Carboxylate-vinyl ester copolymer blend compositions for lubricating oil flow improvement

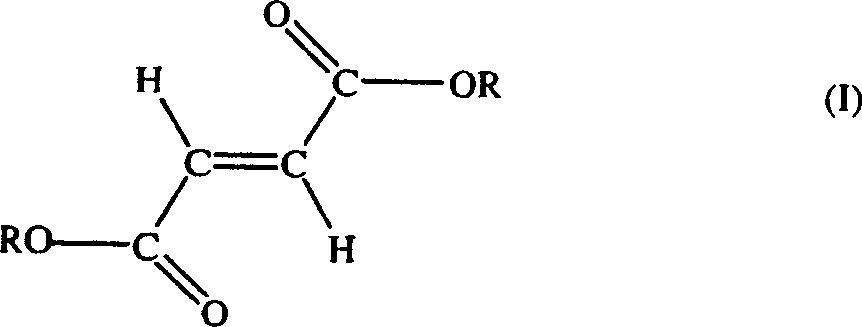

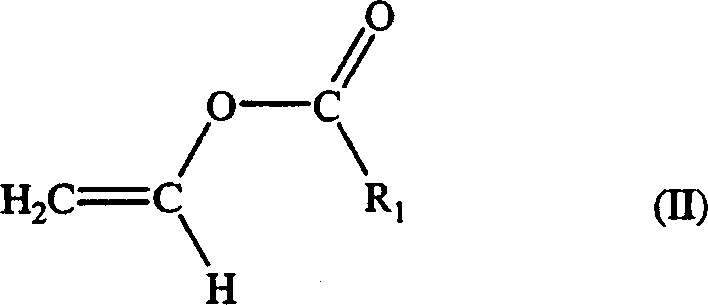

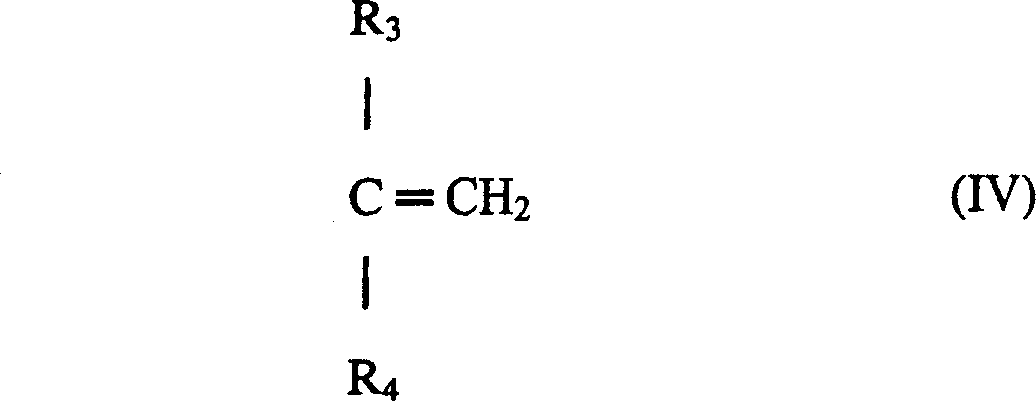

A kind of lubricating oil composition, technology of flow improver, applied in improved lubricating oil composition, fumaric acid ester, compound of carbon number, improve the flow performance of oily composition specifically engine crankcase lubricating composition, Additives for improving its flow properties, additives for low-temperature flow properties, and lubricating oil compositions, which can solve the problem of no disclosure of binary pour point depressants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0114] In group II base material C 12.0 -FVA and C 13.2 -Comparison of FVA with commercially available LOFIs

[0115]A SAE 5W-30 formulation was prepared containing 9.75% of a detergent-inhibitor additive package (comprising the following components: polyisobutenyl succinimide dispersant, calcium sulfonate detergent, zinc dialkyldithiophosphate resistant grinding agent, diarylamine antioxidant), 8.10% viscosity index improver and 82.15% Group II binder. The viscosity index improver consisted of a mixture of 20 wt% ethylene-propylene copolymer containing 50 wt% ethylene and 80 wt% ethylene-propylene copolymer containing 72 wt% ethylene. The base stock has a kinematic viscosity of 22 cSt at 40°C and 4.5 cSt at 100°C, a viscosity index of 118 and a pour point of -18°C. The resulting LOFI-free formulation had a cold start viscosity of 2,500 cP in the CCS test at -25°C and a pour point of -21°C.

[0116] A comparison of the low-temperature performance of various LOFIs is given ...

Embodiment 2

[0124] Formulations containing high-ethylene content olefin copolymer viscosity index improvers

[0125] A SAE 5W-30 formulation was prepared containing 9.75% of the detergent-inhibitor additive package (as described in Example 1), 8.60% of viscosity index improver, and 81.65% of Group II binder. The viscosity index improver is an ethylene-propylene copolymer containing 72 wt% ethylene. The base stock has a kinematic viscosity of 22 cSt at 40°C and 4.5 cSt at 100°C, a viscosity index of 118 and a pour point of -18°C. The resulting LOFI-free formulation had a CCS viscosity of 2,300 cP at -25°C and a pour point of -21°C.

[0126] The use of high ethylene OCPs in such formulations disadvantageously increases the pour point of the lubricating oil. To overcome this pour point disadvantage, the prior art has taught that high- and low-ethylene OCP compositions can be used (see Engel et al. US 3,697,429). But this approach represents a compromise. When adding a low-ethylene OCP to...

Embodiment 3

[0134] In a mixture of Group I and Group III base materials C 12.0 -FVA and C 13.2 -Comparison of FVA with standard LOFIs

[0135] A SAE 5W-30 formulation was prepared containing 8.90% detergent-inhibitor additive package (as described in Example 1), 8.50% viscosity index improver, and 45.43% Group I base and 37.17% Group III Binder. The viscosity index improver consisted of a mixture of 20 wt% ethylene-propylene copolymer containing 50 wt% ethylene and 80 wt% ethylene-propylene copolymer containing 72 wt% ethylene.

[0136] As shown in Table 5, no matter the standard LOFIs (LOFI-1 and LOFI-3 as described above; LOFI-4 is a dialkyl fumarate / vinyl acetate with an average side chain carbon number of 14.0 copolymers), nor combinations thereof, failed to achieve acceptable performance in this base mixture (all failed at yield stress). but C 12.0 -FVA and C 13.2 - Composition of FVA leads to very good low temperature performance.

[0137] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com