A kind of high tear degree CTP plate backing paper and preparation method thereof

A technology of tearing degree and backing paper, which is applied in the field of papermaking, can solve the problems of affecting the forming, damage and influence of the net part, and achieve the effect of increasing the degree of tearing in all directions and improving the degree of tearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

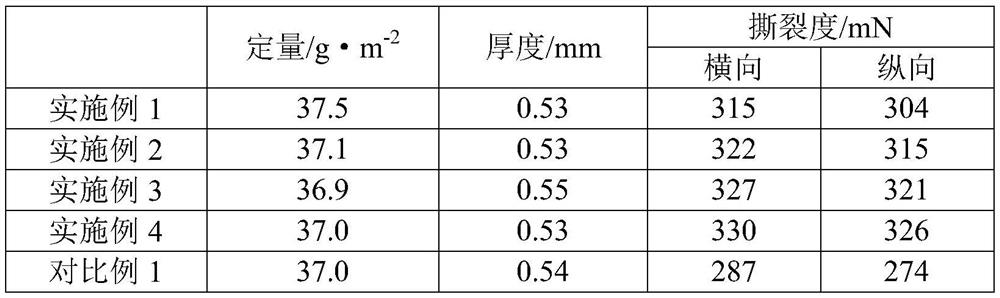

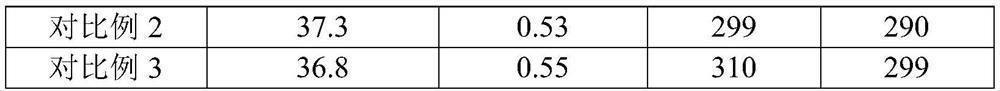

Examples

Embodiment 1

[0062] A CTP plate backing paper, comprising the following raw materials: coniferous wood pulp, hardwood pulp, serinol-methyl acrylate-bis(2-hydroxyethyl)amino(trimethylol)methane copolymer, vinyl acetic acid; The mass ratio of described coniferous wood pulp and hardwood pulp is 5:1; The addition amount of described serinol-methyl acrylate-bis(2-hydroxyethyl)amino(trimethylol)methane copolymer is 2.0% of the total dry weight of leaf wood pulp and hardwood pulp; the addition of the vinyl acetic acid is 0.5% of the total dry weight of softwood pulp and hardwood pulp.

[0063] Prepare the above-mentioned CTP plate backing paper by the following steps:

[0064] (1) Preparation of serinol-methyl acrylate-bis(2-hydroxyethyl)amino(trimethylol)methane copolymer:

[0065] (1.1) Under nitrogen protection and a temperature of 25° C., a mixed solution of methyl acrylate and methanol was added dropwise to a methanol solution of serinol, and reacted for 4 hours; then methanol and unreacted...

Embodiment 2

[0077] A CTP plate backing paper, comprising the following raw materials: coniferous wood pulp, hardwood pulp, serinol-methyl acrylate-bis(2-hydroxyethyl)amino(trimethylol)methane copolymer, vinyl acetic acid; The mass ratio of described softwood pulp and hardwood pulp is 6.5:1; The addition amount of described serinol-methyl acrylate-bis(2-hydroxyethyl)amino(trimethylol)methane copolymer is 2.3% of the total dry weight of leaf wood pulp and hardwood pulp; the addition of the vinyl acetic acid is 0.6% of the total dry weight of softwood pulp and hardwood pulp.

[0078] Prepare the above-mentioned CTP plate backing paper by the following steps:

[0079] (1) Preparation of serinol-methyl acrylate-bis(2-hydroxyethyl)amino(trimethylol)methane copolymer:

[0080](1.1) Under nitrogen protection and a temperature of 27°C, add the mixed solution of methyl acrylate and methanol dropwise to the methanol solution of serinol and react for 3.5 hours; then distill under reduced pressure to...

Embodiment 3

[0092] A CTP plate backing paper, comprising the following raw materials: coniferous wood pulp, hardwood pulp, serinol-methyl acrylate-bis(2-hydroxyethyl)amino(trimethylol)methane copolymer, vinyl acetic acid; The mass ratio of described coniferous wood pulp and hardwood pulp is 8:1; The addition amount of described serinol-methyl acrylate-bis(2-hydroxyethyl)amino(trimethylol)methane copolymer is 2.5% of the total dry weight of leaf wood pulp and hardwood pulp; the addition of the vinyl acetic acid is 0.8% of the total dry weight of softwood pulp and hardwood pulp.

[0093] Prepare the above-mentioned CTP plate backing paper by the following steps:

[0094] (1) Preparation of serinol-methyl acrylate-bis(2-hydroxyethyl)amino(trimethylol)methane copolymer:

[0095] (1.1) Under nitrogen protection and a temperature of 30° C., a mixed solution of methyl acrylate and methanol was added dropwise to a methanol solution of serinol, and reacted for 3 h; then methanol and unreacted met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com