A modified tri-block copolymer electrolyte membrane and its preparation method

An electrolyte membrane and tri-block technology, applied in the field of electrolytes, can solve problems such as difficult separation and treatment, easy flocculation and instability of aluminum trichloride, and achieve high ion exchange capacity, safe and environmentally friendly preparation process, and optimized use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides a preparation method for the above-mentioned modified triblock copolymer electrolyte membrane, comprising the following steps:

[0033] Add the modified tri-block copolymer SEBS, excess trimethylamine and dimethylformamide into the reactor with a solid content of 5~20wt%, stir and react at 40°C for 24 hours, and then apply the reaction solution on a clean horizontal glass On the board, a film is naturally formed, placed in an environment of 60°C, the solvent is volatilized, and the film is peeled off to obtain a modified triblock copolymer electrolyte membrane.

[0034] In the present invention, the modified tri-block copolymer SEBS has the structure shown in formula II:

[0035] Formula II ,

[0036] In the formula, m, n, p are independently integers from 50 to 3000, 0

[0037] The present invention also provides a preparation method for the above-mentioned modified three-block copolymer SEBS, comprising the following...

Embodiment 1~7

[0045] Embodiment 1~7: the preparation of modified triblock copolymer SEBS

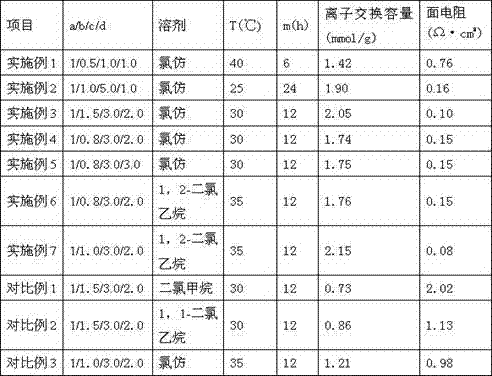

[0046] Add SEBS (containing a mmol of phenyl, commercially available, product brand Kraton G1652M), b mmol of 2-chloroacetic acid, cmL of solvent and d mmol of trifluoroacetic anhydride into a round bottom flask equipped with a condenser tube and a drying tube , stirring at temperature T for reaction time m, then slowly drop the reaction solution into ethanol, filter, soak the precipitate with 30 v% ethanol and wash until the pH is close to neutral, and dry to obtain the modified triblock copolymer SEBS, saved for later use;

[0047] Wherein, the amount of each component, solvent content and type, reaction temperature and time were tested according to the data in Table 1, thereby preparing chloroacetyl-modified SEBS with different chloroacetyl content.

[0048] Then, prepare the modified triblock copolymer electrolyte membrane, the preparation method is as follows:

[0049] Weigh respectively 1.0 g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com