Olefin acid resin and preparation method thereof

A technology of olefinic acid and olefinic acid ester, applied in the polymer field, which can solve the problems of coating and release effects, and no company has developed excipients, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

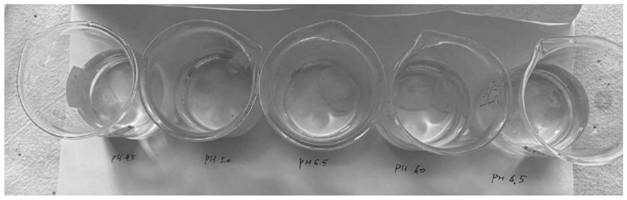

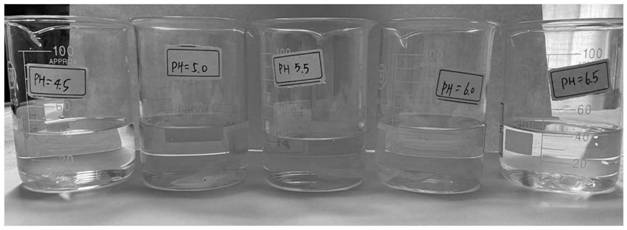

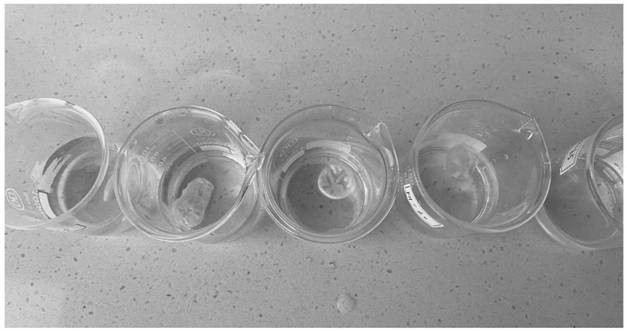

Image

Examples

Embodiment 1

[0056] A kind of synthetic method of alkene acid resin, comprises the steps:

[0057] Step 1: Mixing monomers, water, and emulsifiers to prepare a monomer emulsion;

[0058] Mixed monomers are 100g, including 70g of olefinic acid and 30g of olefinic acid ester;

[0059] Alkenic acids consist of the following components:

[0060] Vinyl acetic acid: 30wt%;

[0061] Acrylic acid: 25wt%;

[0062] Crotonic acid: 45wt%;

[0063] Alkenic acid esters consist of the following components:

[0064] Hydroxyethyl methacrylate: 13wt%;

[0065] -2-hydroxyethyl acrylate: 8wt%;

[0066] Ethyl 2-propyl acrylate: 32wt%;

[0067] Ethyl acrylate: 42wt%;

[0068] The emulsifier is cetyltrimethylammonium chloride, the dosage is 4g;

[0069] 300g of water;

[0070] Step 2: Put 80% of the monomer emulsion in the reaction vessel, raise the temperature to the initiation temperature of 50-65°C, add the initiator solution and the remaining monomer emulsion dropwise, and add the dropwise time for...

Embodiment 2

[0074] A kind of synthetic method of alkene acid resin, comprises the steps:

[0075] Step 1: Mixing monomers, water, and emulsifiers to prepare a monomer emulsion;

[0076] Mixed monomer is 100g, wherein, olefinic acid 80g, olefinic acid ester 20g;

[0077] Alkenic acids consist of the following components:

[0078] Vinyl acetic acid: 35wt%;

[0079] Acrylic acid: 20wt%;

[0080] Crotonic acid: 45wt%;

[0081] Alkenic acid esters consist of the following components:

[0082] Hydroxyethyl methacrylate: 15wt%;

[0083] -2-hydroxyethyl acrylate: 5wt%;

[0084] Ethyl 2-propyl acrylate: 35wt%;

[0085] Ethyl acrylate: 45wt%;

[0086] The emulsifier is cetyltrimethylammonium chloride, the dosage is 2g;

[0087] 300g of water;

[0088] Step 2: Put 80% of the monomer emulsion in the reaction vessel, raise the temperature to the initiation temperature of 50-65°C, add the initiator solution and the remaining monomer emulsion dropwise, and add the dropwise time for 1 hour;

...

Embodiment 3

[0092] A kind of synthetic method of alkene acid resin, comprises the steps:

[0093] Step 1: Mixing monomers, water, and emulsifiers to prepare a monomer emulsion;

[0094] Mixed monomers are 100g, including 60g of olefinic acid and 40g of olefinic acid ester;

[0095] Alkenic acids consist of the following components:

[0096] Vinyl acetic acid: 15wt%;

[0097] Acrylic acid: 35wt%;

[0098] Crotonic acid: 50wt%;

[0099] Alkenic acid esters consist of the following components:

[0100] Hydroxyethyl methacrylate: 10wt%;

[0101] 2-hydroxyethyl acrylate: 10wt%;

[0102] Ethyl 2-propyl acrylate: 35wt%;

[0103] Ethyl acrylate: 45wt%;

[0104] The emulsifier is cetyltrimethylammonium chloride, the dosage is 2g;

[0105] 300g of water;

[0106] Step 2: Put 90% of the monomer emulsion in the reaction container, raise the temperature to the initiation temperature of 50-65°C, add the initiator solution and the remaining monomer emulsion dropwise, and add the dropwise time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com