Viscosity adjustment device realizing intermittent graphite feeding and used for printing

A viscosity adjustment and intermittent technology, applied in transportation and packaging, dissolving, mixing machines, etc., can solve problems such as insufficient mixing, and achieve the effect of sufficient mixing and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

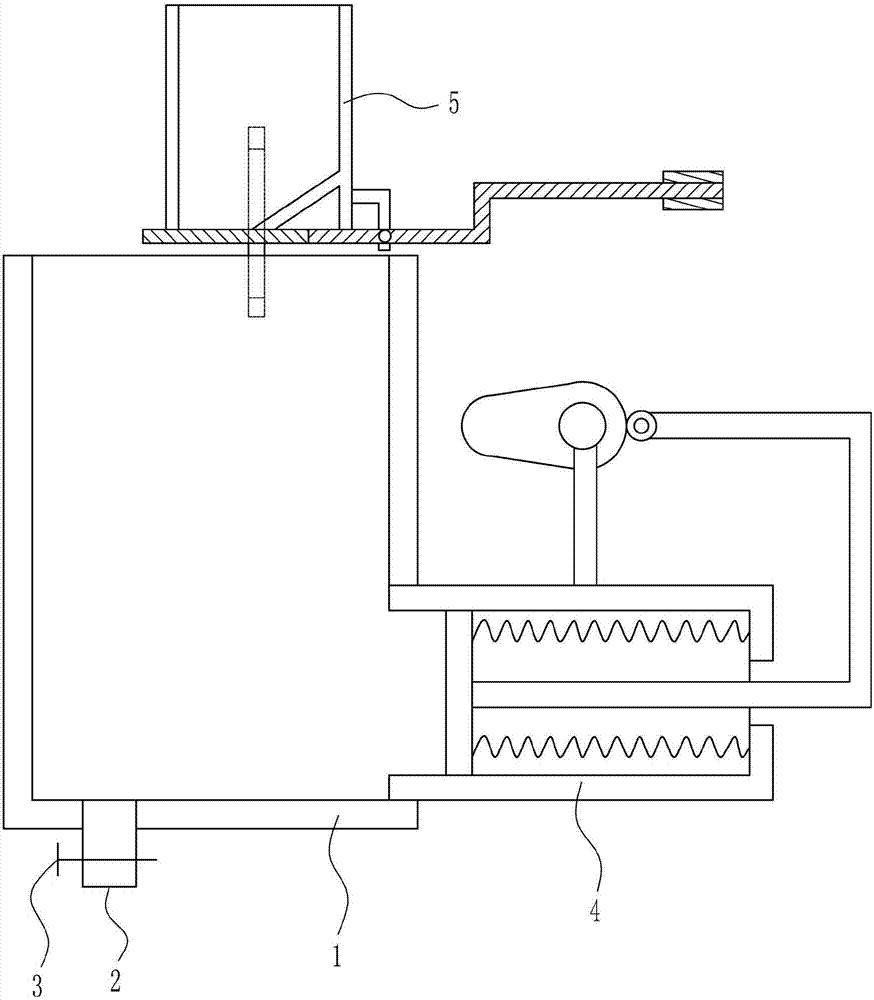

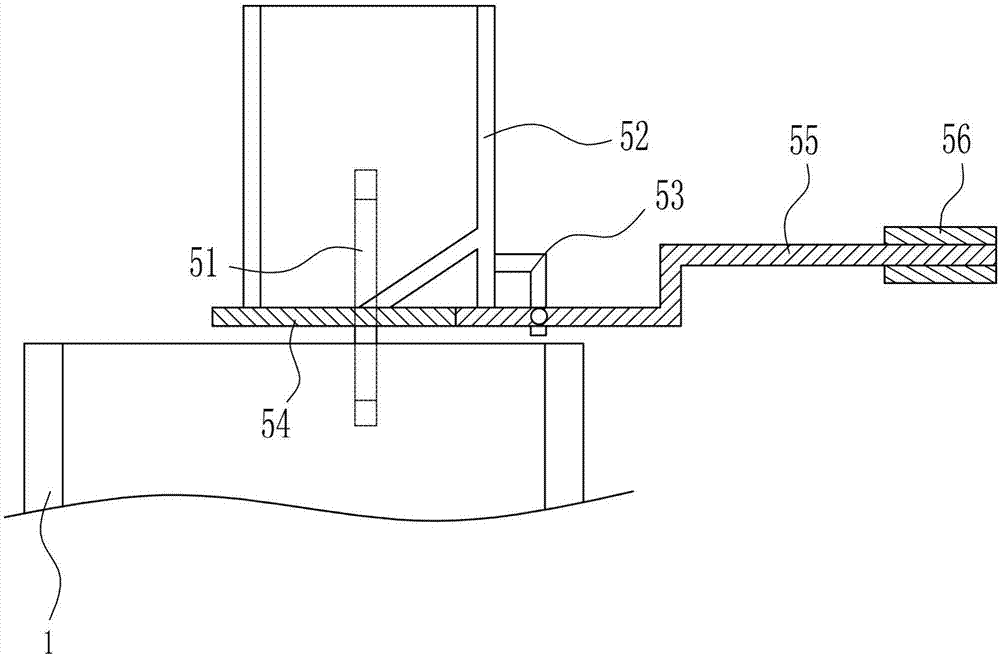

[0030] A device for intermittent feeding of graphite for printing, such as Figure 1-5 As shown, it includes a mixing box 1, a discharge pipe 2, a valve 3, a stirring mechanism 4 and a feeding mechanism 5. The bottom of the mixing box 1 is connected with a discharge pipe 2, and a valve 3 is arranged on the discharge pipe 2. The mixing box A stirring mechanism 4 is connected to the top of the mixing box 1, and a feeding mechanism 5 is connected to the lower right side of the mixing box 1.

Embodiment 2

[0032] A device for intermittent feeding of graphite for printing, such as Figure 1-5 As shown, it includes a mixing box 1, a discharge pipe 2, a valve 3, a stirring mechanism 4 and a feeding mechanism 5. The bottom of the mixing box 1 is connected with a discharge pipe 2, and a valve 3 is arranged on the discharge pipe 2. The mixing box A stirring mechanism 4 is connected to the top of the mixing box 1, and a feeding mechanism 5 is connected to the lower right side of the mixing box 1.

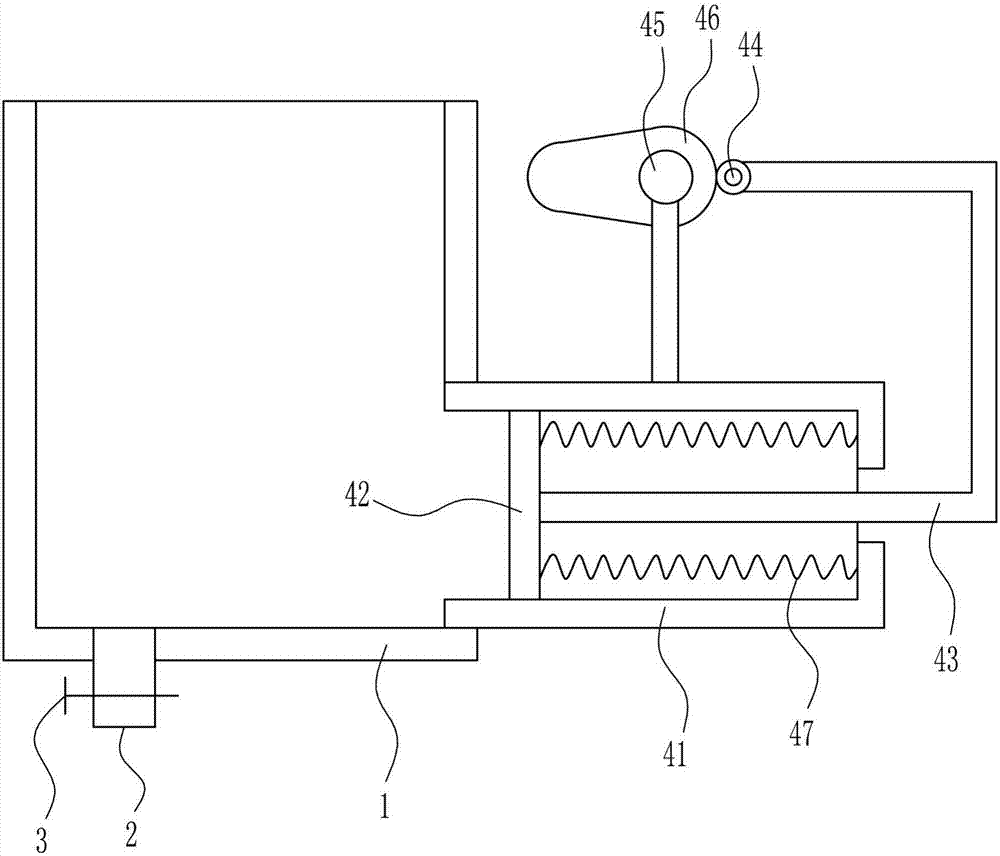

[0033]Stirring mechanism 4 comprises cylinder body 41, piston 42, moving bar 43, first contact wheel 44, motor 45, cam 46 and first spring 47, and the right side lower part of mixing box 1 is connected with cylinder body 41, and inside cylinder body 41 A piston 42 is provided, a first spring 47 is connected between the upper and lower sides of the piston 42 and the upper and lower sides of the rear portion of the cylinder body 41, the middle part of the right side of the piston 42 is connect...

Embodiment 3

[0035] A device for intermittent feeding of graphite for printing, such as Figure 1-5 As shown, it includes a mixing box 1, a discharge pipe 2, a valve 3, a stirring mechanism 4 and a feeding mechanism 5. The bottom of the mixing box 1 is connected with a discharge pipe 2, and a valve 3 is arranged on the discharge pipe 2. The mixing box A stirring mechanism 4 is connected to the top of the mixing box 1, and a feeding mechanism 5 is connected to the lower right side of the mixing box 1.

[0036] Stirring mechanism 4 comprises cylinder body 41, piston 42, moving bar 43, first contact wheel 44, motor 45, cam 46 and first spring 47, and the right side lower part of mixing box 1 is connected with cylinder body 41, and inside cylinder body 41 A piston 42 is provided, a first spring 47 is connected between the upper and lower sides of the piston 42 and the upper and lower sides of the rear portion of the cylinder body 41, the middle part of the right side of the piston 42 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com