Movable material mixing equipment for building

A material mixing and moving technology, which is applied in the direction of mixing operation control, mixing operation control device, clay preparation device, etc., can solve the problems that affect the quality of construction, the inability to mix materials, and uneven material components, etc., to improve the effect, Increase the swing range and fully mix the materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

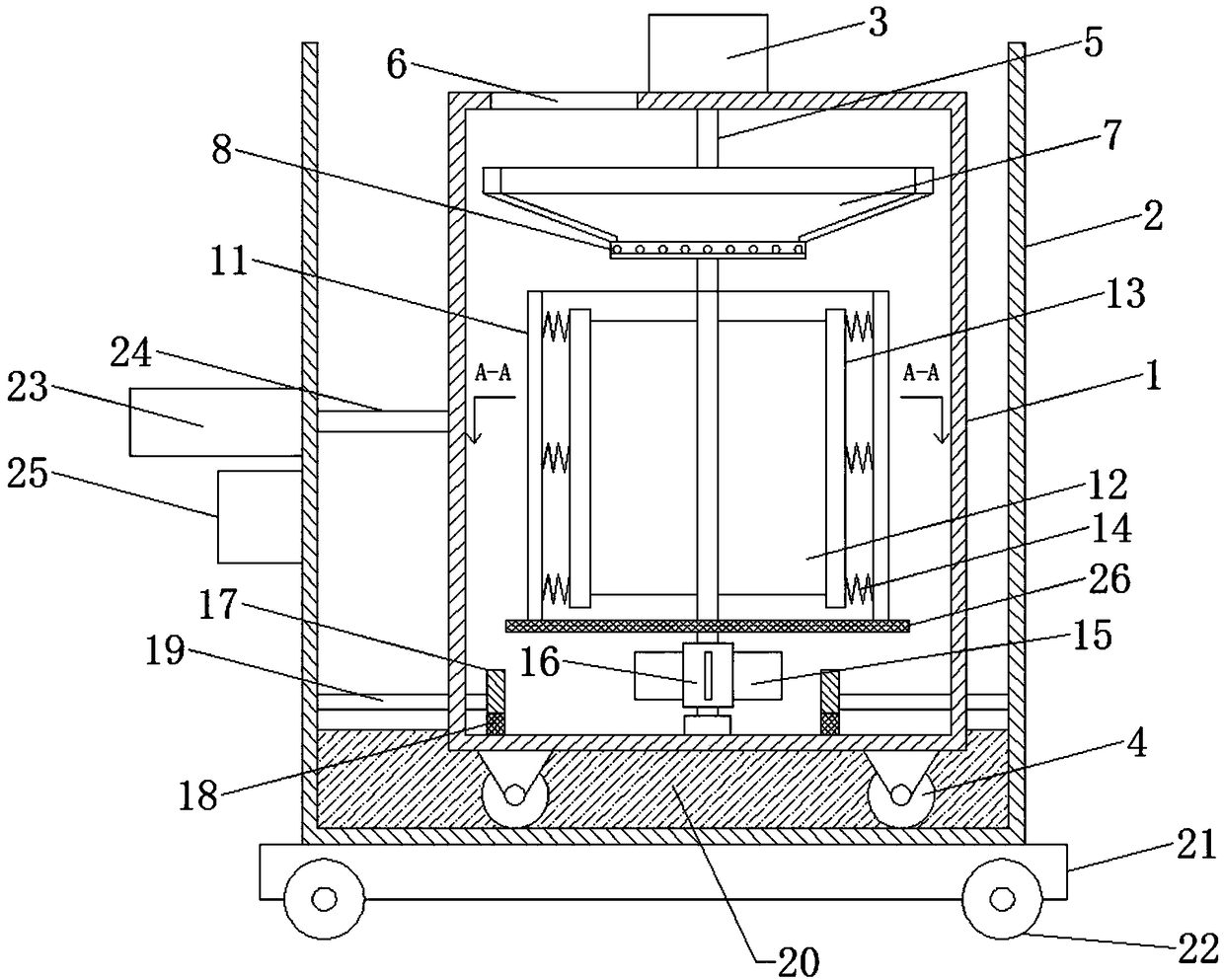

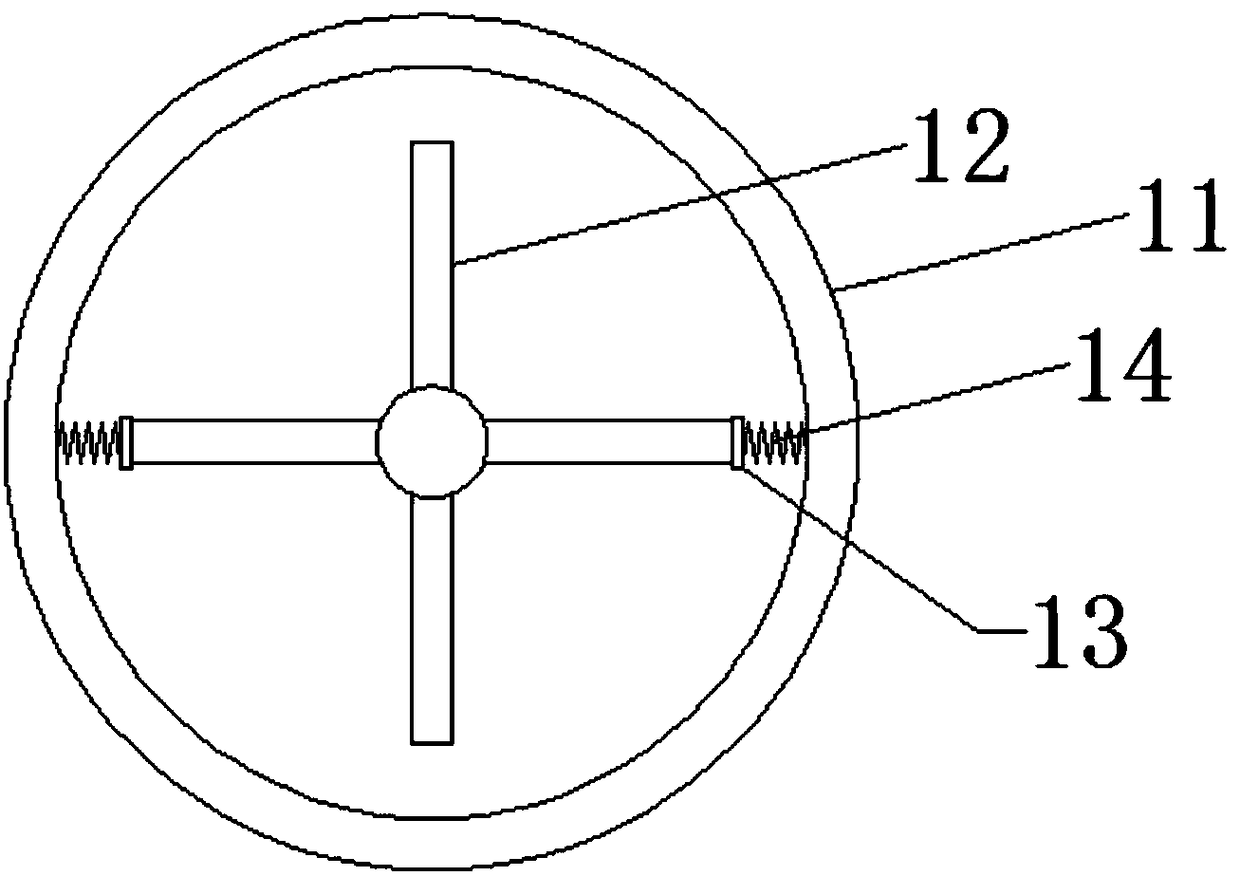

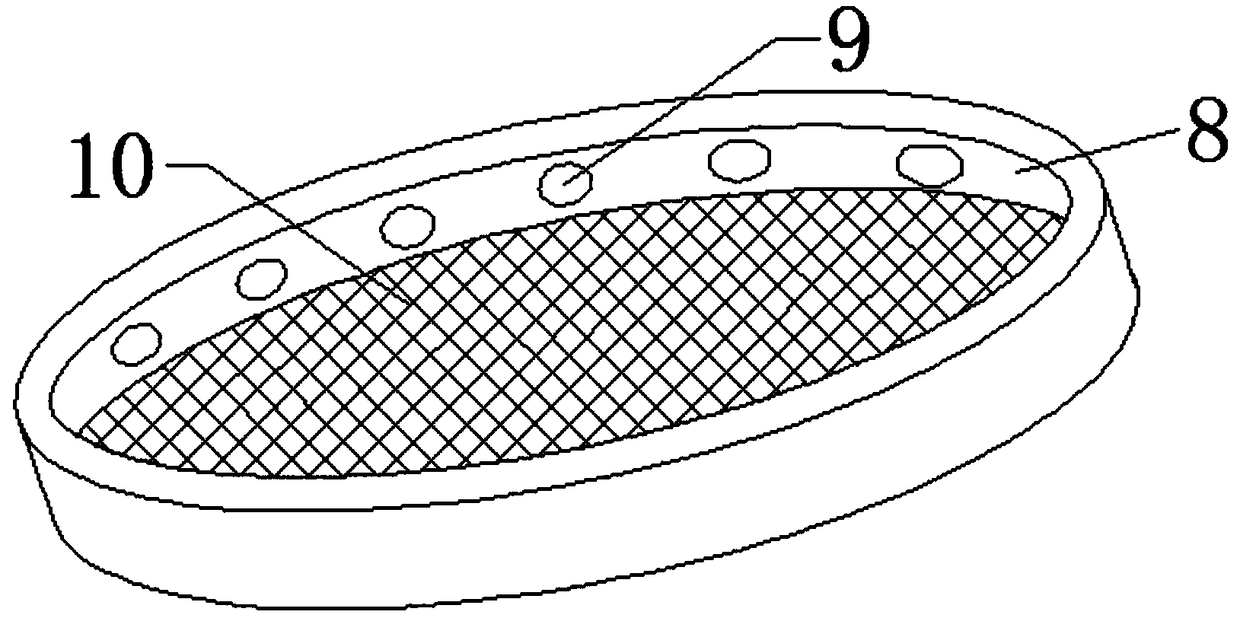

[0017] Please refer to the figure, in the embodiment of the present invention, a mobile material mixing equipment for construction includes a cylinder 1, a casing 2, a motor 3 and a feed port 6; the cylinder 1 is located in the casing 2, and the casing 2 The upper end is set as an opening, and the bottom of the housing 2 is fixedly equipped with a horizontal base 21, and a plurality of rollers 22 for moving are installed on the underside of the base 21, so that the equipment can be moved easily and used flexibly in the construction process; A plurality of moving wheels 4 are fixedly installed on the bottom of the cylinder 1, and the moving wheels 4 are located in the cylinder 1, so that the cylinder 1 can move horizontally in the shell 2, and the bottom of the shell 2 is filled with lubricating oil for lubrication. oil 20, reducing the friction between the lubricating oil 20 and the bottom of the shell 2, making the cylinder 1 easier to move in the shell 2 and easier to push; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com