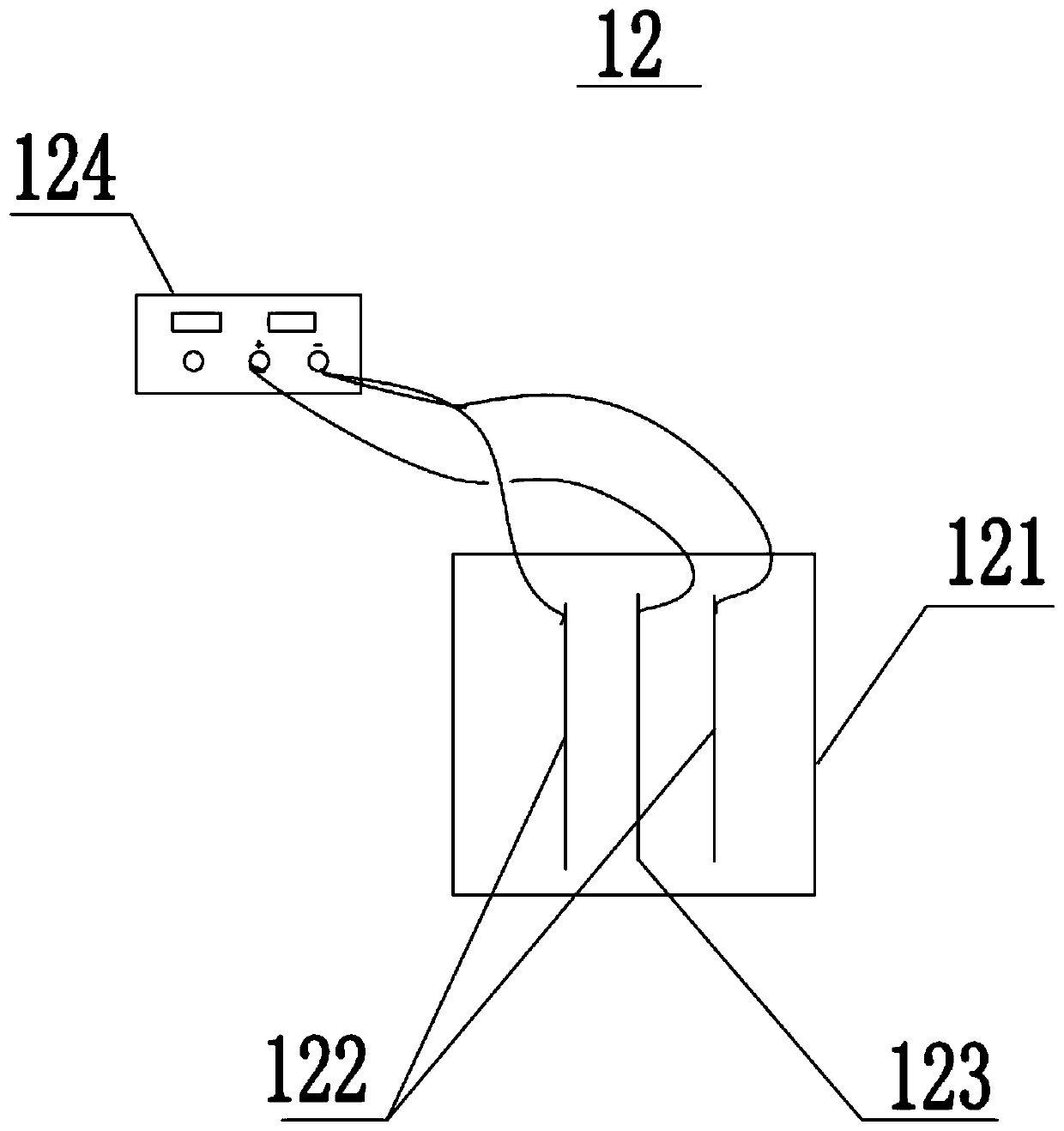

[0035] figure 1 It is the structural representation of a kind of calcium hypochlorite, calcium chlorate, calcium perchlorate preparation device in the embodiment of the present invention; As figure 1 As shown, the present invention provides a preparation device for calcium hypochlorite, calcium chlorate and calcium perchlorate, including a primary electro-oxidation unit 1 , a secondary electro-oxidation unit 2 and a tertiary electro-oxidation unit 3 . Among them, the primary electrooxidation unit 1 is used for electrooxidizing calcium chloride brine and producing calcium hypochlorite solution; the secondary electrooxidizing unit 2 is used for electrooxidizing calcium hypochlorite solution and producing calcium chlorate solution; the tertiary electrooxidizing Unit 3 is used to electrooxidize calcium chlorate solution and produce calcium perchlorate solution.

[0036] Where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com