Catalytic cracking fractionating tower oil slurry circulating heating system

A catalytic cracking and fractionation tower technology, applied in fractionation, distillation separation, separation methods, etc., can solve the problems of oil slurry coking, achieve the effect of improving the quality of oil slurry, solving the problem of oil slurry coking, and avoiding tower flushing accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

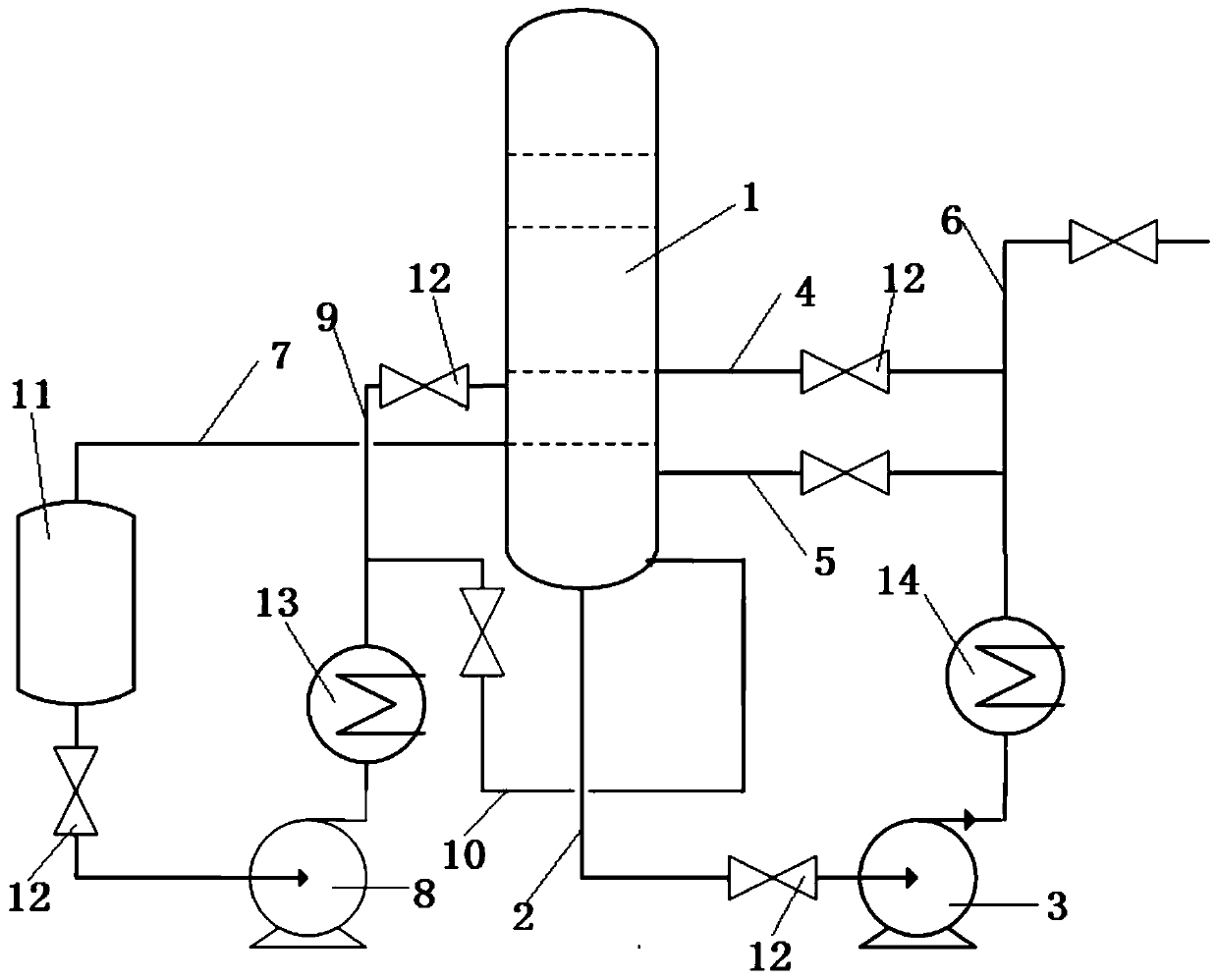

[0020] like figure 1 As shown, the present embodiment provides a catalytic cracking fractionation tower oil slurry circulation heat extraction system, comprising a fractionation tower 1, the oil slurry outlet at the bottom of the fractionation tower 1 is connected with an oil slurry discharge pipe 2, and the oil slurry discharge An oil slurry pump 3 is provided on the pipe 2, and the outlet of the oil slurry discharge pipe 2 is connected to the feed port of the first heat exchanger 14, and the heat exchange medium of the first heat exchanger 14 is deoxygenated water at 103°C. The outlet of a heat exchanger 14 is respectively connected with the oil slurry pipe 4 of the upper return tower, the oil slurry pipe 5 of the lower return tower and the oil slurry pipe 6 of the outer return tower, and the outlet of the oil slurry pipe 4 of the upper return tower is connected with the upper part of the fractionation tower 1. The oil slurry port of the return tower is connected, the outlet...

Embodiment 2

[0023] On the basis of embodiment 1, it also includes the oil refinery tank 11, the fractionation tower 1, the oil refinery tank 11 and the second heat exchanger 13 are connected successively by the oil refinery discharge pipe 7, and the oil refinery tank 11 can play a role The role of pipeline buffer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com