Chlorinated butadiene rubber material, and preparation method and application thereof

A technology of chlorinated butadiene and rubber materials, which can be used in transportation and packaging, vehicle parts, tire parts, etc., and can solve the problems of low tear strength, poor wet skid resistance, and poor high temperature resistance. Achieve comprehensive performance improvement, easy control, good flex resistance and resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

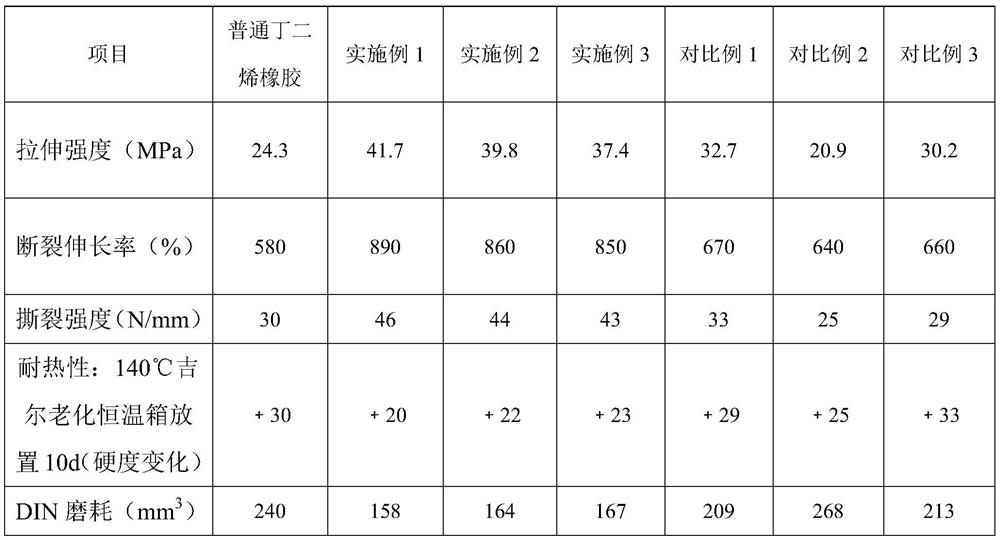

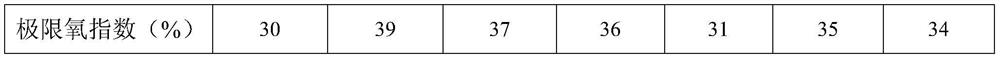

Examples

Embodiment 1

[0033] A preparation method of chlorinated butadiene rubber material, comprising the following specific steps (raw materials are in parts by weight):

[0034] S1. Add 100 parts of 1,3-butadiene, 200 parts of n-hexane and 0.8 parts of diethylene glycol dialkyl ether into the polymerization reactor, and under the protection of nitrogen, the temperature in the polymerization reactor is raised to 60 ℃, then add 1.5 parts of initiator A, control the pressure to 0.85MPa, and polymerize at this temperature for 1 hour to obtain a primary polymerization reaction mixture;

[0035] S2. Add the primary polymerization reaction mixture in S1 to another polymerization reactor, raise the temperature to 60°C under the protection of nitrogen, add 2 parts of initiator B, control the pressure to 0.85MPa, and perform secondary polymerization at this temperature Reaction 2h, obtain secondary polymerization reaction mixture;

[0036] S3. Add 2 parts of KH-570 to the secondary polymerization reactio...

Embodiment 2

[0040] A preparation method of chlorinated butadiene rubber material, comprising the following specific steps (raw materials are in parts by weight):

[0041]S1. 100 parts of 1,3-butadiene, 300 parts of cyclohexane and 1.2 parts of ethylene glycol dialkyl ether are added to the polymerization reactor, and under the protection of nitrogen, the temperature in the polymerization reactor is raised to 70°C, then add 1 part of initiator A, control the pressure to 0.7MPa, and polymerize at this temperature for 1.5h to obtain a primary polymerization reaction mixture;

[0042] S2. Add the primary polymerization reaction mixture in S1 to another polymerization reactor, raise the temperature to 70°C under the protection of nitrogen, add 1.5 parts of initiator B, control the pressure to 0.7MPa, and perform secondary polymerization at this temperature React for 2.5h to obtain the secondary polymerization reaction mixture;

[0043] S3. Add 3 parts of tetrachlorosilane to the secondary pol...

Embodiment 3

[0047] A preparation method of chlorinated butadiene rubber material, comprising the following specific steps (raw materials are in parts by weight):

[0048] S1. Add 100 parts of 1,3-butadiene, 400 parts of benzene and 2 parts of ethylene glycol dialkyl ether into the polymerization reactor, and raise the temperature inside the polymerization reactor to 80°C under the protection of nitrogen , then add 0.5 parts of initiator A, control the pressure to 0.65MPa, and polymerize at this temperature for 2 hours to obtain a primary polymerization mixture;

[0049] S2. Add the primary polymerization mixture in S1 to another polymerization reactor, raise the temperature to 80°C under the protection of nitrogen, add 1 part of initiator B, control the pressure to 0.65MPa, and perform secondary polymerization at this temperature React for 3h to obtain the secondary polymerization reaction mixture;

[0050] S3. Add 5 parts of KH-550 to the secondary polymerization reaction mixture of S2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com