Production technology for autoclaved aerated concrete building block

A concrete block and production process technology, which is applied in the field of aerated concrete, can solve the problems of excessive radioactive substances, tight supply and demand of raw materials, easy to mix unevenly, etc., and achieve the effect of increasing surface area, light weight and good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific examples.

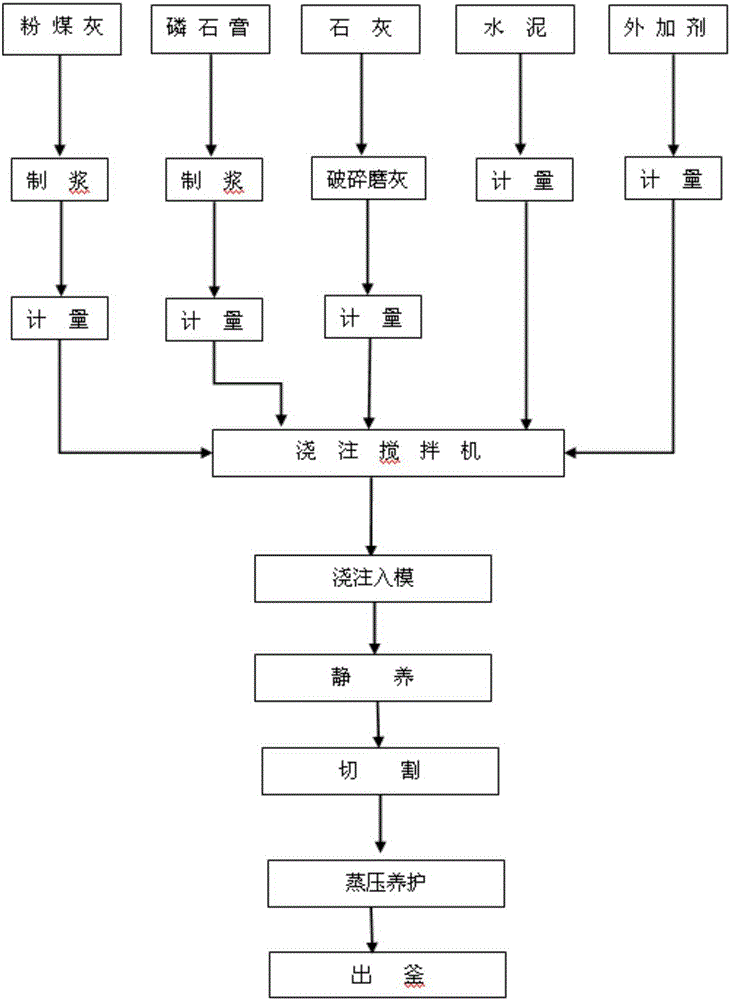

[0021] Such as figure 1 Shown, a kind of production technology of autoclaved aerated concrete block is characterized in that, comprises the following steps:

[0022] The specific content percentages of the material formula are as follows: fly ash: 65%, cement: 15%, lime: 14%, phosphogypsum 5.5%, aluminum powder: 0.5%;

[0023] 1) Slurry preparation: Grind the fly ash with a ball mill, the fly ash is ground to a particle size ≤ 0.045mm, and then sent to the slurry making tank, add water and stir for 1 hour to make fly ash slurry, phosphogypsum Add water and stir for 1 hour to make phosphogypsum slurry, and then crush the lime with a ball mill to grind lime powder;

[0024] 2) Mixing ingredients: send lime powder and cement into the electronic powder weighing scale, and after cumulative measurement, send them to the pouring mixer, send the fly ash slurry to the electronic weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com