Long-acting wire rope hemp core grease

A technology of steel wire rope and hemp core grease is applied in the field of lubricating and protective materials, which can solve the problems of low kinematic viscosity, easy flow, easy leakage and flow, etc., and achieves the effect of strong affinity, improved rust resistance and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A kind of long-acting steel cord hemp core grease, its composition is as follows by weight percentage: palm wax 13%, microcrystalline wax 19%, naphthenic high-viscosity oil 15%, paraffin-based high-viscosity oil 28%, dialkyl two Zinc thiophosphate 1.6%, nonyl diphenylamine 1.4%, ethylene acetic acid 8.5%, polyisobutylene 12.5%, calcium sulfonate 1%.

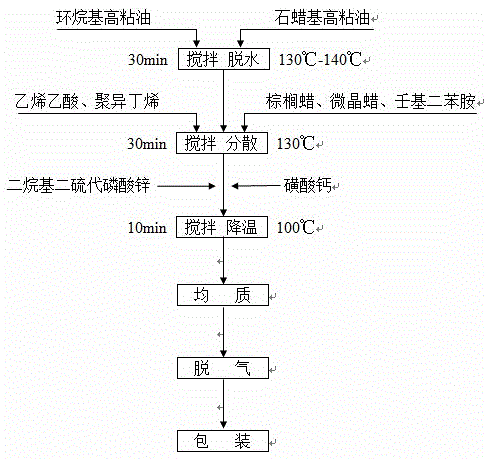

[0050] refer to figure 1 , a preparation process for long-acting steel wire rope hemp core resin, comprising the following production steps:

[0051]S1. Put naphthenic-based high-viscosity oil and paraffin-based high-viscosity oil into a reaction tank, raise the temperature to 130-140° C., stir for 30 minutes, and dehydrate to obtain the first preform.

[0052] S2. Add palm wax, microcrystalline wax, nonyl diphenylamine, ethylene acetic acid, and polyisobutylene to the first preform obtained in S1, continue stirring for 30 minutes, and fully disperse at 130° C. to obtain the second preform.

[0053] S3. Add zinc dialkyl ...

Embodiment 2

[0056] A kind of long-acting steel cord hemp core grease, its composition is as follows by weight percentage: Palm wax 17%, microcrystalline wax 16%, naphthenic high-viscosity oil 19%, paraffin-based high-viscosity oil 24%, dialkyl two Zinc thiophosphate 4.6%, nonyl diphenylamine 4.4%, ethylene acetic acid 6.4%, polyisobutylene 8.5%, calcium sulfonate 0.1%. The preparation process is the same as in Example 1.

Embodiment 3

[0058] A kind of long-lasting steel cord hemp core grease, its composition is as follows by weight percentage: palm wax 16%, microcrystalline wax 18%, naphthenic high-viscosity oil 18%, paraffin-based high-viscosity oil 27%, dialkyl two Zinc thiophosphate 3%, nonyl diphenylamine 2.9%, ethylene acetic acid 4.5%, polyisobutylene 10%, calcium sulfonate 0.6%. The preparation process is the same as in Example 1.

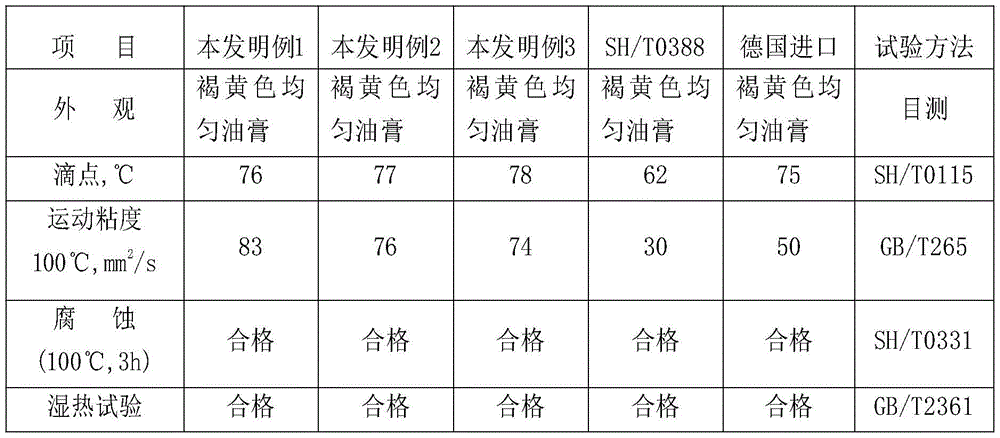

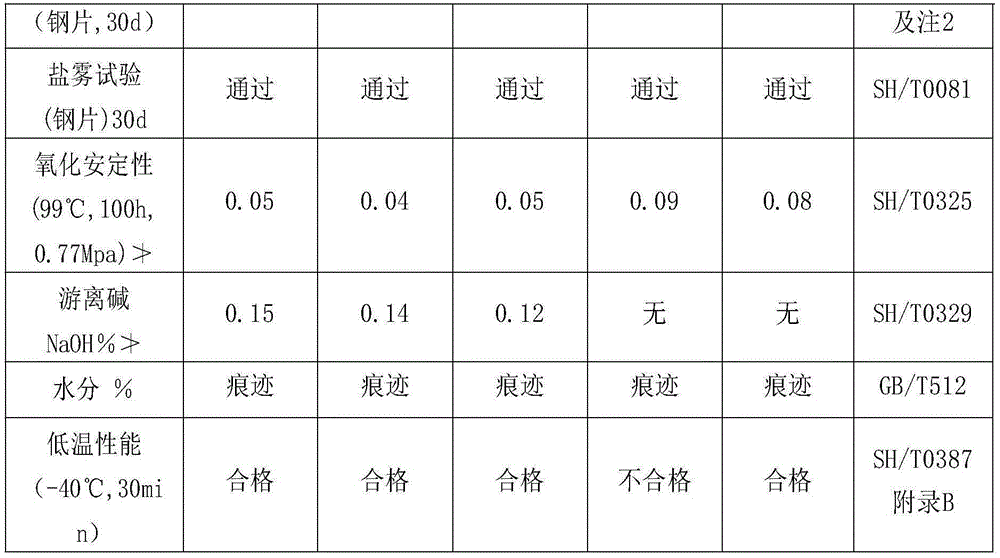

[0059] The following are the comparative tests between the above-mentioned three examples and the existing products, and the data source is the testing center of the technical supervision department.

[0060] Performance comparison of this product with similar products at home and abroad

[0061]

[0062]

[0063] Comparing the three examples of the invention with the SH / T0388 product and imported products: From the data point of view, Inventions 1, 2, and 3 have basically the same dropping point because the mass percentages of the two waxes are basically the same....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oxidation stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com