Method for preparing oxygen-enriched super-crosslinked resin based on Friedel-Crafts alkylation reaction and application of oxygen-enriched super-crosslinked resin

An alkylation reaction and super-crosslinking technology, which is applied in the application field of oxygen-rich super-crosslinked resins, can solve the problems of small adsorption capacity, long time for adsorption equilibrium, poor adsorption selectivity, etc., and achieve increased adsorption capacity and specific surface area The effect of increasing and increasing the oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1) Preparation of oxygen-enriched precursor resin:

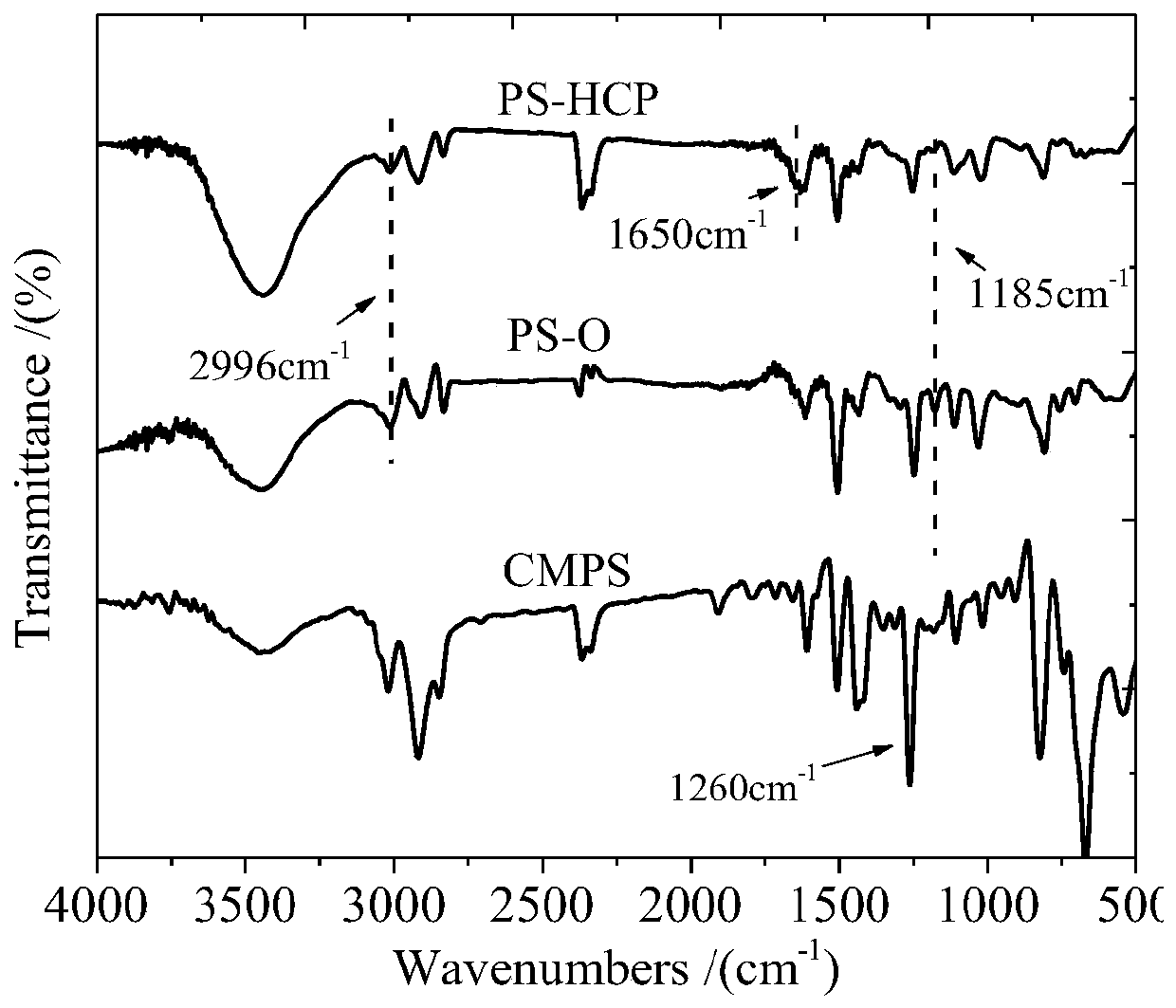

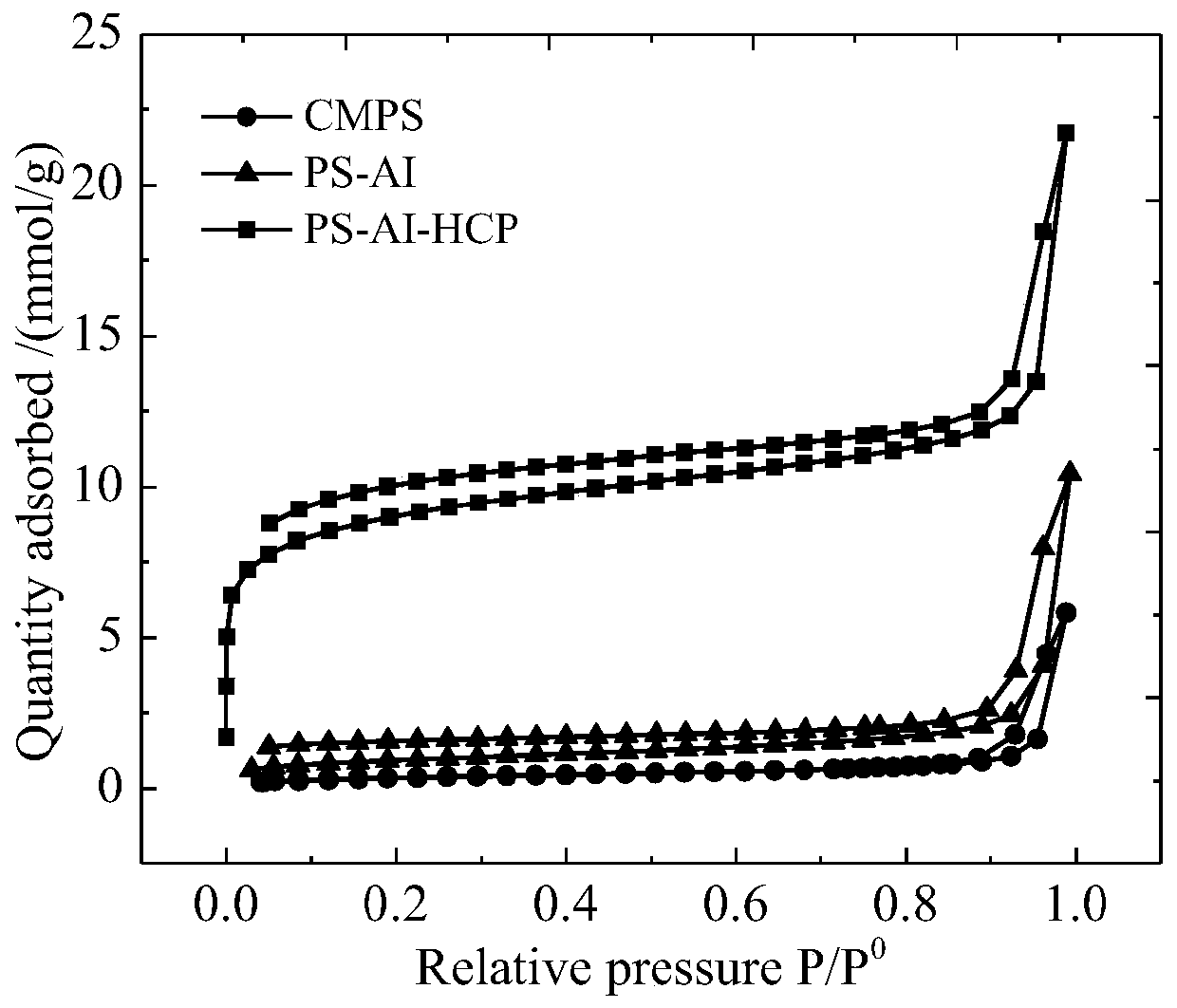

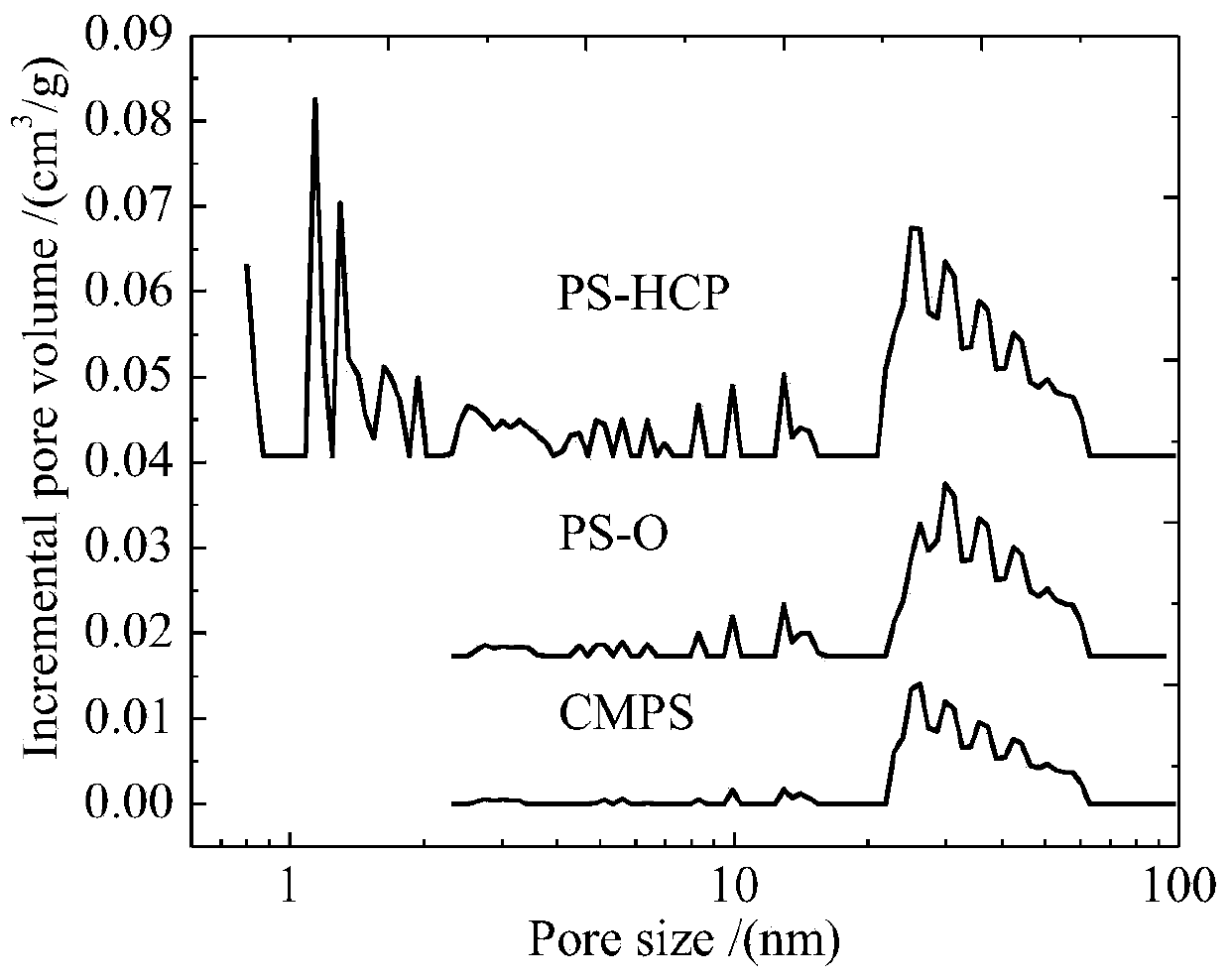

[0041] Place a 500mL three-necked round-bottomed flask on a water bath equipped with a mechanical stirrer, a condenser and a thermometer, add 20g of chloromethylated cross-linked polystyrene, add 120ml of 1,2-dichloroethane, swell overnight, add 10.5g of anisole and 8g of ferric chloride, stirred for 30min until completely dissolved, then heated up to 40°C for Friedel-Crafts reaction for 8-12h, then terminated the reaction with 50% ethanol aqueous solution, poured out the reaction mother liquor, and used a mass fraction of 1% hydrochloric acid aqueous solution and absolute ethanol were washed alternately for 3 to 5 times, and extracted with absolute ethanol for 8 to 24 hours to obtain the oxygen-rich precursor resin PS-O; The molar amount of chlorine in styrene is the same. Infrared characterization as figure 1 As shown, the oxygen-rich precursor tree resin PS-O is at 1260cm -1 The C-Cl stretching vibration of benz...

Embodiment 2

[0048] 1) Preparation of oxygen-enriched precursor resin

[0049] Place a 500mL three-necked round-bottomed flask on a water bath equipped with a mechanical stirrer, a condenser and a thermometer, add 20g of chloromethylated cross-linked polystyrene, add 120ml of 1,2-dichloroethane, swell overnight, add 13.46g of p-phenylene dimethyl ether and 8g of ferric trichloride, stirred for 30min until completely dissolved, then heated up to 40°C for Friedel-Crafts reaction for 8-12h, then terminated the reaction with 50% ethanol aqueous solution, poured out the reaction mother liquor, and used mass Washing alternately with 1% hydrochloric acid aqueous solution and absolute ethanol for 3 to 5 times, and extracting with absolute ethanol for 8 to 24 hours to obtain the oxygen-enriched precursor resin PS-O. The molar amount of p-xylylene ether is the same as the molar amount of chlorine in the chloromethylated cross-linked polystyrene. Infrared characterization shows that the precursor tr...

Embodiment 3

[0056] 1) Preparation of oxygen-enriched precursor resin:

[0057] Place a 500mL three-necked round-bottomed flask on a water bath equipped with a mechanical stirrer, a condenser and a thermometer, add 20g of chloromethylated cross-linked polystyrene, add 120ml of 1,2-dichloroethane, swell overnight, add 23.61g of biphenyl dimethyl ether and 8g of ferric trichloride, stirred for 30min until completely dissolved, heated to 40°C for Friedel-Crafts reaction for 8-12h, then terminated the reaction with 50% ethanol aqueous solution, poured out the reaction mother liquor, and used mass The fraction is 1% hydrochloric acid aqueous solution and absolute ethanol, wash alternately 3 to 5 times, and extract with absolute ethanol for 8 to 24 hours to obtain the oxygen-rich precursor resin PS-O; the molar dosage of biphenyl dimethyl ether and chloromethyl The molar amount of chlorine in chemically cross-linked polystyrene is the same. Infrared characterization shows that the oxygen-rich p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com