Conduction oil system

A heat-conducting oil and heat-conducting oil circuit technology, used in the transportation of passenger cars, tank cars, railway car body parts, etc., can solve the problems of heat-conducting oil generating organic acid, equipment corrosion, etc., to prolong the life of equipment, safe production process, and avoid kinematic viscosity. added effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

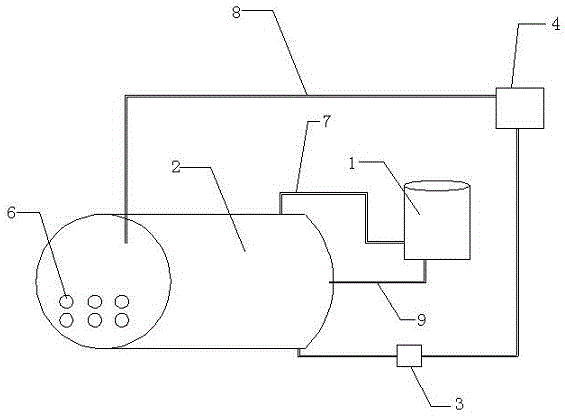

[0007] Such as figure 1 As shown, a heat transfer oil system includes a heat transfer oil circuit 8 and a heat transfer oil anti-oxidation device. The heat transfer oil circuit 8 is composed of an oil storage tank 2, a gear oil pump 3 and a reactor 4 connected in series through oil pipes. The heat transfer oil anti-oxidation device includes a cold oil container 1, the heat transfer oil with a temperature lower than 70 degrees Celsius is added in the cold oil container 1, a thermometer is fixed on the cold oil container 1, and the cold oil container 1 The bottom is connected to the oil storage tank 2 through the oil pipe 9, and the exhaust pipe 7 on the upper part of the oil storage tank 2 is connected to the cold oil container 1, and the mouth of the exhaust pipe 7 in the cold oil container 1 is located at the heat transfer oil level the following.

[0008] When in use, the electric heater 6 heats the oil storage tank 2, and the air is isolated by the heat-conducting oil whos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com