Method for preparing biodiesel by using biological enzyme

A biodiesel and bio-enzyme technology, applied in the field of oil chemistry, can solve the problems of short service life of bio-enzyme, unsatisfactory catalytic effect, low conversion efficiency, etc., achieve high conversion rate, promote catalytic efficiency, and reduce shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

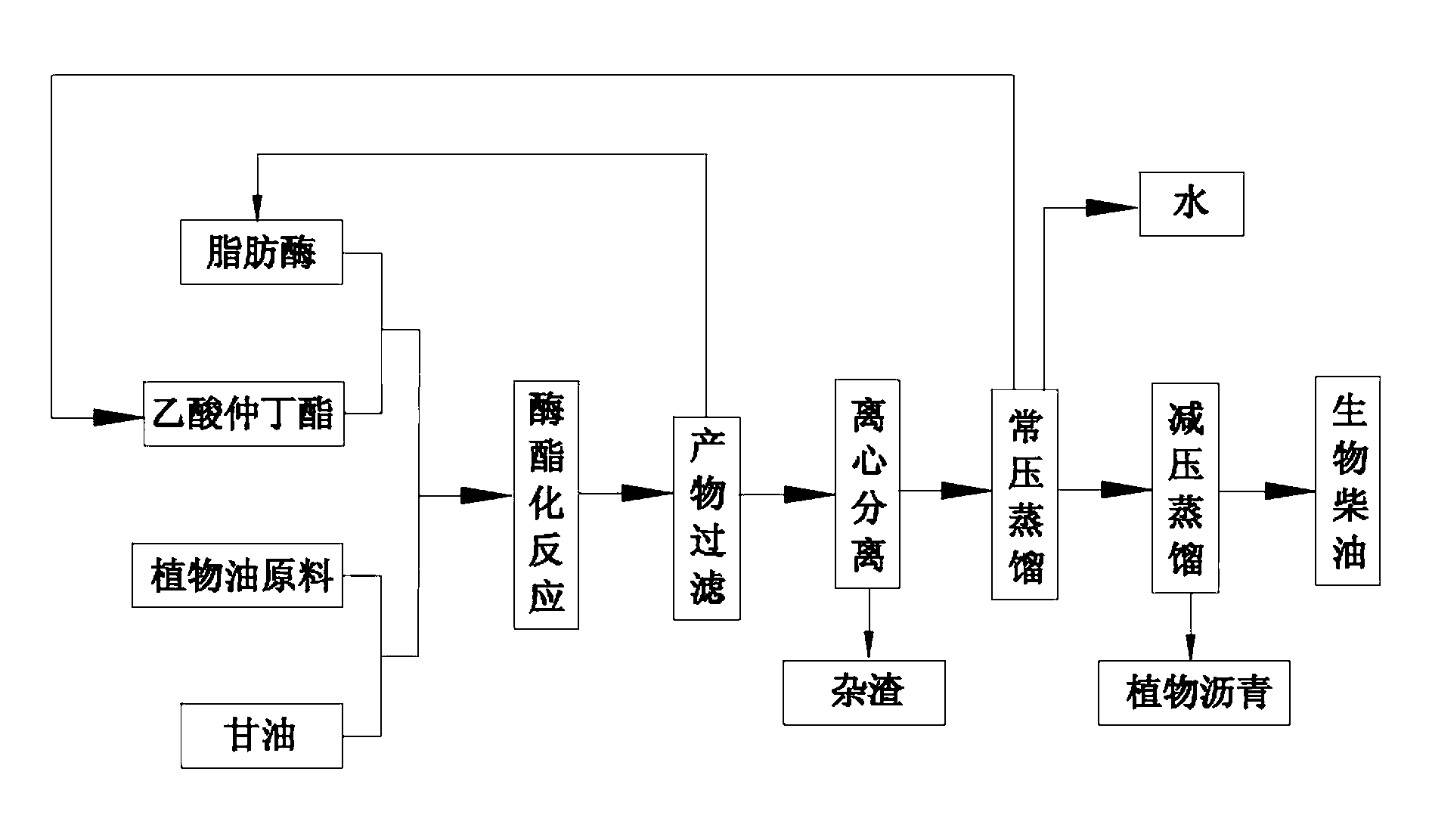

Method used

Image

Examples

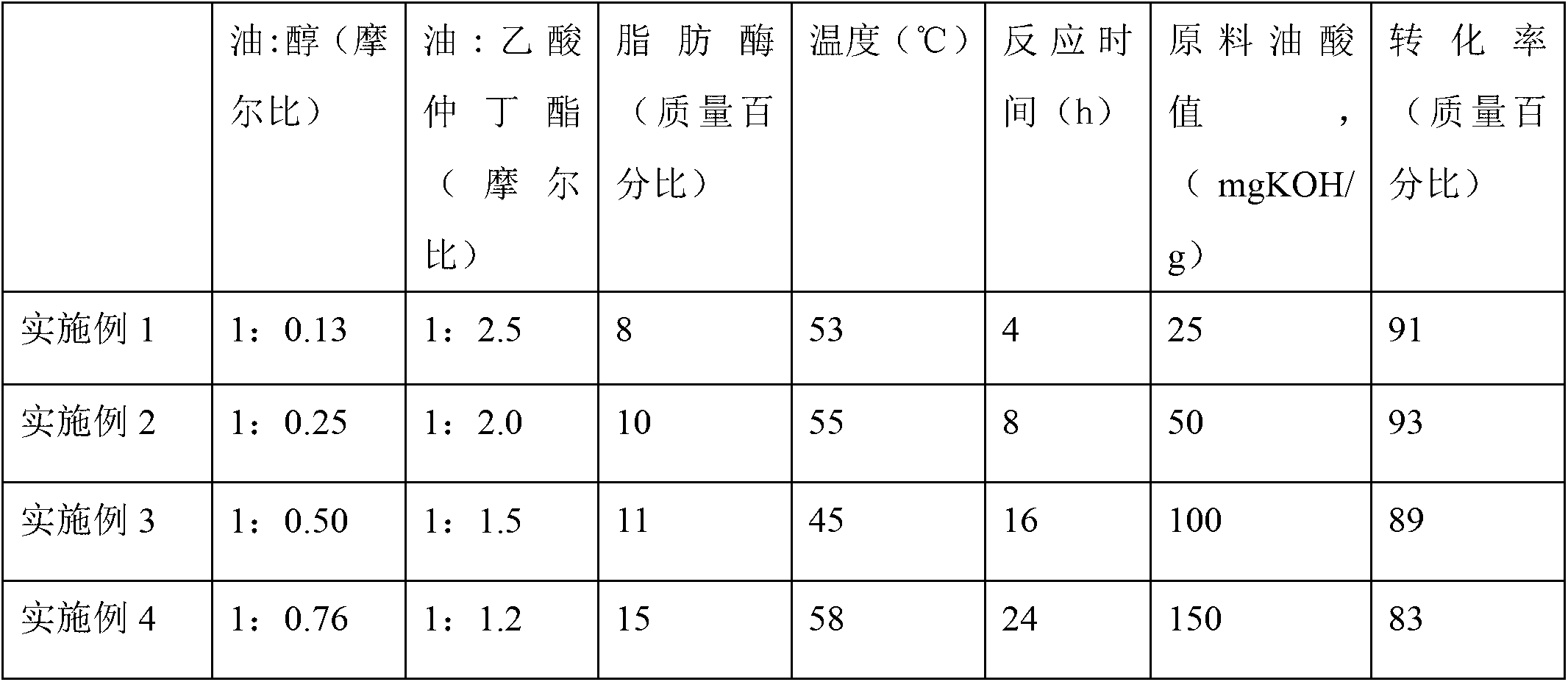

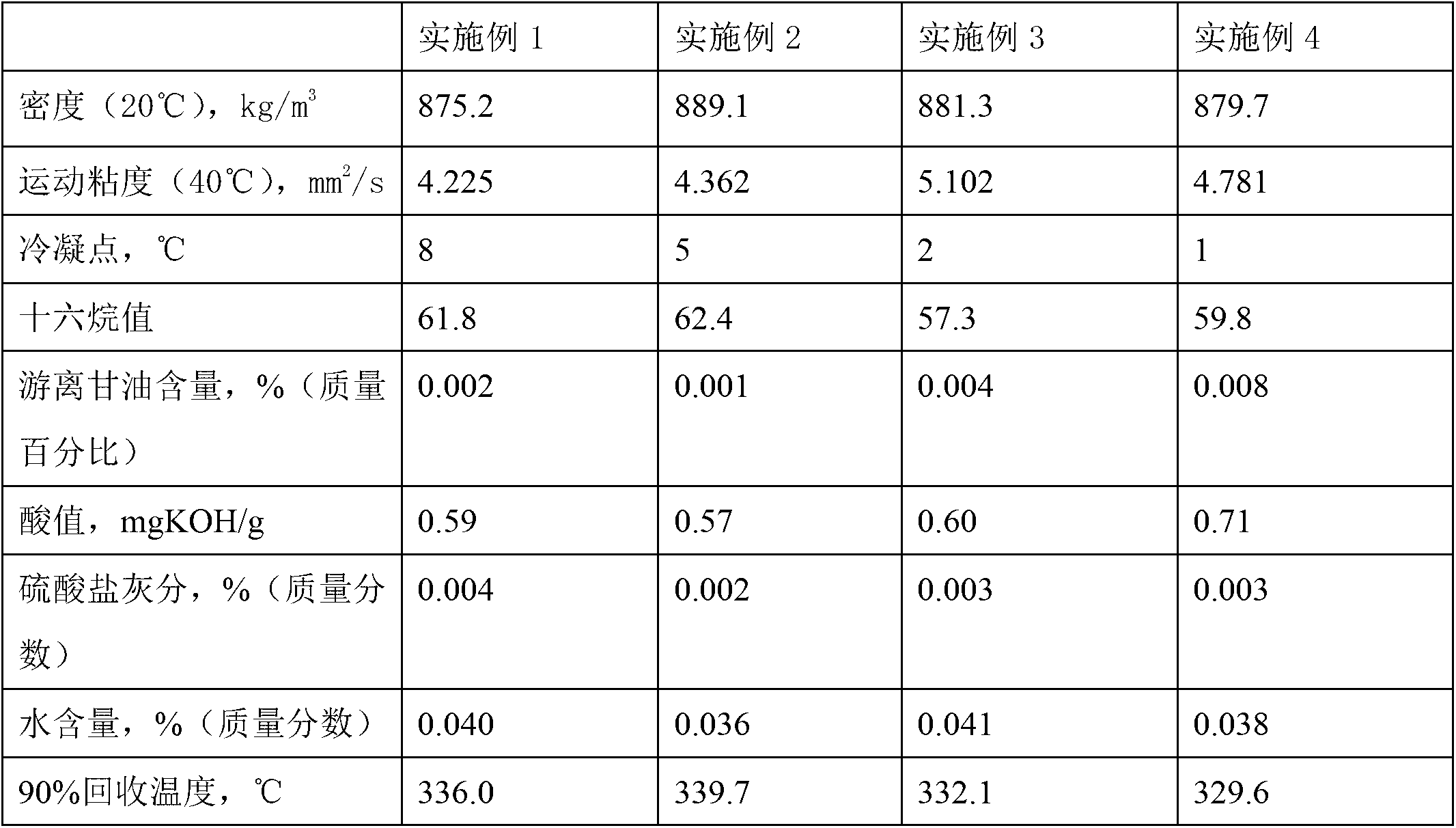

Embodiment 1

[0019] (1) First, mix 1000kg of palm oil with an acid value of 25mgKOH / g and 13.7kg of glycerin to form liquid A, and mix it evenly at 53°C, then mix 341.25kg of sec-butyl acetate with 8% of total mass of lipase Liquid B and mixed at 53°C. After the lipase is fully activated, liquid A and liquid B are mixed in an enzyme esterification reactor at a constant temperature of 53°C to fully react for 4 hours.

[0020] (2) The gas oil produced by the esterification reaction is precision filtered, the enzymes in the gas oil are separated and recovered, and the lipase is separated and then enters a centrifuge at a speed of 5500 rpm to separate impurities.

[0021] (3) The gas oil after centrifugal separation is subjected to atmospheric distillation to separate the excess sec-butyl acetate and the water produced by the reaction, and then after 0.002MPa vacuum distillation, the light phase and heavy phase are used to produce biodiesel and plants asphalt.

Embodiment 2

[0023] (1) First, mix 1000kg of soybean oil with an acid value of 50mgKOH / g and 27.3kg of glycerin to form liquid A, and mix it evenly at 55°C, and then mix 273.12kg of sec-butyl acetate with 10% of the total mass of lipase. B solution, and mix at 55°C, after the lipase is fully activated, then mix A solution and B solution in an enzyme esterification reactor at a constant temperature of 55°C to fully react for 8 hours.

[0024] (2) The gas oil produced by the esterification reaction is precision filtered, the enzymes in the gas oil are separated and recovered, and the lipase is separated and then enters a centrifuge at a speed of 5500 rpm to separate impurities.

[0025] (3) The gas oil after centrifugal separation is subjected to atmospheric distillation to separate the excess sec-butyl acetate and the water produced by the reaction, and then after 0.002MPa vacuum distillation, the light phase and heavy phase are used to produce biodiesel and plants asphalt.

Embodiment 3

[0027] (1) First, 1000kg of rapeseed oil with an acid value of 100mgKOH / g and 54.7kg of glycerin are mixed to form A liquid, and mixed uniformly at 45℃, and then 204.8kg of sec-butyl acetate is mixed with 11% of total mass of lipase Make liquid B and mix it at 45°C. After the lipase is fully activated, liquid A and B are mixed in an enzyme esterification reactor at a constant temperature of 45°C for 16 hours.

[0028] (2) The gas oil produced by the esterification reaction is precision filtered, the enzymes in the gas oil are separated and recovered, and the lipase is separated and then enters a centrifuge at a speed of 5500 rpm to separate impurities.

[0029] (3) The gas oil after centrifugal separation is subjected to atmospheric distillation to separate the excess sec-butyl acetate and the water produced by the reaction, and then after 0.002MPa vacuum distillation, the light phase and heavy phase are used to produce biodiesel and plants asphalt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com