Long-acting steel wire rope hemp core grease

A technology of steel wire rope and hemp core grease, applied in the field of lubricating and protective materials, can solve the problems of reducing the service life of steel wire rope, shortening the service life, prone to accidents, etc., achieving stable working state and structure, improving oxidation resistance, and good shear stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

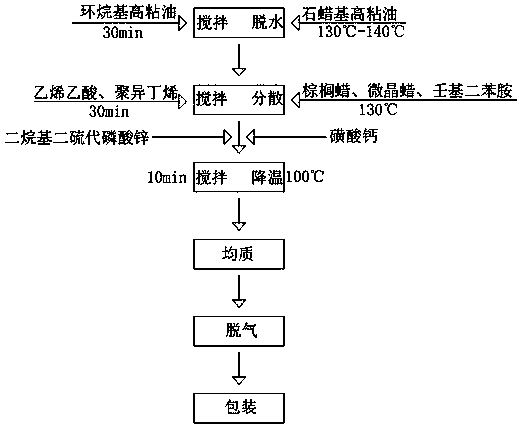

Method used

Image

Examples

Embodiment 1

[0022] A long-acting steel wire rope hemp core grease, the weight ratio of each component of the long-acting steel wire rope hemp core grease is as follows: palm wax 13%, microcrystalline wax 19%, naphthenic high viscosity oil 15%, paraffin base high viscosity oil 28% , zinc dialkyl dithiophosphate 1.6%, nonyl diphenylamine 1.4%, ethylene acetic acid 8.5%, polyisobutylene 12.5%, calcium sulfonate 1%, ethylene acetic acid is ethylene-vinyl acetate copolymer, calcium sulfonate is a A kind of synthetic calcium sulfonate with high base value, among which, palm wax and microcrystalline wax have good compatibility and high melting point. At the same time, it has strong affinity for naphthenic high-viscosity oil and paraffin-based high-viscosity oil, and has excellent solubility, Dispersion force, can quickly form a lubricating colloidal structure, and act as a thickener. Because of the double-ring structure, the naphthenic high-viscosity oil has a good shear stability of the colloida...

Embodiment 2

[0030] A long-acting steel wire rope hemp core grease, the weight ratio of each component of the long-acting steel wire rope hemp core grease is as follows: palm wax 17%, microcrystalline wax 16%, naphthenic high viscosity oil 19%, paraffin base high viscosity oil 24% , zinc dialkyl dithiophosphate 4.6%, nonyl diphenylamine 4.4%, ethylene acetic acid 6.4%, polyisobutylene 8.5%, calcium sulfonate 0.1%, ethylene acetic acid is ethylene-vinyl acetate copolymer, calcium sulfonate is a A high base number synthetic calcium sulfonate.

[0031] The present invention also provides a preparation method of long-acting steel wire rope hemp core grease: comprising the following steps:

[0032] S1): Put naphthenic-based high-viscosity oil and paraffin-based high-viscosity oil into the reaction tank, heat up to 135°C, stir for 30 minutes, and dehydrate to obtain the first prefabricated material;

[0033] S2): Put palm wax, microcrystalline wax, nonyl diphenylamine, ethylene acetic acid and ...

Embodiment 3

[0038] A long-acting steel wire rope hemp core grease, the weight ratio of each component of the long-acting steel wire rope hemp core grease is as follows: palm wax 16%, microcrystalline wax 18%, naphthenic high-viscosity oil 18%, paraffin-based high-viscosity oil 27% , zinc dialkyl dithiophosphate 3%, nonyl diphenylamine 2.9%, ethylene acetic acid 4.5%, polyisobutylene 10%, calcium sulfonate 0.6%, ethylene acetic acid is ethylene-vinyl acetate copolymer, calcium sulfonate is a A high base number synthetic calcium sulfonate.

[0039] The present invention also provides a preparation method of long-acting steel wire rope hemp core grease: comprising the following steps:

[0040] S1): Put naphthenic-based high-viscosity oil and paraffin-based high-viscosity oil into the reaction tank, heat up to 140°C, stir for 30 minutes, and dehydrate to obtain the first prefabricated material;

[0041]S2): Put palm wax, microcrystalline wax, nonyl diphenylamine, ethylene acetic acid and pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com