A method for separating and purifying desulfurized gypsum and a device for realizing the method

A technology of desulfurization gypsum and desulfurization slurry, applied in the direction of solid separation, chemical instruments and methods, calcium/strontium/barium sulfate, etc., can solve the problems of poor dehydration effect of desulfurization gypsum, low grade of desulfurization gypsum, and improve resource utilization , Improve the grade and improve the effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for separating and purifying desulfurized gypsum, comprising the step of removing black impurities by adding an alcohol foaming agent and a hydrophobic collector to the desulfurized gypsum slurry in a stirring state.

[0038] The added amount of the alcohol foaming agent is preferably 0.02%-0.05% of the mass of the desulfurized gypsum slurry. More preferably, it is 0.03%.

[0039] The added amount of the hydrophobic collector is preferably 0.1%-0.5% of the mass of the desulfurized gypsum slurry. Preferably it is 0.1%-0.3%. More preferably 0.2%.

[0040] The alcohol foaming agent is preferably an alcohol with 6-10 carbon atoms. Alcohols with 8 carbon atoms are more preferably used, for example, sec-octanol.

[0041] The hydrophobic collector is preferably light diesel oil.

[0042] The adding method of the alcohol foaming agent and the hydrophobic trapping agent is not limited, as long as they can be added and well dispersed.

[0043] In order to better re...

Embodiment 2

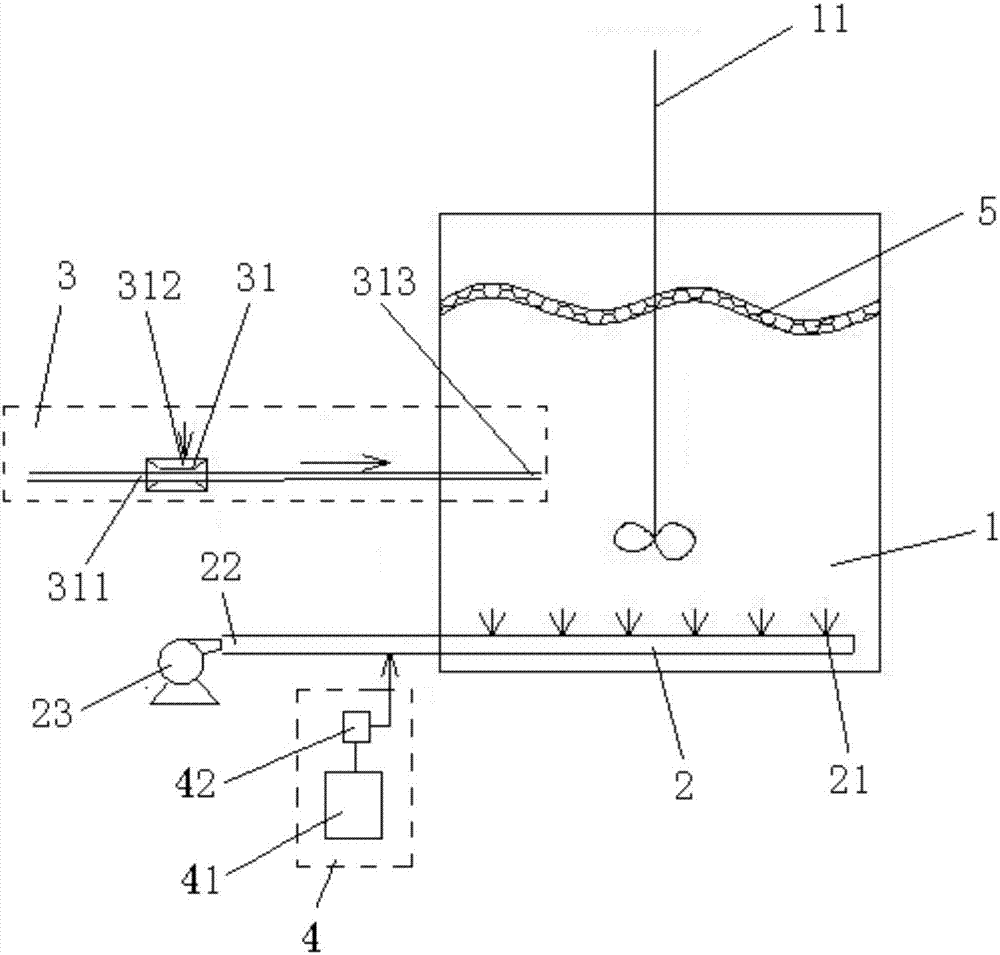

[0048] This embodiment 2 is a specific device for realizing the method for separating and purifying desulfurized gypsum in the above embodiment 1, such as image 3 As shown, it includes a desulfurization slurry pool 1 and an oxidation air delivery pipeline 2, and the air outlet 21 of the oxidation air delivery pipeline 2 (multiple openings are provided to ensure that the oxidation air in the input slurry is evenly dispersed) communicates with the desulfurization slurry pool 1; Wherein, it also includes a collector injection unit 3 and a foaming agent injection unit 4, the liquid outlet of the collector injection unit 3 communicates with the desulfurization slurry pool 1; the liquid outlet of the foaming agent injection unit 4 The port communicates with the oxidizing air delivery pipe.

[0049] Wherein, the desulfurization slurry tank 1 is also equipped with a stirrer 11 for stirring the desulfurization gypsum slurry therein. The desulfurization slurry pool 1 is also connected...

Embodiment 3

[0056] In Example 3, white mud produced in the production process of a paper mill in Shandong Province was used as calcium-based solid waste to desulfurize the flue gas of a coal-fired experimental boiler, and white mud desulfurized gypsum was used as the experimental object. The specific experimental process is as follows:

[0057] The white mud desulfurization gypsum separation device test was carried out on the flue gas desulfurization device of the 2t / h coal-fired experimental boiler. The white mud comes from a paper mill in Shandong Province. The size of the boiler desulfurization slurry pool is 1500mm×1000mm×1200mm. The rotation speed is 30rpm, and the density of desulfurization slurry is 1012kg / m 3 . like Figure 4 shown.

[0058] Second-octanol is used as a foaming agent, and the amount of secondary-octanol is 0.03% of the amount of slurry, injected into the oxidation air delivery pipeline 2 through the foaming agent injection unit 4, and dispersed into the desulfur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com