Reusable lubricating oil filtering device

A technology for filtering device and lubricating oil, applied in the direction of lubricating composition, separation of immiscible liquids, etc., can solve problems such as hidden dangers in stable operation, and achieve the effect of reducing equipment failure rate, reducing oil cost, and improving kinematic viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

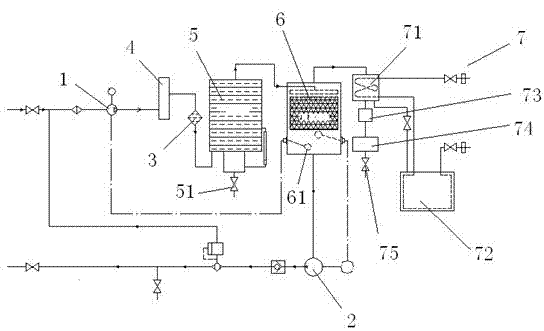

[0012] A kind of reusable lubricating oil filtering device of the present invention, see figure 1 , the device includes an oil inlet pump 1, an oil discharge pump 2, an infrared heater 4, an oil-water separator 5, a three-dimensional vacuum separation tank 6 and a water circulation condensation separation device 7, and the oil-water separator 5 is connected with the oil inlet pump 1 through an infrared heater 4, and the The oil pump is connected with the motor. A coarse filter 3 is arranged between the oil-water separator 5 and the infrared heater 4; the upper end of the vacuum three-dimensional separation tank 6 is connected with the oil-water separator 5 and the water circulation condensation separation device 7, and the lower end of the vacuum three-dimensional separation tank 6 is connected with the oil discharge pump. A liquid level control device 61 is provided in the vacuum three-dimensional separation tank 6 . A drain port 51 is provided at the bottom of the oil-water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com