Ethylene oligomerization catalyst and preparation method

An ethylene oligomerization and catalyst technology, applied in the field of ethylene oligomerization catalyst and preparation, can solve the problems of excessive C activity, decrease, and low carbon olefins, etc., and achieve the effects of high oligomerization reaction activity, high yield and low content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

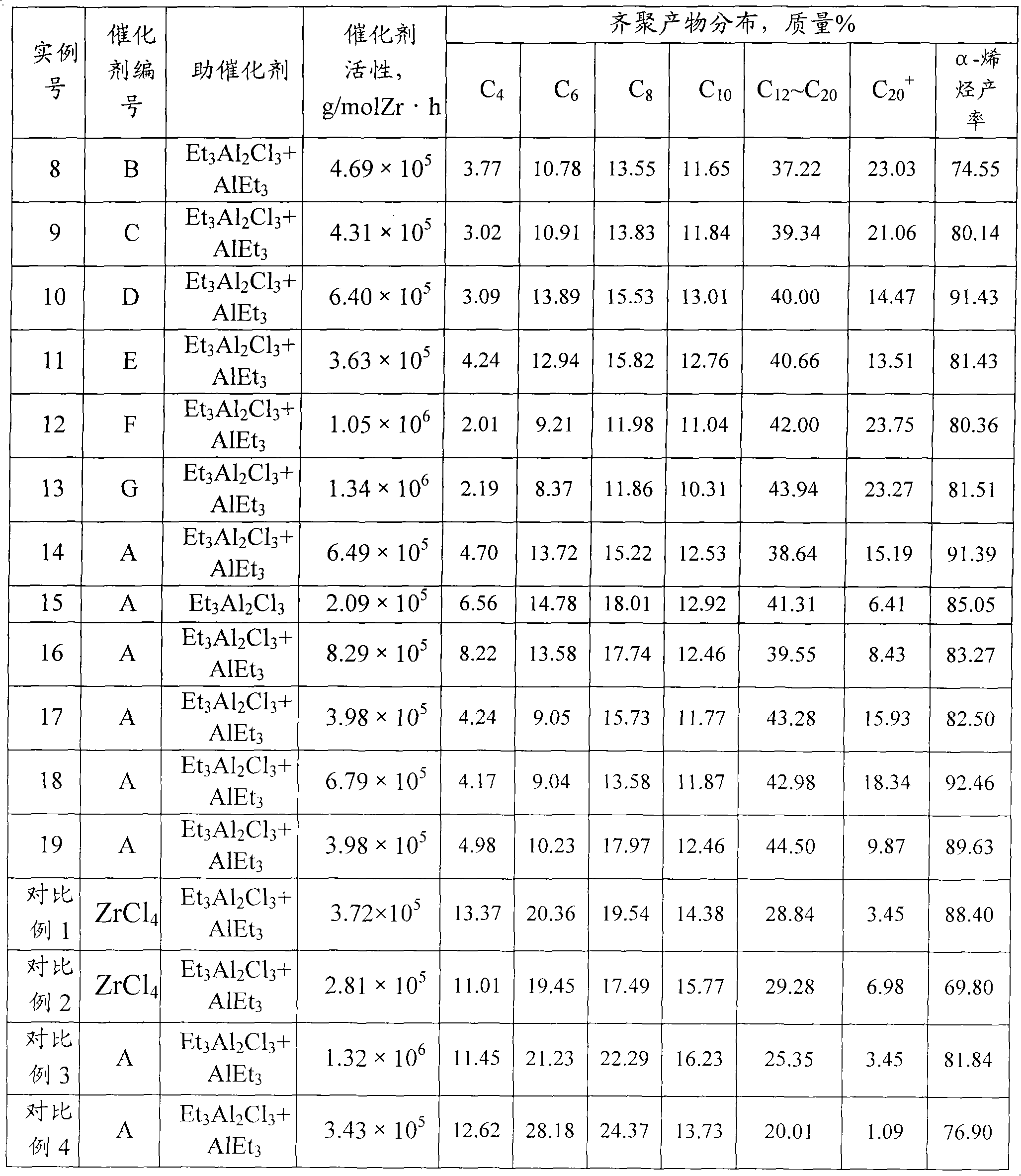

Examples

preparation example Construction

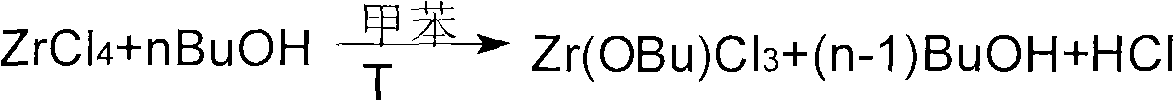

[0027] The preparation method of the catalyst provided by the present invention comprises the steps of stirring evenly in zirconium tetrachloride suspension aromatic hydrocarbon, adding butanol to fully react, cooling down to -5-5°C and adding SiCl x R 4-x Fully reacted silicon-containing compounds, SiCl x R 4-x In, R is C 1 ~C 4 Alkyl or C 6 ~C 8 The aryl group, x is an integer of 1-4.

[0028] The butanol described in the above method is preferably n-butanol.

[0029] The molar ratio of butanol and zirconium tetrachloride added in catalyst preparation is 3-9:1, preferably 3-6:1, and the reaction temperature of zirconium tetrachloride and butanol is 60-120°C, preferably 70-100°C .

[0030] After the reaction of zirconium tetrachloride and alcohol, SiCl added during silicon modification x R 4-x The molar ratio with zirconium tetrachloride is 0.1~18:1, preferably 6~12:1, SiCl x R 4-x The reaction temperature with butanol is -5 to 5°C, preferably 0 to 5°C.

[0031] ...

example 1

[0038] Preparation of the oligomerization catalysts described in the present invention.

[0039] Suspend 10mmol of zirconium tetrachloride in 26g of toluene, stir at 70°C for 1 hour, add 30mmol of n-butanol, reflux at 85°C for 4 hours, cool down to 0°C, add 80mmol of silicon tetrachloride for 4.0 hours, add 7.0 g of toluene to obtain the oligomerization catalyst solution A that the zirconium concentration is 0.2 mol / liter, by quantitatively analyzing the HCl generated, the mol ratio of each component is recorded as follows:

[0040] Zr(On-Bu)Cl 3 : 2.0 SiCl 3 (On-Bu): 6.0SiCl 4

example 2

[0042] Preparation of the oligomerization catalysts described in the present invention.

[0043] Suspend 2.33g (10mmol) of zirconium tetrachloride in 34.6g of toluene, stir at 70°C for 1 hour, add 40mmol of n-butanol, reflux at 100°C for 4 hours, cool to 0°C, add 0.8mmol of tetrachloride Silicon was reacted for 3.0 hours, and 5.45 g of toluene was added to obtain an oligomerization catalyst solution B with a zirconium concentration of 0.2 mol / liter. By quantitatively analyzing the generated HCl, the molar ratio of each component was recorded as follows:

[0044] Zr(On-Bu)Cl 3 : 0.8SiCl 3 (On-Bu): 2.2 (n-BuOH)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com