Smokeless vehicle diesel oil and preparation method thereof

A technology for diesel and vehicles, which is applied in the petroleum industry, liquid carbon-containing fuels, fuel additives, etc. It can solve the problems of high production cost, high proportion of standard kerosene added, smokeless or low-smoke diesel that cannot meet the national standard requirements, etc. Achieve good safety performance, reduce sulfide content and carbon monoxide content, and good start-up performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

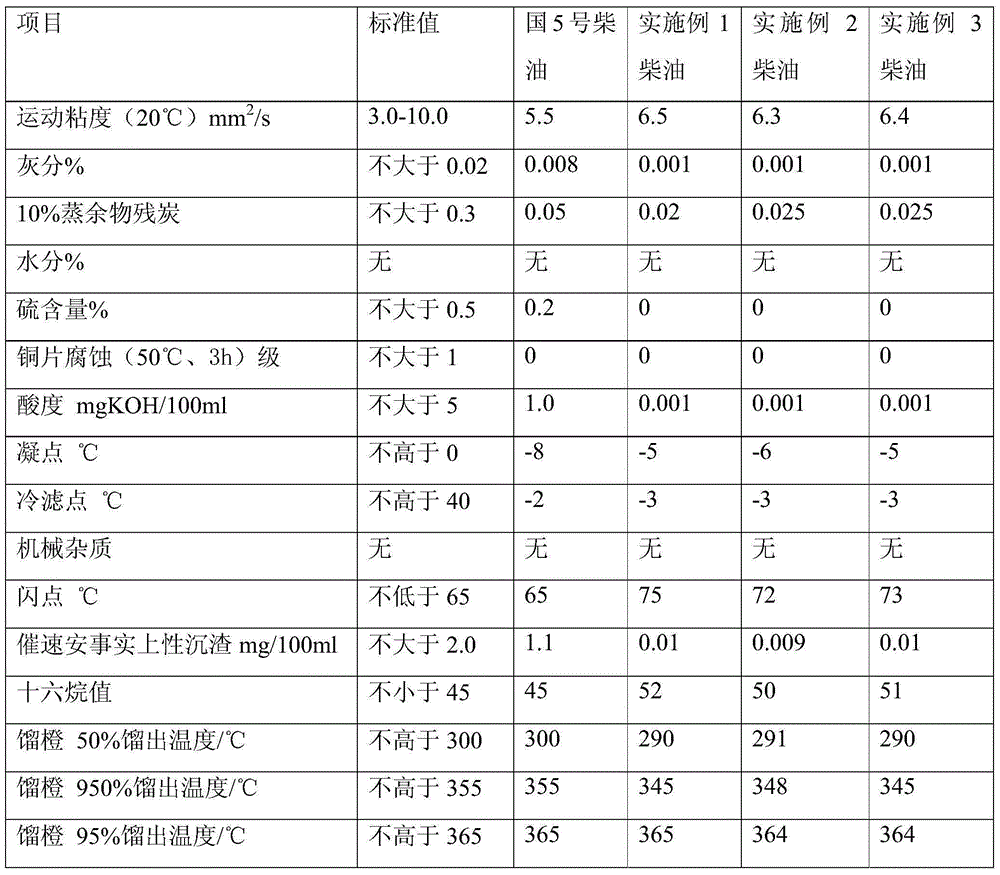

Examples

Embodiment 1

[0026] A kind of diesel oil for smokeless vehicles, including: 200kg of kerosene, 100kg of vegetable oil, 250kg of refined waste oil, 300kg of self-made smokeless oil, 50kg of antifreeze and pour point depressant, 10kg of standard increasing agent, and 35kg of flame retardant.

[0027] Described kerosene is commercially available aviation kerosene, purchased from Qingdao Sanmu Environmental Protection Technology Co., Ltd.; described vegetable oil is soybean oil, purchased from Tianjin Fuying Industry and Trade Co., Ltd.; described antifreeze and pour point depressant are commercially available products, Purchased from Wuhan Xingyinhe Chemical Co., Ltd.; the standard increase agent was purchased from Beijing Loctite Chemical Store; the described flame retardant was commercially available and purchased from Beijing Loctite Chemical Store.

[0028] Described finishing waste oil is prepared by the following method:

[0029] ①Removal of impurities: put the purchased waste oil into ...

Embodiment 2

[0039] A kind of diesel oil for smokeless vehicles, including: 180kg of kerosene, 110kg of vegetable oil, 250kg of refined waste oil, 300kg of self-made smokeless oil, 50kg of antifreeze and pour point depressant, 10kg of standard increasing agent, and 35kg of flame retardant.

[0040] The types and purchasers of kerosene, antifreeze and pour point depressant, standard-increasing agent, and flame retardant are the same as in Example 1, and the preparation methods of refined waste oil and self-made smoke-free oil are all the same as in Example 1. The preparation method of diesel oil is the same as that of Example 1; the difference is that the vegetable oil is peanut oil, purchased from Tianjin Fuying Industry and Trade Co., Ltd. The No. II smoke-free vehicle diesel oil was prepared.

Embodiment 3

[0042] A kind of diesel oil for smokeless vehicles, including: 220kg of kerosene, 90kg of vegetable oil, 250kg of refined waste oil, 300kg of self-made smokeless oil, 50kg of antifreeze and pour point depressant, 10kg of standard increasing agent, and 35kg of flame retardant.

[0043] The types and purchasers of kerosene, antifreeze and pour point depressant, standard-increasing agent, and flame retardant are the same as in Example 1, and the preparation methods of refined waste oil and self-made smoke-free oil are all the same as in Example 1. The preparation method of diesel oil is the same as that of Example 1; the difference is that the vegetable oil is Jatropha curcas seed oil, purchased from Tianjin Fuying Industry and Trade Co., Ltd. No. III diesel oil for smoke-free vehicles was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com