Special mixing rubber for insulating low-temperature-resistant wire core, and preparation method thereof

A technology of mixing rubber and low temperature resistance, applied in the field of rubber, can solve the problems of poor physical and mechanical properties, easy damage to cables, affecting the development of cables, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

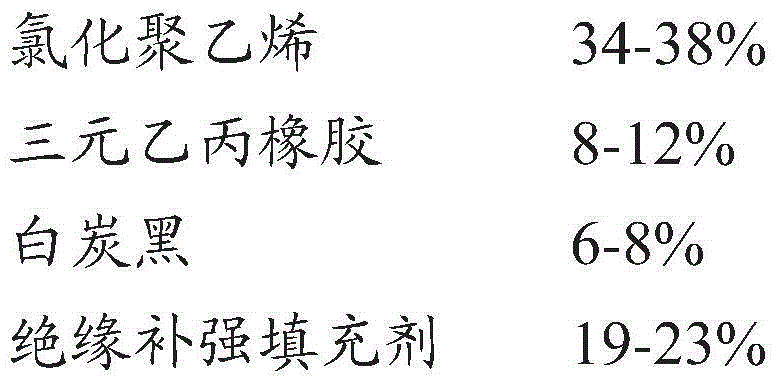

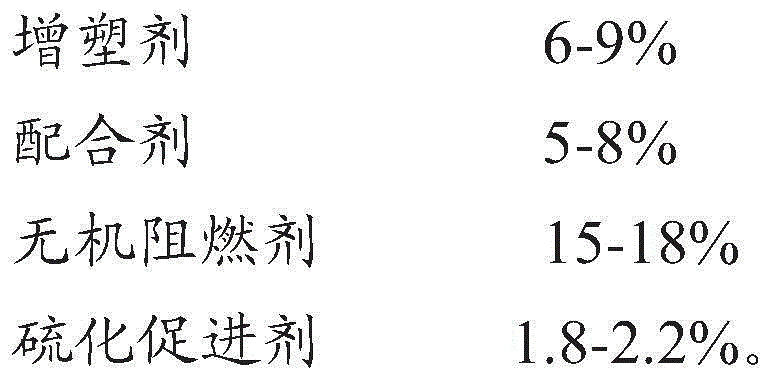

Method used

Image

Examples

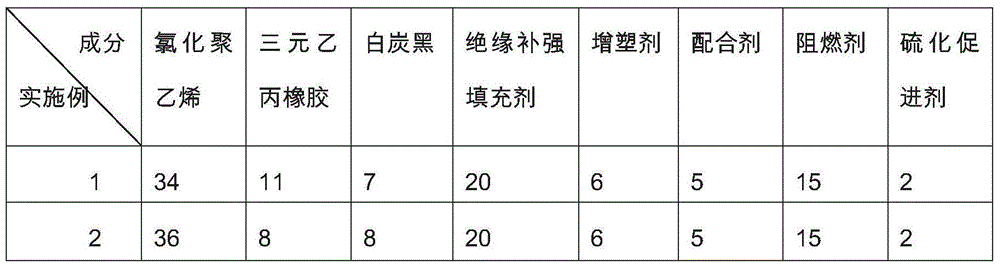

Embodiment 1-2

[0029] According to the following steps, the special compound rubber for insulating low temperature resistant wire cores involved in the present invention is manufactured

[0030] Prepare glue, according to the content ratio in Table 1, in the order of (chlorinated polyethylene → flame retardant, white carbon black, insulating reinforcing filler, compounding agent → plasticizer → EPDM rubber) The raw materials are accurately weighed and set aside for later use.

[0031] The first mixing: pre-mix compounding agent, flame retardant, white carbon black, reinforcing filler and chlorinated polyethylene, first add half of the pre-mixed materials, then add plasticizer, and then add the rest The pre-mixed materials, finally put the EPDM rubber into the internal mixer, mix for 60-90 seconds, then clean, mix for 60-90 seconds, clean again, mix again for 90-120 seconds, then discharge the material , made into mixed A rubber for use. ,

[0032] The second mixing: put the rubber A and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com