Patents

Literature

39 results about "Vinylacetic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

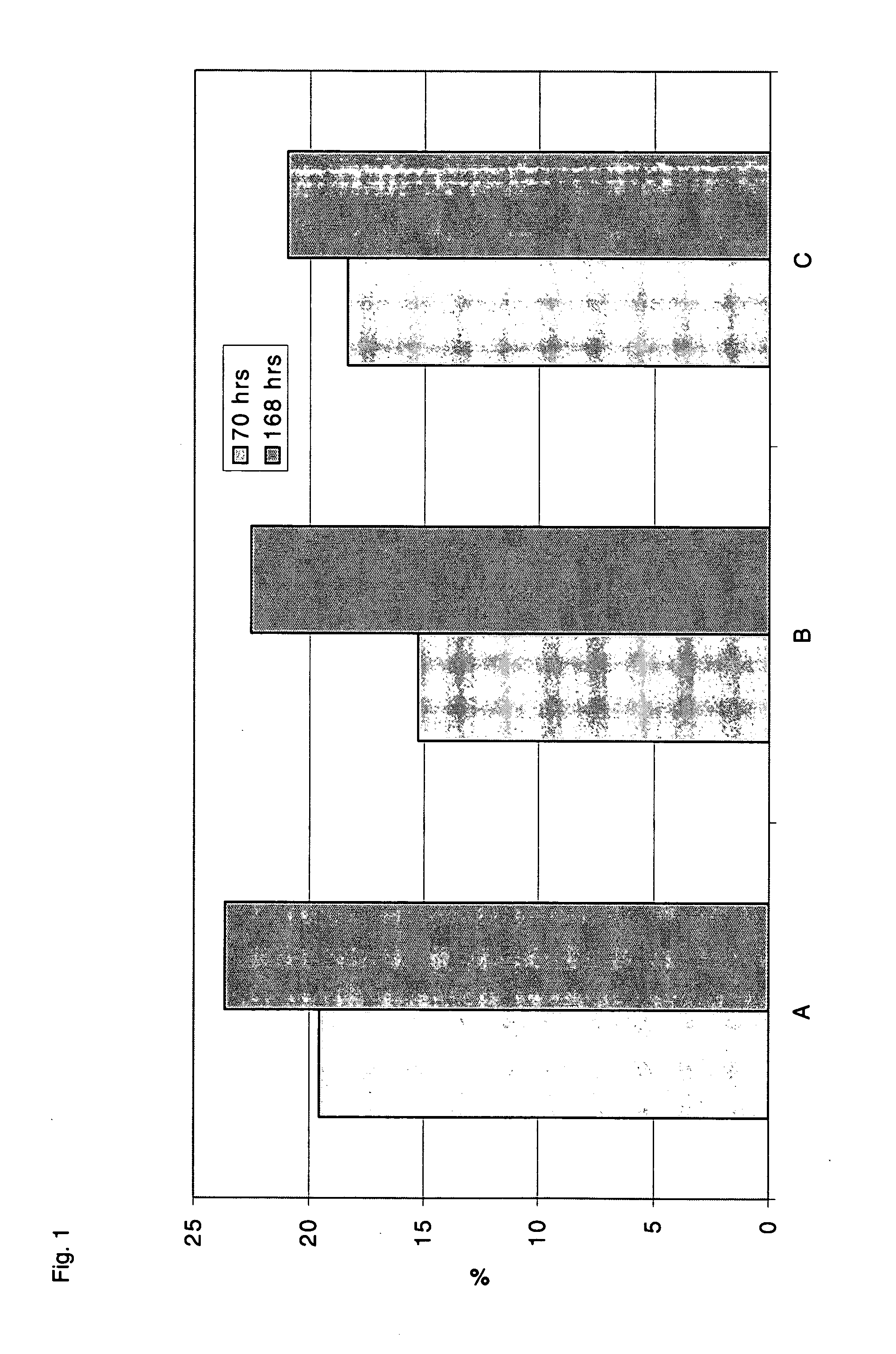

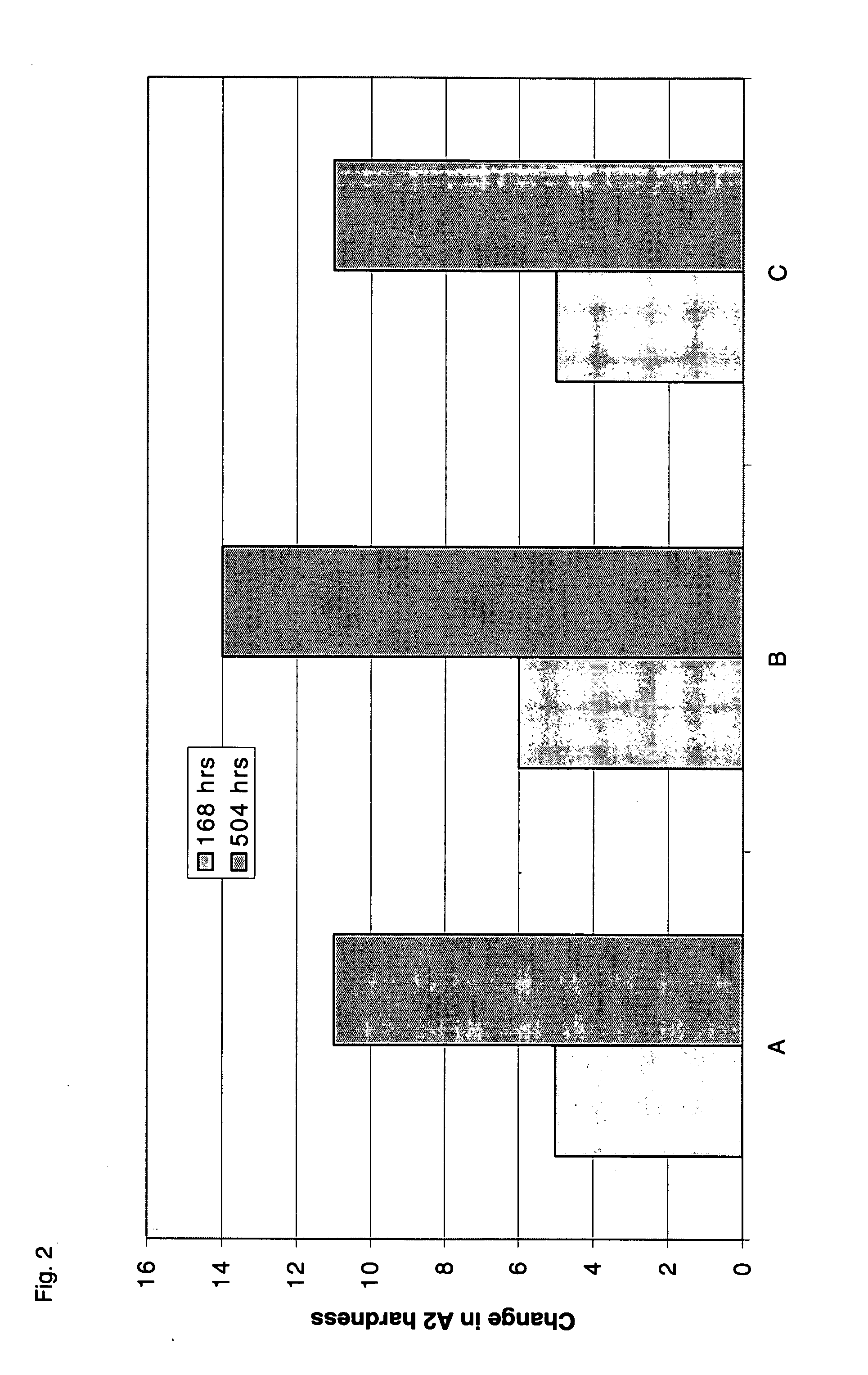

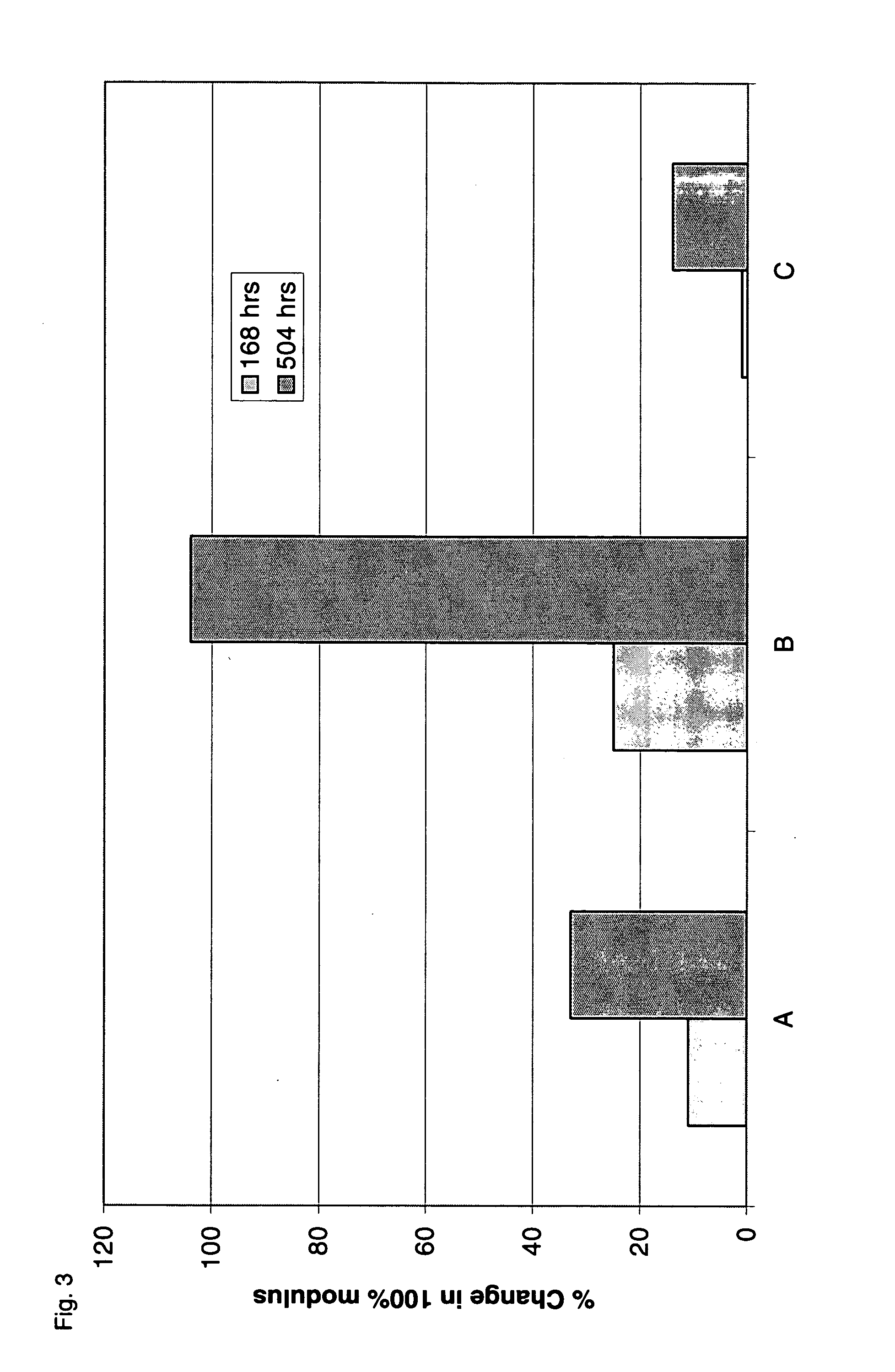

Polymer blends comprising nitrile rubber

The present invention relates to a polymer blend containing of at least two different hydrogenated nitrile rubbers and at least one olefin-vinylacetate or olefin-acrylate rubber, a rubber compound containing said polymer blend and at least one filler, a curable rubber compound containing said rubber compound and at least one vulcanization agent and a shaped article containing said rubber compound.

Owner:BAYER CA

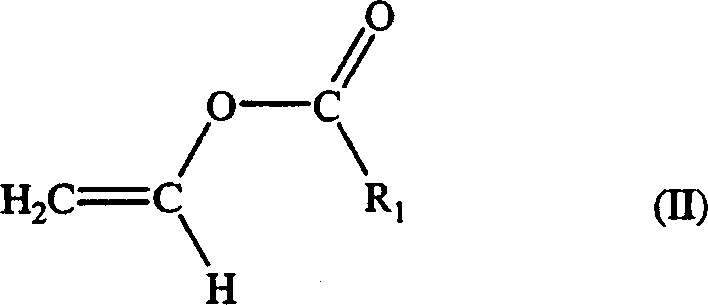

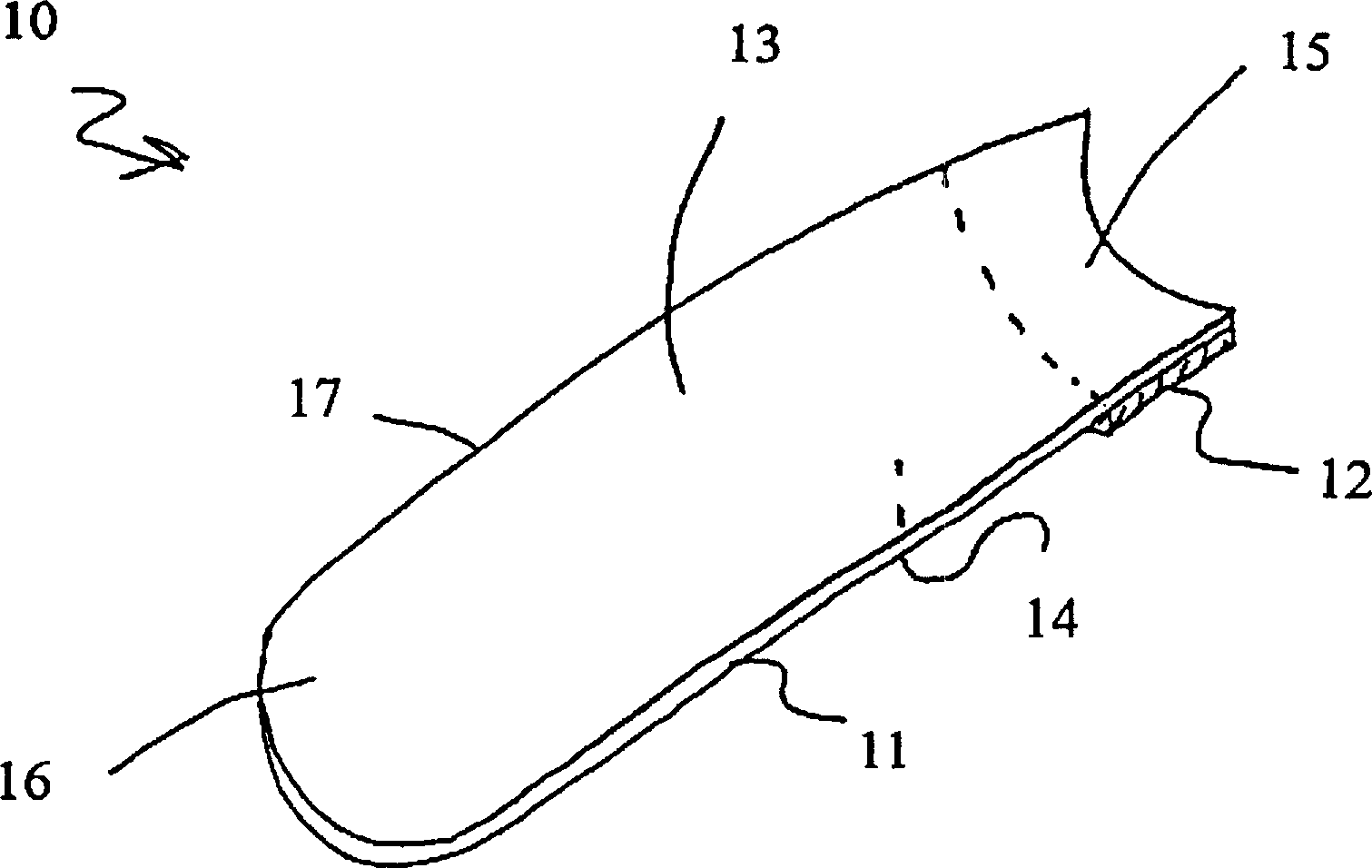

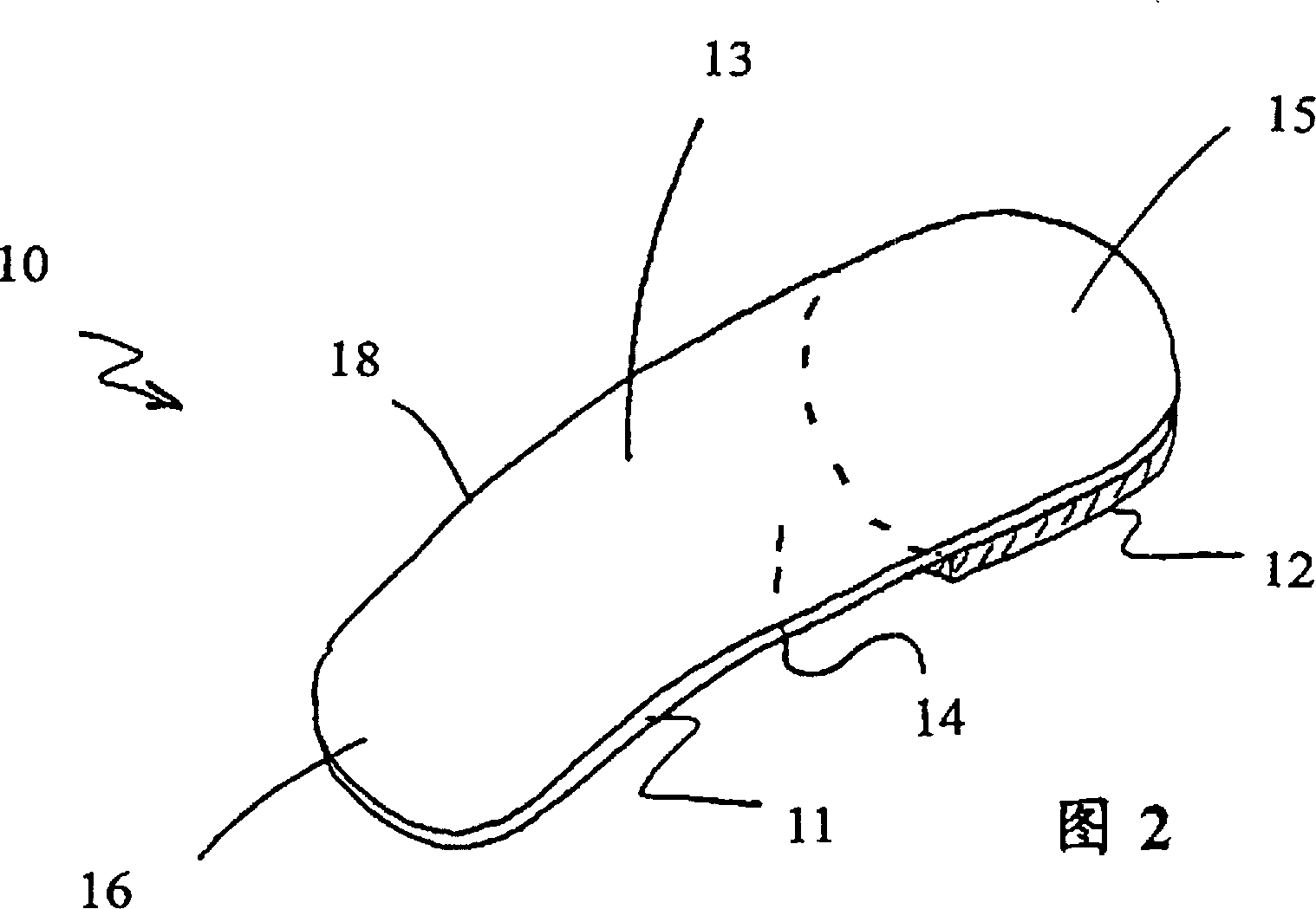

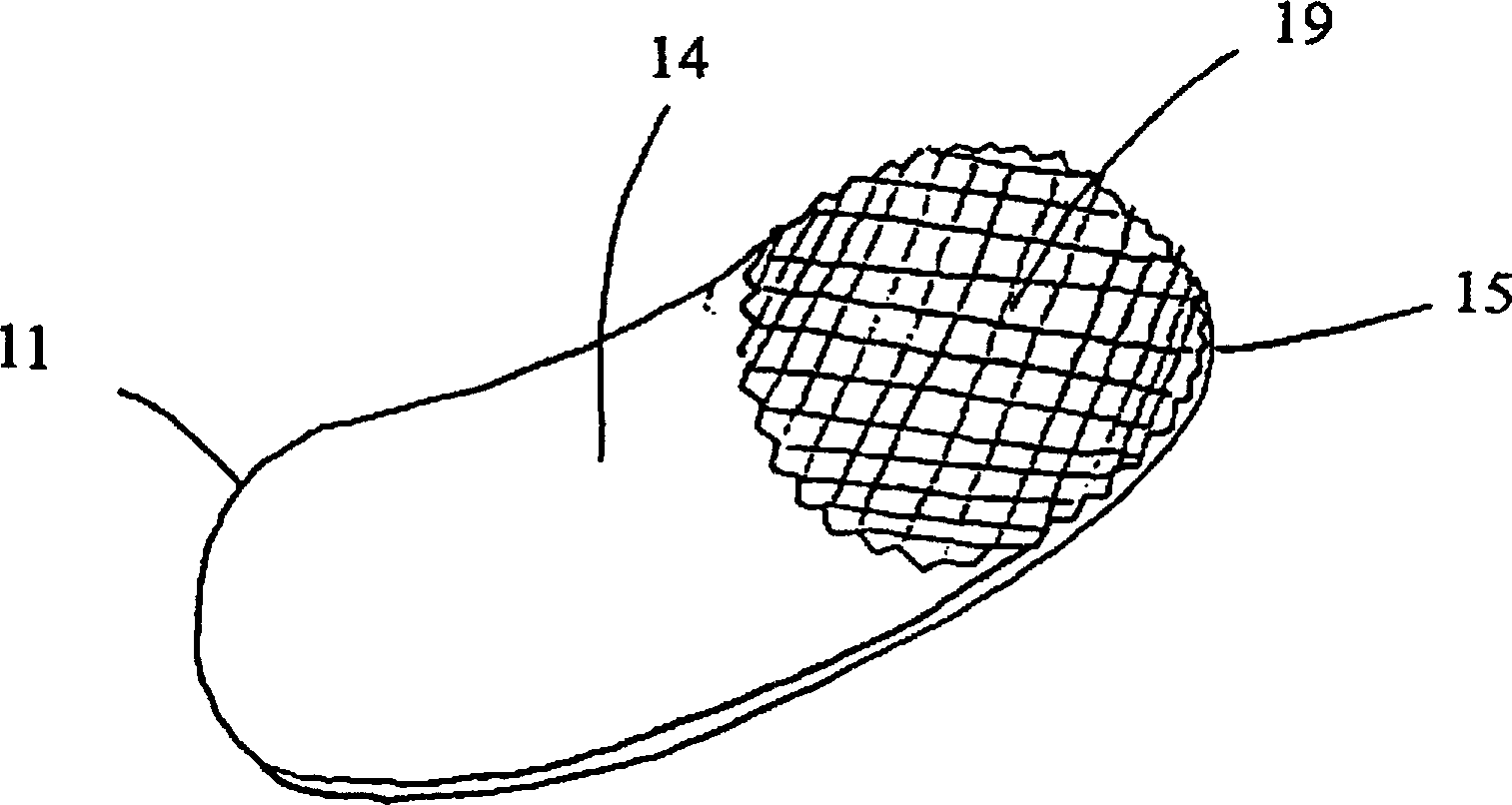

Aderent, flexible hydrogel and medicated coatings

InactiveCN1261288AImprove toleranceGood flexibilitySurgeryPharmaceutical containersEpoxyActive agent

The adherent coating of the invention comprises a stabilizing polymer together with an active agent (a hydrophilic polymer and / or a bioactive agent) in a layer bonded to the surface of a medical device. This invention encompasses the coating liquids used for coating medical devices, methods of coating the devices, and the coated devices. The stabilizing polymer is selected to entrap the active agent in a coating that has a high degree of flexibility and has improved bonding to a wide variety of substrates. Preferred stabilizing polymers are cross-linkable acrylic and methacrylic polymers, ethylene acrylic acid copolymers, styrene acrylic copolymers, vinyl acetate polymers and copolymers, vinyl acetal polymers and copolymers, epoxy, melamine, other amino resins, phenolic polymers, copolymers thereof, and combinations.

Owner:STS BIOPOLYMERS

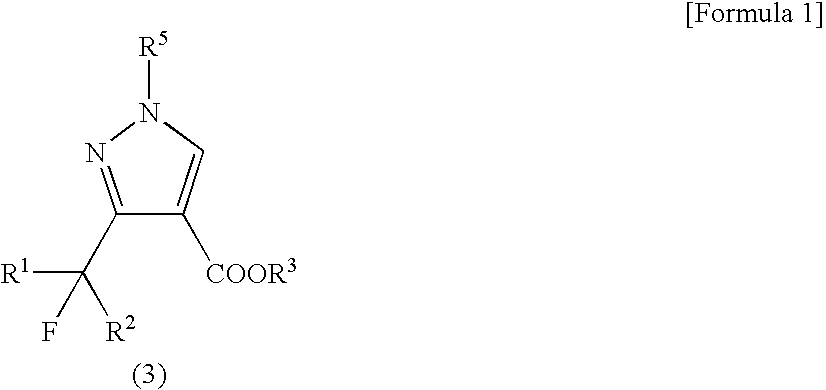

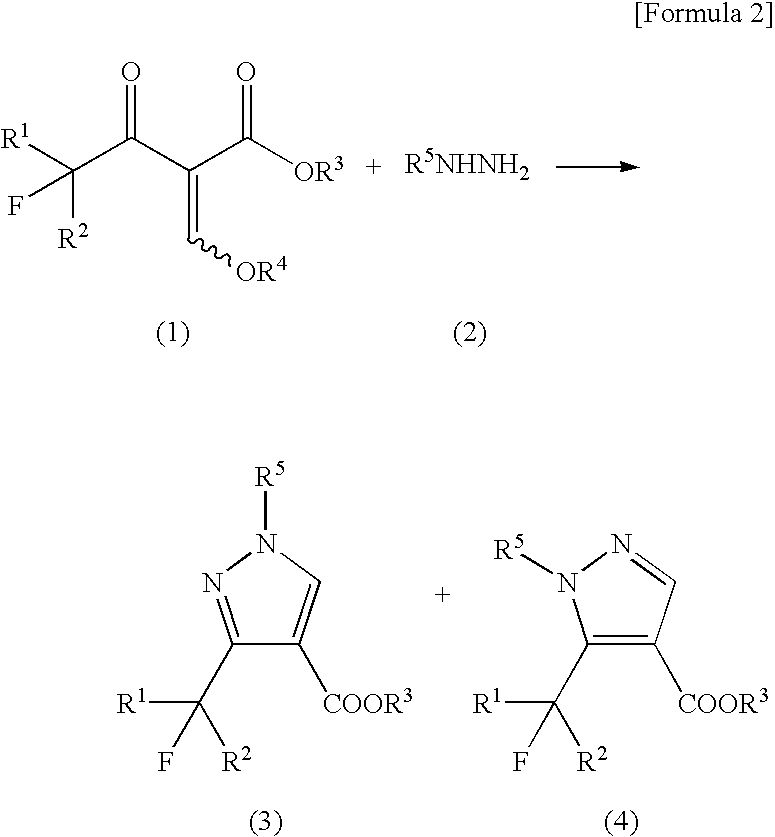

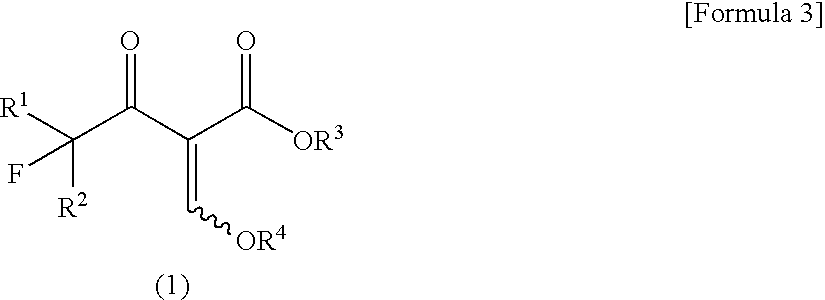

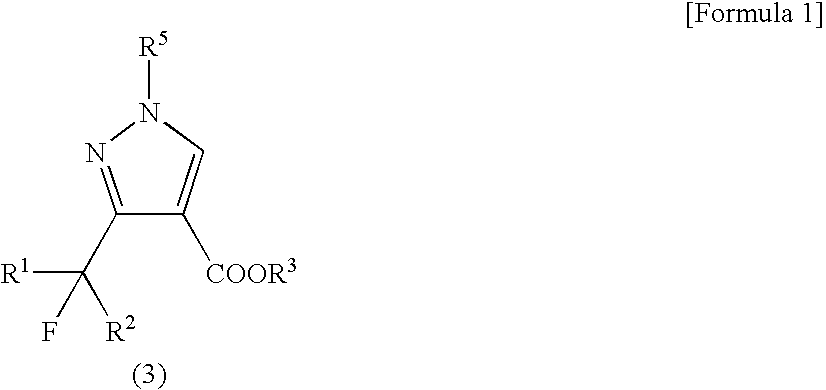

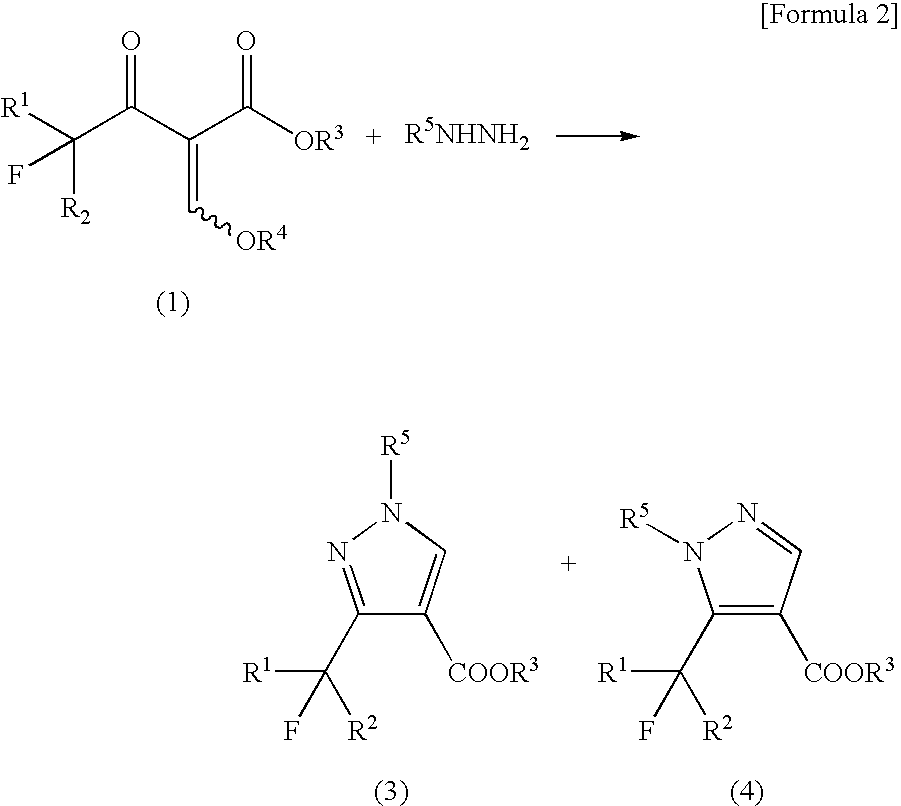

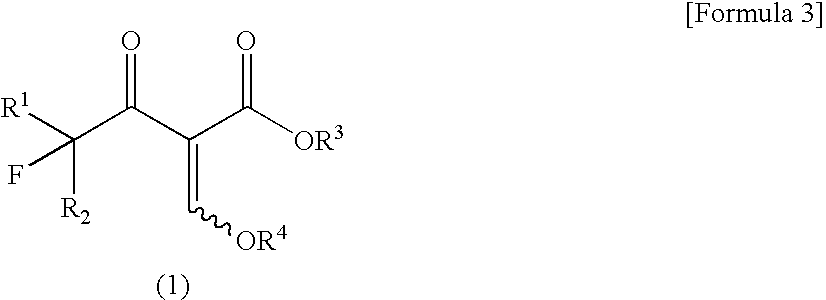

Process for producing 1-substituted-3-fluoroalkylpyrazole-4-carboxylate

In a process for producing 1-substituted-3-fluoroalkyl-pyrazole-4-carboxylate (3) by a reaction of 2-alkoxymethylenefluoroacylacetate (1) and hydrazine (2), the reaction is conducted in the presence of a base and water, to produce 1-substituted-3-fluoroalkylpyrazole-4-carboxylate (3) with high selectivity and yield. This novel process enables to produce 1-substituted-3-fluoroalkylpyrazole-4-carboxylate (3), which is useful as an intermediate for pharmaceuticals and agrochemicals, with high selectivity and yield by simple and safe operations.

Owner:SAGAMI CHEM RES CENT +1

Method for preparing filling leather fatliquoring agent

The invention provides a method for preparing a filling leather fatliquoring agent, comprising the following steps: (1) a component A and a component B or a component A, a component B and a component C undergo copolymerization in the presence of initiators, wherein the component A is at least one of natural oil containing unsaturated fatty acid, long carbon chain unsaturated fatty acid, ester of long carbon chain unsaturated fatty acid and long carbon chain unsaturated fatty acid amide; the component B is at least one of acrylic acid, methacrylic acid, ethyl acrylic acid, maleic acid, fumaric acid, glutaconic acid, vinyl acetic acid, maleic anhydride and glutaconic acid anhydride; and the component C is at least one of styrene, vinylacetate, vinyl propionate, acrylate, methacrylate, acrylamide and methacrylamide; (2) alkali is added in polymers generated after copolymerization to undergo neutralization reaction with the polymers; and (3) the neutralized polymers are mixed with the natural phospholipids. The method is economical and environmentally friendly.

Owner:ZHEJIANG IND & TRADE VACATIONAL COLLEGE

Process for Producing 1-Substituted-3-Fluoroalkylpyrazole-4-Carboxylate

ActiveUS20080154045A1Highly selectively producedSimple and safe operationOrganic chemistrySafe operationAgrochemical

In a process for producing 1-substituted-3-fluoroalkyl-pyrazole-4-carboxylate (3) by a reaction of 2-alkoxymethylenefluoroacylacetate (1) and hydrazine (2), the reaction is conducted in the presence of a base and water, to produce 1-substituted-3-fluoroalkylpyrazole-4-carboxylate (3) with high selectivity and yield. This novel process enables to produce 1-substituted-3-fluoroalkylpyrazole-4-carboxylate (3), which is useful as an intermediate for pharmaceuticals and agrochemicals, with high selectivity and yield by simple and safe operations.

Owner:SAGAMI CHEM RES CENT +1

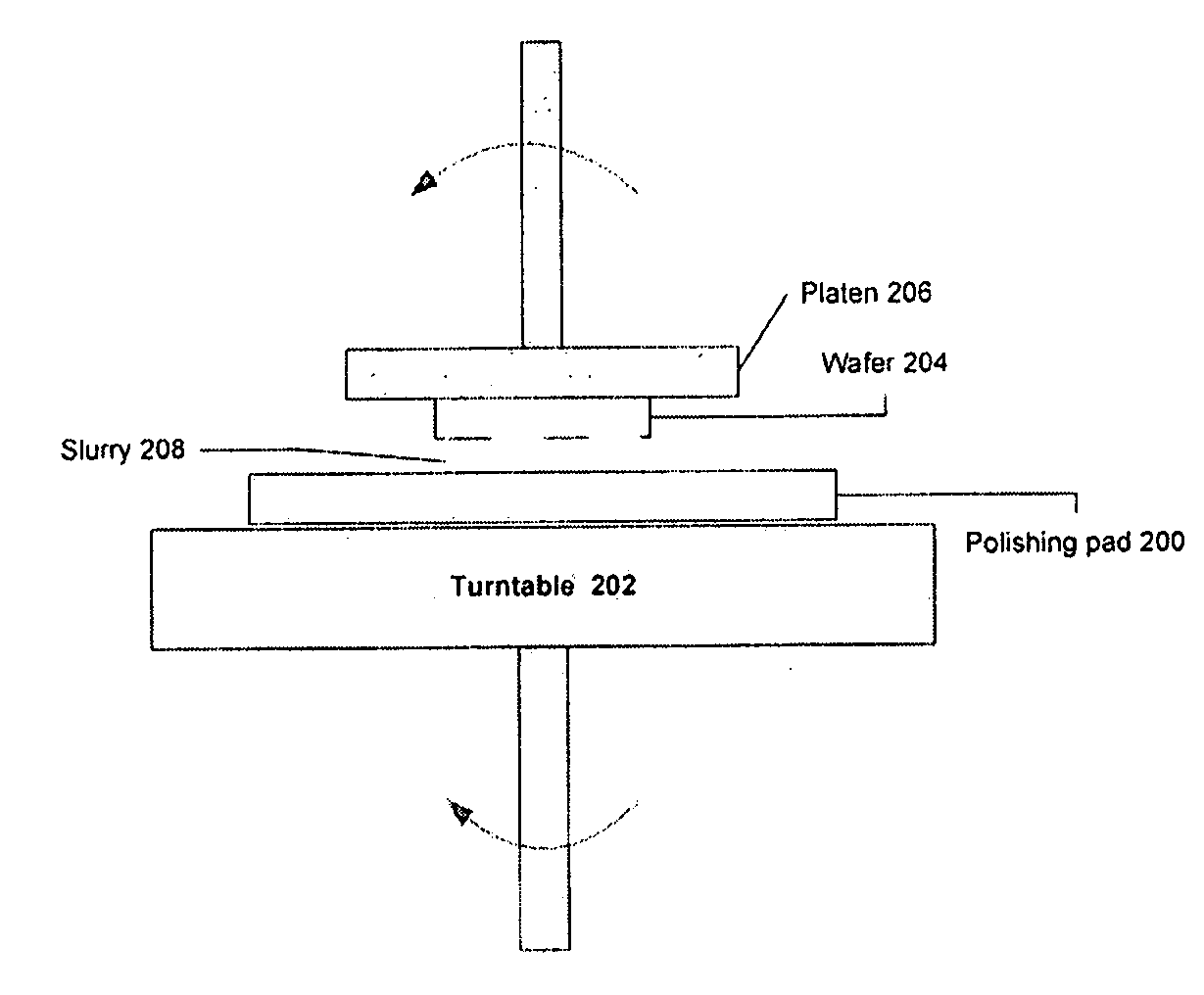

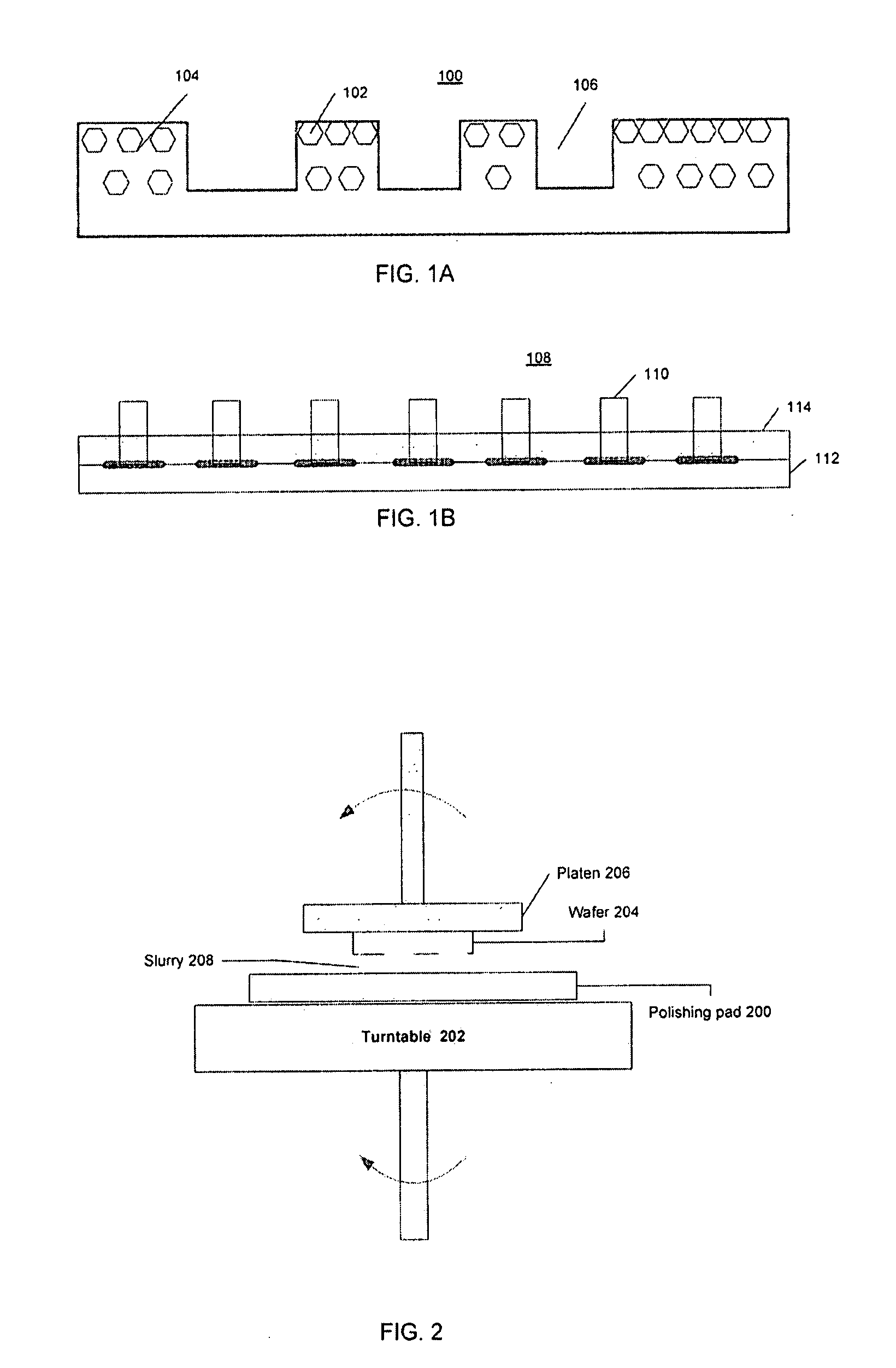

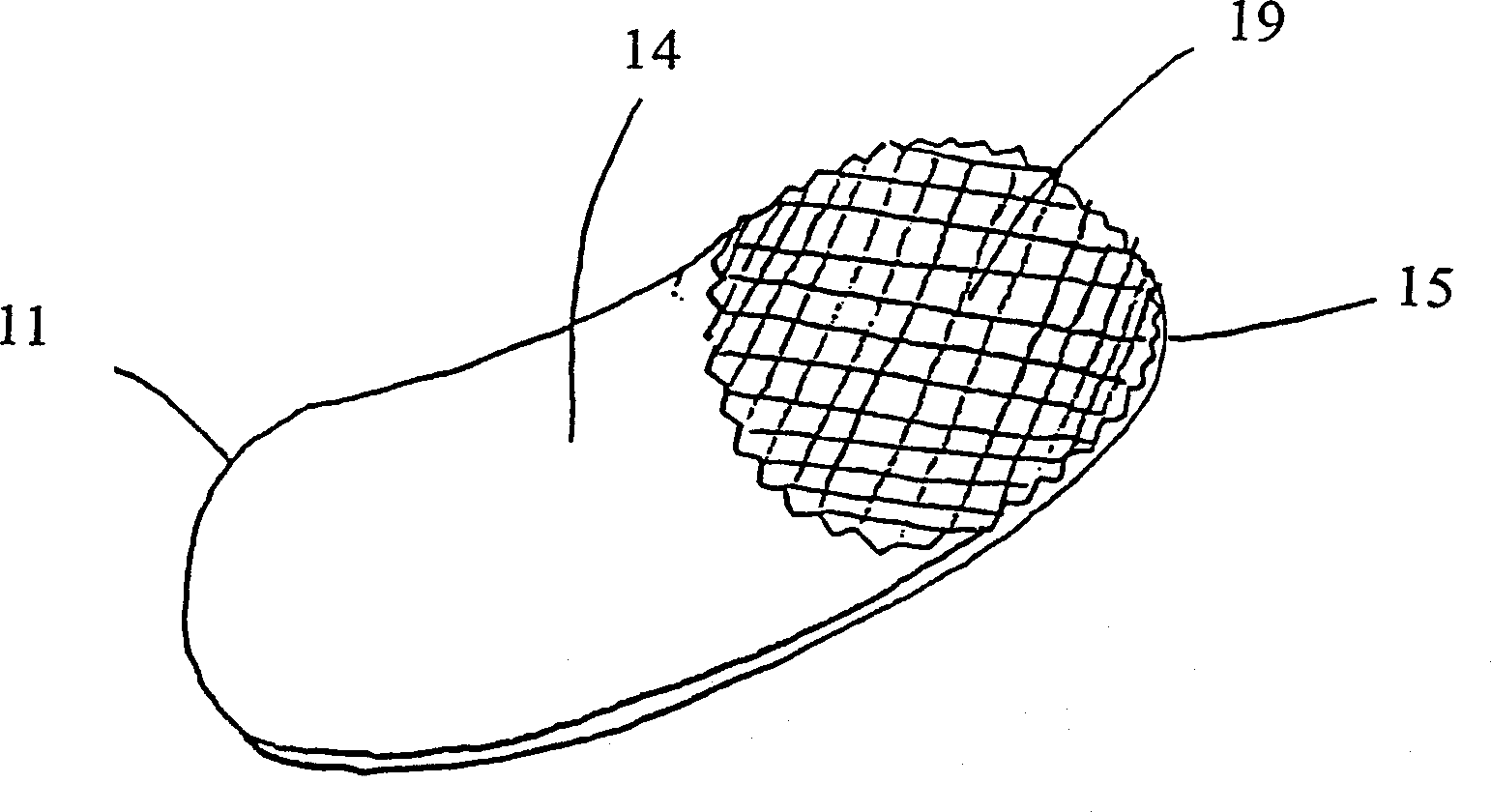

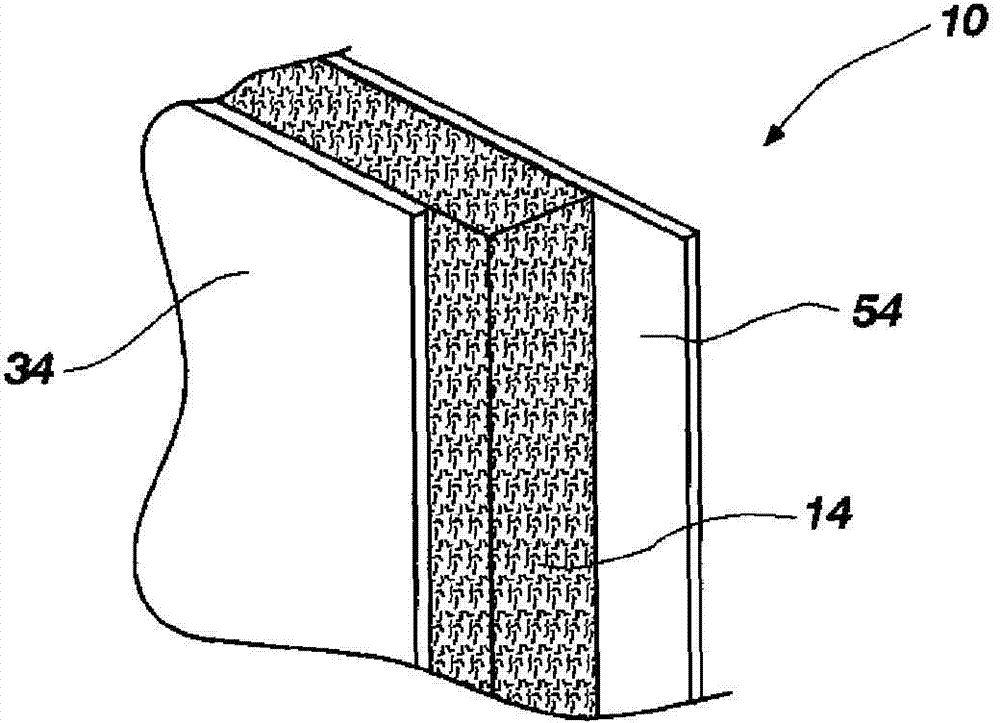

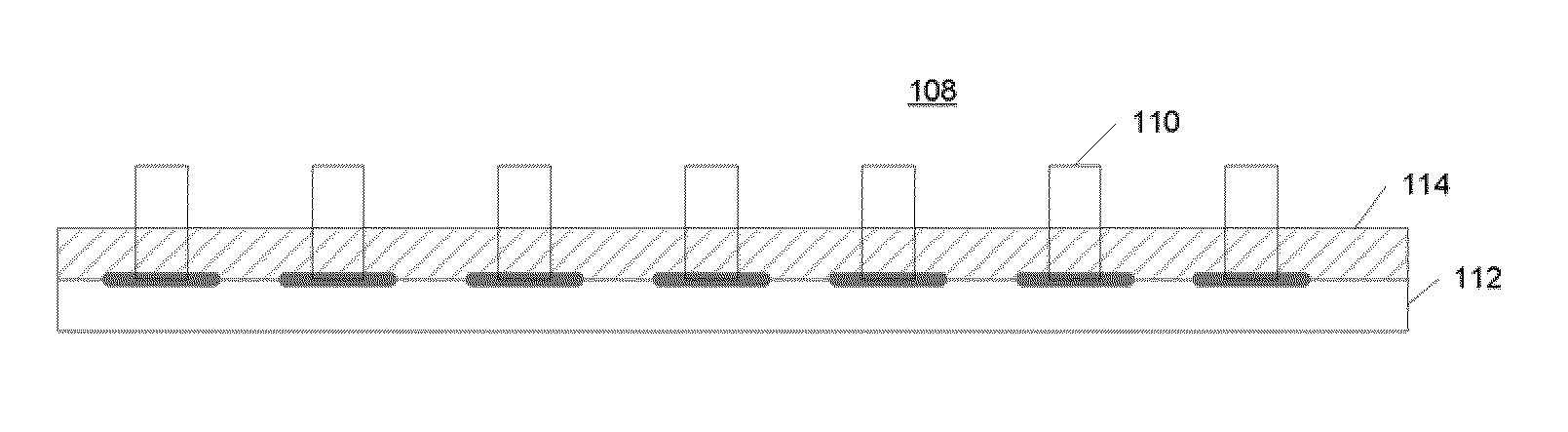

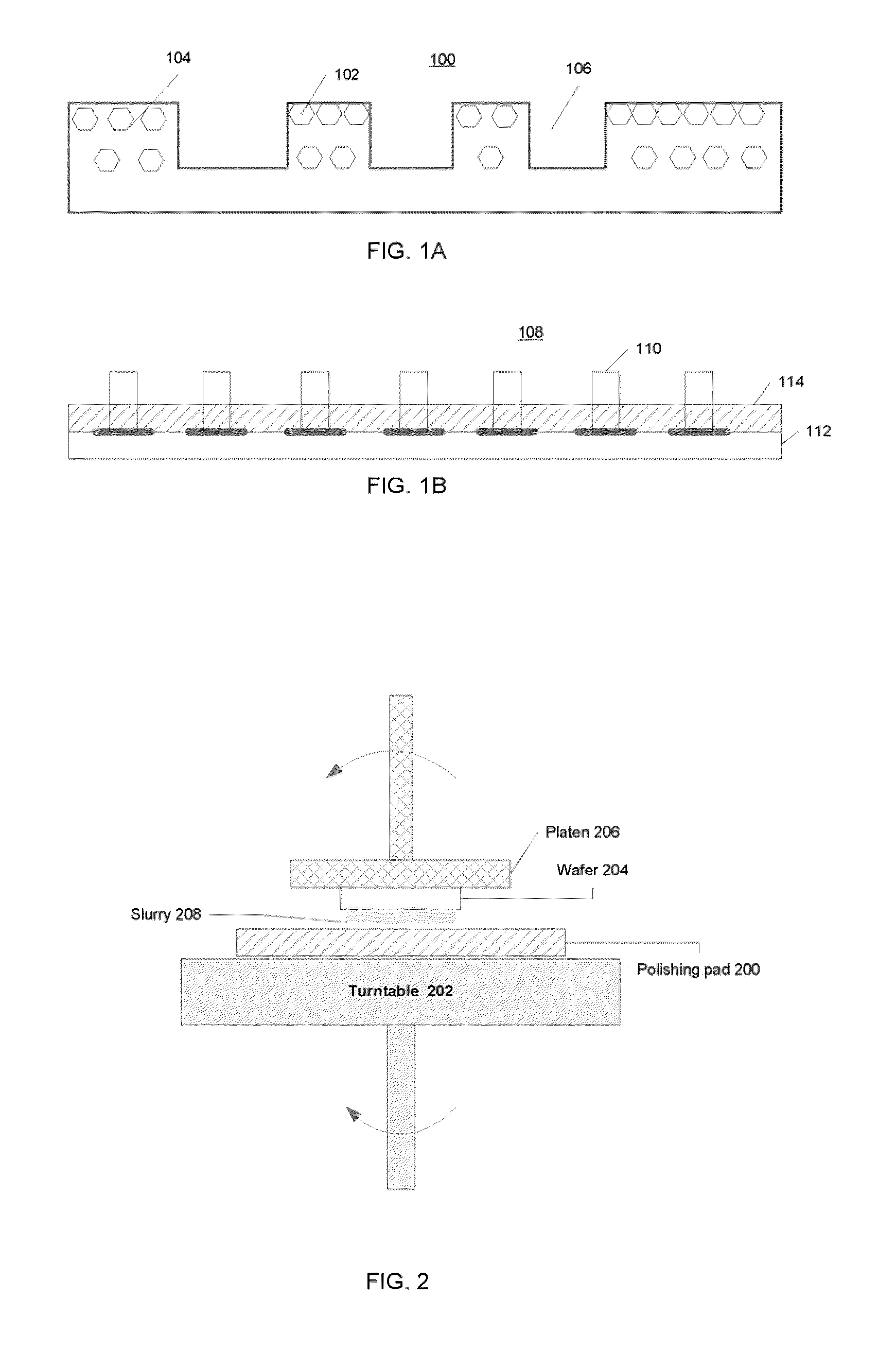

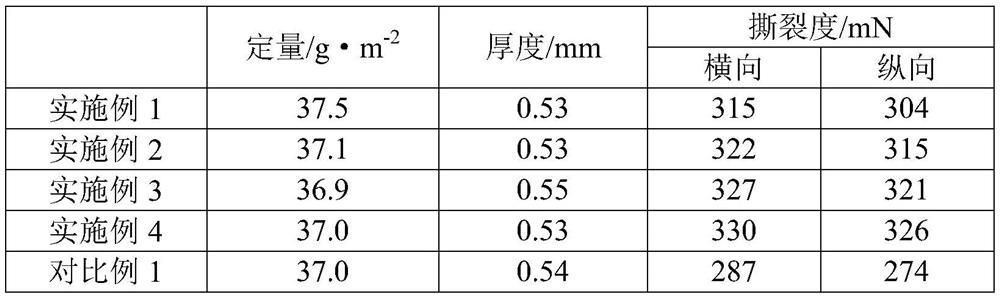

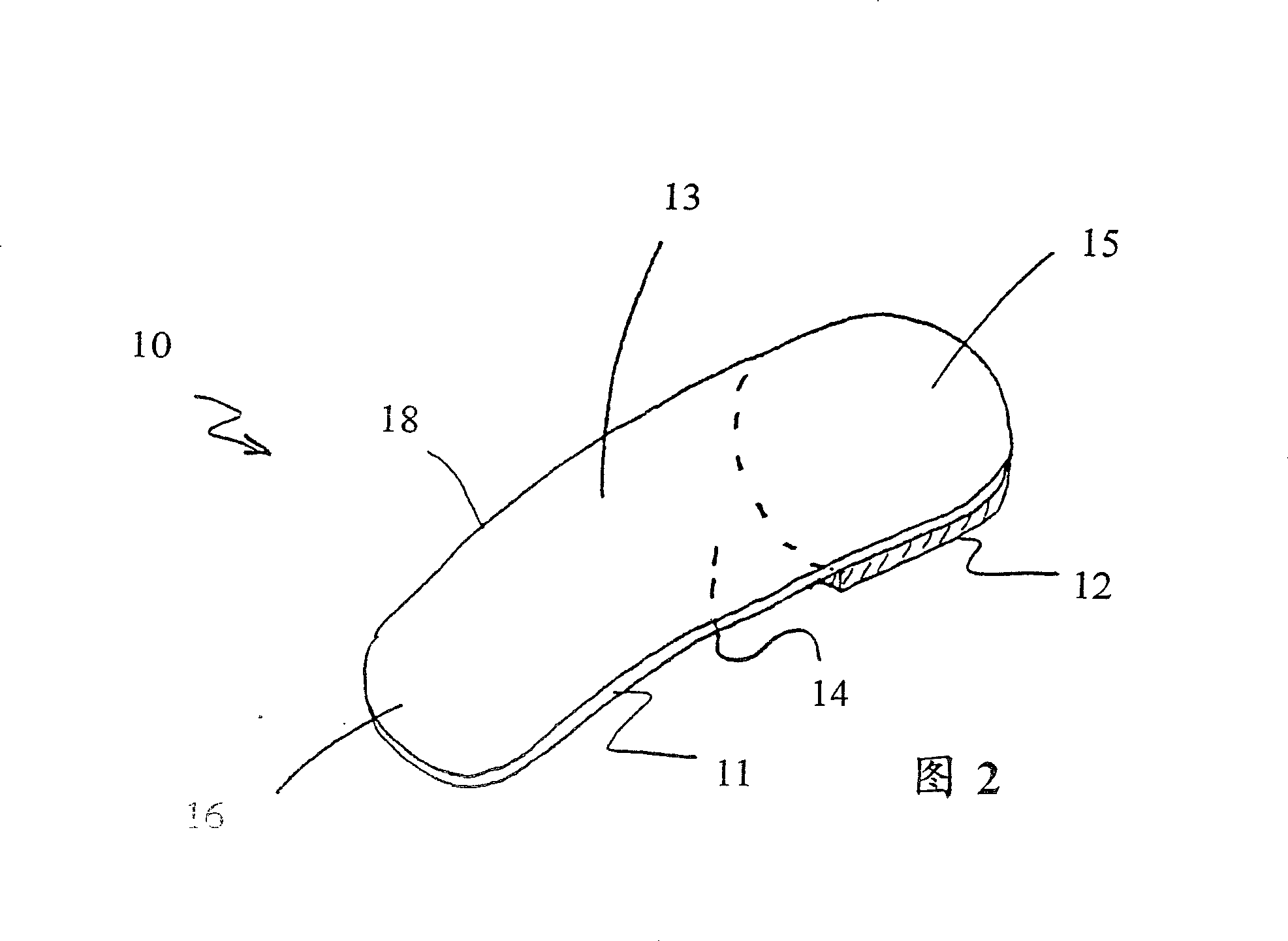

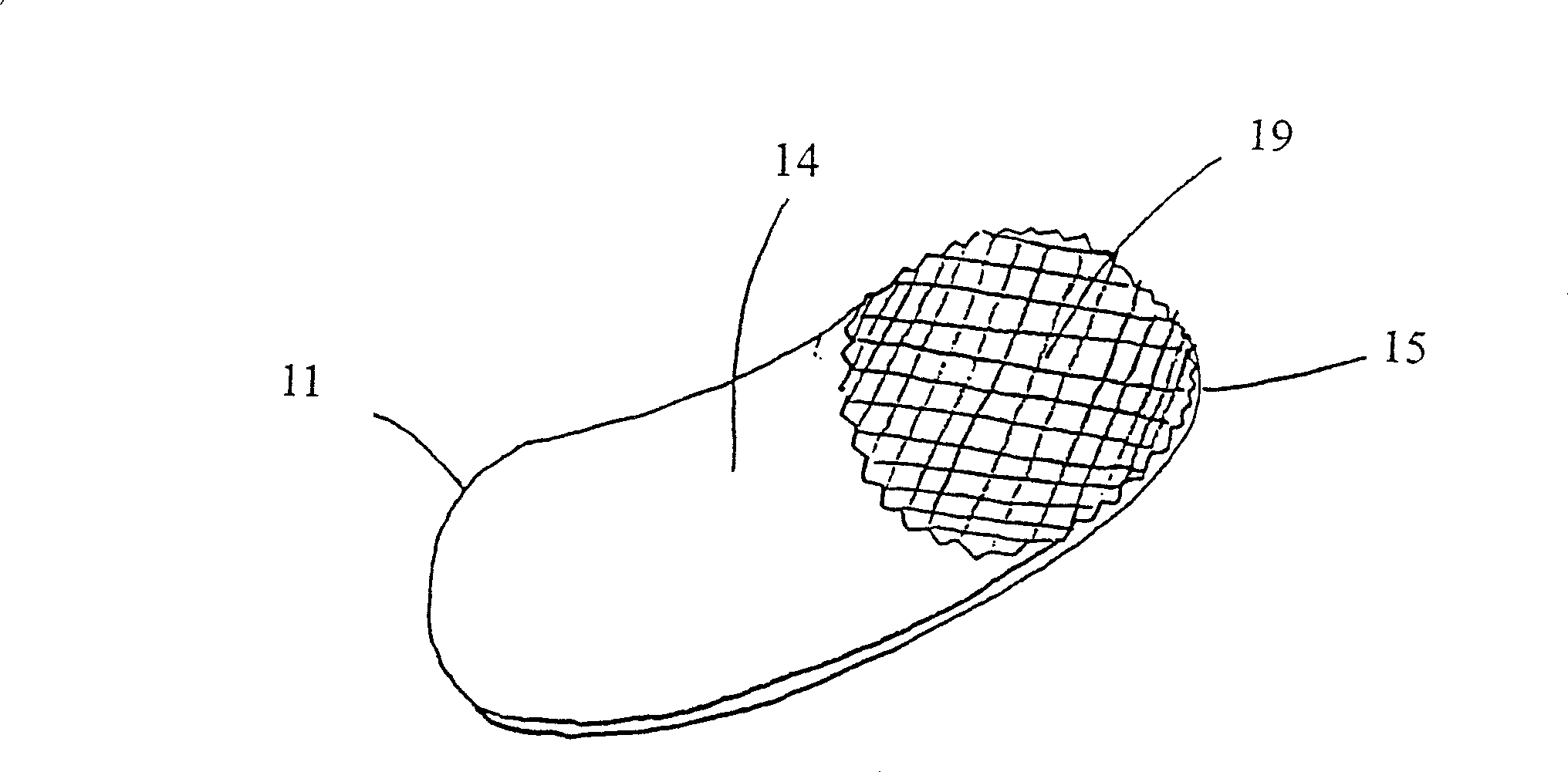

Polishing pad and method of use

InactiveUS20090061744A1Reduce defectsPolishing machinesRevolution surface grinding machinesMethacrylateFlexural modulus

A polishing pad has one or more polishing elements made from a hydrogel material having an intrinsic ability to absorb water. The hydrogel material may or may not have micropores, but has a water absorption capability of 4%-60% by weight, a wet tensile strength greater than 1000 psi, a flexural modulus greater than 2000 psi, and a wet Shore D hardness between 25-80, inclusive. The hydrogel material may be made from one or a combination of the following moieties: urethane, alkylene oxides, esters, ethers, acrylic acids, acrylamides, amides, imides, vinylalcohols, vinylacetates, acrylates, methacrylates, sulfones, urethanes, vinylchlorides, etheretherketones, and / or carbonates.

Owner:SEMIQUEST

Novel hydrotalcites, syntheses, and uses

Synthetic hydrotalcites of the general formula [M2+1-xM3+x(OH)2]x+[An−x / n.mH2O]x−where M2+ is a divalent cation, M3+ is a trivalent cation and An− is an organic anion selected from straight chain carboxylates of C16-C18 acids, carboxylates of aromatic acids, carboxylates of acrylic acid, unsaturated carboxylates of methacrylic acid, unsaturated carboxylates of vinylacetic acid and C2 and higher organic acids containing heteroatoms such as nitrogen, phosphorous, sulfur and halogens are disclosed, along with methods of synthesis and uses.

Owner:FUJII MASAKI +5

Pre-glued ornamental fingernail accessory

InactiveCN1860955AGood removal effectCosmetic preparationsOther chemical processesEmulsionAqueous solution

Owner:KMC EXIM

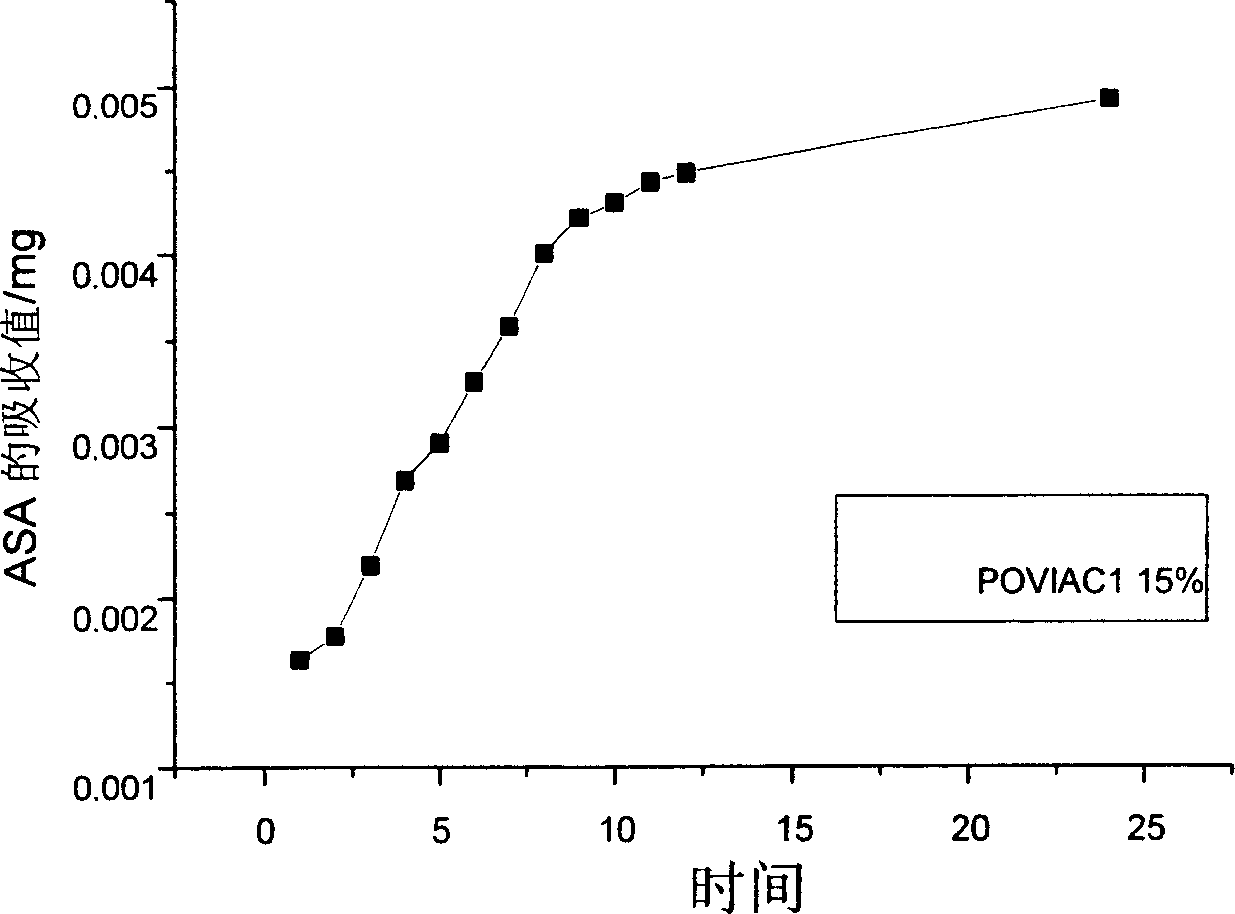

Method for producing resin composition for solar cell sealing material, resin composition for solar cell sealing material, solar cell sealing material, and solar cell module

InactiveUS20120024376A1Good storage stabilityHigh transparencyOther chemical processesVehicle sealing arrangementsPolymer scienceElectrical battery

An object of the present invention is to provide a method for producing a resin composition for solar cell sealing material which is capable of lowering a cost by shortening of a processing time and has good storage stability. Further, another object of the present invention is to provide a solar cell sealing material having excellent transparency due to no generation of lumps therein by using the obtained resin composition for solar cell sealing material. A method for producing a resin composition for solar cell sealing material according to the present invention includes: preparing an ethylene-vinyl acetate copolymer (A) containing a vinyl acetate unit in an amount of 25 to 35 wt % and a crosslinking agent (B), whose impregnation weight with respect to 1 g of the ethylene-vinyl acetate copolymer (A) per 24 hours at a temperature of 23° C. is in the range of 40 to 80 mg, as raw components; and impregnating the crosslinking agent (B) into the ethylene-vinyl acetate copolymer (A) at a temperature of 15 to 80° C.

Owner:TOYO INK SC HOLD CO LTD +1

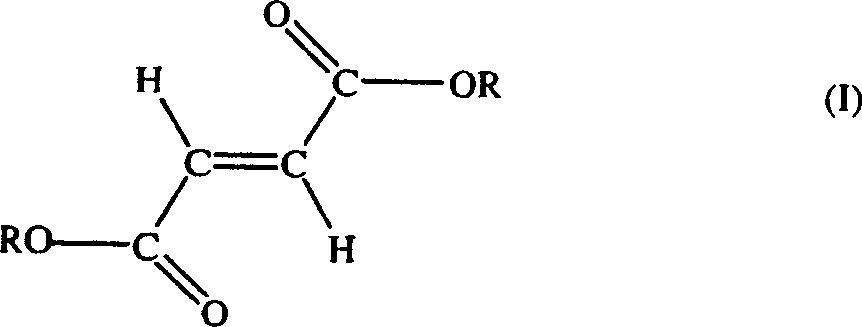

Carboxylate-vinyl ester copolymer blend compositions for lubricating oil flow improvement

Compositions for improving at least the low temperature flow properties of high viscosity index, high saturates, low sulfur lubricating oils (also known as American Petroleum Institute Group II and Group III oils). The compositions comprise a mixture of lubricating oil flow improvers (LOFIs) that are specified first and second component copolymers of unsaturated dicarboxy esters, including a first component which is a polymer or copolymer of a carboxylate containing pendent ester groups wherein the average side chain carbon number is between 11.0 and 12.4, such as dialkyl fumarate / vinyl acetate copolymer, and a second component which also is a polymer or copolymer such as dialkyl fumarate / vinyl acetate copolymer, but wherein the average side chain carbon number is between 12.7 and 15.0. Alternatively, each of the polymers or copolymers can be esterified styrene / maleic anhydride copolymer, or esterified olefin / maleic anhydride copolymer provided that each of the two components has the specified, different average side chain carbon numbers.

Owner:INFINEUM INT LTD

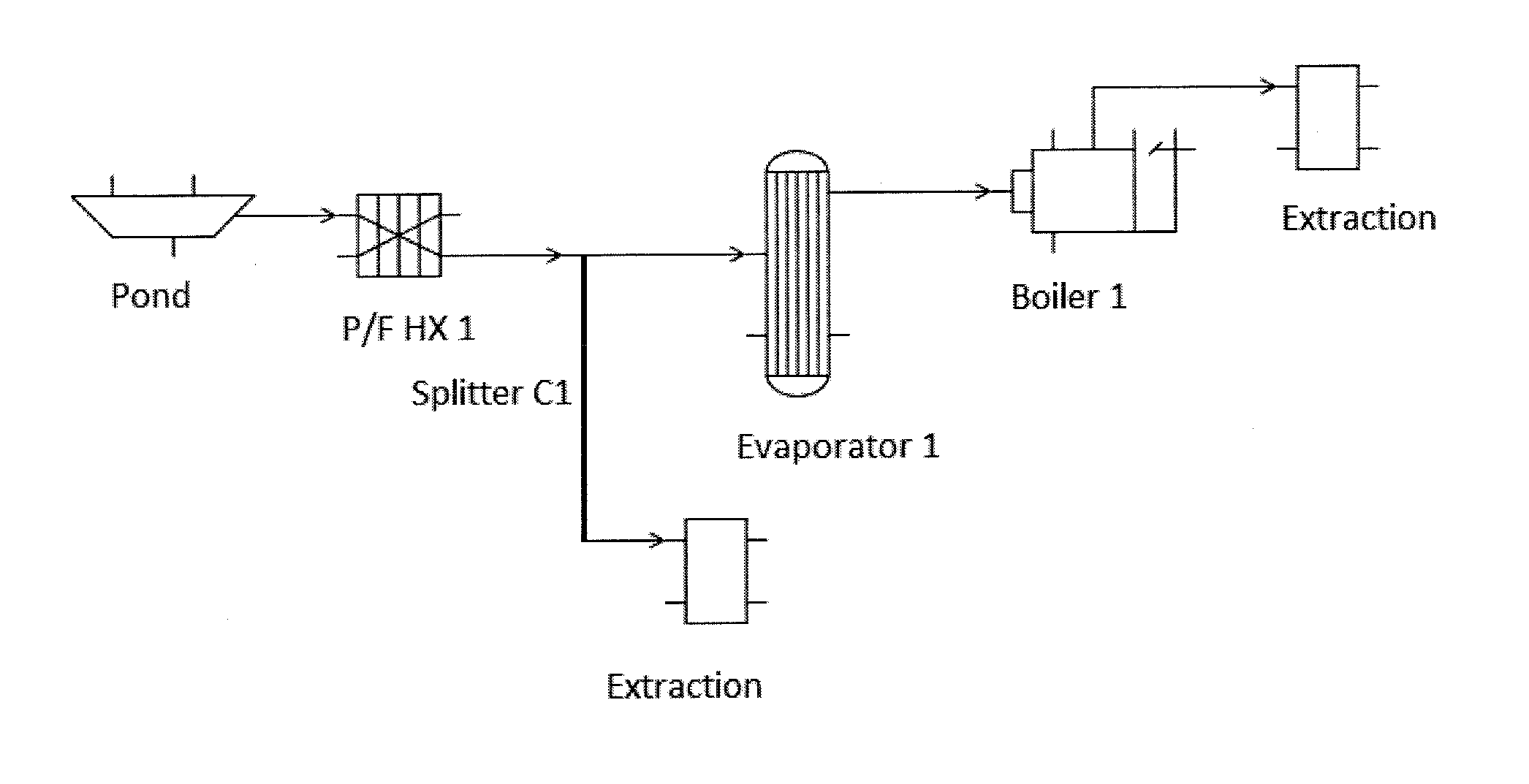

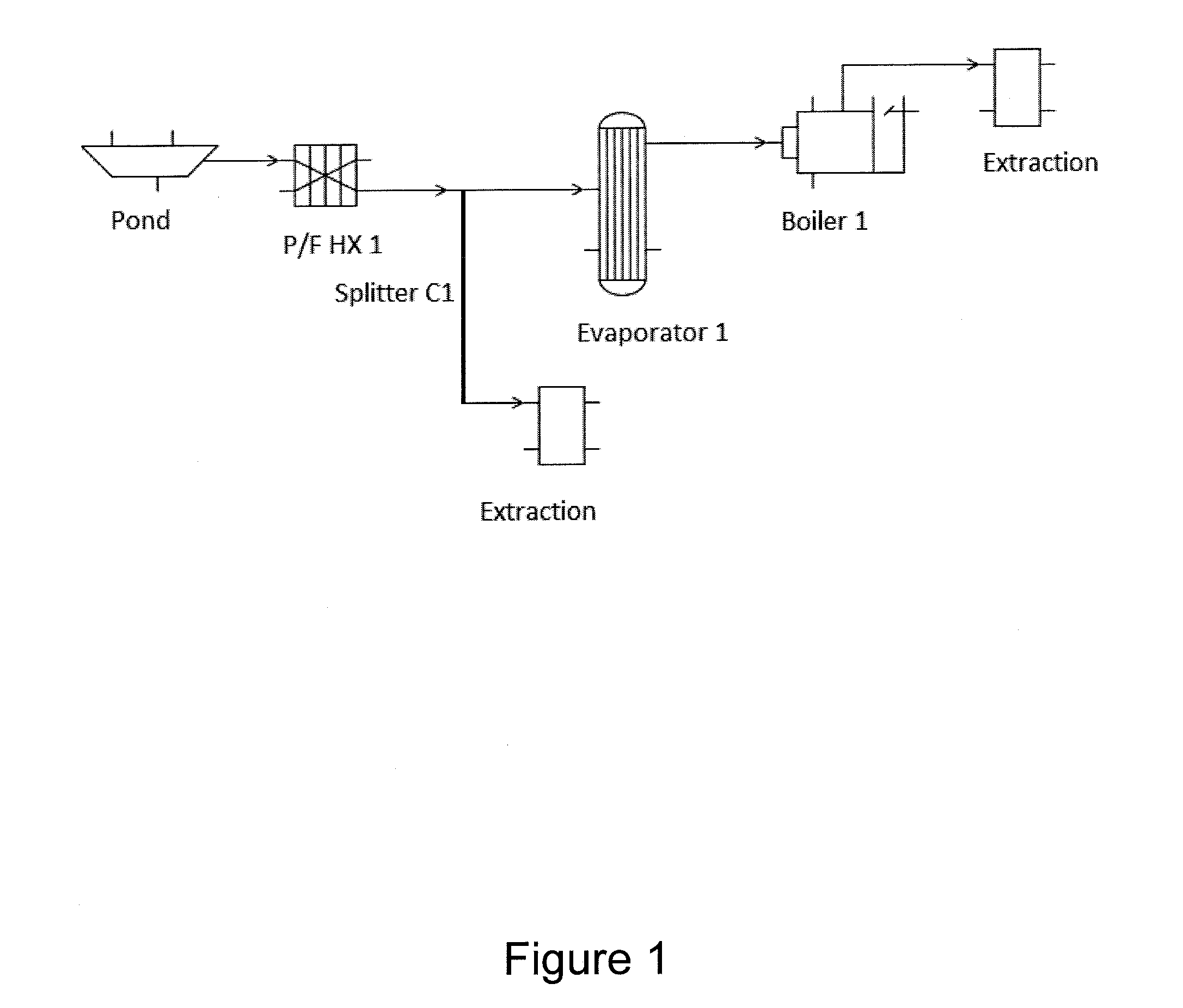

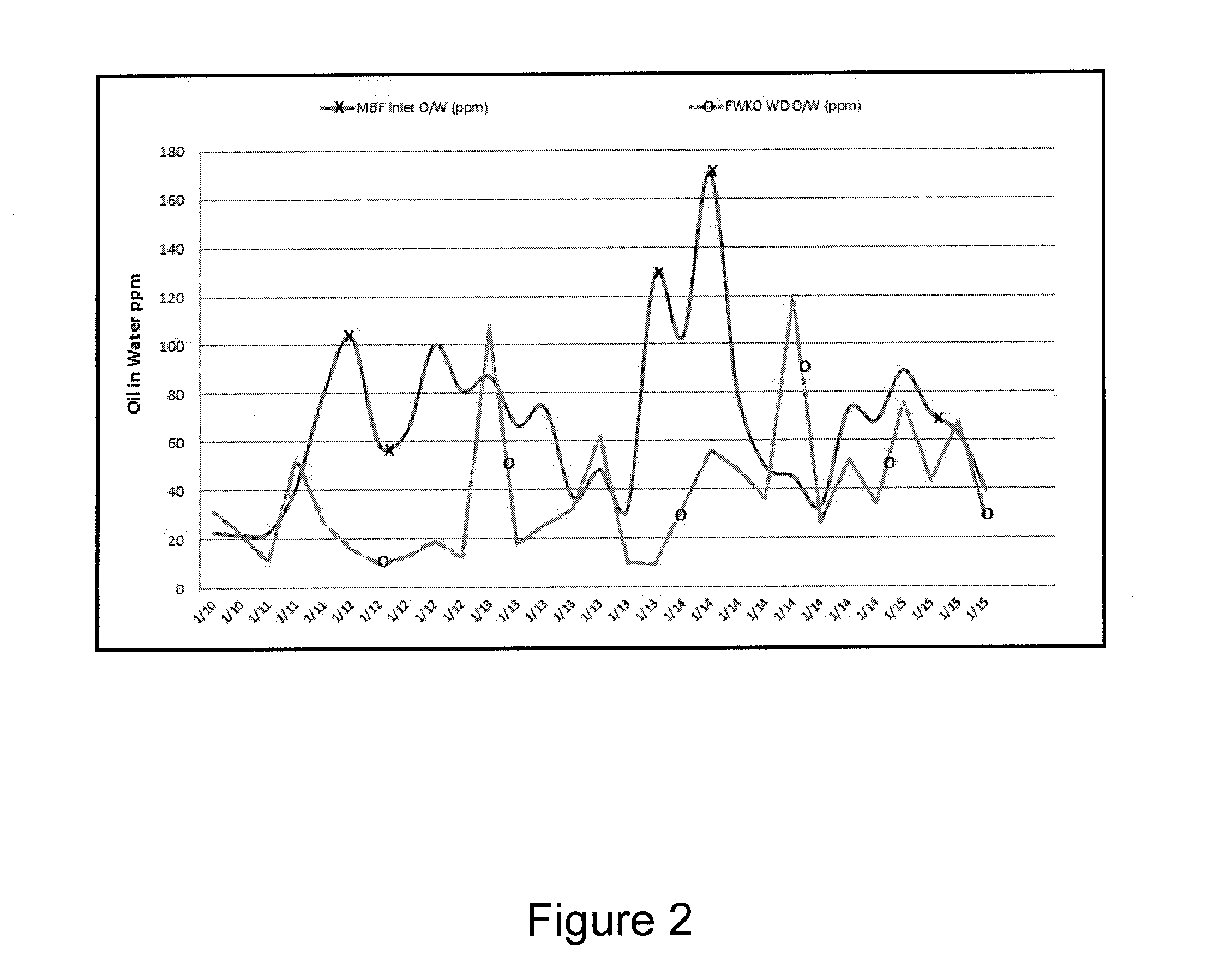

Fouling mitigation in equipment used during hydrocarbon production

ActiveUS20140263078A1Preventing and reducing foulingPrevent scalingScale removal and water softeningNature of treatment waterWater useEthylene Homopolymers

Methods for dispersing foulants are disclosed herein. Various effective dispersant compositions are also disclosed. The dispersant composition can include a silt dispersant and a hydrocarbon dispersant. Generally, the silt dispersant can be a homopolymer or a copolymer of one or more monomers, and the monomers can be one or more of acrylic acid, methacrylic acid, α-halo acrylic acid, maleic acid, itaconic acid, vinyl acetic acid, allyl acetic acid, fumaric acid, β-carboxylic acrylate, and their salts. The silt dispersant can also be a terpolymer of acrylic acid, acrylamide, and sulfonated acrylamide. The hydrocarbon dispersant can be a non-ionic surfactant or a nonylphenol or a nonylphenol ethoxylate, such as a high EO 9 Nonyl phenol resin. Also disclosed are methods for preventing or reducing fouling in equipment that contacts water used during a hydrocarbon production process.

Owner:CHAMPIONX USA INC

Hydrotalcites, syntheses, and uses

Synthetic hydrotalcites of the general formula[M2+1-xM3+x(OH)2]x+[An−x / n·mH2O]x−where M2+ is a divalent cation, M3+ is a trivalent cation and An− is an organic anion selected from straight chain carboxylates of C16-C18 acids, carboxylates of aromatic acids, carboxylates of acrylic acid, unsaturated carboxylates of methacrylic acid, unsaturated carboxylates of vinylacetic acid and C2 and higher organic acids containing heteroatoms such as nitrogen, phosphorous, sulfur and halogens are disclosed, along with methods of synthesis and uses.

Owner:SUNOCO INC (R&M)

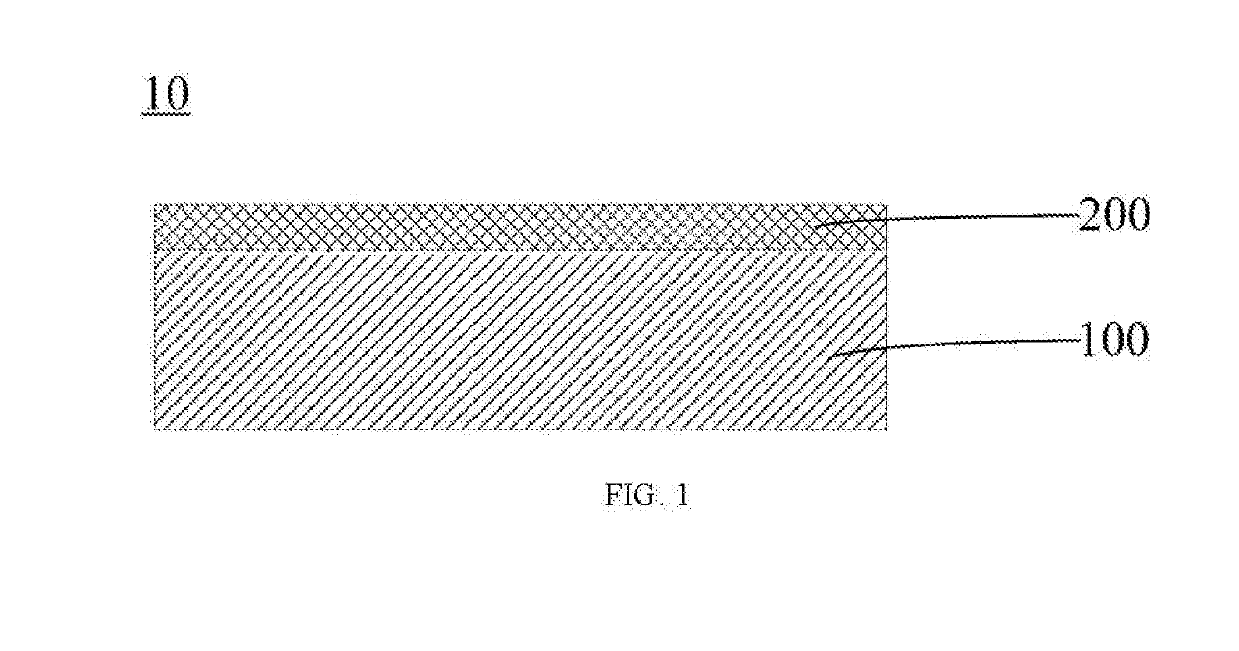

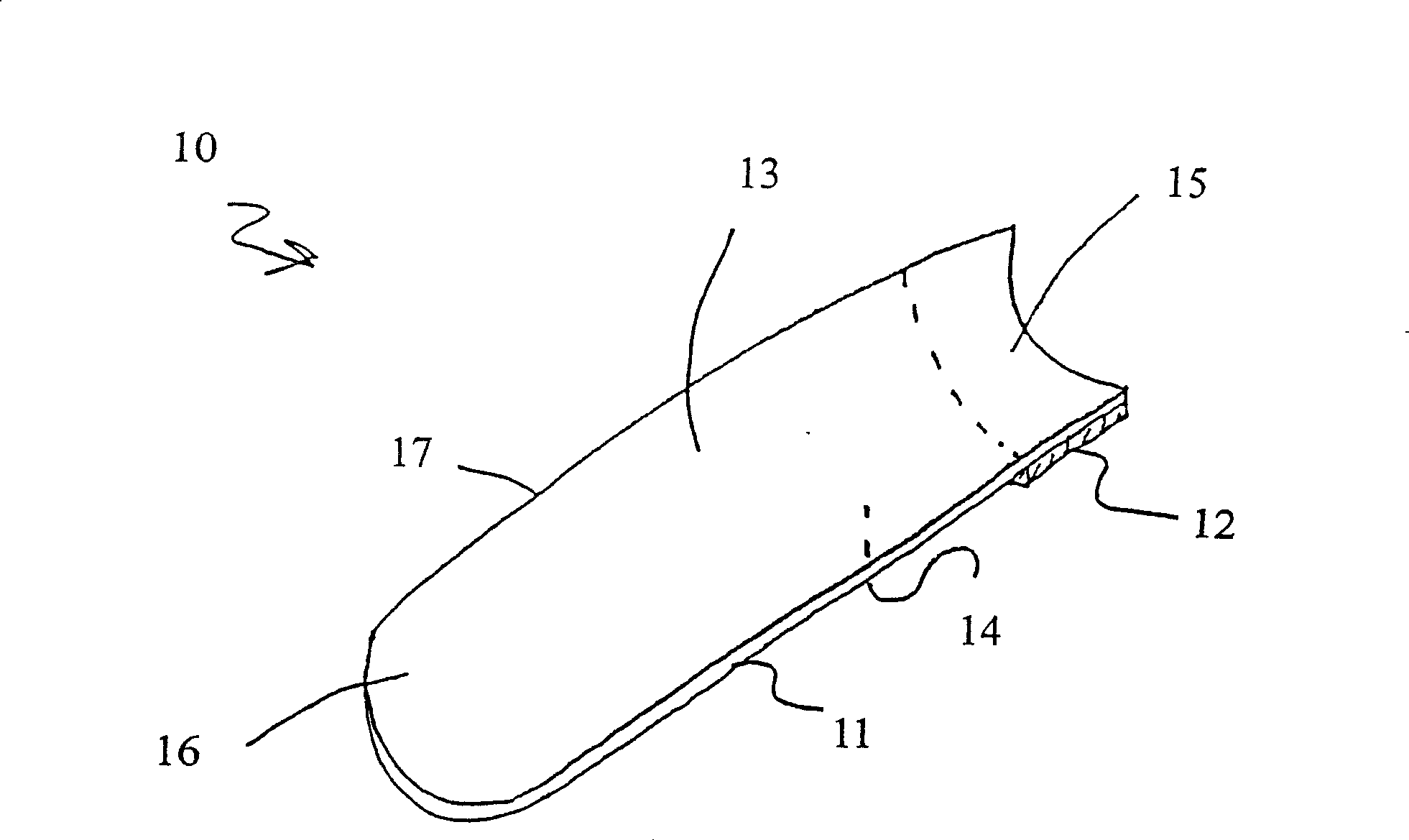

Low-temperature thermal laminating film and preparation method and application thereof

ActiveUS20190284452A1Low costNon-macromolecular adhesive additivesAdhesive articlesPolymer scienceAntioxidant

The present disclosure provides a low-temperature thermal laminating film (10), and a preparation method and the use thereof. The low-temperature thermal laminating film (10) includes a film substrate (100) and an adhesive layer (200), wherein the adhesive layer (200) is disposed on the film substrate (100), and the raw materials of the adhesive layer (200) include an ethylene-vinyl acetate resin, a tackifier and an antioxidant, wherein the weight percentage of the ethylene-vinyl acetate resin is 70%-90%, the weight percentage of the tackifier is 5%-25%, and the weight percentage of the antioxidant is 3%-5%. The adhesive layer (200) in the low-temperature thermal laminating film (10) has a strong bonding force with the film substrate (100), and the low-temperature thermal laminating film can be laminated at relatively low-temperatures and can achieve a good laminating effect.

Owner:GUANGDONG EKO FILM MFG CO LTD

Novel hydrotalcites, syntheses, and uses

Synthetic hydrotalcites of the general formula [M2+1-xM3+x(OH)2]x+[An−x / n·mH2O]x−where M2+ is a divalent cation, M3+ is a trivalent cation and An− is an organic anion selected from straight chain carboxylates of C16-C18 acids, carboxylates of aromatic acids, carboxylates of acrylic acid, unsaturated carboxylates of methacrylic acid, unsaturated carboxylates of vinylacetic acid and C2 and higher organic acids containing heteroatoms such as nitrogen, phosphorous, sulfur and halogens are disclosed, along with methods of synthesis and uses.

Owner:FUJII MASAKI +5

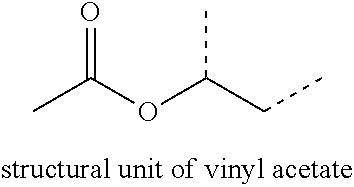

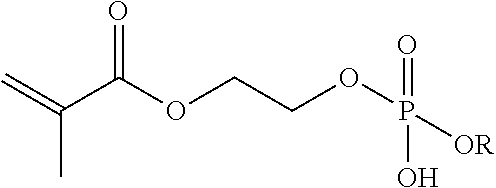

Vinyl acetate binders in an above-critical PVC coatings composition

The present invention is an above-critical coating composition comprising an aqueous dispersion of polymer particles, pigment particles, and extender particles wherein the polymer particles comprise from 80 to 99.8 weight percent structural units of vinyl acetate and from 0.1 to 6 weight percent structural units of a phosphorus acid monomer. The composition shows surprisingly improved hiding with increased particle size of the polymer particles.

Owner:DOW GLOBAL TECH LLC +1

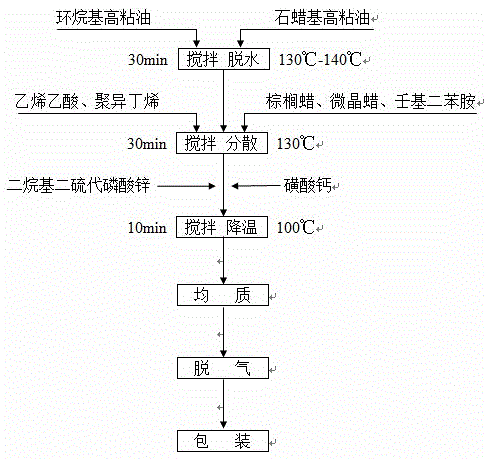

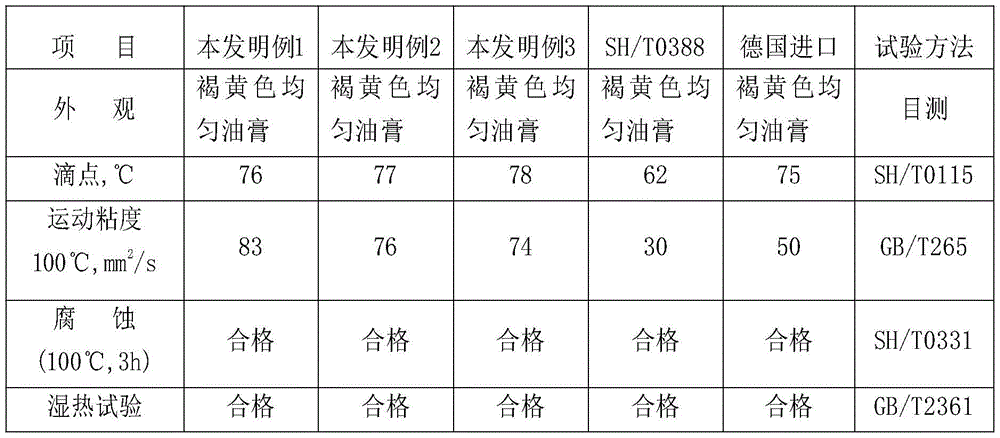

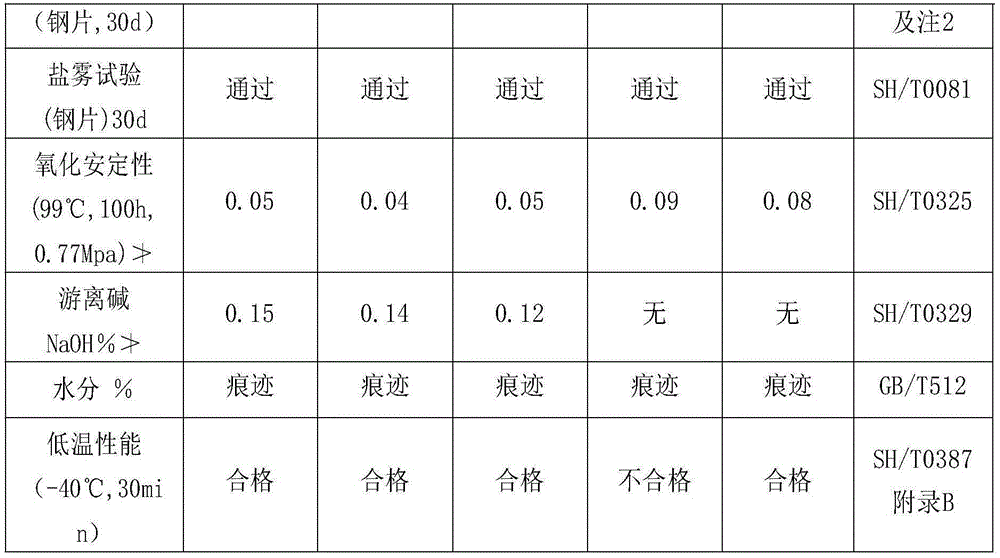

Long-acting wire rope hemp core grease

InactiveCN105542924AGood compatibilityHigh melting point (dropping point)Textile cablesLubricant compositionParaffin waxMicrocrystalline wax

The invention relates to a long-acting wire rope hemp core grease. The long-acting wire rope hemp core grease comprises 13-17wt% of palm wax, 16-19wt% of microcrystalline wax, 15-19wt% of naphthenic high-viscosity oil, 24-28wt% of paraffinic high-viscosity oil, 1.6-4.6wt% of zinc dialkyl dithiophosphate, 1.4-4.4wt% of nonyldiphenylamine, 4.5-8.5wt% of vinylacetic acid, 8.5-12.5wt% of polyisobutylene and 0.1-1wt% of calcium sulfonate. Compared with hemp core greases in the prior art, the long-acting wire rope hemp core grease has the advantages of high dropping point, no flowing in hot weather, fast online solidification after rope immersion, no loss, energy saving, no pollution to environment, large kinematic viscosity data, good adhesiveness, and realization of good fluidity and no flowing of a grease film in the motion and compressed processes. Prominently, the property of traditional hemp core greases (including imported hemp core greases) is changed to become weakly alkaline (the free base value is not greater than 0.15, NaOH%), so oxidation is effectively inhibited, generated free acids are neutralized, SH / T0325 oxidation stability test and SH / T0331 corrosion test are extremely well passed, the safe service life of a wire rope is effectively prolonged, and use environment is purified.

Owner:GUANGZHOU ROSTON PETROCHEM CO LTD

Novel hydrotalcites, syntheses, and uses

InactiveUS20050020749A1Pigmenting treatmentGroup 3/13 element organic compoundsHydrotalciteMedicinal chemistry

Synthetic hydrotalcites of the general formula: [M2+1-xM3+x(OH)2]x+[An−x / n·mH2O]x−where M2+ is a divalent cation, M3+ is a trivalent cation and An− is an organic anion selected from straight chain carboxylates of C16-C18 acids, carboxylates of aromatic acids, carboxylates of acrylic acid, unsaturated carboxylates of methacrylic acid and unsaturated carboxylates of vinylacetic acid are disclosed, along with methods of synthesis and uses.

Owner:FUJII MASAKI +6

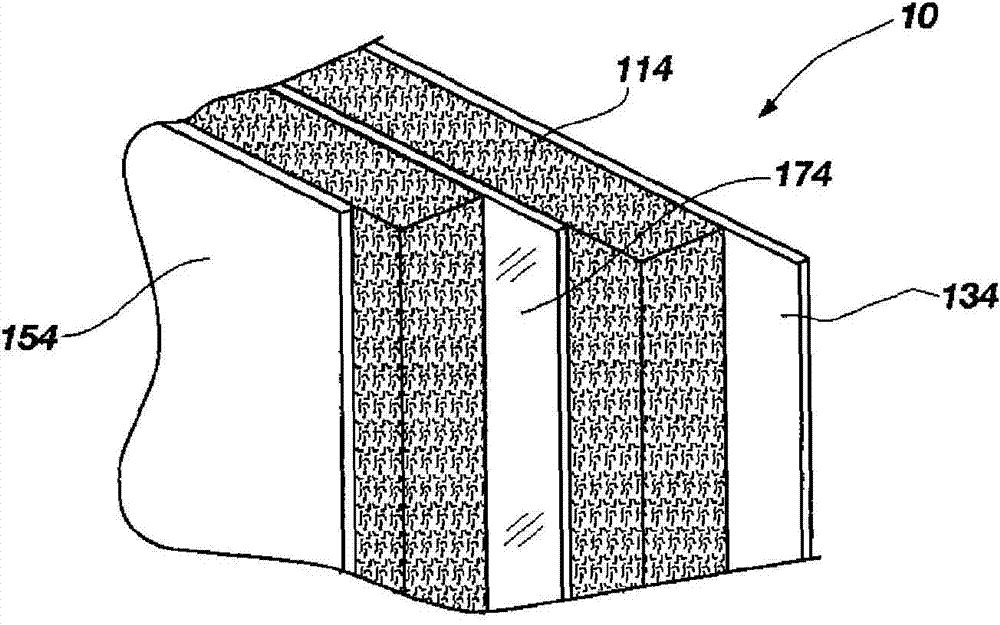

Wallboard materials incorporating a microparticle matrix

ActiveCN103758276AUnderstanding contributionSolid waste managementHeat proofingMicroparticleSodium silicate

A method of forming a wallboard material can include forming a mixture including microparticles, sodium silicate and vinyl acetate. The mixture can be disposed between a metallic facing membrane and a second facing membrane. The mixture can then be heat cured in a single step sufficient to form a wallboard material having the metallic facing membrane and the second facing membrane attached to a core matrix. The heat curing time is complete in less than about 1.5 hours without causing damage to the wallboard material.

Owner:ASHTECH IND LLC

Composite biomaterials for bone implants

The invention relates to bone implant biomaterials comprising an inorganic phase which is formed by calcium salts, mainly by phosphates and hydroxy- and carbonate-apatites, and an organic phase containing polymers derived from vinyl acetate and crotonic acid. The inventive biomaterials, which can be dense or porous, have different reabsorption speeds when used as implants in living tissue depending on the type and proportion of the constituent phases thereof. Said biomaterials can also be used as supports in the production of systems for the controlled release of pharmaceuticals.

Owner:CENT NACIONALDE INVESTIGACIONES CIENTIFICAS CNIC

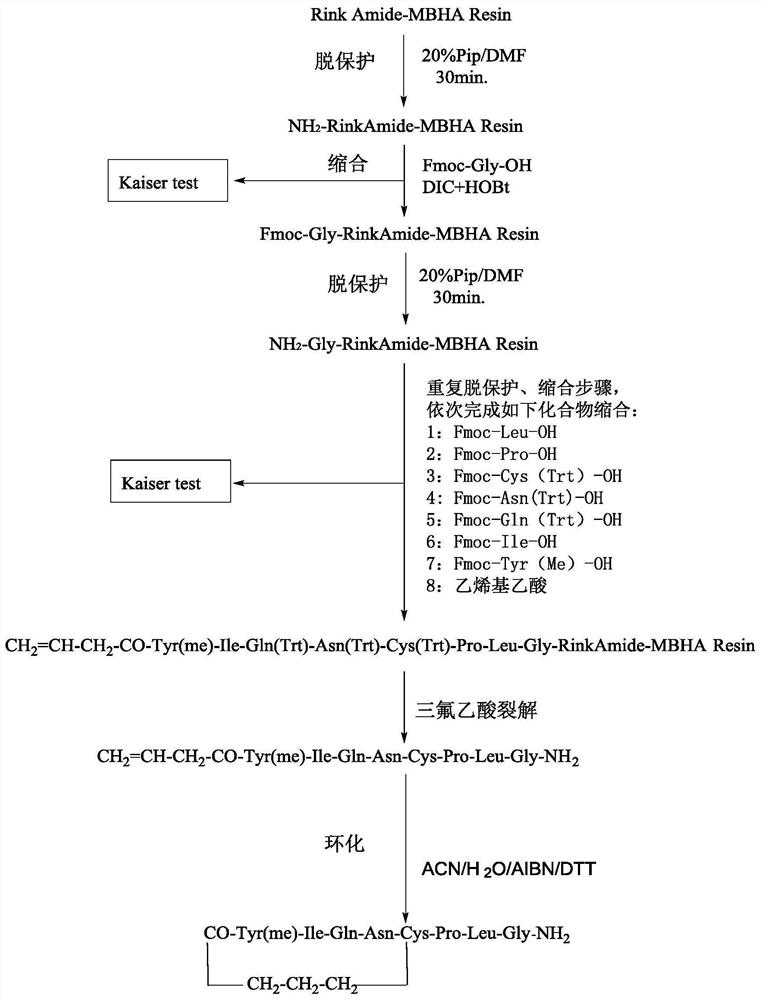

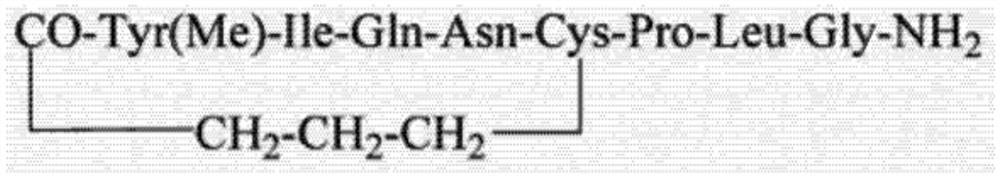

Synthesis method of carbetocin

ActiveCN112094324AImprove the efficiency of the cyclization reactionHigh purityOxytocins/vasopressinsPeptide preparation methodsPharmaceutical drugDrugs preparations

The invention belongs to the field of polypeptide drug preparation methods, and relates to a synthesis method of carbetocin. The synthesis method of carbetocin comprises the following steps of (1) using Rink Amide MBHA Resin as a carrier, performing swelling treatment, and then, sequentially coupling protected Gly, protected Leu, protected Pro, protected Cys, protected Asn, protected Gln, protected Ile and protected Tys to swell Rink Amide-MBHA Resin through a condensation reaction, and performing drying to obtain peptide resin 1; (2) performing reaction on the peptide resin 1 with vinylaceticacid to obtain peptide resin 2; (3) cracking the peptide resin 2 to obtain a carbetocin intermediate I; and (4) performing cyclization reaction on the carbetocin intermediate I to obtain the carbetocin. The synthesis method has the advantages of high reaction selectivity, quick reaction, few by-products and impurities, high yield, safety, environment protection, simplicity and easy operation.

Owner:NINGBO SANSHENG BIOLOGICAL TECH CO LTD

Hydrotalcites, syntheses, and uses

Synthetic hydrotalcites of the general formula[M2+1−xM3+x(OH)2]x+[An−x / n.mH2O]x−where M2+ is a divalent cation, M3+ is a trivalent cation and An− is an organic anion selected from straight chain carboxylates of C16-C18 acids, carboxylates of aromatic acids, carboxylates of acrylic acid, unsaturated carboxylates of methacrylic acid and unsaturated carboxylates of vinylacetic acid are disclosed, along with methods of synthesis and uses.

Owner:SUNOCO INC (R&M)

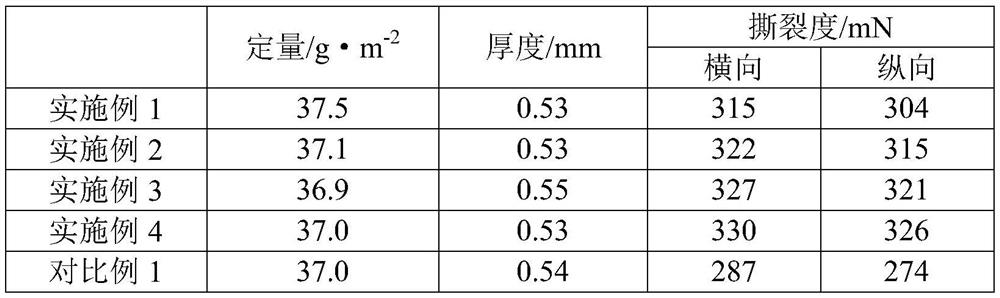

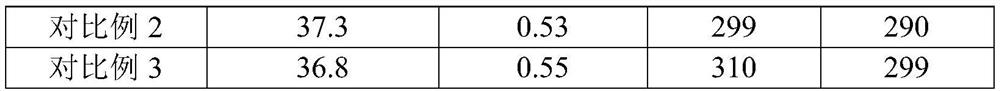

A kind of high tear degree CTP plate backing paper and preparation method thereof

ActiveCN111691219BIncreased isotropic tearImprove retentionNatural cellulose pulp/paperNon-macromolecular organic additionAcetic acidPolymer science

The invention relates to the technical field of papermaking, and discloses a high-tear CTP plate lining paper and a preparation method thereof. The CTP plate backing paper includes the following raw materials: coniferous wood pulp, hardwood pulp, serinol-methyl acrylate-bis(2-hydroxyethyl)amino(trimethylol)methane copolymer, vinyl acetic acid; The mass ratio of coniferous wood pulp and hardwood pulp is 5~8:1; The addition amount of described serinol methyl acrylate bis (2 hydroxyethyl) amino (trimethylol) methane copolymer 2.0-2.5% of the total dry weight of leaf pulp and hardwood pulp; the added amount of vinyl acetic acid is 0.5-0.8% of the total dry weight of softwood pulp and hardwood pulp. The CTP plate backing paper of the present invention is by adding serinol-methyl acrylate-bis(2-hydroxyethyl)amino(trimethylol)methane copolymer inside, and grafting vinyl acetic acid on the surface, effectively improving the Isotropic tearing.

Owner:XIANHE CO LTD

Wear-resistant coated wire with stable structure and preparation method thereof

InactiveCN106243787AImprove the wear resistance coefficientStrong adhesionCoatingsFiberWear resistant

The invention discloses a wear-resistant coated wire with stable structure and a preparation method thereof. The wear-resistant coated wire comprises a wire matrix and a coating. The coating comprises nanometer silica, nanometer calcium carbonate, vinyl acetate, vinyl butyl acetate, polyvinyl alcohol, epoxypropane, polyethylene wax, cellulose ether, fatty alcohol polyoxyethylene ether, acrylate, polydimethylsiloxane, polyethylether, rare earth, attapulgite, montmorillonite, silicon carbide, polyamide, high-carbon ferro-chrome powder and PAN-based carbon fiber. The wear-resistant coated wire with stable structure disclosed in the invention has the advantages of good wear resistance, adhesion, etc.

Owner:安徽飞弧焊业股份有限公司

Preglued nail decorative accessory and making method thereof

InactiveCN1247133CGood removal effectCosmetic preparationsToilet preparationsEmulsionAqueous solution

Owner:KMC EXIM

Polishing pad and method of use

InactiveUS20110244768A1Reduce defectsAbrasion apparatusSemiconductor/solid-state device manufacturingMethacrylateFlexural modulus

Owner:BAJAJ RAJEEV

Composition for treating and coating concrete surface

InactiveCN1425634AImprove moisture resistanceCoatingsWater-setting substance layered productDiseaseAdhesive

The invention relates to a composition for treating the surface of concrete or wall papering to improve the moisture proofing and heat insulating property in concrete structure and to allow a far infrared ray useful to precaution and cure kinds of diseases of the human body to be radiated, the crowd living in houses with concrete structure. The composition is prepared by mixing 30-40 wt% of far infrared ray radiating material and 25-40 wt% of rice bran, and pulverizing the mixture to a size of 150-200 mesh; and mixing 30-45 wt% of adhesive with the mixture uniformly. The far infrared ray radiating material is selected from: mica, yellow soil powder, vermiculite, silica and mixture thereof; the adhesive is selected from: an acetic vinyl resin emulsion, an urea resin, a poly(vinyl alcohol), a glue and a OKONG bond and mixture thereof. Moreover, composition also includes charcoal powder.

Owner:吴忠一

High-tearability CTP plate backing paper and preparation method thereof

ActiveCN111691219AIncreased isotropic tearImprove retentionNatural cellulose pulp/paperNon-macromolecular organic additionMeth-Papermaking

The invention relates to the technical field of papermaking, and discloses high-tearability CTP plate backing paper and a preparation method thereof. The CTP plate backing paper is prepared from the following raw materials: softwood pulp, hardwood pulp, serinol-methyl acrylate-bis(2-hydroxyethyl)amino(trismethylol)methane copolymer and vinylacetic acid, wherein the mass ratio of the softwood pulpto the hardwood pulp is 5-8: 1; the dosage of the serinol-methyl acrylate-bis(2-hydroxyethyl)amino(trismethylol)methane copolymer is 2.0-2.5% of the total dry weight of the softwood pulp and the hardwood pulp; the dosage of the vinylacetic acid is 0.5-0.8% of the total dry weight of the softwood pulp and the hardwood pulp. According to the CTP backing paper, the serinol-methyl acrylate-bis(2-hydroxyethyl)amino(trismethylol)methane copolymer is added into the CTP backing paper, and the surface of the CTP backing paper is grafted with the vinylacetic acid, so that the tearing strength in all directions is effectively improved.

Owner:XIANHE CO LTD

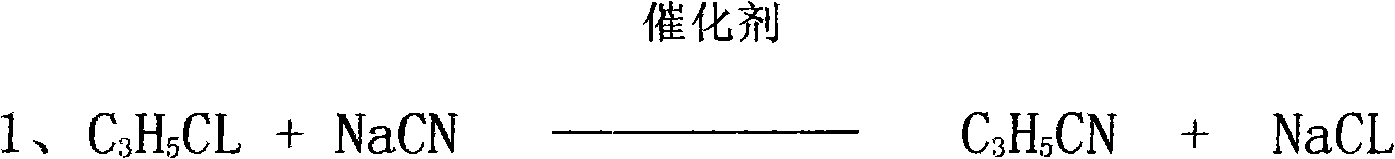

Preparation method of vinyl isobutyl acetate

ActiveCN101781206AImprove responseEasy to implementOrganic compound preparationCarboxylic acid esters preparationIsobutyl alcoholIsobutyl acetate

The invention relates to a new synthesis way of vinyl isobutyl acetate, belonging to the field of medicine intermediate synthesis technology. The preparation method of the vinyl isobutyl acetate comprises the steps of: first, using chloropropene and sodium cyanide to prepare allylcyanide under the action of catalyst based on quantitative mixture ratio; after alkaline washing and water washing, leading the allylcyanide to react with isobutyl alcohol and concentrated hydrochloric acid in the water to prepare the vinyl isobutyl acetate; and finally, after alkaline washing and water washing, preparing finished product of the vinyl isobutyl acetate in a layered way. The method has the characteristics of being short in process route, not adopting solvent, being mild in condition, high in yield,easy in implementation of reaction and the like.

Owner:WEIFANG DACHENG SALT & CHEM IND

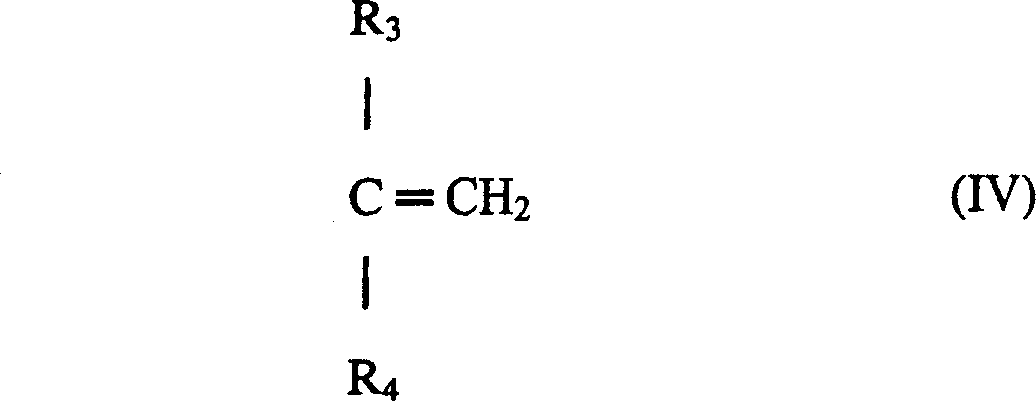

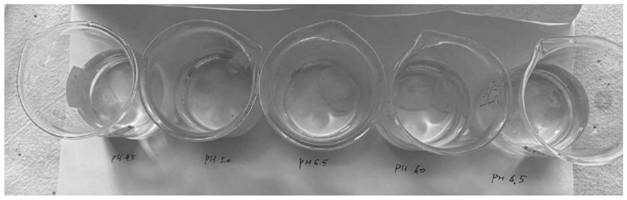

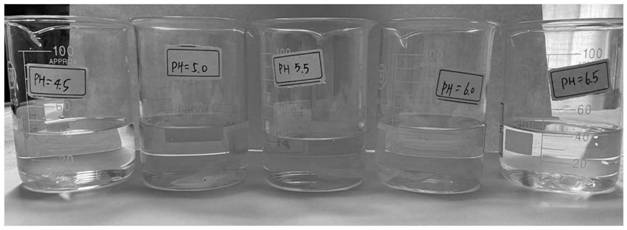

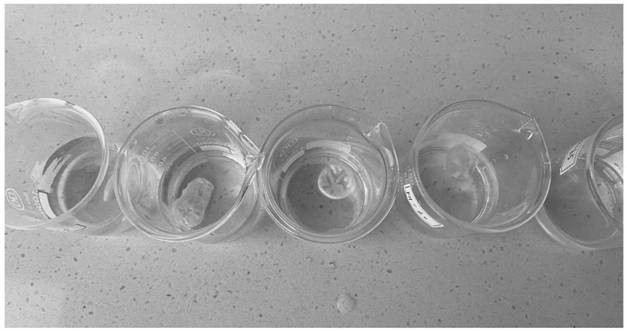

Olefin acid resin and preparation method thereof

The invention belongs to the technical field of polymers, and discloses olefinic acid resin. The resin is obtained by forming a mixed monomer from olefinic acid and olefinic acid ester according to a ratio of (60-80wt%):(20-40wt%) through free radical polymerization. The olefin acid is composed of the following components: 15-35 wt% of vinyl acetic acid, 20-35 wt% of acrylic acid, and 40-60 wt% of butenoic acid. The olefin acid ester is composed of the following components: 10-15 wt% of hydroxyethyl methylacrylate, 5-10 weight percent of acrylic acid-2-hydroxyethyl ester, 30-35 weight percent of 2-propyl ethyl acrylate, and 40-45 wt% of ethyl acrylate. In the pH range of 5.5-6, the auxiliary material can rapidly swell / dissolve, and the swelling / dissolving speed of the auxiliary material is obviously reduced when the pH range is exceeded.

Owner:贵州省欣紫鸿药用辅料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com