Mixing and stirring equipment for coating production

A technology of mixing and stirring equipment, applied in mixers, mixer accessories, shaking/oscillating/vibrating mixers, etc., can solve the problems of lack of pretreatment means, quality of finished paint products, and obstruction of stone powder mixing and stirring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

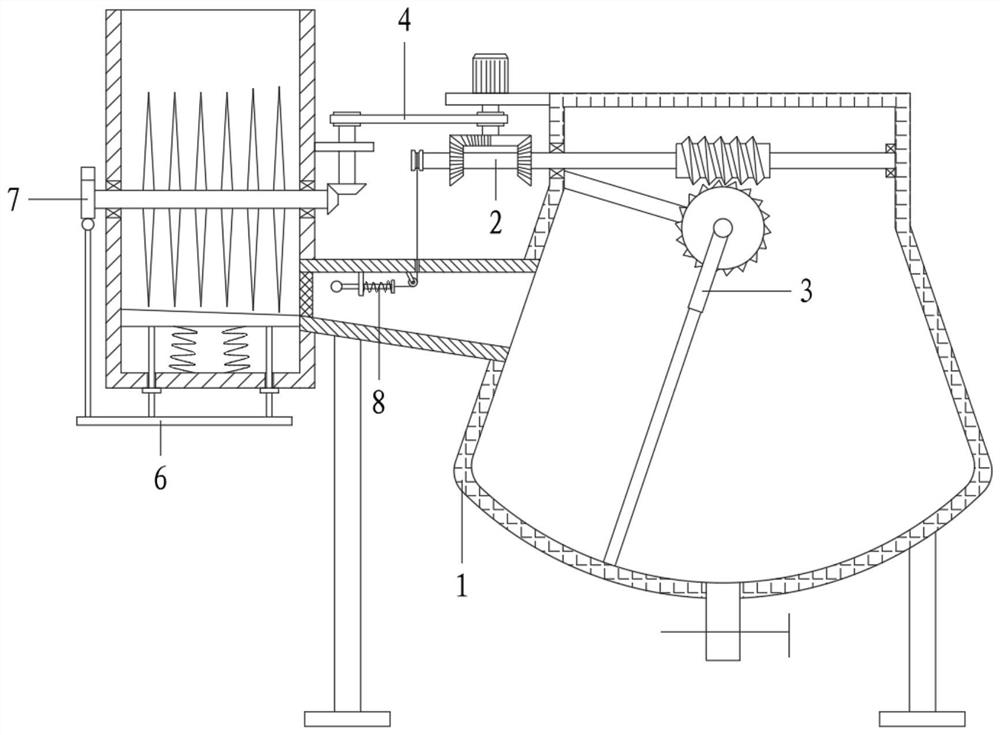

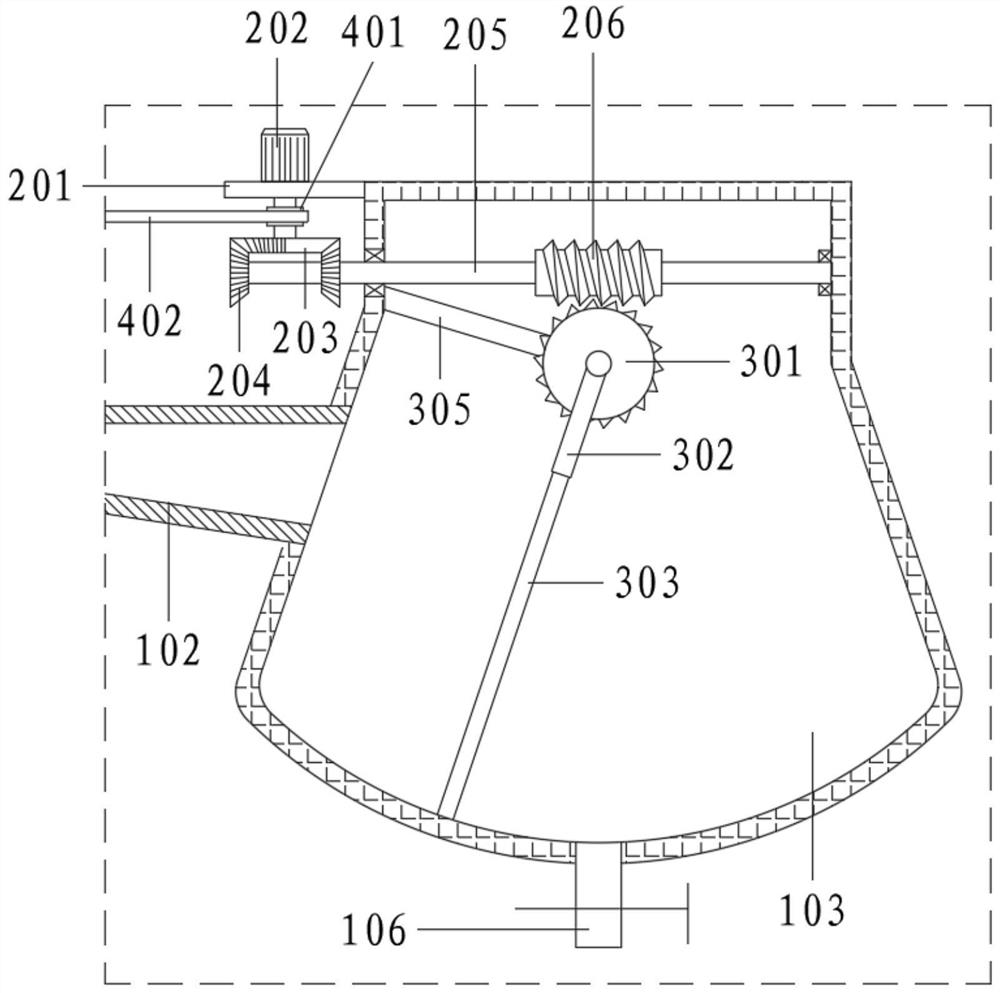

[0065] With reference to the accompanying drawings, a mixing and stirring equipment for paint production includes a tank assembly 1, a driving assembly 2, a stirring assembly 3, a transmission assembly 4 and a crushing assembly 5;

[0066] The tank assembly 1 includes a raw material barrel 101, a feed pipe 102, a stirring tank 103, a material guide plate 104, a screen 105, a paint discharge pipe 106 and a leg 107; the right side of the raw material barrel 101 is connected to the stirring tank 103 through the feeding pipe 102 The upper part; the bottom of the feeding pipe 102 is arranged with a high left and a low right, and a screen 105 is also installed at the left end; a material guide plate 104 is housed in the raw material barrel 101, and the top surface of the material guide plate 104 is processed with a slope that is high on the left and low on the right. The left end of 102 is set corresponding to the right end of the material guide plate 104; the bottom of the stirring ...

Embodiment 2

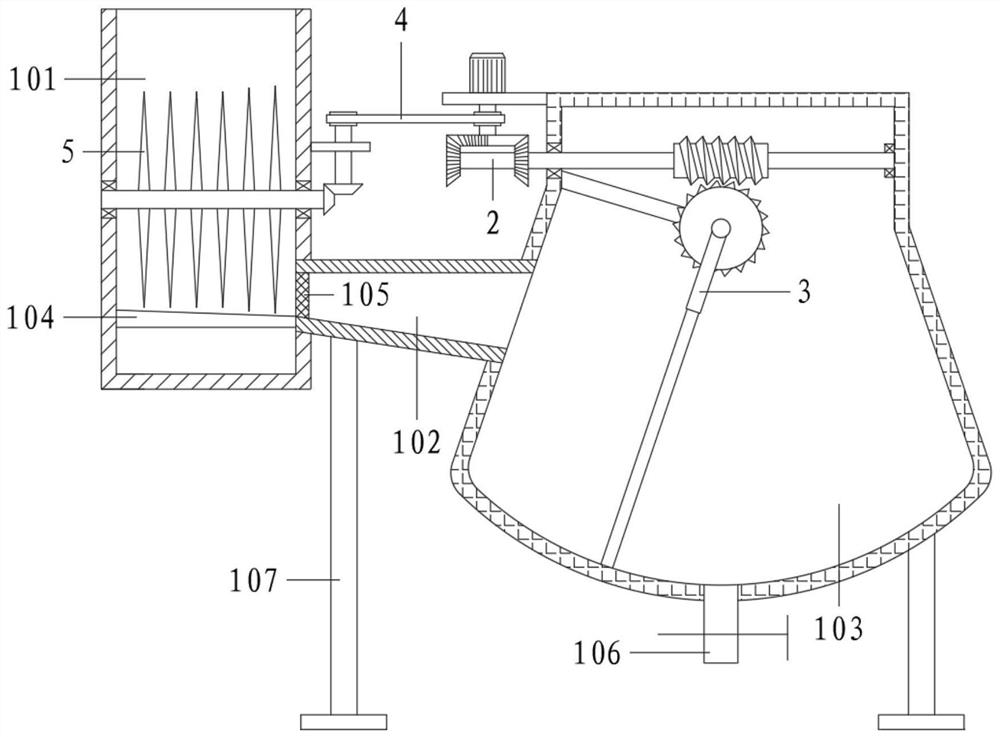

[0069] With reference to the accompanying drawings, a mixing and stirring equipment for paint production includes a tank assembly 1, a driving assembly 2, a stirring assembly 3, a transmission assembly 4 and a crushing assembly 5;

[0070] The tank assembly 1 includes a raw material barrel 101, a feed pipe 102, a stirring tank 103, a material guide plate 104, a screen 105, a paint discharge pipe 106 and a leg 107; the right side of the raw material barrel 101 is connected to the stirring tank 103 through the feeding pipe 102 The upper part; the bottom of the feed pipe 102 is arranged with a high left and a low right, and a screen 105 is also installed at the left end; a material guide plate 104 is fixed inside the raw material barrel 101, and the top surface of the material guide plate 104 is processed with a slope that is high on the left and low on the right. The left end of the pipe 102 is set corresponding to the right end of the material guide plate 104; the bottom of the ...

Embodiment 3

[0086] The difference from Embodiment 2 is that the material guide plate 104 of this embodiment is movable.

[0087] It also includes a pushing assembly 6; the pushing assembly 6 includes a push-pull rod 601, a type of connecting rod 602, a limit block 603 and a type of spring 604;

[0088] The material guide plate 104 is slidably connected in the raw material barrel 101, and a type of spring 604 is connected to the bottom surface of the raw material barrel 101; The bottom is also connected with a push-pull rod 601 ;

[0089] Specifically, under the action of a type of spring 605, the material guide plate 104 always has a tendency to move upward, and is prevented from colliding with the crushing knife 503 by the action of the limit block 603; The stone powder blocks that the knife 503 has fully acted on will accumulate on the material guide plate 104, pull down the push-pull rod 601 and drive the material guide plate 104 to move down a certain distance synchronously, then rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com