Polishing pad and method of use

a technology of polishing pad and surface, which is applied in the field of polishing pad, can solve the problems of ineffective removal and common surface defects of hard pads, and achieve the effect of reducing the number of sand particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

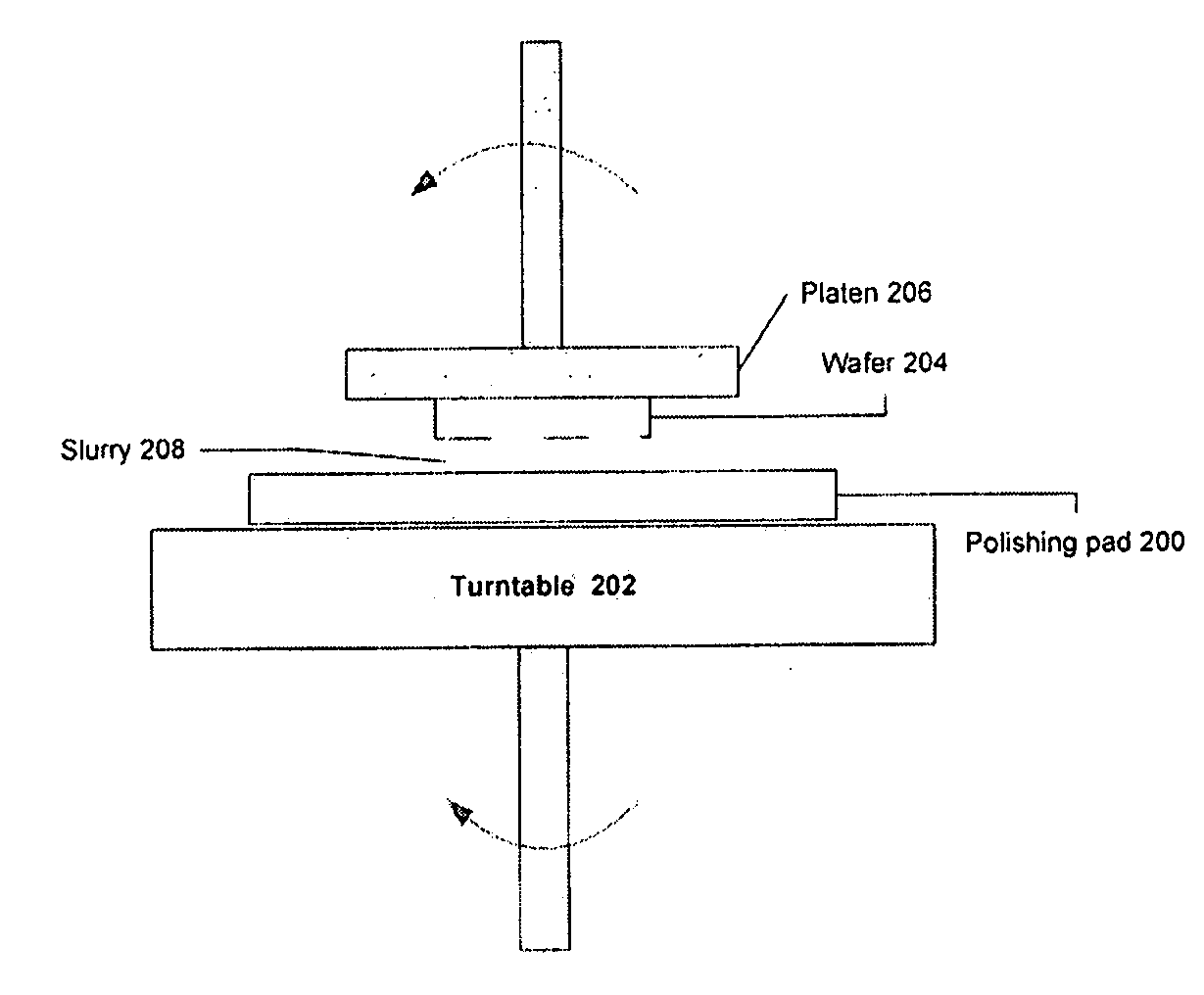

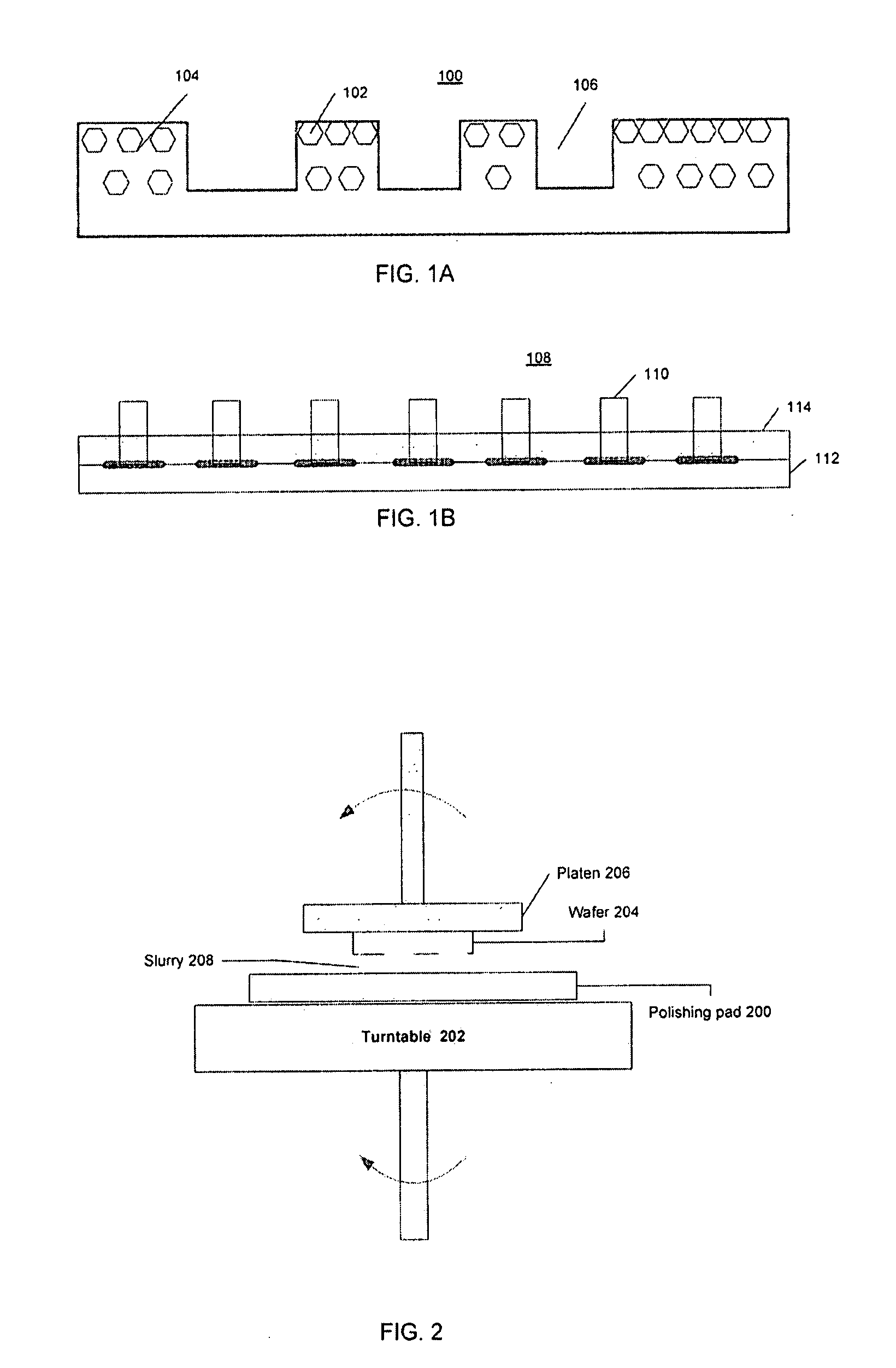

[0012]Described herein are a polishing pad with reduced defectivity, methods of using such a pad, and materials useful for making CMP polishing pads with reduced defectivity. As indicated above, CMP involves removing films from the surface of a wafer by pressing a polishing pad against the wafer and rotating these elements relative to one another in the presence of a polishing composition (e.g., a slurry). During the polishing process, a slurry layer forms between the wafer and the pad, thus forming a hydrodynamic boundary layer. Maintaining a uniform fluid layer between the pad and wafer during polishing is important. In cases where the boundary layer is minimized or completely eliminated, the pad may directly contact the wafer leading to a two-body interaction causing higher defectivity. In contrast, a highly lubricated interface will allow more uniform polishing, as well as minimize defectivity. This is particularly important in the case of copper CMP, where the film being polish...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com