Preparation method of vinyl isobutyl acetate

A technology based on isobutyl acetate and vinyl, applied in the field of drug synthesis, can solve the problems of harsh reaction conditions, cumbersome process routes, and low product yields, and achieve the effects of easy reaction, short process route, and good yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

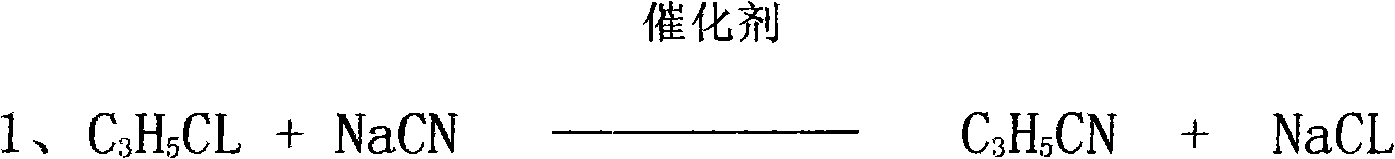

[0026] (1) Preparation of allyl cyanide (II): 100ml deionized water, 2gNa 3 PO 4 and 4gCuCL 2 Put it into a 500ml flask, stir and heat up to 23°C, drop in 40g of allyl chloride, stir evenly, and then dropwise add 85g of a mass concentration of 30% sodium cyanide solution to the flask, and use hydrochloric acid to adjust the pH value to about 4 during the dropping process. The temperature is 38°C-42°C; keep the temperature for 4 hours after the dropwise addition is completed.

[0027] (2) Purification treatment of allyl cyanide (II): in the flask filled with allyl cyanide (II), add dropwise a mass concentration of 15% dilute sodium carbonate aqueous solution for neutralization, adjust the pH value to about 7, and then use 400ml to remove Wash with deionized water for three times, and the temperature is controlled at 42°C. After standing still for 0.5 hours, the organic layer was separated. Weighed allyl cyanide (III) 32.9g.

[0028] (3) Preparation of crude isobutyl vinyl ...

Embodiment 2

[0031] (1) Preparation of allyl cyanide (II): 80ml deionized water, 2g Na 3 PO 4 and 4g CuCl 2 Put it into a 500ml flask, stir and heat up to 20°C, put in 40g of allyl chloride, stir evenly, add 85g of sodium cyanide solution with a mass concentration of 30% dropwise into the flask, adjust the pH value to 6 with hydrochloric acid during the dropwise addition, and control the temperature 40°C-42°C; keep warm for 1 hour after the dropwise addition is completed.

[0032] (2) Purification treatment of allyl cyanide (II): dropwise add mass concentration 20% sodium hydroxide solution in the flask containing allyl cyanide (II) for neutralization, adjust the pH value to 6.5, and then use 400ml deionized Water washing, washing three times, the temperature is controlled at 45 ℃. After standing for 1 hour, the layers were separated, and the organic layer was separated. Weighed allyl cyanide (III) 32.9g.

[0033] (3) Preparation of crude isobutyl vinyl acetate (IV): 32.9 g of allyl c...

Embodiment 3

[0036] (1) Preparation of allyl cyanide (II): 120ml deionized water, 2g Mg 3 (PO 4 ) 2 and 4gCuSO 4 Put it into a 500ml flask, stir and heat up to 30°C, drop in 40g of allyl chloride, stir evenly, and then dropwise add 85g of a mass concentration of 30% sodium cyanide solution to the flask, and use hydrochloric acid to adjust the pH value to about 3 during the dropping process. The temperature is 38°C-40°C; after the dropwise addition, keep warm for 2 hours.

[0037] (2) Purification treatment of allyl cyanide (II): add dropwise a mass concentration of 15% dilute sodium carbonate aqueous solution in the flask containing allyl cyanide (II) for neutralization, adjust the pH value to 7.5, and then use 3500ml deionized Water washing, washing three times, the temperature is controlled at 40 ℃. After standing still for 0.5 hours to separate the layers, the organic layer was separated and weighed to obtain 32.9 g of allyl cyanide (III).

[0038](3) Preparation of crude isobutyl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com